Notes Field ENGINEERING TECHNICAL

advertisement

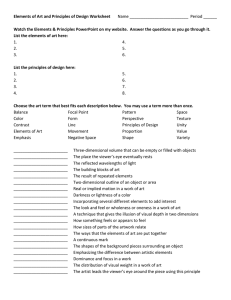

71Y ENGINEERING TECHNICAL NOTESTECHNICAL REPORTS DATA RETRIEVALMANAGEMENT PROFESSIONAL DEVELOPMENT FIELD SYSTEM VOLUME -pp NUMBER 6 Notes Field AFFINE FOCAL LENGTH 11 ADJUSTMENT TEST MOTIVATING YOUR YOUNGER WORKERS THE SDEDC TREE/SHRUB WASHINGTON OFFICE PLANTER NEWS FOREST SERVICE UýS U.S. DEPARTMENT OF AGRICULTURE JUNE 1979 UýS ENGINEERING Volume Information 1 NOTES FIELD Number l 6 has been developed for guidance of employees publication its and its Department of Agriculture-Forest Service contractors and State agencies. The Department of Agriculture assumes no contained this respon-sibility of the United cooperating in States Federal for the interpretation or use The use of this information names of trade firm or corporation convenience Such of the reader. use does not of any product or service by the United of others that may be suitable. The text in the publication must not be construed or policy except engineers and engineering not intended by as FSM exclusively references. personal an should is official of the type FOREST SERVICE D.C. and to the exclusion author and mandatory instructions of material in the publication issue however DEPARTMENT OF AGRICULTURE Washington employees. for the information of the respective for engineers. U.S. own endorsement or approval procedures read each its of Agriculture opinions or approved Because technicians publication constitute States Department the represents -recommended in this by other than 20013 this publication all is AFFINE FOCAL J. LENGTH B. ADJUSTMENT TEST Stewart Engineering Staff Group Region 3 photo-graphy. There are several makes of stereoplotters on the market that will not mechanically accommodate 8.25-inch 209.55-mm aerial produce The data 209.55-mm has length It been question is can these stereoplotters be used to to National Standards using 8.25-inch Map Accuracy focal length photography suggested that an affine problem and allow these 209.55-mm photography. solution would solve the focal to use 8.25-inch stereoplotters The purpose of this test was to determine if National Map Accuracy Standards see table can be obtained by setting 8.25-inch 209.55-mm photography in a 6-inch 153-mm focal length stereo-plotter. See table. NATIONAL Item Accuracy Standard Map MAP ACCURACY STANDARDS Minimum Contour Interval TEST Spot Elevation ft 4.85 COMPARISON Horizontal ft North ft East 1.21 2.0 2.0 First Operator 0.42 0.37 0.42 Affine Solution 1.05 0.63 1.00 Second Operator 1.09 0.45 0.49 1 Step 1 Step 2 cor-rect Set an 8.25-inch stereomodel in the Topocart using the focal length setting. With the stereomodel relatively read the pass points and ground control points. oriented The ground coordinates for the pass points and control were The data were collected on a 11 previously established. ratio with the stereomodel scale. The model selected was in relatively rough terrain with the control points located on most of the extreme elevation points. Set the focal length of the Topocart to approximately 6 inches 153 then relatively orient the stereomodel. With relative orientation completed correct for the affine vertical scale adjustment. This adjustment is obtained by the following formulael mm 1 K where Planimetric cck scale K Plotting camera focal length Aerial camera focal length Vertical ratio clk ck K 153.0 mm 209.94 0.7288 1000 0.7288 1.372.12 cal-culated In this case the planimetric scale was on a 11 ratio the vertical scale was 11.3721 ratio with respect to the stereomodel. The affine by correction for the shift of the the following formulae2 ck Dx K CK Dy where Tip Tilt w Dy Grads Pg Following Topocart Photo is the 1-K2 Pg is xý xw movement y movement 63.66 per radian x principal point correction.for this model 69 Tilt point grads grads Amount of Amount of Dx K 1-K2 Pg principal -0.58 grad 209.941 - 0.72882 -0.58 0.728863.66 2 -1.23 mm in the Tip 0.67 grad 209.941 - 0.7288 Photo 0.72882 0.67 0.72882 -0.64 0.72882 0.67 63.66 1.42 mm 68 Tilt -0.64 grad 209.941 - 0.728863.66 Tip 0.67 -1.36 mm _ grad 209.941 - 0.728863-66 1.42 mm con-trol scale adjustment After the vertical control reading were recorded. Figures 1 through 1 and 2. Figure for the data made the pass CONTROL 84 84 84 NG FOR SETUP 168T6 1682. H and adjustments of the data collected in steps listing of the data used as a standard adjustment listings shown in figures 3 and 4. is a 2 Figure 5 shows the purpose of moving the principal photo carriers to recover the nadir point. 0 points show 4 1 was HECK AUTO 799752.12 796154.62 PASS point VALUE on the 1090.00 T610ý00----84 84 84 1683 1691. T69-2. 1693. 84 -20O7 2207. 84 621857.37 623069.12 U0 9I 624954.25 --7942rr 2103. 2104. 0. 626006.00 627163.87 624711.25 623408.50 625371.37 624774.25 Figure 7538.61 7310.32 7523.77 7380.98 7316.62 7589e7_7___ IN FILE _ _ . -----_--------- 7353.60 7569.40 0.00 0.00 0.00 CONTROL 25 800435.62 797589.37 795314.62 797288.75 796480.75 795550-97 797644.37 800540.37 -7-25-976.1-2 84 84 98 7303.27 7295.86 1 control 1.--Standard 3 data. - LENGTH FOCAL KIND 3 MOD 68- 69 FL n n n 3 MOD n n STANDARD 0 69 0 0 0 FL OVER 0 ALL _-i LE FOCAL-LF--_ _1 AFTER LEAST ERROR 0.87 69. 68. 68- 0 FOCAL 1 S0.093 KIND CHECK SQUARE PLANE FIT 0.85N 0 1 1 1 1 0 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 1 1 11 0 0 0 0 0 0 0 0 - 0.67E 0.57EL RESIDUALS NUM 1 IDFNT NORTH 1683. -0.75 16820 1681. 2 3 EAST ELEV 0.10 0.91 -0.35 0.63 0.55 0.92... 1.24 1.09 -0.63 0.03. -0.00 -0.69 ------11 4 1691 5 1692. -0.33 7 2102. 0.25 8 2 10 0-.$2 141 10 STANDARD -____ -0.09 -- 3 2007. ----2L04A---2207. 9 _ -0.15 -0.99 -0.67 - -1.20_.. IlL17 -0.49 0.03 -0.19 -0.76 0.78 -0.34 0.63 -0.57 0.52 -0.21 ERROR-AFTER POLYNOMIAL CURVE 0.52 OVER ALL D 0.37N lbfl3.- ._.. 0.42EL UAL ..NORT NUM FIT 0.47E -D EAST ELEV 0.05 16 0.25 -0.47 -0q IIýDB-----.--4 6 7 8 10 1682. 1681. 1691. -_16_92ý1693. ýin2. 2103. 2104. 0.75 -0_.1.8 _... 0.09 0.78 -0.53 -0.03 0.59 -0.13 -0.29 0..1b 0.12 -0.00 0.-6-1 Figure 0.45 2.-- Data - 2 -0.22 -Q6 7 -0.62 0.24 - - -0.32 -0.25 0.08 -0.40 1.04 -n. o i 0.14 0.03 _ _.. - adjustments--plotter focal first operator. 4 ----- length - 209.94 mm LENGTH FOCAL CHECK --5 --7 KIND 3 MOD 68- S0.173 69 FL 1 - FOCAL LE 0 FOCAL LE 0 1 1 1 1 1 1--1 1 1 1 0 0 0 0 0 0 0 0 69. 6$. -i4---6- 1 F-L -ý-9 0---0-- -------STANDARD ------- ERROR SQUARE AFTER LEAST 1 PLANE r51N 3 FIT r69E -2 3-9-E-L -8 RESIDUALS NUM NORTH IDENT 1 3 -6.92 3.99 2.45 -1.00 -2.00 -1.94 - 1681. ----4-------16-91. 1692. 1-. - 2102. R 9 11 22070 --ST-ANDARP---R-RORAFTR 1.12 OVER ALL -3 2 -3.01 2.33 2.06 - 11 - 0.98 2.13 1.58 -2.36 -0.38 -4.29 3074 POLYNOMIAL 0.63N 6 5 -0.29 -1050 06- -2.39 -0.49 -0.77 -0.02 1O3.- -3.79 0.33 3.34 3.09 1.47 2007. ELEV 2.15 0.18 1.83 1683. --l-682 EAST CURVE FIT 1.00E - -- -- _ -- -- 1.05EL --..---N4A---S.I-D1lALS-_._ -TDNT 2 4 NORTH EAST -0.31 -0.03 1682. -0.31 l6cgle --0r2-7-- 1691. -0.07 -0.66 -0.44 -- ELEV 0.1 1.63 -0.21 1.26 0.24 0.26 -1.13 -1.93 -0.55 0.98 1.40 --- -1 0.45 -0.78 -064 - 0.-29 ------- - x34---10 6 13 1693. 2ýA2r 22103. 1.26 -0.81 2104 0.04 -2-- -0.7----__ - -1.69 -0.53 --- --8.84 -0.65 0.12 0.98 .. 110 Figure 3.--Data adjustments--plotter focal first operator. 5 length 153.0 mm . FOCAL KIND 3 MOD 69 68- LENGTH FOCAL L 0 0 3 0 EE 1 --1.04 50.124 KIND CHECK MOD 00 ARD 0 0 69 0 0 FL FOCAL 1 LE 0 1 1 1 1 1 1 0 0 0 0 0 0 0 0 PLANE FIT - ------ OVER 1 0 AFTER LEAST SQUARE ERROR 0 68. 68- 0 0 ALL 0.66N 0.51E - 1.21EL 0.64-2 RESIDUALS NORTH EAST -0.34 1 1692. - 3 4 6 . Tbr. I2 1681. 1683. - -g 10 2102. 1 27017.._. r -0.38 -0.11 0.22 0.99 1.06 -0.06 -0.30 2104. X103. 8 - ELEV 0.21 -0.28 0.52 -0.01 -0.61 0.03 -0.65 -0.67 0.10 -1.07 -0.22 -0.13 0.63 STANDARD ERROR AFTER POLYNOMIAL fY9R OVER ALL 0.45N - CURVE - -0.58 -0.40 1.76 -2.61 0.10 1.37 -0.71 -0.78 0.86 0.40 - FIT 0.49E 1.09EL RESIDUALS NUM IDENT NORTH EAST ELEV Os4-0-5 1 3 4 1693. -1$92. 1691. 16816 1682. 0.36 -0.14 -- 6-- ý68ýý ... 7 2007. 8 2-1-04-.---- 9 2103. 0.17 tji0ý 2207. Figure _--O-.33 -2.35 0.01 0.48. 4.--Data 0.13 -0.10 -0.78 -0.73 0.51 -0.09 -0.67 -0.39 -0.12 0.16 -0.37 0.39 -.9-9-----11 -0.01 0.20 0.93 --0-.-GO--- 0.52 032 1.96 -0.45 -0.28 r ifi - - - - 0.83 adjustments--plotter focal second operator. 6 Length 209.94 mm X PL Y PL PP NP clk Movement in the X direction Movement in the Y direction Plotter lens Principal point Nadir point Plotter focal length Y .- v I y N P x 1 P P -1 PP NP Y x Figure 5.--Movement of principal point for recovery of nadir. 7 on photo Ac-curacy 153 The results of this test support the conclusion that 6-inch National obtain to Map be used focal length stereoplotters can Standard data by using the affine solution. mm that the affine data fall within the expected In this accuracy range when two operators do the same project. case the two operators used the correct focal length 209.94 mm in the stereoplotter. for the aerial photography The test data show for this test was taken with a ZEISS Aerial The aerial photography The planned with calibrated focal length of 209.94 mm. Camera a this is scale of 112000 flight height is 8250 feet photography used for this The 2514.6 m. photogrammetric plotter Topocart of 1700. test has a C-factor REFERENCE NOTES 1AZbertz Jorg and Kreiling Walter. translated by G. Richter Karlsruhe 2FormuZae furnished by Photogrammetric 1975 Wichmann Kern Instruments 8 Inc. Guide MOTIVATING YOUR Henry YOUNGER C. WORKERS Ruark deliber-ately workers who take a day off at the slightest excuse or foul up a job are causing major problems for American industry to both private and government according studies. Bored Whatever the reasons the resultant casualties are costing us dearly in both productivity and dollar losses. It is becoming obvious many of the traditional .approache to motivate workers are no longer as they used to be. nearly as effective dif-ferent be-havior Todays young worker has a different set of mores and values a sense of responsibility and perhaps a less sharply focused to become. feeling for what he wants persons now in management learned long is motivated. There is an effective reason people do or dont do even if that visible or easily understood. Most ago that all human for what is not readily reason why why man-agement. what affects people Managers also have learned that understanding from them is an essential and what will bring forth desired actions part of leadership and an indispensable component of effective But thats a much harder skill to acquire today. sub-ject The traditional Monday morning hangover holiday and day after payday blues are still with us but todays young worker may also be to the effects of drugs and the shove it syndrome. oppor-tunity The shove it syndrome It occurs when even promising young workers decide you can shove it I can do better and disappear-out the door. This happens despite extensive training and very good at considerable freely furnished by management cost. C. Ruark. This article of Technical Photography PTN Copyright Henry in the April first appeared Publishing Corporation Avenue Hempstead N.Y. 11550 Rudolph Masche and Edward The Forest Service Wagner Publishers/Editorial Directors. that reprint permission has been granted for use in this Field The authors permission is required for Notes only. from this reprint. acknowl-edges anyreproduc-tion issue 1979 250 Fulton 9 motiva-tional indus-try cut down these problems in younger workers for whom factors are far more complex than they ever were for their parents is drawing attention from many skilled personnel in What follows is a roundup of some trends and and business. shown recent studies and ideas by reports compiled in connection with my consulting practice. How to communication with the worker at all levels is an absolute to offset such situations. Many workers feel themselves necessity in trapped boring routine repetitive work situations and physically and sometimes When uncomfortable and emotionally taxing operations. the level of work conditions are and added dangerous demanding it off Thats when the shove motivation drops syndrome rapidly. strikes. Effective economic downturn fear of job loss is Even in times of comparative The younger the factor it with not nearly was previous generations. worker today is more ready to move on to somewhere else that is just as good or even better even to another region of the country or foreign nations. atten-tion wages creates what one study describes as positive among many workers but less so for younger ones than older Increased ones. studies show more and more younger workers refuse to continue in working situations with many negative factors. They prefer to move on often claiming there is no future for them within the Other company. What do they want Better working conditions more flexible hours and shift assignments and more responsibility for ones own efforts seem to be prime positive factors in building job satisfaction and A practical career ladder staying power in younger workers. also seems clearly leading to more responsible job opportunities effective attractive to many especially when coupled with training and a formal work/study program leading to technical on-the-job expertise profes-sional partici-pant Many studies indicate once the younger worker is hooked on a working situation which he sees can lead to solid opportunity and status he is perhaps an even more eager learner and than was his father. Similar studies show young women are as than their motivated or even more motivated by such opportunities male colleagues. There have been many changes in values and lifestyles over the past and we must expect even more. But that doesnt mean two decades in them to work effectively must share them or even with agree you 10 ef-fective judg-ment. What it does mean is that you understand with the younger worker. such changes for what they mean in relation to your and appreciate workers. Theres no simple way to do this. To do so requires for each situation and with enough one-to-one communication overall and balanced members to ensure an perspective group willing-ness dialog carried out with flexibility humor and a is perhaps the major tool. listen and understand Today tools unavoidable and one of the strongest human managment Personal its to there are. communica-tion There are many techniques and it pays to look to improve at these. and strengthen such related to but often more important is closely than fact You must learn to listen workers finding. younger with and to achieve an empathetic understanding carefully attempt well takes as as This workers. persuasion persistence. younger But it can provide reliable and valid guidelines for the judgments you must make. Feeling finding with and Leadership style has a very strong influence on both acceptance Studies show that personal effectiveness in stimulating workers. traits of the leader mean less than other elements with younger workers. What really counts is that the leader must be perceived more than his subordinates about the group task and how as knowing it effectively. to accomplish Two major clusters of behavior focus of studies of leadership and attitudes have been the main One cluster is labeled recently. autocratic authoritarian task-oriented the other democratic Both oversimplify leadership but equalitarian group-oriented. foundation for an examination of what leaders they can provide a lead--and thus do when a starting they point in your own really in terms of your problems. self-examination We know there are influence another and how to do it the relationships limited number of ways in which one person can He can coerce or coax.tell what to do to work. or share the decision making and concentrate on with workers rather than job execution. a For those who work with the younger employee a special blend of is needed. But first start with an these clusters and approaches of skills and relationships. examination your own interpersonal contrast what to do Learn from the used and you years ago. Compare look into the and values of lifestyles your younger changes and Then youre ready to consider the moves they may employees. to you. indi-cate 11 handled younger workers can anchor your organization with and talent opportunity understanding and may well be your most creative and productive working partners tomorrow. Properly 12 THE SDEDC TREE/SHRUB PLANTER Ted L. Pickett Mechanical Engineer Center Equipment Development San Dimas California Over the past several years engineers and technicians at the San Center Dimas Equipment Development SDEDC have been developing two pieces of equipment to revegetate steep slopes along roadsides. Work on a steep-slope seeder has been completed and reported upon see Field Notes August 1978 Vol. 10 No. 8 pp. 22-24 and Equip Work on a tree/shrub Tips February 1979 No. 7977 1301. planter the latest status of this effort is presented continues in this short article. under-taken hill-side road-side The to develop and. test a seeder and a planter was project to reduce the costs and improve the efficiency of stabilizing soil on slopes newly created during road construction in mountainous terrain. Other goals were to minimize the esthetic impact of of replanting on revegetation increase the effectiveness and reduce lake and stream slopes protect hillside watersheds The device reported here is a crane attachment siltation. that transplants tree and shrub seedlings with minimum soil disturbance. The criteria established the implement should for development of the planter Operate on cutbanks or fill slopes is irregular and littered up to 11 were even that if terrain op-portunity Plant tall--these container-grown for first nursery stock time planting that maximizes Handle stock from containers up to 8 inches seedlings can be as large as 2 inches in cross section and have an overall height and 45.7 cm Be capable The latest of exact-spot planting not SDEDC tree/shrub planter prototype tested at San Dimas. It planted successfully 13 the success 20.3 cm 5.1 cm square of 18 just row figure several 1 inches planting. has been varieties of F.--Figure 1 -SDEDC tree/shruua pZantor prototype. shrub seedlings and was used on slopes of approximately 60 percent without Further field establish problems. testing to implement any reliability production rates plant survival and. planting costs is in the Pacific now being conducted Northwest Region. The planter can be carried and positioned by either hydraulic or even by cable cranes second cable drum figure 2 if is available to keep the planter Some of the properly oriented from the road with the cranes can reach over 100 feet 30.5 The planter has a 24-tube carousel each tube planter attached. inches is 2.5 6.35 cm in diameter and 21.5 inches 5L6l cm to each of the three feet of the high. Sharpened shovels attached planter hold the implement on the slopes during the planting cycle. cranes a. m 14 A seedling can be inserted into the ground at a rate of one every seconds. After the tree orshrub seedlings are removed from their containers and are loaded into the carousel tubes the crane the operator places planter on the slope. The planting cycle once initiated by the operator is fully automatic electric over First debris is scalped or scraped off the ground where the seedling is to be inserted. Next a hole is augered and the rotates a rachet mechanism lines up a carousel tube with the augered hole. hydrau-lic. ca-rousel 15 seed-ling As alignment occurs a high-velocity blast of water propels a down the carousel tube through a drop tube into the hole in the ground. Finally a packing foot compacts the soil around the root system while forming a small depression for water. SDEDCs final design will have two planter mechanisms one at either end of the frame. They will be arranged to plant seedlings 6 feet 1.8 apart. The hydraulic power supply now being used should be for both planters. adequate m Figure 2.--Cable crane positioning 15 tree/shrub planter. WASHINGTON OFFICE NEWS OPERATIONS Harold L. Strickland Assistant Director OF ENGINEERING DRAWINGS AND SPECIFICATIONS Administra-tive engineer-ing For some time we have been revising our portion of the Filing FSH 6209.11 in a manner that will accommodate System Handbook of microfilming your project records. This has led to Managements approval for Region 6 to microfilm all drawings and the purchase of 3M-201 Reader-Printers for each Forest in Region 6. re-lated the Region 6 approval Following a letter 6230-April 13 1979 was sent to Regional Foresters Station Directors and Area Directors that authorized the microfilming of all engineering drawings and the subsequent disposal of the original documents. We support this action and recommend that it be applied to specifications and documents. project There are some problems associated with such an undertaking for it to work you must have documents and plans that are suitable for microfilming the necessary equipment for reading the microfilms and access to equipment that will produce hard copies. of Material Preparation is not much we can do about our old plans as a rule you can get a fair microfilm image from them. However when you prepare new drawings there are some things you can do that will ensure a The following are some recommendations for top quality microform. microfilming all project data There 1. Use original 2. Use the 3. Use the microfiche a reduction documents with 35 full-sized drawings mm aperture card for microfilming format for drawings format for specifications ratio of 124 and 24x 17 and other i MICROFILMING re-sult reader-printer re-sul Produce all microforms in a black line image that 4. as is Lettering negative images. easier to read. This will - In making all drawings charts graphs tables plats and other material that include lettering. take particular care to ensure size to that the size of lettering in the final copy is of adequate be read from the reader-printer. Many microform readers and do not bring the image back to its original size as a letters and numerals must be of sufficient size to make the retrieved image legible. re-duced minimum letter height of the final copy must be 0.125 inch and capital letters not lower case should be used. 0.3175 The cm of between adjacent letters should be twice the thickness Spacing If the material is to be reduced to a final form the letter lines. that is smaller than the original drawing such as a drawing to fit on the of-a photographically publication the page minimum letter height applies to the reduced copy that will be microfilmed not to the original drawing therefore the lettering on an original drawing might have to be oversized to obtain the minimum letter height. dimen-sions should be twice the size 0.25 inch or 0.635 cm of the Headings text letters. between lines should be no less than half the Spacing letter height. Letters should be bold straight and open type if used instead of hand lettering should conform to the same and style. Lines For the same reasons given in the preceding paragraph line weight should be 0.01 inch 0.025 cm or heavier. Open spaces between lines should be four times at least 0.04 inch or 0.102 cm that of the line weight. micro-graphic We and Standards to develop are working with Consultation standards for all engineering These drawings and documents. will include an indexing system to be used on a Service-wide basis the standards and indexing will be incorporated into our Directives Until these are published we recommend system. you use the as interim guidelines. pre-ceeding you have 235-8077. If any questions on micrographics 18 call Al Colley on FTS TECHNOLOGICAL Heyward Assistant SLASH WARMS IMPROVEMENTS Taylor Director T. WALLA WALLA Devel-opment A lightweight cable yarding system developed by the Equipment Center at Missoula recently yielded an unexpected benefit to. the citizens of Walla Walla Washington when the yarder was used on a logging slash utilization project on the Umatilla National Forest. slash was made available as firewood Normally inaccessible to the citizens of Walla Walla a community about 28 miles 45 km In 29 days 3050 cords 11056.128-m3 of Western-larch and away. Douglas-fir were removed from steep slopes and piled on a roadside. Eighty-five to ninety percent of this choice firewood was picked up by citizens to stock their woodburning-stoves and fireplaces. In fact energy valued at $224000 was made available by the Forest Service--enough energy to heat 470 Walla Walla homes for 1 year. This project saved the citizens of Walla Walla money and achieved the land management objective of reducing fire hazards. The direct cost to the government for removing the slash was $2.87 per cord 3.625 m3. When the cost of equivalent energy for fuel oil and natural gas are averaged for the Walla Walla area the firewood made available was worth $86.181 per cord 3.625 m3. elec-tricity This fuels project should interest the Northwest Forests because the Umatilla able to rid themselves were of accumulated on managers For example in the slash a problem common throughout the region. Pacific Northwest Region in 1978 more than 326000 acres 132000 hectares of forest residues slash were created from an annual timber harvest of nearly 4-1/2 billion board feet Since 1961 in Washington and approximately 10-1/2 million m3. million acres 1 million hectares over 2-1/2 approximately Oregon of untreated slash have accumulated. In Montana and Idaho the accumulation exceeds 700000 acres approximately 280000 hectares. approxi-mately Z values for WaZZa WaZZa were equivalent furnac-e oil--$.50 natural gas--$.3915 per hundred cubic per gallon $.50 per 0.3 cubic meters electricity--$.0174 feet $.3915 per 2.8 hundred per kilowatt hour wood--$86.18 per cord $86.18 per 3.625 m3. Energy 19 Prototype yarder treating slash on 20 the UmtiZZa National Forest. mate-rial ob-vious other Forests have made this residue available to citizens Although to them and the removal cost is much the wood is often inaccessible Slash treatment is usually done by higher for the Government. costs for Handling burn chipping or masticating. prescribed has an are high and the burning of large concentrations Some slash remains untreated and impact on air quality. of untreated residues are .eventuall decays however accumulations fire hazard. Residues also represent a waste of natural a potential effects on wildlife and watersheds. resources and have undesirable Land managers are often unable to treat slash because steep slopes and heavy fuel loadings are inaccessible by rubber-tired skids and for a large cable yarding system. Other factors are uneconomical such as the spacing of residual trees number and height of stumps and soil conditions might prevent treatment. inexpen-sive Clear-water In January 1977 Harry Cummings a fire management officer on the Forest requested that the Missoula Equipment Clearwater National Center MEDC design and build a lightweight Development In tests on the yarder for removing slash. prototype Forest the yarder2 met production goals while removing slash It was this cost on steep slopes. selectively and at an acceptable the Umatilla that enabled the fuel on managers prototype yarder treat their slash while contributing National Forest to effectively to the people of Walla Walla. a substantial savings energy The potential for using slash as an energy source is enormous from fuels managers. should receive increased attention yarder are available from MEDC Bldg. 1 Fort a-re Montana 59801. Drawings and specifications in the distribution 1979. fall of for 2Publications.on Missoula planned and the Missoula 21 INVITATION TO READERS OF FIELD NOTES Every reader is a potential you would of an article for Field Notes. author you have a news item or If ac-curate short article Material share with to Service we engineers you invite send to for it Field Notes. in publication like submitted to the Office for publication Washington should be reviewed by the Washing-ton Regional respective informative Office to and of that see interest to the information is current timely FSM Forest Service Engineers technically 7113. The length of may vary from several short sentences to several typewritten pages however short articles or news items are preferred. All material submitted to the Office should be typed double-spaced and ideally all illustrations should be original material submitted drawings prints glossy Field Notes is or negatives. distributed from the Washington Area Headquarters Forests Office directly and Forest Service retirees. If to all you ask your Office Manager or the Regional Engineering Coordinator to increase the number of copies sent to your office. also available from the Washington Office. mailing to their should Regional R-1 R-2 R-3 submit material for publication Station currently Technical list Field personnel Regional are not Data Systems Copies of back issues are or questions concerning Field Notes Coordinators Dittmer R-4 Ted Wood R-9 Fred Hintsala M. Ryser Juan Gomez R-5 Walt Weaver R-10 F. Melvin Royal Coordinators and on the should direct R-6 Kjell R-8 Bob questions WO Bakke concerning Engineering Attn P.O. - format editing USDA Staff Gordon L. RP-E Bldg Rome Editor Box 2417 Washington Telephone Baxandall Bowers problems to Forest Service W. Al Colley D.C. 20013 Area Code 703 235-8198 publishing dates and other