An Experimental Device for Critical Surface

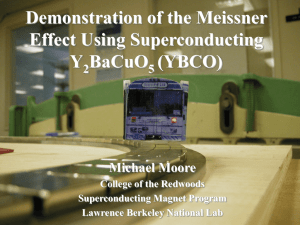

advertisement