INFORMATION ENGINEERING TECHNICAL SYSTEM

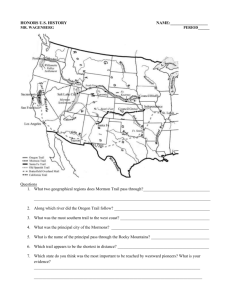

advertisement

oppp ENGINEERING TECHNICAL FIELD INFORMATION NOTES DATA TECHNICAL RETRIEVAL REPORTS TEXTS CURRENT AWARENESS SYSTEM s FOREST SERVICE JULY 1975 UýS U.S. DEPARTMENT OF AGRICULTURE UýS ENGINEERING This publication The Forest text the The and Because publication monthly is not mandatory of the not of technicians is the Department interpretation of nature or of as of opinions or policy except material should the in issue or FSM by publication each read the recommended all however exclusively for engineers. published for distribution this Service and no assumes Agriculture use personal construed instructions type intended newsletter be Department of Agriculture-Forest U.S. exchange to published technical or administrative represents must and engineering engineers This publication procedures references. this the author approved a Service personnel. in respective newsletter and ideas of information engineering among monthly a is FIELD NOTES information employees of to its retirees by other only. for responsibility than its the own employees. The use of trade convenience evaluation any product of firm or corporation the reader. conclusion or service Such use names is does not recommendation to the exclusion for the information constitute endorsement of others or an approval which may be and official of suitable. June 18-27 6/18-21 - Cut out Miles hitch 10-day Begin Trail 108 Route and stay two nights at days on Route Creek to Pack Bridge. between clean 6/22 - Cut Creek to Wrong Creek Then Trail. Be sure to repair out beyond 109. Any Wrong Creek 109 from any damaged Drain 14.5 on two Trail 108 bridges all and bogs bars. 110 to junction Trail tion with water all at while working Trail Route Creek and Ray Creek. or replace 110 Trail with Trail extra time can 164 and 164 junc- be used on Trail 2 110 cutting out draining and rerouting the junction bogs. 6/23 - Cut out Headquarters 6/24 - Cut out Trail 111 to Trail Rock 165 as far 5 as possible. Creek Cabin. Stay at Rock Creek 9 Cabin. 6/25 - Meet 6/26 - Cut out Trail fence pasture 6/27 - Shovel Pass. bad bog on the at rocks Return Figure 1. - Trail 110 from Gates with Park to Wrong it. Check Creek. any extra time. off switchbacks stock and try and bridge 111 on east side of Route Creek to Ear Mountain for the weekend. Portion of Annual Trail Maintenance Plan 8 - A CASE STUDY FOREST TRAIL MAINTENANCE PLANNING John W. Transportation Platt Group Analysis Region 5 Bob Richmond Teton Lewis Ranger District Forest Clark National Region 1 success-fully This on the Teton Ranger District miles of trails and slightly District the south to Mountains 1 Forest Region Clark National the Continental unique Bob in Marshall east side 500 Rocky of the area and the spectacular Wilderness with facilities Together with the Sun River from the access on the Lewis and District located regards to transportation 20 miles of roads. the primary provides it is The Teton 1966. since more than the popular to system that has been operating the trail maintenance planning discusses paper mountains of Divide. approxi-mately Some may statistics recreation visitor help days system from while big game District be an hunters and hunters by population way to outfitters govern continue to make centers within dominate the the fall. a trail 1974 with 150-mile radius of system during Demands on scheme was put the the trail maintenance while adequate increase planning a 10000 about FY Total perspective. in are during it Because of this decrease. efficient situation network trail and commercial recreationists funds for the to use generated Backpackers summer months found this District on the experienced 60 percent of the District. the Teton put effect into and use of every trail maintenance dollar. mainte-nance particu-larly maintenance planning Trail summer and developed early fall on the trail from reports from crews condition fire is year-round foreman and are collected. District trail patrol spring late These data are men roving trail reports from public users foreman is also These surveys afford him another the winter. During the process. and wilderness prevention The a and use information surveys by the trail the commercial outfitters. snow District conditions responsible for making evaluate invalu-able trail surveys during and notice conditions result of snow experience input slides or other snow/water on the District the judgmental maintenance plan about is the annual trail prepared be accomplished preparing damage. fig. plans. use 1. opportunity be needed With over A provides chart to the spring as a of the trail foreman are an process. a detailed description wall chart titled is in 10 years trail maintenance and conditions collected throughout that This will contributions into the trail maintenance planning From knowledge job to where immediate attention Trail Maintenance updated annually 1 the year an annual trail of the trail maintenance is also used in and remains posted on the wall TRAIL MAINTENANCE NO. 1 101 102 2 Two Meadow- Heart Butte North Badger ý0 PERCENT OF STANDARD 1 NAME pPý 3 4 5 6 H H H 14 ýýZ- 7 20 8 40 9 60 80 10 11 YEAR MAINTAINED REMARKS 66 67 68 69 70 71 72 73 74 75 12 13 14 15 16 17 18 19 20 21 22 and Signed Blazed 1971 H M M 100% 6 to Std. 1970 103 South Birch Fork M L M 10 Lower 3.5 Mile Creek Realigned 1969 Flood Damage Figure 2. - Trail Maintenance Chart After of the District office relative 2 chart fig. by the management involved on it a particular to used of the on the chart and use levels as trail foreman Plan. consideration give Three standards standards. the planning formulating specific Rocky Mountain Front Unit Plan and the Wilderness in H- Heavy Use factors are ultimate management objectives for the Management and Engineering manuals with more defined are desired trail system are obtained Marshall and needs conditions local overall many Although trail. the primarily determined maintenance standards planned 2 depicts Figure contains. it of these documents the Ranger and the framework Within that be served for each to Service Recreation from the Bob direction glance the trail maintenance history a to express these criteria in terms The trail. at of any trail on the District. of the information specifies objectives convenient is from Forest 3 column see significance format of the chart and the nature The may anyone that so current status and the are follows Heavy use been have trails identified to serve as the primary out-sloping routes for providing smooth relatively access or puncheon crossed dry with is trail is well drained where tread Trail of existing manipulation or other necessary used bridges areas of the District. special The grading. bars ditches water nonroaded and may involve surfacing treatments corduroy to is material or other native for surface runoff without or rerouted Bogs are drained measures. Streams and other cross-drainage necessary. to be intended and are or by other means. culverts mainte-nance If a dry crossing then impractical is and limbed back to allow convenient and other permitted wet safe trail passage of horseback riders pack stock These trail vehicles. The established. are crossings intended trails are brushed is snowmobiles receive high standard to annually. Moderate Use M- Often these trails branch off from the heavily used ones. smooth neces-sary negotia-tion Tread conditions are intended and measures special user safety. drained Trail and pack The to be only runoff is Stream and trail is by allowed as material are necessary for are wet crossings unless structures are drains are and limbed allow slow to but safe passage and slopes are corrected washouts native existing unless they with outsloping and water bars bogs well drained cross brushed Blowdowns stock. as smoothness are not employed obtain surface or rerouted. for safety. riders to of horseback to allow safe main-tained. of the trail and to Low Use Surface runoff investment. protect trail. left unless they that is intended L- travel Tread conditions is present potential in this standard. at except are hazardous only to are not locations the extent necessary to accomplished only for purposes Blowdown encouraged. resource reroutes by users. to are maintained and brushing not due damage and cross-drainage Cleaning Horseback the prevent resource damage. Typically these A game trails of defining slides and other obstructions trail type facility are maintained is probably are all once every three years. The Trail priority placed 2 column High Medium Low indicates Maintenance level by the District Chart in fig. allocating resources 4 also depicts maintenance to chart observers to bring the various 3 a priority. This measure of the importance trails up to their planned CONTACTS VISITOR Day No. 1-2 Yr. 3-4 - Zip 5.6 7-11 No. BOB MARSHALL Day Mo. WILDERNESS Fish Hunt 17 Photo18 Mtn.C.-- N.St. Swim Hike 20 Ride 22 21 23 Camp 4 O Hike Fishing Hunting Swim Photography Hike MountainClimb Ride ZIP w/stock Other No. Saddle stock Route Nature STATE No. pack stock Campsites Study Where 1 With 2 3 No Outfitter Outfitter 1 2 Private Party Organization Spot Pack Contacted Compartment 1 Camp 2 Place Name and No. Trail 3 Road 4 Other 27-28 Information Visitors given questions or comments 29 Given 31 Questions 34 3 stay Type 25 Comet. Contact of Horseback CITY Other 1261 30 party of travel Hike Activities rg Contact Length in 24 Outfitter Info. No. 1 2 CLARK NATIONAL FOREST STREET 19 Other Pvt/O Method 14-15 16 NAME Yr. Stay 12-13 LEWIS 35 32 33 By Asked 36 37 15-2300-2 Figure 3. - Trail User Information Card 4 mainte-nance The maintenance standard. effort is based are considered and desired use the season of use other factors related to the for making were formally in Through August 1971. extended the A estimates. of use data is provide a 6 uses tried for the form good display of In order to make when personnel District poor management due to consistent a record Bob Marshall they encounter users on columns when Priority and Standard trail a trail considered For example when operations. trails have results for the designed originally trails current trail use years with several background personnel show to as on the heavy use District system with the counters. by out grades and the District for conducted survey trails in a visitor-contact filled trail on the chart are included and observations other to Entries in the Traffic Index together and 5 experience difficulties the District cover vegetative Traffic Index relationships program was counter Plan that Wilderness 3. field and technical vandalism fig. trail The of this survey results characteristics by an origin-destination established District The management objectives as with the type and amount of existing situation. particular decisions. emphasize the to factors. combination in soil Length columns Traffic Index and Trail information melding of several upon the previously discussed when and where of decision a mainte-nance assigned high maintenance priority with a planned heavy use maintenance standard this tells the observer that management trend is toward encouraging present low use trail higher immediate a is use by lowering the impedance to though improved travel trail has shifted. The of Standard Percentage of the percentage section a bar chart which is For example current maintenance cycle. of several with the exception bogs The Year section trail are working Determination of the planning and cost 10-day shifts do for a specific may be note to to planned standard its that this 80 percent not is a length days applied trail the to The most is Ranger effective that has been performed a The by the this data. work and economic performance and amounts 5 trail work on a trail. covered by for the two guide for completely as a instructions. and materials Figure District. The form is bosses required. is necessary in accomplishment an example of the amount of to the size. 4 costs work simple and self-explanatory historic have for determining crew of of of a systematic referring device that recordkeeping schedule of the type and By a plan serves foreman and crew or routine is to the length day-to-day the result description trail 21 work or no operating maintenance work. repetitive Equipment its 12 to time manpower procedure established in is District. little for organizing and recording these Daily Records that on the estimates realistic and yet quite comprehensive to up totally is proportion in Column 22 Remarks of the trail maintenance job accounting form used of maintenance crew bosses who require experienced accomplished to date under the might be considered important shaded under the year number for the year. crews is columns 2 of Figure and extent indicates the frequency the crew which a trail the estimated relationship. Maintained The boxes It 11 7 to that need draining accomplished and shaded accordingly. proportional columns maintenance standard shaded to show is a resources required information standard on measure DAILY RECORD No. 15-6500-15 Trail Maintenance TETON Trail RANGER STATION Date No. To From Q Foreman b aj aa ay ý a 03 o yýa me aJý Total Crew Hrs. Cost Meals No. Cost Total Cost Totals Miles Completed Today Travel Miles P. 1 Material Cost Hours Equipment Item No. U. Ton 11/2Ton 6 Pass. Jeep Grand Total Figure 4. - Trail Maintenance Daily Cost and Resource 6 Requirement Used Record Cost Type and amount Recommended A standard Basis of productivity Everyone involved with the standard number crew that can skill levels schedule defines clearly that the The come of variables total trail trail maintenance job exist will find parts in that completed is could at operational are District be made that can for The to assure the Teton District More however contributions Hopefully the field level. approach accidents a schedule. satisfactorily. make major adaptable to analytical such tools do the reader of this paper his particular situation. ADMINISTRATIVE CONSIDERATIONS FOR MANAGERS FACILITY OPERATION AND MAINTENANCE Darrell P. McNenny Environmental Region William C. Sanitary Washington supply and accountability and wastewater at various technical hands-on skills Clow Hank and Handbook Russell and provides Phil when printed organizational will for Trail Maintenance be an excellent Engineer Kolzow Office facilities Health 1 Engineer - Engineering and maintenance the most important aspect of operation Service water 1 to A and WATER AND WASTEWATER Regional Perhaps adhering estimates productivity. breakdowns equipment when of the art of trail maintenance planning. certainly of the Teton weather as difficulties scheme presented above works well the current state forms not that the time and mileage realizes maintenance and adjustments overall approaches and methods IN rapidly create maintenance fundsl only an appraisal of the average provide into play such maintenace planning and represents measure trail expected per day. work. of day-to-day and budgeting developed from the Daily Records of accomplishment terms in scheduling for requesting the activity. for performing procedures Recommended be used. of materials that should is the framework OM levels insures proper mixing of engineering audit and inspection procedures. Management to guide 7 trail Handbook maintenance for the Forest which defines responsibility Draft - Without 1970 Region 5. management systems. and this This mainte-nance. framework the wide variance structures would contribute Therefore operational to and organizational complexity facility ineffective and systems operation management of that the and groups of systems be well planned skills and inefficient imperative is it in and wastewater systems water and structured. super-visory Organization The manager office isolated Any level most levels above that below and Pollution responsibility Forest-wide i.e. levels activities is is responsible the Environmental NPDES. System the at and area technical except of activities EPA Agency in for skills the coordination for Protection of systems operator staffing usually an engineer too remote from the work do not possess the adequate it Elimination Discharge for proper is The manager and maintenance. other agencies National on and maintenance operation instances operation with for level. This individual training programming and the has also and budgeting and jurisdic-tion. account-able a The inspection of systems as necessary. and technical operation efficient The operators engineer of every water for each water the managing to recordkeeping basis proper priority technical therefore is consultation responsible auditing for the effective and wastewater system under and wastewater his be technically system should engineer. Programming and Budgeting Lack of funding the reason is heard throughout the Forest However maintenance of water and wastewater systems. much at a lack of funds the proper control time as it is the. lack or to efficiently public health those funds already and welfare safety are excuse for nonperformance. adequate this operation and maintenance situation not is Closing is an is Since budgeted. related to proper directly maintenance of water and wastewater systems low funding acceptable seems the problem not so program and budget the necessary funds of foresight to utilize and Service for poor operation it priority is pollution and operation not an considered those sites which cannot be funded for which may have to be implemented alternative if resolved. Personnel The matching of proper technical skills with water or wastewater systems operation and considera-tions maintenance requirements of contract test more than one system of test In sample collection many cases and maintain should relatively should simple disinfection operator possibility laboratory of requires a high degree operator staffing training geographic of assigning an operator facilities location to care and for or of establishing Forest-wide can be trained and effectively with systems in conjunction significant to not be overlooked. personnel in establishing be designated management and contributing skills The centralizing routes accomplished without wastewater Factors facilities. current District care must be taken operators the responsibility of system complexity operator include availability is and good judgment. technical ability work schedules interference and trained equipment when with to their insure that OM the primary operator 8 activities to operate However are routinely For example alternate other duties. assure the continued to utilized other duties. is functioning on call of water for fire or other and emergency The leave. and when duties operators. for those systems requiring for water all such the Operators i.e. weekends annual and certified at a specific Forest Service is working toward Much system operators. sessions goal of formal a certification by the State health administered Technical be encouraged major systems or group of systems should all be recruited of the training and the actual departments and the Naashe Missouri Water and Wastewater of should level sick and additional require the recruitment skills. and wastewater supply days will accomplished through the Short-Course are testing mandatory not Although nonwork his complexity of other systems higher of competent training he has to School. obtain Operators the necessary knowl-edge manage-ment become to training certified and recruitment function of the of operators certified at level a specific should be considered. Training is another of plant operations of the training received engineer is system by Forest the logical little used one operator method of operator Benefits which for a group of systems. an on-the-job or coordinate necessity. In addition this training. training Much The programs available he in of these opportunities. take advantage but extremely efficient is and out-of-service in-service order to insure that operators A accomplish to that requires a good overall engineer procedures and maintenance requirements. Service operators person be aware of the formal should management testing utilization the is be expected can employment of from such action include skill level Higher Reduction in less - utilization. Better maintenance of specialized Better opportunity More efficient District and Forest method of to overall boundaries manpower complex systems. manpower. manpower Better of operation skill levels. employ operator skills on a year-round basis. operation. should not restrict logical geographical work areas for this utilization. Testing proce-dures Adequate laboratory treatment and protection are used to regulatory is being the only satisfactory obtained measure performance. limited equipment and considerable control and instructions to by a water They range method of measuring the degree or wastewater system. may dictate testing Many from simple tests which require only complex examinationsrequiring elaborate training to perform the tests and interpret the results. agencies requirements system control. 9 of in addition In some equipment cases to those required for will play a key role in establishing a framework management must Engineering both be and insure quality control. efficient by commercial or State testing and quality control sampling in In laboratories. many for contract sample collection routes Forest-wide Options cases-it is systems and contract most to utilize efficient This will also testing. that independent include available centralized laboratories for several laboratories for each system for testing insure uniformity and preservation. techniques WHY EQUIPMENT DEVELOPMENT DOES IT TAKE SO LONG-Donald L. Sirois Mechanical Engineer Office Washington working toward the development of a new device or equipment system the time - five years four years but seldom less than three - is a fact of life that must requirement When There may be exceptions be accepted. problem follow time-frame but are they all too of the Trail the development To rare. better understand this Traffic Counter. The Need In the mid-60s it became evident that recreation specialists make needed better methods of trail traffic recreational impact. rapid increase in use of the forest A and snowmobiles complicated this work were manual power however they methods surveillance measurement the traffic had serious shortcomings all was recognized throughout and other accurate by hikers task. The and photoelectric treadle switches tallies to the Forest forest managers assessments of the horsemen trailbikes for only tools available cells requiring AC line and the need for new or improved Service. The Innovator This problem stimulated Louis an employee a security Early that Center suggestion Those forest which Forest lost Felton new a Service Technician Forest counting system based idea was forwarded summerFeltons MEDC submitted a early in on an ultrasonic 1967 to submit intrusion alarm - device. his device breeze caused By did not the give spurious to following accurate counts. the Missoula summerdata counts Some 16 Equipment Development from the evaluation showed under ambient wind conditions months had elapsed even since Felton suggestion. months MEDC evaluation. for that the ultrasonic a light for were not wasted. launched their Evaluation search for the of Feltons idea was the platform trail traffic Service needs. 10 counter that would meet all from of the The Search The search were focused of the initial stages physical and qualitative of the desired in the equipment field development survey were as on identification of This device. The trade. is known for the criteria attributes specific as MEDC both development of the criteria counter as established in a follows as invisible nearly as possible and portable self-contained lightweight and eliminate connecting transport for 30 days to operable of recording capable vandalism reduce to power source to provide easy lines minimize maintenance cumulative 9999.000 to counts reduce to recording requirements cost than less $250 of the price good talley-whacker a tempera-tures encoun-tered under operable ranging in weather conditions all from and accurate reliable 120F to all to day and night and all accommodate the in conditions Service sites and Forest all -30 usable assessments. provide to require-ment estab-lished These were established criteria ultrasonic the first three MEDC device was proven unreliable. that would meet the product in for any Equipment which may exist in the criteria. specified Center Development commercial-industrial months of 1968 and shortly thereafter then began a search for a commercial Such an inquiry order to in avoid is the a fundamental equipment developing and which can be used or adapted by the field center. Only one company was found with for our purposes criteria MEDC GCO provided a GCO retrieved and the a range 30 of only seen in a traffic and work 1 to a Optoelectronic pulsed light through an electronic a a light to Nevertheless to through the late summer. periods Feltons counters The of cold required decided to stay with field trials and snow. 115 -volt demonstrated accuracy it meeting any of the With encouragement and from were went well However there 60-Hz power and had reliability never the optoelectronicl the power before approach requirements for unit. light a given source lens. A an impulse a light-emiting reflector located second lens to a photosensitive triggers to the field for testing. streamline the electronics and reduce system using a circuit that in close company GCO. 50 pounds MEDC Thus came that that data even during battery-operated is beam of feet. GCO sent the unit weighed counter. with conversion was accurate were some problems product call prototype counter counter and the unit produced a well device. counter. 11 diode LED in at the distance Interruptions in this case across the receiving a that trail light produces returns are sensed a the by After a number of DC-powered - 26 months With the project going well become more locate companies additional turned it DCO out for a that company had years ahead of any counter a contract MEDC prototype a decided could units reported were proving GCO DCO During - period this the extra effort the field for to they circuits tried to A paid off. to small was discovered. were that was two injection laser device the worse. for counters were inadequate and having $1000 rose from $250 to technology. that well call 20 sent 20 for do some design studies on counter unit with a fullium aernside counters unstable to MEDC had seen. Efforts were of DCOs new development. that the failures the battery They build counters At the same time the project took a turn field was negotiated contract a were received and Feltons suggestion. after with optoelectronic familiar highly-technological As engineers production prototype counters. June 1969 in testing GCOs with discussions then directed toward negotiating Information received inaccurate giving for field needs. In addition battery problems and the projected cost from the daily and having counts DCO prototypes for production per unit. pro-jected MEDC had made in their counter for 1971. was out but Another they all DCO MEDC decided to counters was made new several months eight and season field make improvements to these were also an improved optoelectronic initiate 1970 GCO design with production untested but ideas and only alternative for the available to encourage new offer was a could viable have to effort proposed With no other high. season commitment a time was running and the untested before 1970 the cost field design developed by their engineer David Gasvoda. Gasvodas The Design circuitry of Gasvodas been examined however was one-forth that of the risk worth unit and the range was reduced by using dry the cells Power taking. was doubled had been added which enabled Power consumption events. made the advantages GCOs best to insure count-accuracy from that of any of the units that had previously unit differed 50 counter that lasted to consumption A feet. reject timing circuit spurious 60 days under continuous operation. The project was moving was completed by February 1970. and had sensitive to The again and so was the clock. be relocated Tests indicated that to second prototype was assembled - avoid electronic time this all prototype of Gasvodas first some of the components interference performance design were too with other components. criteria A were met and the design was frozen. Gasvoda-designed MEDC called back 10 of counter. necessary Gasvoda circuit GCOs counters With these on hand boards. trail traffic By counters a May MEDC to the to use as housing contract units for the was awarded had assembled adjusted Rocky Mountain 12 Region. new for the construction tested of the and delivered 10 They had met the deadline With the deadline them for work field and contracted new the changes various and drawings and testing The Forest This and should were finalized now had 20 hand-built system and housing and rapidly were prototypes traffic that counters use. trail worked directed specifications Four years of searching 1971. January MEDC The unit a few minor after Next built. for Service-wide in units and modified Gasvoda design would that of the optical progressed ended the development of the have Service five GCO 10 remaining work effort of counters purchase mass production for the They were confident redesign was frozen design toward quantity efforts received locations. for the necessary redesign mass production. to permit their them MEDC behind trials at counter but but didnt. it meet these did not all com-pany Informa-tion the field needs.. A contract was negotiated in January and was awarded MEDC contract The 256. counters before RIM be isolated not $59000 the and attempt suspend the contract developed 51 had isolate to to be were added counters 23 when July engineers flew counters to small a so for a Recreation available 90-foot operating MEDC SDI delivery by mid-July for 1. the specified study a team of for bids were issued produce 205 counters to Incorporated 60 counters smoothly and an additional of serious trouble signs RIM the by August requests contract were targeted counters goal of having study The Dimensions Scientific The counters of the had responded. Mexico. new were not achieving problem could The a progressed first bidder New meet could Management The 29 bidders the lowest to Albuquerque in that for mass production March in SDI reported With only range. SDIs The that the a few days They found plant. rejected. of a total for left the that was to only alternative the problem. Question Each component Why werent seemed system tested perform better than the specifications required. to prob-lem the counters Extensive the 75-foot range achieving were made yielding reams of data a computer was used a last between a correlation establish earlier were compared prototypes was finally The identified. numbers stamped on batch with No and performance. design criteria effort the manufacturers and measurements tests for analysis in an attempt to those used in the SDI production manufacturer phototransistor As progress was made. the phototransistors his the in The units. had changed used product but photo-transistor not number. the part that could provide a MEDC then made efforts workable and reasonably and reinstated the SDI contract and moving 256 A had passed but seasons field forward trail traffic happy Note ending Under a to with quantity except TCS it is slightly direction. equipment contract Scientific trail traffic discounts. visible a The and were acceptable a five-year GSA with Feltons suggestion a positive counters the Gasvoda-designed units in during 90-1 that has an increased new final met as their hours. 13 in inspection or exceeded Four vain the project was alive was made on schedule the contract Incorporated model TCS-90 at is still all specifications. is compared to manufacturing a cost of $275 the original Also there as a project. model meets or exceeds of 120 feet They found delivery date of April 1972. had not been Dimensions daylight range new semiconductor manufacturer phototransistor. development counter This find a to priced counter for single criteria an improved model 75 feet for the TCS-90. NEWS WASHINGTON OFFICE ENGINEERING AND STANDARDS CONSULTATION Charles R. Weller Assistant Director engi-neers WA TER RESOURCES - FEDERAL POWER COMMISSION WORKSHOP These two and others working separate sessions held the the water end-to-end /2 days were 2-1 first in to development resource week the during devoted which recommendations resulted in several sessions will be of interest of April 7 in San Francisco Water Resources to there were two Basically area. California Some Service Coordination Workshop. Power Commission-Forest days Engineering while the last 2-1 /2 of certifi-cation were a joint Federal the more and recommendations involved decisions significant agreements with the inventory coordination of the people designing dams procedures The recommendation will as make needed it to dams which the establish will be most dam system should visible Service revisions generate to acquisition specific involves interest the certification seem to be program Of safety licenses. level. listings program. need to have a of existing Center Collins Computer Fort special the recommendation The workshop group developed be studied to make it more compatible with the users Another item of dam the Forest at and training national dam Service Power Commission the at inventory possible for Forests with terminals basis. manual issuance of Federal involving the foregoing there are several Conservation Soil of proposed water projects coordination environmental and coordination and inspecting the Forest and reports on an that the inventory needs. The certification of the consensus category in accom-plished task group was that there does dams either in design or inspection. without a Decisions certification will For more detailed information the Regional People Regional probably was Workshop felt needed and that this can be were mostly Federal will result in FS Manual changes year. on the meeting in attendance Offices it is program. be forthcoming over the next workshop. more training be helpful from the FPC Coordination developed will a Although job performance requirements specific which not contact Regional those working in Office attendees water resource of the engineering Power Commission Coordinators and Washington Office representatives. Guest speakers Bogner from other than the two participating Director of Engineering Soil Conservation Service agencies included Robert Simmons Neil Attorney Sam Miles Structural Engineer Corps of Engineers William Wahler Associates Chairman of the Board Woodard Clyde Clevenger Office of the General Counsel William Federal 14 in W.A. Wahler Safety FOREST SER The Lay and James California Division of respect to Many of safety. some and capacity in dams dams of on National condition questionable by the Act more dams than should if a failure life involved any other occur. the Forest fact in in others in this law than land Forest by Congress concern dams control over approximately 1300 of administrative degree are more deeply is built in endanger human could Service of the because passed the United States which these number be covered to 92-367 was the Forest agencies of the large Service has dams of PL Act Safety number the Federal because NA TIONAL DAM SAFETY ACT VICE ACTIVITY IN THE Dam National of the large Of and Gordon Dukleth Associates of Dams. Federal single of a size agency. inspec-tion To date under the terms in the acting been developing a national dam other program by agencies The Forest two types is as recommended dam preparing inspection of an actual not require the institution COE with the or coordination the technical activity COE has the Corps of Engineers COE. than the FS inputs Service does Act Safety and inventory PL 92-367 guidelines and procedures. Dam with the coordination contrasted be divided can activity into of administrative requirements. The technical activity Guidelines Proposed dams data on within consisted inputs for Safety of providing of Inspections the National comments on Dams COE the COE and providing publication with inventory Forests. inspec-tions The other major input the administrative the actual planning conducting all financing discussed in detail Expanding on these two inventory people in in early seven 1974 problems and Service at comments to the by Region on the The cards. last the same differences within interpreted COE occasions. several 4 August time serve with USDA Technical for before Department-wide the best advantage Soil involving of both the administration being developed of the inspection SCS and in it it FS. early program is the felt Review the COE Act filled inspections were Safety was decided Service was combined by the COE. These recommendations 15 needs COE safety to In order to best reflect Conservation the Departmental recommendations were submitted actual dam and comments. review those of the for Guidelines was given Dam by the involved and computer Staff engineers 1300 dams covered from each Region compiled into a FS reply then The which occurred the first action Regional Office the FS report on the dam inventory the report boxes of computer distributed by the Forest efforts the Washington January on regarding and State versus Federal problems staffing major types of activity Through data. and working with the Corps on Recommendations implementation of the safety program. inspections were coordination involves to FS combine the SCS. By resolving comments would be the comments were received with those of the SCS. The October 1974. also the subject were to cover of recommendations subject such as Who will be responsible How will the for inspections be financed inspections Of the approximate to be inspected FS and SCS comments and 60000 suggestions dams of comments on Long Dams Assistant and a second as comments on key points summarize the Department A program for dam safety The proposed program on Federal that is dams The program needs The COE is Dam COE plans to present preparing Safety will reflect the foregoing continuing coordination setting policy for should signed by Robert The following comments of require that private to the respective States final Agriculture is dams located agency standards for before in July the report the Washington and implementation the national completing Congress time adjustments. staffing also suggestions between and of the dam. recommendations to life area of responsibility. a comprehensive implementation plan to establish package efforts The publication. remain the responsibility of the Federal should letters Program of dams. to be revised in Program and the final and Education. level National needed to assure protection urgently arrangements and financial currently for the National a letter with management charged frames after 1975 by Research Act which need Department program lands be included Federally-owned as the below or adjacent located property COE Safety of the suggested of Agriculture is Dam on April 18 for Conservation Secretary COE by the program were provided the by the were forwarded to on two occasions one prior to publication Inspection covered 1975 to it is Congress. dam inventory. not known how There Office and the engineers will it be that are the Corps. TECHNOLOGICAL IMPROVEMENTS Heyward T. Taylor of Engineering Assistant Director THE NCHRP REPORT USE OF BITUMINOUS EMULSIONS compre-hensive By mid- or late-summer the Transportation report of Highway on Research Board the use of bituminous emulsions. Practice report under the National 16 The will be distributing a report will be issued as a Synthesis Cooperative Highway Research Program NCHRP. as Forest Service engineers been have active the report and serving on the Advisory co-authoring The and to the development of the report. Panel NCHRP this giving direction study and the Federal officials study as well the study to by the American was jointly sponsored of State Highway. and Transportation Association in initiating Energy Administration. The report Forest is well done. Service engineers materials Among contains It having information considerable in responsibilities and maintenance engineers construction that should be of the roads and trail program. find the report will direct use to Design useful. particularly the topics discussed are - Chapter One of emulsified asphalt Development Introduction. use of asphalt specifi-cations materials cationic energy comparisons technical service Chapter Asphalt institute Two - Structural design Chevron - Chapter Four cost Design. design - General emulsion Chapter Six surfaces roadside slurry - composition hardness abrasion shape particle surface chemistry Introduction emulsion storage and pumping Construction. mixes spray applications - texture surface discussion. of surfaces laydown of central plant mixes road mixing of aggregates for design and mix design spray application systems aggregate stockpile management preparation tests AASHTO considerations discussion. Mineralogical Aggregates. gradation Chapter Five control safety and grade construction of type analysis. Materials selection absorption durability deleterious materials considerations selection mixtures. seals emulsion-aggregate porosity needs technical training Chapter Three density environmental emulsions emulsion asphalt history of emulsions Maintenance. compaction plant operations of emulsion mixes hints on construction. surfaces Asphalt central maintenance of aggregate uses of emulsified asphalts. Chapter Seven - Research Appendix A - Glossary Appendix B Appendix C - Gradations Appendix D - Aggregate Appendix E - Estimate - Emulsion test methods and and application their significance. rates for seal coats and surface treatments. gradations of asphalt procedure. 17 for slurry seals. emulsion content using surface area In the past several Forest means problem Forest Service Some free. Emulsions designing Emulsified in Annual Meeting of Asphalt First The 1974.1 NCHRP it has been by no the following Some paper by A. Pelzner and Pavements Asphalt Emulsion Manufacturers report The Use of Bituminous of the identified problem areas and describes ways and means better bituminous emulsion surfaces. and maintaining constructing well but of these problems were described D.C. many considers been increasingly used for surfacing have material has performed the with Proceedings Washington Association for In general Experiences Hendrickson L. years bituminous emulsions Service roads. assess-ing We have when it asked is consider the We issued this summer. the report own their Research Board to furnish us extra copies of the report Transportation valuable a needs the will be sending information at source. least After Regions may wish to acquire one copy additional each to Region as we and the contents reviewing from the copies directly Research Board. Transportation OPERATIONS Harold L. Strickland Assistant Director GEOMETRONICSSER With the approval big task of putting been selected Snedeker GSC as new which ASCS in begin full operation 1 together Service Center an organization the Director James F. General facility Service the Geometronics were named to begin their Presently CENTER UPDATE securing Roger R. Chamard Assistant Regional has begun. will for VICE Distributed in Dixon Washington will be co-located the Ogden/Salt during fiscal - File Subject Proceedings preparing is with the in Region Office Geometronics Chamard and proposal the 6 has and Ross his assistants GSC. to secure space for our Agricultural Stabilization and Conservation Lake City Utah year of record the matter the other complexities all together a a for Operations positions. July to start putting Services Administration now space and Engineer the Assistant Director assignments by Memorandum M.R. Howlett fill GSC area. As now planned the GSC will 1977. Designation 1630 To of the First Annual Association. Regional Meeting Information Coordinators From of Asphalt Emulsion Manufacturers GPO 890-947 18