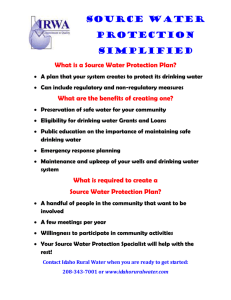

U.S. Environmental Protection Agency Office of Groundwater and Drinking Water

advertisement