Presented By Department of Environmental Health and Safety

advertisement

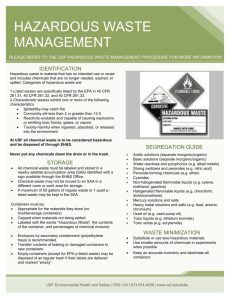

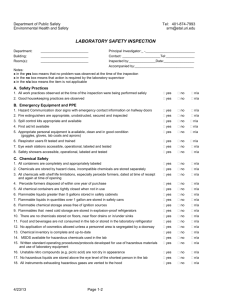

Presented By Department of Environmental Health and Safety www.drexel.edu/facilities/healthSafety/ Content ◦ Laboratory Safety ◦ Occupational Safety and Health ◦ Regulatory Affairs ◦ Emergency Contacts ◦ Safety Training ◦ Service Requests and Forms Lab Safety TrainingRevised 6/2009 2 Research Personnel Laboratory Safety Training Topics Covered ◦ Blood borne Pathogens ◦ Hazardous Waste Management ◦ Emergency Spill Response ◦ Chemical Fume Hood Safety ◦ BSC Safety ◦ Centrifuge Safety ◦ Chemical Hygiene – Hazard Communication ◦ Fire Safety in the Laboratory ◦ Laser Safety ◦ Personal Protection Equipment ◦ Respiratory Protection ◦ Safe Storage and Handling of Compressed Gas Lab Safety TrainingRevised 6/2009 3 Four fundamental principles define all of the work area and procedural precautions set forth in the CHP: ◦ Plan Ahead! Determine the potential hazard associated with an experiment before beginning it. ◦ Minimize Exposure to Hazardous Materials! Do not allow laboratory hazardous materials to come in contact with skin. Use laboratory hoods and other ventilation devices to prevent exposure to airborne substances whenever possible. ◦ Do Not Under Estimate Risks! Assume that any mixture of hazardous materials will be more toxic than its most toxic component. Treat all new compounds and substances of unknown toxicity as toxic substances ◦ Be Prepared for Accidents! Prior to beginning an experiment, know the specific action to take in the event of the accidental release of any hazardous substance. Know the locations of all safety equipment and the nearest fire alarm and telephone, know what telephone numbers to call and whom to notify in the event of an emergency. Keep your coworkers informed of your activities so that they can respond appropriately. Lab Safety TrainingRevised 6/2009 4 Establishes general guidelines/procedures for handling chemicals in the laboratory. The standard operating procedures provide laboratory personnel with baseline information on how to behave/work in a laboratory. Prior to performing any experimental procedures, laboratory personnel should review the general procedures and establish specific procedures when working with certain hazardous chemicals. Lab Safety TrainingRevised 6/2009 5 Acrolein Incident ◦ Highly toxic, highly flammable, highly reactive material ◦ Wearing nitrile gloves ◦ No standard operating procedure ◦ No safety glasses ◦ No laboratory coat ◦ Opening new container of under CFH at edge of workbench ◦ Vertical sash position at 18 inches ◦ Splashed in eye and on body ◦ Vapors spread throughout room ◦ Occupants overcome ◦ Emergency procedure implemented correctly ◦ No major injury Natural Rubber Nitrile Neoprene Butyl PVC Acetaldehyde 1 1 1 4 1 Acrolein 1 1 1 4 1 Benzaldehyde 1 1 1 4 1 Butyraldehyde 1 1 1 4 1 Formaldehyde 1 4 2 4 2 Glutaraldehyde ? ? 4 4 2 Aldehydes Lab Safety TrainingRevised 6/2009 6 Sulfuric Acid Incident # 1 Highly corrosive and highly reactive Wearing nitrile gloves No standard operating procedure No safety glasses No laboratory coat Removing tubing from apparatus under CFH ◦ Horizontal sash position open ◦ Splashed in face and chest ◦ Emergency procedure not implemented properly ◦ ◦ ◦ ◦ ◦ ◦ Did not use eyewash or shower Did not remove contaminated clothing Natural Rubber Nitrile Neopren e Butyl PVC Chromic acid up to 70% 1 3 1 4 3 Hydrochloric acid up to 37% 3 3 3 4 3 Hydrofluoric acid up to 70% 2 1 2 3 1 Nitric acid 70+ % ? 1 1 2 ? Perchloric acid up to 70% 4 4 4 3 4 Phosphoric acid 70+ % 4 4 4 4 4 Sulfuric acid 70+ % 1 1 2 4 2 Inorganic acids ◦ Caused severe burns to face and chest Lab Safety TrainingRevised 6/2009 7 Sulfuric Acid Incident # 2 Highly corrosive and highly reactive Wearing nitrile gloves No standard operating procedure No safety glasses No laboratory coat Reaction by-products – titanium tetrachloride ◦ Removing tubing from apparatus outside local exhaust hood. ◦ Splashed in face ◦ Emergency procedure not implemented properly ◦ ◦ ◦ ◦ ◦ ◦ Did not use eyewash or shower Did not contact public safety directly Natural Rubber Nitrile Neopren e Butyl PVC Chromic acid up to 70% 1 3 1 4 3 Hydrochloric acid up to 37% 3 3 3 4 3 Hydrofluoric acid up to 70% 2 1 2 3 1 Nitric acid 70+ % ? 1 1 2 ? Perchloric acid up to 70% 4 4 4 3 4 Phosphoric acid 70+ % 4 4 4 4 4 Sulfuric acid 70+ % 1 1 2 4 2 Inorganic acids ◦ Caused severe burns to face Lab Safety TrainingRevised 6/2009 8 Metal Perchlorate Complex Incident Highly reactive and explosive Wearing nitrile gloves No standard operating procedure Wearing safety glasses No laboratory coat No explosion barrier No explosive test performed Transferring material from fritted funnel to sample vial on bench top ◦ Exploded in hand ◦ Emergency procedure implemented properly ◦ Caused severe burns and cuts to hand ◦ ◦ ◦ ◦ ◦ ◦ ◦ ◦ Lab Safety TrainingRevised 6/2009 9 T-Butyl Lithium Incident – Not at Drexel ◦ ◦ ◦ ◦ ◦ ◦ ◦ ◦ ◦ ◦ Highly reactive (pyrophoric material) No standard operating procedures Wearing nitrile gloves Wearing safety glasses No laboratory coat Working alone Transferring the material into a syringe Material reacted with air and exploded into flames Emergency procedure not implemented properly Caused severe burns all over Lab Safety TrainingRevised 6/2009 10 ◦ ◦ ◦ ◦ ◦ ◦ ◦ Keep all work areas clean and free of clutter. Clean up the work area on completion of an operation or at the end of each work shift or class. Keep chemicals and equipment properly labeled and stored appropriately. Do not store, handle or consume food or beverages in laboratory areas, refrigerators, or with glassware or utensils that are also used for laboratory operation. Seek information and advice about hazards, review MSDS, plan appropriate protective procedures, and plan positioning of equipment before beginning new operation. Leave lights on during work hours. Provide for containment of toxic substances in the event of failure of a utility service in an unattended operation. Be aware of any unsafe conditions and see that they are corrected when detected. Contact the Department of Environmental Health and Safety for advice. Lab Safety TrainingRevised 6/2009 11 The chemical hygiene plan (CHP) establishes procedural precautions for laboratory personnel to follow during hazardous material manipulations. The section provides the following precautions: ◦ ◦ ◦ ◦ ◦ General precautions Toxic Chemical Precautions Radioactive Material Precautions Flammable Material Precautions Reactive chemicals Lab Safety TrainingRevised 6/2009 12 Mouth suction for pipetting or starting a siphon is strictly forbidden. Do not smell or taste chemicals. Apparatus that can discharge toxic chemicals (vacuum pumps, distillation columns, etc.) should be vented into local exhaust devices or Chemical Fume Hoods. Handle and store laboratory glassware with care to avoid damage. Do not use damaged glassware. Use extra care with Dewar flasks and other evacuated glass apparatus; shield or wrap them to contain chemicals and fragments in the event that implosion might occur. Lab Safety TrainingRevised 6/2009 13 Laboratory personnel working with highly toxic and/or reactive materials must be thoroughly familiar with the general guidelines for safe handling of hazardous materials in laboratories. Preparations for handling highly toxic and/or reactive substances must include: ◦ ◦ ◦ ◦ ◦ Sound and thorough planning of the experiment; Understanding the intrinsic hazards of the substances; Exposure risks; Additional precautions that may be necessary to minimize or eliminate these risks; Reviewing all emergency procedures to ensure appropriate response to unexpected spills and accidents. Laboratory personnel should be specifically trained on the use of certain highly toxic and/or reactive materials. Additional training can be provided to anyone working highly toxic, highly flammable and/or reactive materials. Lab Safety TrainingRevised 6/2009 14 ◦ ◦ ◦ ◦ ◦ ◦ ◦ ◦ ◦ Never work alone. Keep good housekeeping procedures. Plan experiments prudently. Designate areas in the laboratory for only highly toxic and/or reactive material manipulations. Procedures involving highly toxic and/or reactive materials that can generate dust, vapors, or aerosols must be conducted in a chemical fume hood, glove box or other suitable containment device. Proper personal protection equipment must worn at all times to protect worker from exposure (i.e. appropriate gloves; face shield; safety goggles; lab coats; respirators; etc.). Be sure to inspect all personal protective equipment prior to and after use. Equipment used should be isolated and labeled. Always practice good laboratory hygiene. Wash hands, face, neck and forearms. Never remove contaminated equipment from designated area. Lab Safety TrainingRevised 6/2009 15 Handle flammable substances only in areas free of ignition sources. Besides open flames, ignition sources include electrical equipment (especially motors), static electricity, and, for some materials (e.g., carbon disulfide), even hot surfaces. Check the work area for flames or ignition sources prior to using a flammable substance. Never heat a flammable substance with an open flame. Preferred heat sources include steam baths, water baths, oil and wax baths, salt and sand baths, heating mantles, and hot air. Keep containers of flammable substances tightly closed at all times when not in use. Use only refrigeration equipment certified for storage of flammable materials. Lab Safety TrainingRevised 6/2009 16 All hazardous and non-hazardous chemicals must be stored in clearly defined designated areas ◦ The chemical inventory should be kept as small as possible. ◦ Do not store chemicals on top of high cabinets or shelves. ◦ Keep exits, passageways, areas under tables, and emergency equipment areas free of stored chemicals. ◦ Provide a definite storage place for each chemical and return the chemical to that location after each use. ◦ Avoid storing chemicals on bench tops and in fume hoods, except for those chemicals being used currently. ◦ Do not store chemicals on the floor. Lab Safety TrainingRevised 6/2009 17 ◦ Separate chemicals into the following hazard classes: Flammables Acids Organic Acids Inorganic Acids Bases Organic Bases Inorganic Bases Oxidizers Reactives Poisons (i.e. toxic materials, carcinogens) Non-hazardous or non-regulated chemicals Lab Safety TrainingRevised 6/2009 18 ◦ Do not store chemicals in the cabinets under the sink, except for household cleaning agents (i.e. Windex, bleach, soaps, detergents, etc.). ◦ Store chemicals in a cool dry place avoiding direct sunlight ◦ Ventilated storage cabinets shall be used to store extremely hazardous chemicals. ◦ Use chemical storage refrigerators only for chemical storage. Label these refrigerators with the following signage: “No Food or Drink – Chemical Storage Only” ◦ Do not store flammable liquids in a refrigerator unless it is an approved explosion-proof refrigerator. ◦ Safety containers must be used when transporting chemicals (i.e. carts, rubber totes, secondary containers etc.). Lab Safety TrainingRevised 6/2009 19 ◦ Observe all precautions regarding the storage of incompatible chemicals. Oxidizing reagents/Reducing reagents Acids/Bases ◦ Dry chemicals (solid materials) shall not be stored with liquid chemicals. ◦ Store all flammable liquids in a grounded flammable storage cabinet with self-closing doors. ◦ Overspill containers must be used when storing incompatibles together in one cabinet. ◦ Organic Acids can be stored in the flammable storage cabinet. Lab Safety TrainingRevised 6/2009 20 ◦ Acids must be stored separate from bases. Storage in the same cabinet is possible ONLY IF OVERSPILL CONTAINERS ARE USED TO CONTAIN ANY SPILLS. ◦ Separate inorganic and organic bases. These can be stored in the same cabinet. Shelves or overspill containers can be used as a means of separation ◦ Oxidizers must be stored in a cabinet separate from all other chemicals. ◦ Reactive chemicals must be segregated and stored appropriately i.e. flammable cabinet, explosion proof refrigerator, dedicated container etc. Lab Safety TrainingRevised 6/2009 21 ◦ Toxic chemicals, including carcinogens, must be properly labeled and stored in ventilated storage areas. ◦ Small containers should be stored together in unbreakable chemical-resistant secondary containers. ◦ These containers must be labeled either “Caution: High Chronic Toxicity,” or “Cancer Suspect Agent”. ◦ Alphabetical storage of all dry chemicals is not allowed. ◦ Cylinders of compressed gases, empty or full, must be labeled, strapped or chained at all times to a wall or bench top, and must be capped when not in use. Lab Safety TrainingRevised 6/2009 22 ◦ Oxygen and other oxidizing gases must not be stored adjacent to flammable gases (except when in use). ◦ Do not store flammable gases near sources of heat or ignition. ◦ Peroxides or peroxide-forming chemicals must be dated upon receipt and upon opening. ◦ If unable to determine the best possible storage options consult the MSDS for the chemical. If further assistance is need contact the Department of Environmental Health and Safety. Lab Safety TrainingRevised 6/2009 23 Complete chemical name. Abbreviation or chemical symbols are not acceptable Appropriate hazard warnings. For example – irritant; flammable; corrosive; oxidizers etc. All labels must be prominently displayed and legibly written (printed) in English and other language as appropriate for employees and/or students. Lab Safety TrainingRevised 6/2009 24 ◦ Secondary containers (i.e. beakers; Erlenmeyer flask; cap bottles, etc.) Do not require labeling if the materials is used immediately and completely. Do require labeling if the material is not used immediately and completely. ◦ Research samples and small vials Too restrictive to meet the requirements Utilize a number/index system that corresponds to label information for that chemical can be noted in a laboratory notebook. Lab Safety TrainingRevised 6/2009 25 ◦ NFPA diamond. ◦ PI emergency contact. ◦ After hours contact. ◦ Department name and telephone ◦ Date posted. ◦ Additional hazards. Lab Safety TrainingRevised 6/2009 26 ◦ All cabinets, shelves and refrigerators containing chemical storage (including the cleaning supplies) must be labeled with the appropriate warning label (i.e. Flammable, Acids, Bases, Oxidizers etc.). ◦ Refrigerators used for chemical storage must be labeled, with appropriate hazard warnings and with the signage: “No Food or Drink – Chemicals Storage Only.” ◦ Any refrigerator used of food or drink storage must be labeled as such. ◦ Microwaves and centrifuges that could be contaminated with chemicals must be labeled with the appropriate warning labels. Lab Safety TrainingRevised 6/2009 27 Drain disposal is permitted for the following: ◦ Elementary neutralized acidic and basic aqueous solutions. ◦ The final pH value must be between 6 and 9 prior to drain disposal. ◦ The limit of material that may be neutralized is 1 liter. ◦ Common salts, sugars and agars in both liquid and solid forms. ◦ For solids, the material must be dissolved in tap water. ◦ The limit of material that may be disposed is 1 kg of solid or 1 liter of liquid. Lab Safety TrainingRevised 6/2009 28 Drain disposal is prohibited for the following: ◦ ◦ ◦ ◦ ◦ ◦ ◦ ◦ ◦ ◦ ◦ Flammable or explosive materials. Corrosive materials with a pH less 6 or greater than 9. Solid or viscous materials. Materials capable of releasing fumes or vapors. Oxygen-demanding pollutants. Hot wastewater greater than 250 °F. Petroleum, oil, non-biodegradable cutting oil or products of mineral oil origin. No organic chemicals. No heavy metal solutions. Sulfuric, Nitric, Hydrofluoric, Perchloric, and Chromic acid Toxic/Poisonous solids and liquids. Lab Safety TrainingRevised 6/2009 29 ◦ Area at or near a process that generates chemical wastes. ◦ The area must be under the control of the operator of that process. ◦ Each laboratory is designated as a satellite accumulation area. ◦ The responsible party is responsible for following the policies satellite accumulation areas. ◦ Each responsible party shall designate a location in the laboratory as the satellite accumulation area. ◦ The storage of hazardous waste shall comply with the storage requirements outlined in the University’s Chemical Hygiene Plan. Lab Safety TrainingRevised 6/2009 30 Allowable Amounts Accumulated ◦ Accumulate as much as 5 gallons of hazardous waste. ◦ One quart of acutely hazardous waste. ◦ In compatible containers at or near any point of generation. Accumulation Time ◦ There is no limit on accumulation time, however, once a container is full or more than 5 gallons of hazardous waste, or 1 quart of acutely hazardous waste, is accumulated, the full container or excess waste must be moved to the accumulation area within 72 hours. Lab Safety TrainingRevised 6/2009 31 ◦ Hazardous Material Labels (orange label) shall be completed for each waste container. ◦ All containers must be labeled with the complete chemical name of each primary component. Formulas, acronyms and abbreviations are not acceptable. ◦ If possible, the label should include the approximate percentage of each chemical. ◦ Do not place the date or the words “Hazardous Waste” on the container. ◦ Do not place a date on the waste container. Lab Safety TrainingRevised 6/2009 32 ◦ All containers must be kept closed except when it is necessary to add or remove material. ◦ Evaporation of waste in the chemical fume hood is STRICTLY PROHIBITED. ◦ All containers must be maintained in good condition (i.e. no rust, dents, or leaks, etc.) ◦ All containers must be compatible with the hazardous wastes they contain. Lab Safety TrainingRevised 6/2009 33 ◦ Access to the chemical pick-up request form in online at http://www.drexel.edu/facilities/healthSafety/ under the Service Request link. ◦ Chemical pick-up request form should be immediately filled out when: Unwanted and old chemical reagents need to be removed. The satellite accumulation waste container is full. There is more than 5 gallons of hazardous waste. One quart of acutely hazardous waste accumulated. ◦ Department of Environmental Health and Safety shall respond to chemical pick-up request within 72 hours of receipt of request. Lab Safety TrainingRevised 6/2009 34 ◦ The request must list all the materials that need to be removed. ◦ Any materials not listed will not be removed until a chemical request form is filled out. ◦ If the material is improperly labeled it will not be removed until proper labeling is present. ◦ Open containers will not be removed from the laboratory. Only closed containers will be removed. Lab Safety TrainingRevised 6/2009 35 ◦ Dispose of all contaminated materials as infectious waste i.e. sharps, gloves, drip pads, gowns, etc. ◦ Sharps are any item that when broken or intact can pierce or scratch the skin. ◦ Non-sharp contaminated materials must be disposed in the provided infectious waste containers. ◦ Sharps must be disposed in a approved properly labeled sharps container. ◦ Non-sharp items contaminated or not must not be disposed in the sharps containers. ◦ All containers more than 2/3 full should be closed/sealed until it is picked up for disposal Lab Safety TrainingRevised 6/2009 36 ◦ Infectious waste containers must remain inside the laboratory at all times prior to pick-up. ◦ Containers must not be placed in hallway at any time. ◦ Infectious waste is removed by outside contractor. ◦ Request a pick-up by contacting Department of Environmental Health and Safety at 215-895-5919 ◦ Infectious waste containers can be requested at http://www.drexel.edu/facilities/healthSafety/ under the Service Request link. Lab Safety TrainingRevised 6/2009 37 ◦ Spills greater than 500ml/gm. ◦ Any amount of Acutely Hazardous waste ◦ Select Agent Release ◦ Hazardous Gas Release ◦ Mercury Releases Lab Safety TrainingRevised 6/2009 38 ◦ The list of acutely hazardous chemicals can be accessed at http://www.drexel.edu/facilities/healthSafety/ under the Laboratory Safety link in the Chemical Hygiene Plan. ◦ This list shall be referenced prior using hazardous materials to ensure it is not acutely hazardous. ◦ All spills that occur in vacant laboratories shall initially be identified as a major spill. ◦ Report all minor spills involving the release of materials in quantities greater than 100 milliliters to the Department of Environmental Health and Safety at 215895-5919. Lab Safety TrainingRevised 6/2009 39 ◦ Notify persons in the immediate area that a spill has occurred. ◦ If contaminated immediately implement personal decontamination procedures. ◦ Avoid breathing vapors, mists or dust of the spilled material. ◦ Turn off all ignition sources if possible. ◦ Evacuate room and close the door. ◦ Contact Drexel Public Safety’s 24-Hour Call Center at 215-895-2222. Lab Safety TrainingRevised 6/2009 40 ◦ In order to asses the situation be prepared to provide the following information: Name and call-back number The location of the spill (building and room number) Type of material spilled The amount of material that spilled ◦ Remain on or near the telephone until you have received instructions from the Public Safety or Department of Environmental Health and Safety. Lab Safety TrainingRevised 6/2009 41 ◦ If contaminated immediately implement personal decontamination procedures prior to cleaning up the spill. ◦ Review MSDS and acutely hazardous material list prior to clean-up. ◦ Proper personnel protection equipment will be donned during clean up of all hazardous materials. ◦ ◦ Reference personnel protection equipment selection charts. If the proper personal protective equipment is not available then contact Department of Environmental Health and Safety for assistance. Contain spilled material(s) using absorbent pads and/or socks. ◦ ◦ Paper towels will not be used for containment of spill nor will they be used for clean up. Lab Safety TrainingRevised 6/2009 42 ◦ Neutralize spilled material(s) using the appropriate neutralizing agent. ◦ Clean up neutralized material using dustpan and/or plastic scoop. ◦ Place neutralized material in hazardous waste bags. Dispose of as hazardous waste. ◦ Wash the area where the spill has occurred with water several times making sure no residue is left behind. Dispose of any towels used as hazardous waste. ◦ All emergency equipment shall be decontaminated and stored. ◦ All non-disposable personal protective equipment shall be decontaminated and stored. ◦ All disposable personal protective equipment and clean-up materials shall be disposed of as hazardous waste. ◦ Always use extreme caution when cleaning up hazardous substances. Lab Safety TrainingRevised 6/2009 43 Appropriate eye protection is worn by all persons in laboratories and areas where hazardous materials are used or stored. ◦ Eye protection consists of safety glasses with side shields, goggles or face shield, or full-face respirator. ◦ Eye protection is required whether or not one is actually performing experimental operations. Employees/students are required to wear appropriate gloves when an employee has the potential for direct contact with blood, hazardous chemicals, infectious agents, or other hazardous materials. Select gloves appropriate for the task. Gloves protect differently for each chemical. For more information concerning glove selection contact Department of Environmental Health and Safety. Gloves must not be worn in hallways, elevators, or public areas. If hazardous materials must be transported from one area to another, glove one hand to hold the product/apparatus or push cart and use a clean ungloved hand to open doors, press buttons, etc. Lab Safety TrainingRevised 6/2009 44 Employees/students are required to wear lab coats when there is the potential for direct contact with blood, hazardous chemicals, infectious agents, very hot or very cold materials, or any other hazardous materials. Lab coats must be worn only in the laboratory area and are to be removed upon exiting the laboratory. If respirator protection is need then contact the Department of Environmental Health and Safety. Use any other protective apparel and equipment as appropriate. Know the locations of personal protection equipment (PPE) and how to obtain additional materials when necessary. If appropriate PPE is not readily available do not initiate experiments involving hazardous chemicals. The Principal Investigator shall provide proper personal protection equipment for all personal in the research laboratory. Lab Safety TrainingRevised 6/2009 45 An inventory of all chemicals (all hazardous chemicals, nonhazardous chemicals, chemical cleaning agents, samples, etc.) must be conducted in each laboratory. A copy of this inventory will be maintained by the P.I., a second copy will be maintained in each lab as the first page of the MSDS book and a third copy will be sent to the Department of Environmental Health and Safety. Additional inventories must be prepared annually. As new chemicals are obtained, chemical inventory sheets must be updated accordingly. Lab Safety TrainingRevised 6/2009 46 Product Information Composition Hazard Identification First Aid Measures Fire Fighting Measures Accidental Release Measures Handling and Storage Exposure control and personal protection Physical and Chemical properties Stability and Reactivity Toxicology Information Ecological Information Disposal Consideration Transportation Information Regulatory Information Other Information Lab Safety TrainingRevised 6/2009 47