M A I N T E N A N C... F O R B L E E D... F L U S H E D P...

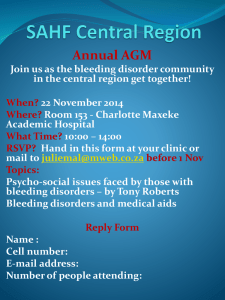

advertisement