Power Measurements: Simulations and Measurement*

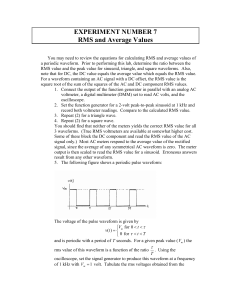

advertisement

Int. J. Engng Ed. Vol. 21, No. 1, pp. 26±32, 2005 Printed in Great Britain. 0949-149X/91 $3.00+0.00 # 2005 TEMPUS Publications. Power Measurements: Simulations and Measurement* JACK DENTON Purdue University, Department of Electrical and Computer Engineering Technology, West Lafayette, IN 47907-2021, USA. E-mail: denton@purdue.edu ELAINE COONEY Department of Electrical and Computer Engineering Technology, Indiana University Purdue University Indianapolis, Indianapolis, IN, USA A laboratory exercise was developed employing RMS voltage and power measurements for nonstandard waveforms. The purpose was to educate the student in the method of RMS and power measurement calculations beyond the common sinusoidal waveforms and to reinforce the practice of `know your equipment'. The waveform used was a damped sinusoid and was implemented in a LABVIEW VI developed for generating output voltage signals from input formulas using a data acquisition module. The RMS measurements were investigated using MATLAB, oscilloscopes, digital multi-meters and a second LABVIEW VI. The student analyzed the resulting data and a discussion of various discrepancies ensued. capabilities when used and understood properly. It is human nature to become complacent with measurements that are consistently correct in repeated applications, especially so when only the same or similar signals are used, such as with the sinusoidal signals previously mentioned. The prime components of the educational objective are to teach and reinforce the proper methods to calculate and measure power and RMS voltages. The use of various benchtop measurement instruments and analyzing the resulting data reinforce these objectives. The large variation in results due to the measurement methods and algorithms built in to the instruments causes the student to consider the proper measurement methods. A key feature of this laboratory experiment is educating the student by highlighting measurement discrepancies in such a way as to show how approximations of the instrumentation yield improper results and how proper analysis is required for accurate data acquisition. The lab experiment presented in this paper starts with analytical RMS voltage and power calculations of a complex signal using MATLAB, setting a theoretical baseline for the data being collected. The complex signal is generated by a LabVIEW VI, which is experimentally measured using benchtop digital multi-meters (DMMs) and an oscilloscope on a load. The experimental data of the oscilloscope is downloaded into a second MATLAB program that computes the exact solution for the RMS voltage on the data. The experiment continues with a second LabVIEW VI that computes in real time the exact analytic solution for average power and RMS voltage. All results and discrepancies are collected and discussed. INTRODUCTION ROOT MEAN SQUARE (RMS) measurement and calculations are quite complex when one begins to consider noise, phase, and accuracy of the signal [1] or RMS power measurements [2]. Some basic methods of determining the RMS current of a signal are the heat method, the graph method, the multiply and sum method and the math rule method [3±5]. The heat method employs equating the heat generated in a resistor from the unknown current and matching that heat in a second resistor using a test DC current. The remaining three methods are variations on a theme by determining the RMS calculation using graphical techniques, A/D conversion, and analytical mathematics. This paper uses analytical mathematical techniques. Two common problems that arise during the course of studying applied electrical engineering are that the RMS value of any signal defaults to 0.7071 times the magnitude of the signal, and that the results from laboratory measurement equipment are inviolate. The first problem stems from the fact that all the waveforms used in the beginning level courses are purely sinusoidal signals, which has an RMS value of 0.7071 times the magnitude of the signal, and this gets extended to all waveforms regardless of complexity. The second problem exists due to human nature as well as the nature of modern test equipment. Modern test equipment is highly feature-laden and, at the push of a function button, analysis is automatically computed and displayed. The equipment has excellent features and measurement * Accepted 4 August 2004. 26 Power Measurements: Simulations and Measurements 27 Fig. 1. MATLAB script file to compute the RMS value of a user-defined function. EXPERIMENT The laboratory experiment started with the calculation of the analytical RMS value of the signal function using MATLAB. The mathematical equation of the waveform was analyzed for theoretical RMS voltage and power using standard mathematical techniques, which were implemented using MATLAB. The equation to compute the RMS value of a voltage waveform v t was [5], s T Vrms 1=T v2 t dt 1 0 The voltage waveform used in this experiment (2) was a damped sinusoidal function and was repeatedly outputted for a period of 0.5 seconds. The output of the voltage waveform was implemented using a LabVIEW VI on a data acquisition (DAQ) module and will be described later. v t 5eÿ10t cos 2100t 2 The theoretical computation for the voltage waveform v t was implemented using the MATLAB script file shown in Fig. 1. A skeleton script file was available to the students, as they were novices in MATLAB programming. They were required to input the repetitive signal period and equation into the provided MATLAB script file and add a final line to calculate the power. The computation from the MATLAB calculation yielded the theoretical RMS value of the waveform, which was 1.1182 volts. Using this result, the power delivered to a 1000 load was calculated using (3) and was found to be 1.3 mW. The results from all the methods were collected and compared (Table 1). P 2 VRMS R 3 The next step was to generate the actual output voltage waveform. The waveform, being nonstandard, could not be easily generated using an arbitrary waveform generator or other conventional benchtop equipment. A VI from the LabVIEW library was modified and redesigned to generate a voltage waveform that was placed on a 1000 load. The LabVIEW VI, called `Formula_Wave.vi', generates a repetitive output voltage from an inputted formula using a DAQ (National Instruments Model 6040E). The program `Formula_Wave.vi' is included, along with a description of its operation. The front panel with the outputted waveform is shown in Fig. 2. The RMS voltage was measured on the output voltage waveform using the benchtop oscilloscope and two different digital multi-meters and the resulting power was calculated. Additionally, the oscilloscope data was downloaded and analyzed by a second MATLAB program that calculated the RMS voltage and power values. The MATLAB file required the student to enter the period of the signal, the oscilloscope data file, and a line to calculate the power. The MATLAB program calculated the exact solution of the RMS voltage as outlined in equation (1) using numerical integration. The MATLAB script file used to analyze the oscilloscope data is shown in Fig. 3. Typical measured and calculated values are shown in Table 1. Table 1. Typical measurement data of VRMS and resulting power calculation VRMS (volts) Power (mW) Error (%) from Theory MATLAB Theory Oscilloscope MATLAB Data DMM #1 DMM #2 1.118 1.249 0 3.060 9.360 273 1.123 1.300 0.5 0.150 0.022 98 0.873 0.760 28 28 J. Denton and E. Cooney Fig. 2. Formula_Wave.vi front panel outputting v t 5eÿ10t cos 2100t Finally, another LABVIEW VI (Average_ Power_&_RMS_Voltage.vi) was developed to measure and calculate the RMS voltage and average power in real time and continuously from the VI outputting the repetitive signal. A simultaneous output and measurement was performed on the load and a current sense resistor. The circuit setup is shown in Fig. 4. The VI continuously calculated the RMS voltage and average power and displayed the result along with the signal. The formula used to calculate the average power is indicated in equation (4), where v(t) and i(t) are the instantaneous voltage and current, respectively. A display of the front panel for the `Average_Power_&_ RMS_Voltage. Fig. 3. MATLAB script file to compute the RMS voltage and power from downloaded oscilloscope data. Power Measurements: Simulations and Measurements 29 Fig. 4. DAQ (model #6040E) circuit connections used to simulate 1000 load for the `Average_Power_&_RMS_Voltage.vi'. vi' with a single cycle of the measured waveform and calculated data is shown in Fig. 5. T v t i tdt 4 Pave 1=T 0 The circuit in Fig. 4 simulated a load of 1000 and introduced a sense resistor to determine the current using differential voltage measurement techniques. This prompted a discussion of the use of a current sense resistor and differential measurements. The crux of the discussion for the current sense resistor was to use a low-value resistance in order not to unnecessarily perturb the signal or drop too much voltage. Also, to ease measurement and calculation, a value of 1 ohm proved useful. Ohm's law is V IR, and for R 1 , this leaves V I. Differential voltage measurements were discussed in comparison to ground-referenced measurements for improved accuracy and reduction in noise. The students analyzed the resulting RMS voltages and power data for all the methods and a discussion of various discrepancies was required. The methods employed to measure or calculate RMS voltage by the bench-top measurement equipment was investigated and how its `assumptions' about signals can be problematic. The resulting measured and calculated RMS voltages data indicated that the MATLAB theoretical Fig. 5. Average_Power_&_RMS_Voltage.vi front panel plotting the output for v t 5eÿ10t cos 2100t and measuring the average power and RMS voltage. 30 J. Denton and E. Cooney calculation was the baseline for data comparison. The two DMMs measured the voltage signal using a `true RMS measurement'; however, it was found that this was `true' only for sinusoidal signals. DMM measurements on any other signal type required the use of a `correction factor' (CF). However, the typical CF presented in the DMM operation manuals was for square, triangle and ramp wave, and a note indicating that more complex signals would require the user to determine the CF. The RMS voltage measurement technique that the oscilloscope used was not evident even from the manufacturer's instrument manual, but was discovered to measure the RMS value of the first peak encountered on the oscilloscope screen, regardless of repetition, damping or other possible waveform complexities. It was also determined that the oscilloscope took the RMS value to be 0.7071 of the encountered peak, thus again assuming a sinusoidal signal. The data waveform that the oscilloscope measured was downloaded into a MATLAB program that numerically calculated the exact RMS solution on the data. The resulting calculated data was only 0.5% from the theoretical, indicating that the oscilloscope signal and data were correct, but the oscilloscope internal RMS function was limited in its application. LABVIEW VI Two LABVIEW VIs were developed for this laboratory experiment: one to create and output a complex waveform from the DAQ 6040E card, and the second to measure the power dissipated by a component. The program Formula_Wave.vi' (see Fig. 2) was an adaptation of the VI `Formula Waveform Example.vi' that was shipped as an example VI with LabVIEW. The example VI allowed the user to enter a formula, vary the frequency, amplitude, and offset of the signal, and change the sample rate and number of samples per waveform. It plotted the resulting waveform. Added to this existing VI was the code necessary to output the calculated signal to the DAQ card, including calls to Analog Output Configure (`AO Config.vi'), Analog Output Write (`AO Write.vi'), Analog Output Start (`AO Start.vi'), and Analog Output Clear (`AO Clear.vi') (See Fig. 6). The `AO Start.vi' is configured for continuous output, so the waveform output was repeated until the `Stop' button was pressed on the front panel. The other LabVIEW VI written for this project is `Avg_Power_&_RMS _Voltage.vi'. The front panel can be seen in Fig. 5, and the programming diagram in Fig. 7. This VI used the analog input Fig. 6. LabVIEW programming diagram for `Formula_Wave.vi'. Power Measurements: Simulations and Measurements 31 Fig. 7. Programming diagram for `Avg_Power_&_RMS_voltage.vi'. channels of the DAQ 6040E card in differential mode to measure the voltage across the load, and the voltage across a current sense resistor. The voltages were formatted in arrays that contain 5000 samples. The load voltage waveform was converted to a single RMS voltage value, using the `Basic Averaged DC-RMS for 1 Chan.vi', and displayed. The sense voltages were converted to current by dividing by the `Sense Resistor in Ohms' control value, which was set by the user before running the VI. The current values were multiplied by the load voltages to calculate the instantaneous power. The load voltage, current, and instantaneous power were presented on a waveform graph. The instantaneous power was then numerically integrated over one set of samples, and divided by the number of samples in the period. The result was the average power over one set of 5000 samples. This process was repeated continuously until the `Stop' button was pressed. CONCLUSIONS The laboratory experiment reintroduced the concept of RMS voltage and power measurements to the students, with the addition of utilizing a complex non-standard waveform. The method of comparing the widely deviating results of various measurement instruments required the student to evaluate the various methods of the instrumentation measurement methods and calculations. The basic limitations of the instrumentation corresponded to the limitations that the student had prior to the laboratory experiment. The learning outcome objective of this laboratory experiment was for signal waveform power measurements and calculations, which was teamed with introducing an engineering awareness of instrumentation operation and limitations. Up to this point in the students' experience, experimental procedure would yield the same answers as theory. Of course, the proper procedure and knowledge of equipment operation will always yield the `correct' answer, but the idea that the instruments can be `wrong' comes a quite a surprise to the students. This laboratory experiment highlighted the importance of measurement and equipment knowledge by challenging the experience that the students held previously. The students responded with questions regarding the possibility of other measurements being incorrect, such as oscilloscope 32 J. Denton and E. Cooney FFT measurements performed in a previous experiment. The students were challenged one last time, with the question `How do you know that the LabVIEW and MATLAB programs are correct?' and who wrote them, how, and what assumptions were made in the programs. The use of MATLAB and LabVIEW was critical for the objectives of the laboratory experiments. It allowed the use of a complex nonstandard waveform that was essential to the lab operation. It allowed for quick and accurate calculations. This alleviated, from the student viewpoint, the difficulty of calculations. The student was allowed to reflect on the ramifications of the problem. This lab experiment can be adjusted for a variety of objectives. The output could be a conventional waveform (sine, square, triangle, etc.) and the RMS voltage and power can be compared and contrasted and CF calculated. The RMS measurements and calculations can be forced to be `incorrect' by changing the period of the repeating waveform in the calculations and VIs, and the erroneous results can be compared to the correct. Noise can easily be added to the LabVIEW analysis, and the resulting effects can be analyzed. REFERENCES 1. C. Thomsen and S. Shearman, For RMS measurements, accuracy depends on speed and noise, R&D Magazine (retrieved 10 September 2003 from: http://www.rdmag.com/features/0202ni16.asp). 2. E. Persson, Making and interpreting power measurements on arc lamps and ballasts, Application Notes, Nicollet Technologies Corp., 2002 RadTech Proceedings (2000) (retrieved 10 September 2003 from: http://www.nictec.com/articles/articles-list.html). 3. D. Lancaster, Tech musings, May 1997 (1997) (retrieved 9 September 2003 from www.tinaja.com). 4. W. E. Ott, A new technique of thermal RMS measurement, IEEE Journal of Solid-State Circuits, 9(6) (1974), pp. 374±380. 5. W. H. Hayt, Jr., and J. E. Kemmerly, Engineering Circuit Analysis, third edition, McGraw-Hill, New York (1978), pp. 342±352. John Denton is an Associate Professor in Electrical and Computer Engineering Technology in the Purdue University, School of Technology in West Lafayette, Indiana. He received his Ph.D. in Electrical Engineering from Purdue University in 1995. His areas of interest and expertise are analog electronics, RF electronics and electronic materials. Elaine Cooney is an Associate Professor in Electrical and Computer Engineering Technology at the Purdue School of Engineering & Technology at Indiana University Purdue University Indianapolis. She received her B.S.E.E. from General Motors Institute and M.S.E.E. from Purdue University in West Lafayette. Her areas of expertise include analog electronics, electronics manufacturing and test engineering. Professor Cooney's current research interests include laboratory instrumentation and control, both in the local and remote teaching environments.