Jeff D. Poel for the degree of Master of Science...

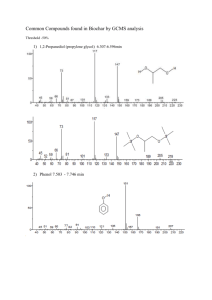

advertisement