SERVICE HANDBOOK FOR STANDARD RESIDENTIAL FVIR GAS WATER HEATERS

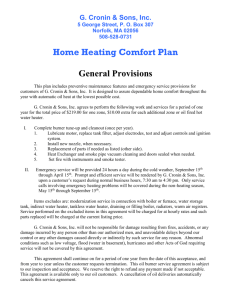

advertisement