AND POTASSIUM DE B. Sc. (Eng.) (Met.), University of ...

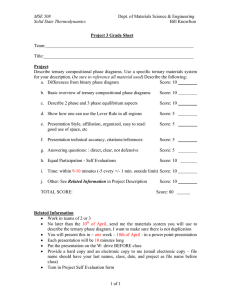

advertisement