19, 1981 ................. Certified by.........................................

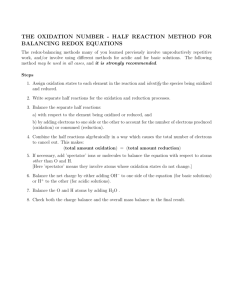

advertisement