Document 11495927

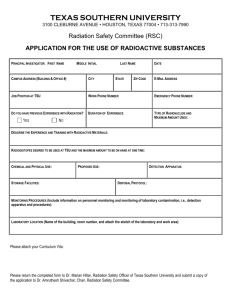

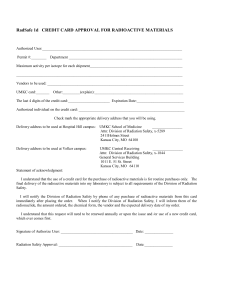

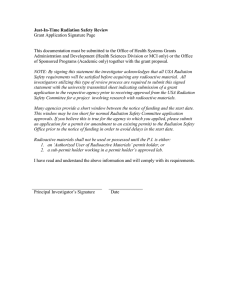

advertisement