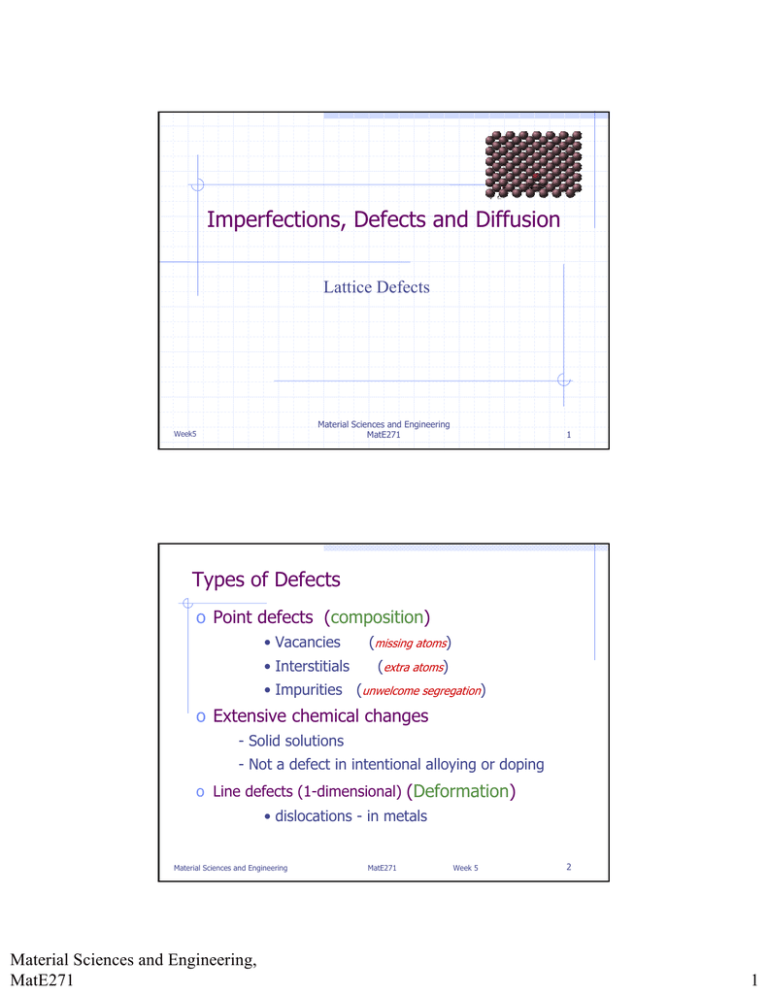

Imperfections, Defects and Diffusion Types of Defects Lattice Defects o

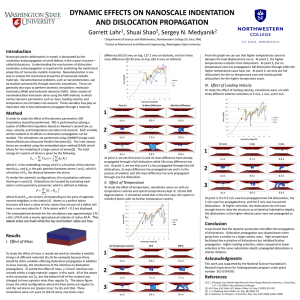

advertisement

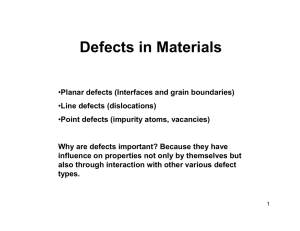

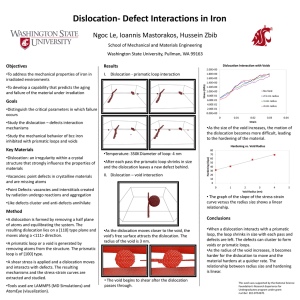

Imperfections, Defects and Diffusion Lattice Defects Material Sciences and Engineering MatE271 Week5 1 Types of Defects o Point defects (composition) • Vacancies (missing atoms) • Interstitials (extra atoms) • Impurities (unwelcome segregation) o Extensive chemical changes - Solid solutions - Not a defect in intentional alloying or doping o Line defects (1-dimensional) (Deformation) • dislocations - in metals Material Sciences and Engineering Material Sciences and Engineering, MatE271 MatE271 Week 5 2 1 Types of Defects, cont. o Interfacial defects (2-dimensional) (Properties) - surfaces - both interior (pore walls) and exterior (surface of material) - interfaces -(grain boundaries) o Bulk-Volume defects (3-dimensional) - cracks, foreign inclusions, other phases (including pores). Material Sciences and Engineering MatE271 Week 5 3 Point Defects in Metals Self Interstitial Interstitial Impurity Vacancy Substitutional Impurity Material Sciences and Engineering Material Sciences and Engineering, MatE271 MatE271 Week 5 4 2 Point defects o Vacancy An empty atomic site o Interstitial An atom somewhere other than an atomic site - Self-interstitial - Impurity interstitial o Substitutional impurity Some “foreign” species on an atomic site Material Sciences and Engineering MatE271 Week 5 5 Line Defects: Dislocation in Metals Responsible for large mechanical deformation in crystalline solids -Linear (one dimensional) defect around which some of the atoms are misaligned Material Sciences and Engineering Material Sciences and Engineering, MatE271 MatE271 Week 5 6 3 Types of Dislocations - Edge Dislocation: A portion of an extra plane of atoms - Screw Dislocation: Helical atomic displacement around a line extending through the crystal - Mixed Dislocation: Some edge, some screw nature Material Sciences and Engineering MatE271 Week 5 7 MatE271 Week 5 8 Edge Dislocation Material Sciences and Engineering Material Sciences and Engineering, MatE271 4 Burgers vector b Perfect crystal dislocated crystal b-represents the magnitude of the structural defect Material Sciences and Engineering MatE271 Week 5 9 MatE271 Week 5 10 Screw Dislocation Material Sciences and Engineering Material Sciences and Engineering, MatE271 5 Mixed Dislocation Material Sciences and Engineering MatE271 Week 5 11 Why are Dislocations Important? The motion of dislocations is the principle mechanism whereby metals deform Material Sciences and Engineering Material Sciences and Engineering, MatE271 MatE271 Week 5 12 6 Why? Energy, Energy, Energy! o Lower energy than breaking all bonds in a plane at once Material Sciences and Engineering MatE271 Week 5 13 Shear occurs by dislocation movement producing permanent (plastic) deformation by “slip” Textbook ch6, pp 212-218 Direction of Slip plane dislocation movement Material Sciences and Engineering Material Sciences and Engineering, MatE271 MatE271 Week 5 14 7 Edge Dislocation Motion - 3D Material Sciences and Engineering MatE271 Week 5 15 Slip occurs along densely packed directions on densely packed planes Material Sciences and Engineering Material Sciences and Engineering, MatE271 MatE271 Week 5 16 8 (Plane)[Direction] pairs designate “slip systems” (e.g., in FCC and HCP) pp 215 Material Sciences and Engineering MatE271 Week 5 17 Dislocation movement and ductility • A large number of independent slip systems are required for good ductility in polycrystalline materials so grains can deform to accommodate their neighboring grains Common in many metal structures (bcc and fcc) • Dislocations are very complex in ceramic structures. This and complications of like charged ions encountering each other during slip make dislocation movement almost impossible in ceramics Therefore ceramics are not ductile, they are brittle Material Sciences and Engineering Material Sciences and Engineering, MatE271 MatE271 Week 5 18 9 Impediments to easy dislocation movement • Impurity atoms (“solute hardening”) • Intersection with other dislocations (entanglement) (“work hardening”) • Grain boundaries (dislocations “pile up”) • Small dispersed inclusions (“precipitation hardening”) • All of these affect ductility and yield strength of a metals Material Sciences and Engineering MatE271 Week 5 19 Grain boundaries and other dislocations impede the movement of dislocations causing “hardening” Dislocations Material Sciences and Engineering Material Sciences and Engineering, MatE271 MatE271 Week 5 20 10 Material Science Investigative Techniques “Microscopy” • Optical microscope surface microstructure (~ 1µm) • Scanning electron microscope (SEM) Surface microstructure, analytical chemistry (~50-100 nm) • Transmission electron microscope resolve the atomic structure from a very thin foil (30 Ao), (~1 Ao) • Atomic force microscope 3D surface topography, electrical, magnetic scanning (~1 nm) Material Sciences and Engineering MatE271 Week 5 21 Reading Assignment Shackelford 2001(5th Ed) – Read Chapter 4, pp 115-136, 145-150 Read ahead Chapter 5, pp 158-181 Material Sciences and Engineering Material Sciences and Engineering, MatE271 MatE271 Week 5 22 11