I <

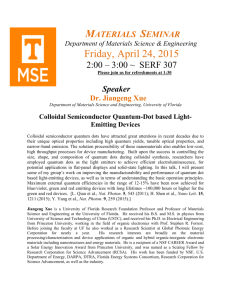

advertisement