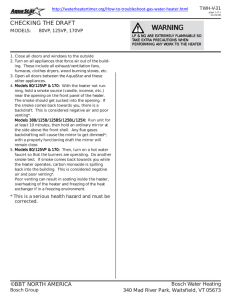

INSTALLATION, OPERATION, AND SERVICE MANUAL HIGH EFFICIENCY GAS WATER HEATER

advertisement