Cheaper Fuels for the Light-Duty Fleet Opportunities and Barriers

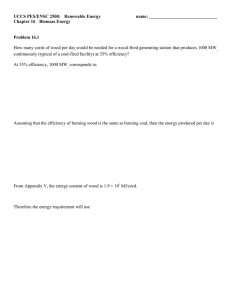

advertisement