VEHICLE/UNDERLINE BRIDGE COMPATIBILITY ASSESSMENTS Gauging & Loading Seminar, London

VEHICLE/UNDERLINE

BRIDGE COMPATIBILITY

ASSESSMENTS

Gauging & Loading Seminar, London

4 th November 2015

AGENDA

BACKGROUND PROJECT SCOPE

INTEROPERABILITY

BRIDGE COMPATIBILITY

ASSESSMENT PROCESS

PROJECT DELIVERABLES

INTRODUCTIONS

MATTHEW KYNOCH

Project Manager

DAVID GIBSON

Task Manager & Lead Author

BRIAN STEWART

Bridge Dynamics Specialist

BACKGROUND

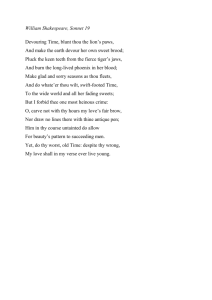

Studies have been conducted on the compatibility of passenger vehicles and railway bridges across the European Union

Current and future train architectures obtained to future proof bridge design requirements

Implication is that design requirements for infrastructure (particularly bridges) may need to be enhanced to accommodate faster and heavier vehicles

Understand implications on potential revisions to GE/RT8006 & EN 1991-2

BACKGROUND

Key requirements of vehicle/underline bridge compatibility assessments:

–

Structures to have sufficient load carrying capacity for the safe & serviceable passage of the proposed rolling stock formations

– The bridge structures are to have an appropriate dynamic response to ensure that the resultant vibrations are not excessive to avoid the risk of ballast instability

BACKGROUND

What are the risks associated with ballast instability?

Cause

Excessive vibrations due to the operation of high speed trains

Effect

Loss of ballast interlock

Void formation

Loss of sleeper base

/ side friction & end restraint

Loss of sleeper base

/ end friction & side restraint

Consequence

Loss of vertical support

Loss of lateral support

Loss of longitudinal support

TRAIN

DERAILMENT

BACKGROUND

Vehicle characteristics that dictate dynamic behaviour

– Variation of loading along length of train

– Axle loads

– Axle/bogie spacing & coach length

– Operational speed

BACKGROUND

Bridge characteristics that dictate dynamic response

–

Structural form

– Span

– Natural frequencies

Material Key

Analysis: Analysis 1

Cross-beam Mild Steel Ungraded (N m kg C)

Main Girder Mild Steel Ungraded (N m kg C)

Rail - 60kg-m

Bar-to represent ballast

Steel Plate-Mild Steel Ungraded (N m kg C)-with ballast

Rail Bearer- Mild Steel Ungraded (N m kg C)

–

–

–

Mass

Stiffness

Damping

THY

THY

THY

THY

THY

THY

THY

THY

THY

THY

THY

THY

THY

Y

THY

Z

THY

X

THY

THY

THY

THY

THY

THY

THY

THY

THY

THY

Span

THY

THY

THY

THY

THY

PROJECT SCOPE

Further understand compatibility of current and future rolling stock with real bridges to avoid the risk of ballast instability by:

–

Establishing current industry

‘state of the art’ knowledge on ballast stability

– Enhancing the understanding of GB bridge population and bridge types potentially sensitive to dynamic induced vibrations

–

Advancing the understanding of influence of bridge skew , torsion and floor vibration with respect to dynamically induced vibrations

PROJECT SCOPE

Understanding ballast behaviour

Historical

Design &

Assessment

Criteria

Today

Literature/ industry review

UIC, DB &

WCML Project

Development of

DEM as early research tool

Shake table tests

Dynamic triaxial tests

Limited advancements with shake table work

Site monitoring

Challenges to existing criteria limited

PROJECT SCOPE

Establish representative GB bridge population

PROJECT SCOPE

PROJECT SCOPE

Establish representative GB bridge population

Parametric studies to simulate dynamic response of representative GB bridges

PROJECT SCOPE

Material Key

Analysis: Analysis 1

Cross-beam Mild Steel Ungraded (N m kg C)

Main Girder Mild Steel Ungraded (N m kg C)

Rail - 60kg-m

Bar-to represent ballast

Steel Plate-Mild Steel Ungraded (N m kg C)-with ballast

Rail Bearer- Mild Steel Ungraded (N m kg C)

THY

THY

THY

THY

THY

THY

THY

THY

THY

THY

THY

THY

THY

Y

THY

THY

Z

THY

X

THY

THY

THY

THY

THY

THY

THY

THY

THY

THY

THY

THY

THY

THY

05/08/2015

Main Girder Accelerations for Real Bridges - Filler Type

All Square and Skew Spans

Centre Girder Going Thru' Centre of Deck - 16.8m Span

Real Trains Envelope

0.6

0.57

0.54

0.51

0.48

0.45

0.42

0.39

0.36

0.33

0.3

0.27

0.24

0.21

0.18

0.15

0.12

0.09

0.06

0.03

0

0

16.8m Square

16.8m 45 Deg - Acute

16.8m 45 Deg - Obtuse

16.8m 20 Deg - Acute

16.8m 20 Deg - Obtuse

20 40 60 80 100 120 140 160 180 200 220 240 260 280 300 320

Speed (kph)

Material Key

Analysis: Analysis 1

Iso1 (Steel UK Network Rail)

Rail - 85kg-m

Steel - Massless

Manipulated Steel - 1/2 inch Floor Plate

Y

Z

X

PROJECT SCOPE

Establish representative GB bridge population

Parametric studies to simulate dynamic response of representative GB bridges

Understand implications of current and future rolling stock architecture on GB bridge population

Enhance existing bridge compatibility assessment process

BRIDGE COMPATIBILITY ASSESSMENT

SPEED

EXISTING

ROLLING

STOCK

FUTURE

ROLLING

STOCK

SAFE &

SERVICEABLE

PASSAGE

OVER

BRIDGE

BRIDGE

FORM

CRITERIA

BRIDGE COMPATIBILITY ASSESSMENT -

ROLLING STOCK

Current and future rolling stock architecture considered

– Existing ‘comparator’ trains

– Reference Load Models (defined in T988) covering range of GB future train architectures

– Proposed high speed trains (e.g. IEP)

– High Speed Load Models (BS EN 1991-2) for new bridge design

– MU Classes (defined in EN 15528: 2015) for classifying multiple units

BRIDGE COMPATIBILITY ASSESSMENT -

BRIDGE FORM

Established representative GB bridge population

Reviewed bridge characteristics and identified parameters likely to influence dynamic performance

Parametric modelling undertaken to understand influence of key characteristics

Understand likely compatibility with rolling stock considered

BRIDGE COMPATIBILITY ASSESSMENT -

ACCEPTANCE CRITERIA

Current acceptance criteria builds upon

European experience

Extensive work undertaken by Network Rail to refine acceptance criteria:

–

Route clearance studies including dynamic modelling and bridge monitoring

– R&D including shake table tests at BAM University

Potential to refine criteria further in the future (through further R&D)

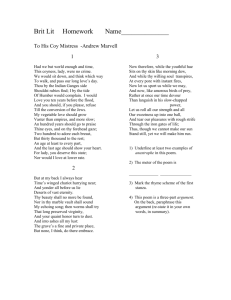

COMPATIBILITY ASSESSMENT PROCESS

New rolling stock proposed operating at >90mph

Stage 1

Vehicle clearance

Parametric study considering generic bridge types

Compare to criteria and identify ‘at risk’ types & spans

Stage 2

Bridge specific clearance

Undertake simple analysis e.g. nonunique, low skew

Compare to criteria and identify need for detailed analysis

Stage 5

Mitigation measures

Stage 4

Bridge site monitoring

Stage 3

Bridge specific detailed analysis

COMPATIBILITY ASSESSMENT PROCESS

Stage 1

Vehicle clearance

Compare proposed rolling stock to RLM parameters

Parametric study considering generic bridge types

Compare to criteria and identify ‘at risk’ types & spans

Train architecture

Train signature

Potential to negate requirement for parametric study for proposed rolling stock

COMPATIBILITY ASSESSMENT PROCESS

Stage 2

Bridge specific clearance

Undertake simple analysis e.g. nonunique, low skew

Compare to criteria and identify need for detailed analysis

Development of guidance tools

Potential to negate requirement for bridge specific work

COMPATIBILITY ASSESSMENT PROCESS

Stage 3

Bridge specific detailed analysis

Rules for simple analysis for greater bridge type coverage

Bridges that do not pass simple analysis

Highly skewed bridges/unique novel bridges

Bridge form

Bridge characteristics e.g. aspect ratio

Potential to reduce requirement for detailed or complex

2D/3D modelling analysis

INTEROPERABILITY

Infrastructure TSI defines target minimum bridge requirements for multiple units in terms of dynamic bridge loading characteristics of vehicles

Opportunity in the future to define interface between the dynamic loading of vehicles, vehicle characteristics and bridge capacity

Understand compatibility of train manufacturers v train architecture aspirations with existing bridge infrastructure

Recommendations will be made for methodology to close out open points

PROJECT DELIVERABLES

Recommendations on the compatibility of current and future rolling stock on the GB bridge network

Enhanced knowledge of GB bridge infrastructure, characteristics and dynamic performance

Enhancements to the existing vehicle/bridge compatibility assessment process

PROJECT DELIVERABLES

Guidance Tools for assessment and design

(e.g. charts)

Recommendations on the development of simple rules to negate requirement for complex bridge analysis during compatibility assessments

Commentary regarding the appropriateness of current Load Models such as HSLM used for bridge design with the Eurocodes

PROJECT DELIVERABLES

Recommendations for R&D to challenge and potentially refine acceptance criteria used within compatibility assessments

Methodology for closing open points within

Infrastructure TSI

www.mottmac.com