The Railways and Other Guided Transport Systems (Safety) Regulations 2006 (as amended)

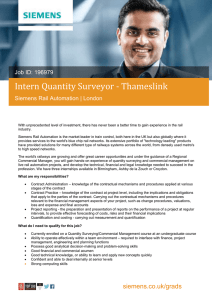

advertisement