Transformation-induced jointing as a gauge for interfacial slip and rock... ⁎ Karthik Iyer ,

advertisement

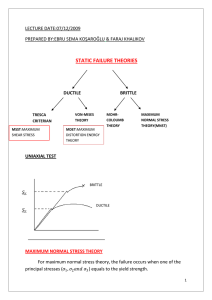

Earth and Planetary Science Letters 280 (2009) 159–166 Contents lists available at ScienceDirect Earth and Planetary Science Letters j o u r n a l h o m e p a g e : w w w. e l s ev i e r. c o m / l o c a t e / e p s l Transformation-induced jointing as a gauge for interfacial slip and rock strength Karthik Iyer a,b,⁎, Yuri Y. Podladchikov a a b Physics of Geological Processes (PGP), University of Oslo, P.O. Box 1048, Blindern, N-0316, Oslo, Norway IFM-Geomar, Wischhofstrasse 1-3, D-24148 Kiel, Germany a r t i c l e i n f o Article history: Received 1 April 2008 Received in revised form 10 October 2008 Accepted 15 January 2009 Available online 15 February 2009 Editor: T. Spohn Keywords: brittle rheology joint formation fracture spacing to layer thickness ratio interfacial slip transformation-induced strain a b s t r a c t Various theoretical and numerical models have been proposed in order to explain joint formation and spacing in layered rock series. However, most of these models assume that the interfaces between the rock layers are perfectly welded, i.e. no slip occurs, and that all the layers are subjected to the same remote strain due to various processes (e.g. tectonic processes). Other factors may also induce extensional strain in rocks, e.g. phase transformations. However, such processes may induce different amounts of strain on the layers in a rock series leading to a strain mismatch between these layers. In this paper, we present a 1-D finite difference linear elastic model which allows joint formation within the middle layer in a three-layer rock series and is induced by a strain mismatch between the fractured, central layer and the surrounding matrix. Furthermore, the central layer in our model is not necessarily welded to the matrix layers and is allowed to slip along the interfaces between these layers if the shear strength of the material at the interface is reached. We find that the final fracture spacing to layer thickness ratio (S/Tf) in such layered systems is directly proportional to the ratio of the tensile and shear strength of the material. Changes in the material properties such as the shear modulus or Young's modulus do not affect these results. A natural analog of joint formation driven by phase transformations is found in the orthopyroxenite dykes of the Leka Ophiolite Complex (LOC), Norway. Joint formation in orthopyroxenite dykes results from serpentinization-driven expansion of the surrounding dunite matrix. Detailed field studies and measurements (583 sample points) yield S/Tf ratios between 0.1 and 1.0 with a mean value of 0.45± 0.20. We demonstrate that the strain mismatch-driven joint formation associated with interfacial slip explains the low S/Tf ratios obtained from field measurements and may also help us constrain rock strength. © 2009 Elsevier B.V. All rights reserved. 1. Introduction Brittle deformation features in rocks such as joints are ubiquitous within the Earth's crust. Brittle deformation accompanying phase transformations in rocks are, however, poorly understood. Thermal and volumetric changes occurring in rocks during phase transformations alter rock rheology (Karato, 1997) and complicate structural reconstructions based on cross-sectional volume/area-balancing methods. Additionally, joints play an important role in controlling various physical properties such as the effective strength and permeability of rocks. Tensile fractures are often observed in layered rocks and are oriented parallel to the maximum compressive stress direction. Fractures of a given set are usually parallel or sub-parallel to each other (Price, 1966; Pollard and Aydin, 1988; Bai and Pollard, 2000a; Mandl, 2005). The open fractures are commonly confined to the fractured layer and do not propagate into the surrounding rock due to termination at a strength anisotropy, e.g. the interface between the fractured layer and the surrounding rock (Gross, 1993; Gillespie et al., ⁎ Corresponding author. IFM-Geomar, Wischhofstrasse 1-3, D-24148 Kiel, Germany. Tel.: +49 431 6002866; fax: +49 431 600 2941. E-mail address: kiyer@ifm-geomar.de (K. Iyer). 0012-821X/$ – see front matter © 2009 Elsevier B.V. All rights reserved. doi:10.1016/j.epsl.2009.01.028 1999; Tindall and Davis, 2003; Fischer and Polansky, 2006). Field relations of fracture spacing in layered rocks have been previously studied with reported fracture spacing to layer thickness ratios (S/Tf) ranging from 0.1 to greater than 10 (Bogdanov, 1947; Novikova, 1947; Kirillova, 1949; Price, 1966; McQuillan, 1973; Narr and Lerche, 1984; Huang and Angelier, 1989; Narr and Suppe, 1991; Gross, 1993; Gross et al., 1995; Wu and Pollard, 1995; Becker and Gross, 1996; Ji and Saruwatari, 1998; Bai and Pollard, 2000a) where fracture spacing is the distance between adjacent fractures along a line perpendicular to the average orientation of the fracture set (Narr and Suppe, 1991; Gross, 1993). Previous studies of fracture formation within layered materials have shown that fracture infilling occurs with increasing applied strain up to a critical fracture spacing to layer thickness ratio (e.g. Garrett and Bailey, 1977; Parvizi and Bailey, 1978; Thouless et al., 1992; Wu and Pollard, 1995). Fracture saturation is a phenomenon where no further infilling of fractures takes place once this critical ratio is reached and the additional strain is accommodated by the opening of existing fractures (Aveston et al., 1971; Wu and Pollard, 1995). The stress-transfer model proposed by Hobbs (1967) has been commonly cited as an explanation for the linear relationship between fracture spacing and rock layer thickness where fracture spacing decreases as long as the applied strain is increased. Bai and Pollard (2000a) pointed out that the Hobbs' model does not account for 160 K. Iyer, Y.Y. Podladchikov / Earth and Planetary Science Letters 280 (2009) 159–166 fracture saturation as fracture infill occurs ad infinitum without any critical threshold for fracture spacing being reached. Another approach to explain fracture spacing in layered rocks is the stress-shadow model caused by the opening of a fracture (Lachenbruch, 1961; Nur, 1982; Pollard and Segall, 1987; Gross et al., 1995; Germanovich and Astakhov, 2004). The fracture-normal stress at the fracture faces is zero in the absence of fluid pressures within the fractures. This stress gradually increases away from the fracture and eventually reaches the remote stress value. There, therefore, exists a region of reduced stresses near a fracture where no other fractures may form as the stress is below the strength of the rock. This region would subsequently constrain the fracture spacing in a rock layer for a given strain. Recently, Bai and Pollard (2000a) have shown that for a three-layer system with perfectly welded interfaces under extension, the critical S/Tf ratio is approximately 1.0. The normal horizontal stress component within the layer and perpendicular to the fractures changes from tensile to compressive when the critical ratio is reached. Bai and Pollard (2000b) have shown that propagation of a pre-existing flaw at the interface of the fractured layer and subsequent propagation through the layer may occur for fracture spacing to layer thickness ratios below 1.0. The propagation of the fracture depends on the initial size and location of flaws present in the layer. They found that the minimum S/Tf ratio for a system with similar elastic constants for the fractured and neighboring layers is 0.273 and ratios below this minimum value may be possible due to factors other than pure extension. The above mentioned models incorporate two important assumptions. Firstly, the models assume that all the layers in the series are subject to the same remote strains. Additionally, the models also assume that the interfaces between the fractured layer and the surrounding layers are perfectly welded together. Nevertheless, slip will occur at the interface between the layers if the interfacial shear stress reaches the interfacial slip strength (Li and Yang, 2007). In this paper, we investigate fracture formation in a layer embedded in incompetent rocks incorporating and driven by a strain mismatch between the fractured, central layer and the surrounding matrix. We present a 1-D finite difference linear elastic model that accommodates the strain mismatch by joint formation within the middle layer. In addition, the central layer in the model is not necessarily welded to the bounding layers and is allowed to slip along the interfaces when the interfacial shear strength is reached. We find that the resulting fracture spacing in the central layer depends not only on the thickness of the layer but also on the material strength. The results show that the final fracture spacing to layer thickness ratio in such layered systems is directly proportional to the tensile strength and inversely proportional to the shear strength of the material. We also show that changes in other material properties such as the shear modulus or Young's modulus do not affect these results. The model results are compared to a natural analog found in the fractured orthopyroxenite dykes of the Leka Ophiolite Complex (LOC), Norway. Fracture formation in the orthopyroxenite dykes occurs as a result of a differential volume increase in the orthopyroxenite dykes and the surrounding dunites during serpentinization. Detailed field studies and measurements yield S/Tf ratios between 0.1 and 1.0. These values cannot be explained adequately by welded interface models due to the fracture saturation effects mentioned above. Independent of this theoretical challenge, field observations also suggest a strong strain mismatch between the orthopyroxenite layers and the surrounding dunite matrix. We demonstrate that the strain mismatch-driven joint formation associated with interfacial slip may explain the field observations. If the model holds true for the processes occurring in the LOC, it may help us to better evaluate the strength of natural interfaces undergoing metamorphism at geological time scales and settings. 2. Numerical modeling In order to understand the effects of shear stress along the interfaces of the middle rock layer on fracture spacing, we use a quasi Fig. 1. 2-D sketch of an elastic layer (M) with length L and height H sandwiched between two rock layers (S). The middle layer, M, is fixed on the left side with respect to horizontal movement (black diamond) and extension is driven by a background strain, εbg. A weak material heterogeneity is introduced in the middle of the layer (white circle) to initiate fracturing. The horizontal normal stress is calculated along the centre of the middle layer (dashed line). Initially, the layer (M) and surrounding matrix (S) are perfectly bonded at the interfaces (gray arrows). Interfacial slip is allowed to occur only when the interfacial shear stress reaches the interfacial shear strength. 1-D, linear elastic, finite difference model of a layer under extension which incorporates fracture formation. The model is based on a threelayer rock formation where the horizontal normal stress within the middle layer, M, is calculated (Fig. 1). The length and height of the modeled layer can be varied. The layer is fixed on the left boundary and extension of the layer is incorporated in the model by the use of a constant remote background strain (Fig. 1). Tensile strength along the middle layer is constant except in the middle where a heterogeneity (80% of tensile strength) is introduced to initiate fracturing. Open fractures are allowed to develop within the middle layer when the normal horizontal stress component, σxx, reaches the prescribed tensile strength of the material, σt. The horizontal stress component is set to zero where fractures occur. The layer interface is decoupled from the bounding layers once the shear stress at the interface reaches the shear strength of the layer. Consider an elastic layer of length L and height H under extension (Fig. 1). By integrating the horizontal force balance equation over the layer thickness, we have: bot τ top Ahσ xx i xy − τ xy + =0 Ax H ð1Þ where ⟨σxx⟩ top τxy bot τxy is the thickness averaged horizontal stress component is the shear stress acting on the top interface of the layer is the shear stress acting on the bottom interface of the layer The average relative horizontal displacement, ⟨ur⟩, is related to the average displacements in the layer, ⟨ul⟩, and surrounding matrix, ⟨ubg⟩, by: hur i = hul i − hubg i ð2Þ Henceforth, quantities that are averaged over thickness are denoted with ⟨ ⟩. K. Iyer, Y.Y. Podladchikov / Earth and Planetary Science Letters 280 (2009) 159–166 The thickness averaged horizontal strain in the layer, ⟨εxx⟩, is given by: hexx i = Ahul i Ax ð3Þ Substituting Eq. (2) in Eq. (3): hexx i = Ahubg i Ahur i + Ax Ax ð4Þ The average mismatch transformation strain between the matrix and the layer, ⟨Δεxx⟩, can be written as: bg l hΔexx i = hexx i − hexx i ð5Þ l where ⟨εbg xx ⟩ and ⟨εxx⟩ are the average transformation strains in the matrix and layer, respectively. However, as ⟨εlxx⟩ = 0, bg hΔexx i = hexx i ð6Þ The thickness averaged horizontal strain in the layer, ⟨εxx⟩, and the relative horizontal displacement, ur, are related by: hexx i = Ahur i + hΔexx i Ax ð7Þ Hooke's Law for linear elasticity states that: hσ xx i = Ehexx i ð8Þ where E is an appropriately chosen elastic constant to represent threedimensional straining in a one dimensional model (i.e. a combination of plane strain in the X–Y plane and constant stress in the Y-direction assumptions). Using Eqs. (7) and (8), we get the interlayer normal horizontal stress by: Ahur i hσ xx i = E + hΔexx i ð9Þ Ax The shear stress acting on the layer can be expressed as a function of the shear modulus (G) and the shear strain (γ): Auy Aux + τxy = Gγ = G Ay Ax ð10Þ where ux and uy are components of the elastic displacement field. Although more elaborate solutions for elastic shear stresses are available (e.g. Ji and Saruwatari, 1998; Li and Yang, 2007), for simplicity reasons, we neglect the variation of the shear stress along the interface and approximate it, similar to the classical Hobbs model (1967), by: top bot τxy = − τ xy ≈G hur i H ð11Þ bot where τtop xy and τxy are the shear stresses at the interface. Two-dimensional Finite Element modeling verified that neither the choice of shear modulus, G, nor the severe oversimplification of this approximation of elastic shear stresses along the interface have any noticeable results for the joint spacing at saturation. In order to accommodate plastic failure at the interfaces, a maximum cut-off for the shear stress (τxy) is imposed and is equal to the shear strength (τs) of the material: 161 this paper, we use the mechanical engineering definition of plastic deformation where plastic yield at the interface occurs when the shear stresses exceeds the elastic limit (Hill, 1950; Zhang 1998). Plastic yielding in this context does not relieve the stress present at the interface but imposes a limit on it as opposed to joint formation within the layer which results in a complete stress drop. We solve for horizontal stress (σxx) and horizontal relative displacement (ur) using Eqs. (1) and (9). In order to calculate shear stress in the layer, we use Eq. (11) in the elastic regime and Eq. (12) in the plastic regime. Therefore, we obtain: 8 u > < −2G r2 Ahσ xx i H = > Ax : 2 τs H if if ur b τs H u G r N τs H G ð13Þ Eqs. (9) and (13) form a closed system of equations for the two unknown profiles, σxx and ur. Sliding of the layer across the frictional interface occurs once the shear strength of the material is reached and the shear stress is kept constant with a value equal to the shear strength. Experiments in rock mechanics show that the unconfined shear strength of a rock may be between three to five times the uniaxial tensile strength (e.g. Afrouz, 1992; Zhao, 2000). Runs were conducted on the numerical model using these values as limits for the shear strength of the layer. In addition to variations in shear strength, the thickness of the modeled layer was also systematically varied to obtain values for the critical fracture spacing to layer thickness ratio. 3. Results 3.1. Modeling The development of the horizontal stress component (σxx) with increasing strain mismatch for a run is shown in Fig. 2. The shear strength of the layer (τs) is kept fixed at three times the tensile strength (σt) for the example run. The initial horizontal stress distribution within the layer is uniform and set to the tensile strength of the heterogeneity in the middle of the layer. Joint formation is initiated at the heterogeneity after which σxx at that point is set to zero (Fig. 2a). The horizontal stress component increases with increasing strain mismatch and results in the formation of joints where σxx reaches σt (Fig. 2b–e). Frictional sliding at the interface occurs when the shear stress (τxy) reaches the shear strength value (τs). The shear stress value at the interface where slip occurs is kept constant and equal to the value of shear strength. The horizontal stress component stops evolving with increasing strain mismatch once the shear resistance at the interface reaches its maximum value and no more joints are formed (Fig. 2e). The resulting fracture spacing to layer thickness ratio for the run where τs = 3σt is 0.166. The model was also run for shear strength values (τs) of the layer equal to four and five times the tensile strength (σt). The length of the layer is kept constant for all runs and the normalized thickness is varied. The minimum fracture spacing to layer thickness ratio obtained for all runs with τs = 3σt is 0.166, for all runs with τs = 4σt is 0.125 and for all runs with τs = 5σt is 0.10 (Fig. 3). It is found that the approximation of shear stress in the elastic regime as shown in Eq. (6) as well as variations of material properties (e.g. Young's Modulus, E) does not affect the results obtained for the fracture spacing to layer thickness ratios (Fig. 3). ð12Þ 3.2. Fracture formation in orthopyroxenite dykes of the Leka Ophiolite Complex The negative sign in the above equation represents the opposing force of friction to the relative direction of motion during sliding. In The Leka Ophiolite Complex outcrops on the island of Leka, NordTrøndelag, Norway and is a part of the Upper Allochthon of the top bot τxy = − τ xy ≈ − τ s 162 K. Iyer, Y.Y. Podladchikov / Earth and Planetary Science Letters 280 (2009) 159–166 Fig. 2. Growth of the normalized horizontal stress component (σxx/σt) in the layer with an increase in strain mismatch. The shear strength of the material (τs) is three times the tensile strength (σt) for the model run. The thickness and length of the layer are kept constant for the run. See text for details. Scandinavian Caledonides (Furnes et al., 1988). The LOC formed as a part of the oceanic lithosphere of the North Iapetus Ocean and was obducted during the Caledonian orogeny between the Ordovician and Silurian periods (Dunning and Pedersen, 1988; Titus et al., 2002) during which the mantle section was folded into an open fold (Maaløe, 2005). The Leka Ophiolite Complex is one of the most completely preserved ophiolites present in the Scandinavian Caldeonides (Prestvik, 1972) and contains all the principle components of an ophiolite, including the mantle section, the layered crustal sequence and the overlying sediments (Fig. 4). The ultramafic units of the LOC are serpentinized to variable degrees (b10 to ~90%). The mm to dm thick orthopyroxenite dykes are of particular interest and are exposed within the layered cumulates (dunite with minor wehrlite) near Steinstind (Fig. 4). The dykes locally crosscut the dunites and wehrlites, and have variable orientations. They are invariably fractured and the spacing between the fractures is positively correlated with the thickness of the dykes (Iyer et al., 2008a). The fractures are always sub-perpendicular to the contact between the orthopyroxenite dukes and the dunite matrix. The process of fracturing in the orthopyroxenite dykes has been attributed to the serpentinization of the dunite matrix (Iyer et al., 2008a,b). One of the important petrophysical effects of serpentinization is the density/ volume changes occurring in the serpentinized rocks. The reaction of orthopyroxene to talc and olivine in the presence of fluids, and subsequently to serpentine, controls a major part of the density changes in the orthopyroxenite dykes which takes place between ~550 and K. Iyer, Y.Y. Podladchikov / Earth and Planetary Science Letters 280 (2009) 159–166 Fig. 3. Plot of the ratios of fracture spacing to layer thickness (S/Tf) against the ratio of tensile to shear strength (σt /τs) of the material for the 1-D FDM layer model with frictional sliding interfaces. The diamonds and circles represent runs conducted with different values of the shear parameters for the elastic regime (e.g. G) and show no variations in the fracture spacing to layer thickness ratios. 650 °C at 1 kbar. The density changes in the dunites during serpentinization are, on the other hand, dominated by the reaction of olivine to serpentine and brucite at temperatures lower than 400 °C at 1 kbar. The density and volume changes in the ultramafic rocks occur at 163 different temperatures and are thus temporally separated which plays an important role in the deformation of the orthopyroxenite dykes. The volume changes occurring in the system, at lower temperatures, will therefore be dominated by the serpentinization of dunite during which the orthopyroxenite dykes are mostly unreactive. Approximately 50–60% serpentinization of the surrounding dunite causes a volume increase of 25% and is also reflected in the bulk volume change calculated from the phase transformations (Iyer et al., 2008b). The expansion occurring in the dunite during serpentinization will impose an extensional strain via the initially welded interface on the orthopyroxenite dykes and cause them to fracture. The surfacenormal direction of the fractures, independent of the dyke orientation, suggests that the dykes are subject to least compressive stresses parallel to the dyke-dunite contact. This is consistent with a stress-field generated by dunite expansion during serpentinization. The geometrical and statistical characteristics of the 2-D fracture networks in the LOC are typical of patterns generated during hierarchical fracturing where the layer is progressively broken up in to smaller domains (Iyer et al., 2008a). Field measurements across cross-sections through the dykes show a linear correlation between the fracture spacing and the layer thickness with a slope of approximately 0.45 ± 0.2 (R2 = 0.67) for 583 data points as shown in Fig. 5. The fracture spacing in the field was measured as the average distance between two adjacent fractures. Care was taken to exclude fractures that did not completely cut through the dykes. The ratio of fracture spacing to layer thickness for Fig. 4. Simplified geological map of the Leka Ophiolite Complex. The orthopyroxenite dykes are embedded in a dunite matrix and are exposed at Steinsind (filled orange circle). The orthopyroxenite dykes are extensively fractured with the fractures oriented sub-perpendicular to the dyke-dunite contact. 164 K. Iyer, Y.Y. Podladchikov / Earth and Planetary Science Letters 280 (2009) 159–166 the fracture spacing to layer thickness ratios at saturation presented above do not depend on elastic material properties. We have considered the optimal scenario that would produce the highest possible fracture density. Any transient or strain reversal effects that deviate from this scenario would produce higher fracture spacing to layer thickness ratios. The aim of the model is to quantify the spacing of fractures driven by phase transformations and does not intend to explain the modes of fracture propagation and initiation. 4.1. Activation of a frictional sliding interface Fig. 5. Scatter plot of layer thickness against fracture spacing (583 data points). Data points plot below the line with a slope of 1 (dashed line) which is expected from extension models (e.g. Bai and Pollard, 2000a, Bai et al., 2000). A linear fit to the data (solid line) gives a slope of 0.45 ± 0.2 (R2 = 0.67). the field data ranges from 0.1 to 1. Two-dimensional observations (plane view) of the fracture networks verify the above narrow fracture spacing observed along the one-dimensional profiles (Iyer et al., 2008a). This slope is considerably less than a critical ratio between 0.8 and 1.2 predicted from 2-D extension models for layered rocks with welded interfaces (e.g. Bai and Pollard, 2000a, Bai et al., 2000; Fig. 5). 4. Discussion The minimum fracture spacing to layer thickness ratios (S/Tf) obtained from the 1-D FDM layer model with interfacial slip is considerably lower than the S/Tf obtained from the previously mentioned 2-D models with perfectly welded layers along the top and bottom boundaries of the interface. From force balance across the layer of height Tf and length S, with a normal horizontal stress component within the layer (σxx) and a shear stress component acting along the interface (τxy): σ xx Tf = 2τxy S ð14Þ σ xx S = Tf 2τ xy ð15Þ If we consider the fracture spacing in the layer with interfacial slip at saturation, and substituting in Eq. (15): σt S = Tf 2τ s Previous 2-D numerical studies of an elastic, layered system with perfectly adhered interfaces under extension predict that further infilling of fractures within the layer is not possible if the fracture spacing to layer thickness ratio (S/Tf) falls below a critical value (0.8 to 1.2) and is independent of the average strain of the fractured layer. A transition in stress-state occurs within the layer when S/Tf ratio is below the critical value and inhibits further formation and propagation of fractures. As discussed above in Section 3.2, equilibrium thermodynamic calculations show that serpentinization of the dunites generates a bulk volume increase of approximately 25%. This expansion translates to 8% strain along any given direction imposed on the embedded orthopyroxenite dykes, for the simple case where expansion of the dunites is isotropic. Previous models with welded interfaces assume that the remote strain imposed on all the layers in the model is equal (e.g. Bai and Pollard, 2000a, Bai et al., 2000). However, the large strain generated by the serpentinization of dunites is not equally imposed on the embedded orthopyroxenite dykes and the surrounding dunites themselves. The strain generated by the expansion of the dunites drives the extension of the orthopyroxenite layers in our model. The misfit in strain between the layer and the surrounding matrix is too large and, cannot be accommodated by elastic deformation alone. Therefore, the interface between the layer and the matrix could be decoupled in order to accommodate the strain. The strain may also be accommodated by ductile deformation. Some of the orthopyroxenite dykes display pinch-swell structures in addition to tensile fractures (Fig. 6). The mechanism and stress pattern involved in the formation of pinch-swell structures is similar to those observed in boudin formation. Boudin formation requires a competent rock layer sandwiched between incompetent rocks (Wegmann, 1932). Stretching parallel to the layering of such a multi-layered rock series results in the rupture of the competent layer while the incompetent layers yield by plastic flow (Ramberg, 1955). Elongation of the rock layers can be due to (a) stretching under tensile stress, (b) compression in a direction perpendicular to the layering or (c) a stress couple at about a ð16Þ The above dependence of fracture spacing on the ratio of tensile and shear strength of the material is similar to the model proposed by Price (1966) and that used by Cox (1952) for fiber pullout, and is much simpler than that developed by Ji et al. (1998) for interbed slip. The result is the same as found by Kelly and Tyson (1965) and Lloyd et al. (1982). Using the values for shear and tensile strength obtained from rock mechanics experiments (Afrouz, 1992; Zhao, 2000), the minimum fracture spacing to layer thickness ratios for τs = 3σt, τs = 4σt and τs = 5σt are 0.166, 0.125 and 0.10, respectively. These minimum ratios are also predicted by the 1-D elastic layer model with interfacial slip and can further constrain the S/Tf ratios observed in the orthopyroxenite dykes. As mentioned in Section 3.1, in the numerical model, elastic effects do not affect the outcome of fracture spacing to layer thickness ratios at saturation. We also find that force balance considerations for Fig. 6. Fractured orthopyroxenite dyke (arrow) with a pinch-swell structure embedded in a dunite matrix. K. Iyer, Y.Y. Podladchikov / Earth and Planetary Science Letters 280 (2009) 159–166 45° angle to the elongation. The expansion of the dunite surrounding the orthopyroxenite dykes fulfils conditions (a) and (b) required for the formation of pinch-swell structures. It is, therefore, possible that some of the strain accompanying the expansion of dunites is associated with the plastic necking of the orthopyroxenite dykes. It could also be possible that the plastic flow resulting in the pinch-swell structures are related to the emplacement of the orthopyroxenite dykes within the surrounding matrix rocks. Furthermore, only a few of the observed orthopyroxenite dykes display pinch-swell structures while others do not show any evidence for ductile flow but are nevertheless similarly fractured. We have indirect evidence, from petrological observations and thermodynamic constraints, of the amount of strain generated during serpentinization of the dunites. As serpentinization occurs throughout the dunites, the accompanying strain would be the same for all regions on the interface between the orthopyroxenite dykes and the dunites. Although joint formation in the orthopyroxenite dykes would relieve some of the strain, the presence of unfractured dyke domains between two consecutive joints suggests that another mechanism, besides joint formation within the dykes, must have released the strain at the interface. The only other mechanism available to the system in order to release strain would be the decoupling of the interface between the dunites and the orthopyroxenite dykes. Hence, microstructures present at the interface between the orthopyroxenite dykes and the dunites may be an important indicator of interfacial slip. However, as serpentinization is an ongoing process in the studied lithologies, any structures present at the interface that might give us direct insight into the slip generated at the interface have been completely obliterated due to the formation of secondary hydrous phases (Fig. 7). Therefore, the necessity of interfacial slip to occur is a theoretical prediction as discussed above. Another important implication of the model is the estimation of the strength of rocks deduced from field observations of fracture spacing to layer thickness ratios. The Leka Ophiolite Complex (LOC) 165 was a part of the oceanic lithosphere formed at a slow spreading ridge (Maaløe, 2005). The average thickness of the oceanic crust is approximately 7.1 ± 0.8 km except at very slow-spreading ridges where the oceanic crust is anomalously thin (White et al., 1992). From Byerlee's Law, the shear strength of rocks at a depth of 6 and 8 km would be approximately 135 and 180 MPa, respectively (Byerlee, 1978; Turcotte and Schubert, 2002). The typical tensile strength of rocks is between 10 and 20 MPa (e.g. Afrouz, 1992; Zhao, 2000). Using these values as constraints for the relation between the fracture spacing to layer thickness ratio and the tensile to shear strength ratio, the model predicts a minimum fracture spacing to layer thickness ratio in the orthopyroxenite dykes of around 0.05. The measured field fracture spacing to layer thickness ratios falls above this predicted minimum ratio. However, the average value of fracture spacing to layer thickness ratios measured in the field is 0.45 ± 0.2. This suggests that shear strength of the rock may be significantly lowered as compared to that predicted by Byerlee's Law which could be an effect of the phase transformations occurring within the rock layer and/or the presence of high fluid pressures. 5. Conclusions The use of interfacial slip between the fractured layer and the surrounding matrix of a layered rock series yields minimum fracture spacing to layer thickness ratios that are significantly lower than the ratios predicted by models with perfectly welded interfaces. We have also shown that the minimum fracture spacing to layer thickness ratio for our model is directly proportional to the ratio of tensile and shear strength of the material. Lower minimum fracture spacing to layer thickness ratios are possible if the difference between the tensile and shear strength of the rock is greater. The fracturing of the orthopyroxenite dykes of the Leka Ophiolite Complex driven by a strain mismatch during serpentinization may have been deformed in a Fig. 7. A. Photomicrograph of the interface between dunite and orthopyroxenite dyke. B. Photomicrograph of the interface (red square in 7A) shows complete serpentinization of the original mineral assemblages. C. Photomicrograph of bastite (altered orthopyroxene) present in the orthopyroxenite dyke away from the interface. D. Photomicrograph of meshtextured serpentinization of olivine present in the dunite away from the interface. 166 K. Iyer, Y.Y. Podladchikov / Earth and Planetary Science Letters 280 (2009) 159–166 similar fashion accompanied by interfacial slip and, therefore, yielding low fracture spacing to layer thickness ratios. The model also provides constraints on the rock strength. Furthermore, the average value of fracture spacing to layer thickness ratios measured in the field suggests that phase transformations and/or fluid pressure could also significantly affect rock rheology. Acknowledgements The authors are grateful to Sergei Medvedev, Dani Schmid, Marcin Dabrowski and Victoria Yarushina, all at PGP, for their constructive comments and criticisms. The authors thank Bjørn Jamtveit (PGP) for his suggestions which helped improve previous versions of this paper. The authors are thankful for the critical reviews of Leonard Germanovich and an anonymous reviewer. This study was funded by a Centre of Excellence grant from the Norwegian Research Council to PGP. References Afrouz, A.A., 1992. Practical Handbook of Rock Mass Classification Systems and Modes of Ground Failure. CRC Press. Aveston, J., Cooper, G.A., Kelly, A., 1971. The Properties of Fiber Composites. IPC Science and Technology Press. Bai, T., Pollard, D.D., 2000a. Fracture spacing in layered rocks: a new explanation based on the stress transition. J. Struct. Geol. 22, 43–57. Bai, T., Pollard, D.D., 2000b. Closely spaced fractures in layered rocks: initiation mechanism and propagation kinetics. J. Struct. Geol. 22, 1409–1425. Bai, T., Pollard, D.D., Gao, H., 2000. Explanation for fracture-spacing in layered materials. Nature 403, 753–756. Becker, A., Gross, M.R., 1996. Mechanism for joint saturation in mechanically layered rocks: an example from southern Israel. Tectonophysics 257, 223–237. Bogdanov, A.A., 1947. The intensity of cleavage as related to the thickness of beds. Sov. Geol. 16 (in Russian). Byerlee, J.D., 1978. Friction of rocks. Pure Appl. Geophys. 116, 615–626. Cox, H.L., 1952. The elasticity and strength of paper and other fibrous materials. Br. J. Appl. Phys. 3, 72–79. Dunning, G.R., Pedersen, R.B., 1988. U/Pb ages of ophiolites and arc-related plutons of the Norwegian Caledonides – implications for the development of Iapetus. Contrib. Mineral. Petrol. 98, 13–23. Fischer, M.P., Polansky, A., 2006. Influence of flaws on joint spacing and saturation: results of one-dimensional mechanical modeling. J. Geophys. Res. 111, B07403. doi:10.1029/2005JB004115. Furnes, H., Pedersen, R.B., Stillman, C.J., 1988. The Leka Ophiolite Complex, Central Norwegian Caledonides – field characteristics and geotectonic significance. J. Geol. Soc. 145, 401–412. Garrett, K.W., Bailey, J.E., 1977. Multiple transverse fracture in 90° cross-ply laminates of a glass fibre-reinforced polyester. J. Mater. Sci. 12, 157–168. Germanovich, L.N., Astakhov, D.K., 2004. Fracture closure in extension and mechanical interaction of parallel joints. J. Geophys. Res. 109. doi:10.1029/2002JB002131. Gillespie, P.A., Johnston, J.D., Loriga, M.A., McCaffrey, K.J.W., Walsh, J.J., Watterson, J., 1999. Influence of layering on vein systematic in line samples. In: McCaffrey, K.J.W., Lonergan, L., Wilkinson, J.J. (Eds.), Fractures, Fluid Flow and Mineralization, Geological Society Special Publication, vol. 155, pp. 35–56. Gross, M.R., 1993. The origin and spacing of cross joints: examples from Monterey Formation, Santa Barbara Coastline, California. J. Struct. Geol. 15, 737–751. Gross, M.R., Fischer, M.P., Engelder, T., Greenfield, R.J.,1995. Factors controlling joint spacing in interbedded sedimentary rocks: integrating numerical models with field observations from the Monterey Formation, USA. In: Ameen, M.S. (Ed.), Fractography: Fracture Topography as a Tool in Fracture Mechanics and Stress Analysis, Geological Society Special Publication, vol. 92, pp. 215–233. Hill, R., 1950. The Mathematical Theory of Plasticity. Oxford University Press, Oxford. 356 pp. Hobbs, D.W., 1967. The formation of tension joints in sedimentary rocks: an explanation. Geol. Mag. 104, 550–556. Huang, Q., Angelier, J., 1989. Fracture spacing and its relation to bed thickness. Geol. Mag. 126, 355–362. Iyer, K., Jamtveit, B., Mathiesen, J., Malthe-Sørenssen, A., Feder, J., 2008a. Reactionassisted hierarchical fracturing during serpentinization. Earth Planet. Sci. Lett. 267, 502–515. Iyer, K., Austrheim, H., John, T., Jamtveit, J., 2008b. Serpentinization of the oceanic lithosphere and some geochemical consequences: constraints from the Leka Ophiolite Complex, Norway. Chem. Geol. 249, 66–90. Ji, S., Saruwatari, K., 1998. A revised model for the relationship between joint spacing and layer thickness. J. Struct. Geol. 20, 1495–1508. Ji, S.C., Zhu, Z.M., Wang, Z.C., 1998. Relationship between joint spacing and bed thickness in sedimentary rocks: effects of interbed slip. Geol. Mag. 135, 637–655. Karato, S., 1997. Phase transformations and rheological properties of mantle minerals. In: Crossley, D., Soward, A.M. (Eds.), Earth's Deep Interior. Gordon and Breach, New York, pp. 223–272. 1997. Kelly, A., Tyson, W.R., 1965. Tensile properties of fibre-reinforced metals: copper/ tungsten and copper/molybdenum. J. Mech. Phys. Solids 13, 329–350. Kirillova, I.V., 1949. Some problems of the mechanics of folding. Trans. Geofian. 6 (in Russian). Lachenbruch, A.H., 1961. Depth and spacing of tension cracks. J. Geophys. Res. 66, 4273–4292. Li, Y., Yang, C., 2007. On fracture saturation in layered rocks. Int. J. Rock Mech. Min. Sci. 44, 936–941. Lloyd, G.E., Ferguson, C.C., Reading, K., 1982. A stress-transfer model for the development of extension fracture boudinage. J. Struct. Geol. 4, 355–372. Maaløe, S., 2005. The dunite bodies, websterite and orthopyroxenite dikes of the Leka ophiolite complex, Norway. Mineral. Petrol. 85, 163–204. Mandl, G., 2005. Rock Joints: The Mechanical Genesis. Springer Verlag, New York. McQuillan, H., 1973. Small-scale fracture density in Asmari Formation of southwest Iran and its relation to bed thickness and structural setting. Am. Assoc. Pet. Geol. Bull. 57, 2367–2385. Narr, W., Lerche, I., 1984. A method for estimating subsurface fracture density in core. Am. Assoc. Pet. Geol. Bull. 66, 637–648. Narr, N., Suppe, J., 1991. Joint spacing in sedimentary rocks. J. Struct. Geol. 13, 1037–1048. Novikova, A.C., 1947. The intensity of cleavage as related to the thickness of the bed. Sov. Geol. 16 (in Russian). Nur, A., 1982. The origin of tensile fracture lineaments. J. Struct. Geol. 4, 31–40. Parvizi, A., Bailey, J.E., 1978. On multiple transverse cracking in glass fibre epoxy crossply laminate. J. Mater. Sci. 13, 2131–2136. Pollard, D.D., Aydin, A., 1988. Progress in understanding jointing over the past century. Geol. Soc. Amer. Bull. 100, 1181–1204. Pollard, D.D., Segall, P.,1987. Theoretical displacements and stresses near fractures in rocks: with applications to faults, joints, veins, dikes and solution surfaces. In: Atkinson, B.K. (Ed.), Fracture Mechanics of Rock. Academic Press, London, pp. 277–349. Prestvik, T., 1972. Alpine-type mafic and ultramafic rocks of Leka, Nord-Trøndelag. Nor. Geol. Unders. (Tidsskrift Artikkel) 273, 23–34. Price, N.J., 1966. Fault and Joint Development in Brittle and Semi-Brittle Rock. Pergamon Press, Oxford. Ramberg, H., 1955. Natural and experimental boudinage and pinch-and-swell structures. J. Geol. 63, 512–526. Thouless, M.D., Olsson, E., Gupta, A., 1992. Cracking of brittle films on elastic substrates. Acta Metall. Mater. 40, 1287–1292. Tindall, S.E., Davis, G.H., 2003. Joint spacing and distribution in deformation band shear zones. Geol. Mag. 140 (1), 1–9. Titus, S.J., Fossen, H., Pedersen, R.B., Vigneresse, J.L., Tikoff, B., 2002. Pull-apart formation and strike-slip partitioning in an obliquely divergent setting, Leka Ophiolite, Norway. Tectonophysics 354, 101–119. Turcotte, D.L., Schubert, G., 2002. Geodynamics, 2nd edition. Cambridge University Press, Cambridge. Wegmann, C.E., 1932. Note sur le boudinage. Soc. Geol. France Compte Rendu 5, 477–489. White, R.S., McKenzie, D., O'Nions, R.K., 1992. Oceanic crustal thickness from seismic measurements and rare earth element inversions. J. Geophys. Res. 97 (B13), 19683–19715. Wu, H., Pollard, D.D., 1995. An experimental study of the relationship between joint spacing and layer thickness. J. Struct. Geol. 17, 889–905. Zhang, Y.X., 1998. Mechanical and phase equilibria in inclusion-host systems. Earth Planet. Sci. Lett. 157, 209–222. Zhao, J., 2000. Applicability of Mohr–Coulomb and Hoek–Brown strength criteria to the dynamic strength of brittle rock. Int. J. Rock Mech. Min. Sci. 37, 1115–1121.