DRAFT COPY

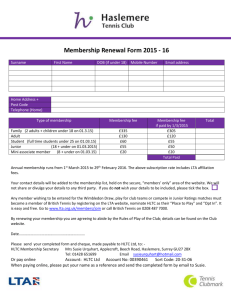

advertisement