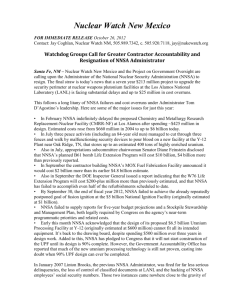

GAO NUCLEAR WEAPONS National Nuclear Security

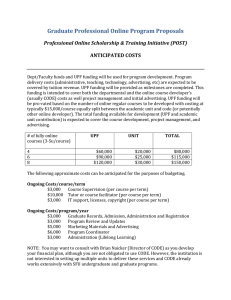

advertisement