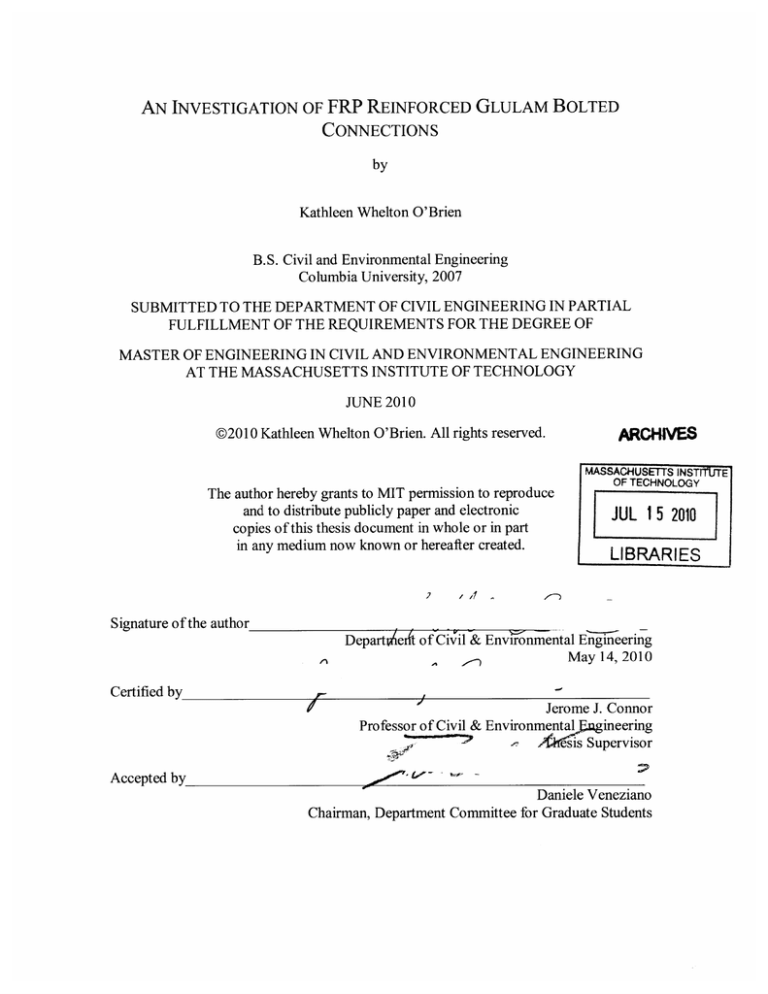

AN INVESTIGATION OF FRP REINFORCED GLULAM BOLTED

CONNECTIONS

by

Kathleen Whelton O'Brien

B.S. Civil and Environmental Engineering

Columbia University, 2007

SUBMITTED TO THE DEPARTMENT OF CIVIL ENGINEERING IN PARTIAL

FULFILLMENT OF THE REQUIREMENTS FOR THE DEGREE OF

MASTER OF ENGINEERING IN CIVIL AND ENVIRONMENTAL ENGINEERING

AT THE MASSACHUSETTS INSTITUTE OF TECHNOLOGY

JUNE 2010

@2010 Kathleen Whelton O'Brien. All rights reserved.

The author hereby grants to MIT permission to reproduce

and to distribute publicly paper and electronic

copies of this thesis document in whole or in part

in any medium now known or hereafter created.

ARCHNES

MASSACHUSETTS INSTM TE

OF TECHNOLOGY

JUL 15 2010

LIBRARIES

'/ /

Signature of the author

Departvderft of Civil & Environmental Engineering

May 14, 2010

Certified by

-

f

Jerome J. Connor

Professor of Civil & Environmental jgineering

.........

Xesis Supervisor

Accepted by

Daniele Veneziano

Chairman, Department Committee for Graduate Students

AN INVESTIGATION OF FRP REINFORCED GLULAM BOLTED

CONNECTIONS

by

Kathleen Whelton O'Brien

Submitted to the Department of Civil and Environmental Engineering

on May 14, 2010, in Partial Fulfillment of the

requirements for the Degree of Master of Engineering in

Civil & Environmental Engineering

Abstract

Wood is often limited in structural applications to relatively small structures due to its

lack of homogeneity and low strength compared to steel and concrete. Wood can become

a more versatile material if used with Fiber Reinforced Polymers (FRP) to form a

composite. This thesis presents the results of an investigation of the increase in yield

strength, ultimate strength, and change in yield mode of wood connections when

reinforced with FRP. Specifically, this thesis investigates the effects of FRP

reinforcement in Laminated Veneer Lumber (LVL) bolted connections under double

shear loading. The FRP investigated consists of uniaxial carbon fibers embedded in a

two-part epoxy. Sixteen sample wood connections were tested. Eight samples were

reinforced with FRP such that the carbon fibers were parallel to the wood fibers. Eight

samples tested were not reinforced and used as a means of comparison. Three sizes of

bolts and two failure modes were investigated. All materials chosen are readily available

and affordable in the current construction market. Finally, the results of a cost vs.

strength gain analysis are presented.

FRP reinforcement of the glue-laminated wood connections under double shear loading

resulted in an increase in yield strength and ultimate strength of all connections tested

when compared to unreinforced samples with the same properties. The addition of FRP

reinforcement changed the yield mode for some samples. However, it seems that FRP

reinforcement is only cost effective in situations in which a higher ultimate strength is

desired, rather than a higher yield strength or change in yield mode.

Thesis Supervisor:

Title:

Jerome J. Connor

Professor of Civil & Environmental Engineering

ACKNOWLEDGEMENTS

I would like to thank the strong women who came before me and paved my path:

EleanorFrancis Whelton O'Brien

Mary Patricia'Nina Pat'Burke

and

Julie Burke O'Brien

TABLE OF CONTENTS

1.

INTRODUCTION

7

2.

BACKGROUND

7

2.1. Engineered Wood

7

2.2. FRP

8

2.3. History of Wood Reinforcement

9

2.3.1. Steel As Reinforcement

9

2.3.2. FRP As Reinforcement

10

2.4. Past Research of FRP Reinforcement of Wood

11

3.

TESTING PROCEDURE

12

4.

SAMPLE ASSEMBLY

14

5.

MATERIAL SELECTION

15

6.

ANALYSIS AND PREDICTIONS

16

7.

8.

9.

6.1. Failure Modes

16

6.2. Failure Mode Calculations

17

DATA

21

7.1. Experimental Data

21

7.2. Cost Data

28

DATA ANALYSIS

28

8.1. Strength Analysis

28

8.2. Cost Analysis

30

DISCUSSION AND RESULTS

31

9.1. Ultimate Strength

31

9.2. Yield Strength

31

9.3. Yield mode

32

9.4. Comparison of ultimate strength, yield strength and yield mode changes

32

10.

CONCLUSIONS

33

11.

REFERENCES

34

LIST OF FIGURES

Figure 1: Parallel and Perpendicular to grain loading

12

Figure 2: Member Geometry and FRP Placement

13

Figure 3: FRP application

Figure 4: Double Shear Failure Modes

15

17

Z calculations

Figure 6: Load vs. Displacement, D = 0.375", Unreinforced

19

Figure 7: Load vs. Displacement, D = 0.375", Reinforced

23

Figure 8: Load vs. Displacement, D = 0.5", Unreinforced

24

Figure 9: Load vs. Displacement, D=0.5", Reinforced

25

Figure 10: Load vs. Displacement, D = 0.75", Unreinforced

26

Figure 11: Load vs. Displacement, D=0.75", Reinforced

27

Figure 5:

22

LIST OF TABLES

Table

Table

Table

Table

1: Calculations for Failure Mode Im

2: Calculations for Failure Mode IV

3: Data Summary, D = 0.375", Unreinforced

4: Data Summary, D = 0.375", Reinforced

20

20

22

23

Table 5: Data Summary, D = 0.5", Unreinforced

24

6: Data Summary, D = 0.5", Reinforced

7: Data Summary, D=0.75", Unreinforced

8: Data Summary, D=0.75", Reinforced

9: Cost Data

10: Data Analysis, D=0.375"

11: Data Analysis, D=0.5"

12: Data Analysis, D=0.75"

25

26

27

28

29

29

30

Table

Table

Table

Table

Table

Table

Table

1. Introduction

Often, the use of timber as a structural material is limited to relatively small structures of

three stories or less. Wood has always had the advantage of being more affordable and, if

harvested and processed correctly, more environmentally friendly than concrete and steel.

However, its lack of consistency and strength make it unfeasible for large structures. Much

research has been done to determine ways of reinforcing wood to enhance its structural

performance. Reinforcement methods include steel rods, steel plates, fiberglass and carbon

fiber reinforced polymers (FRP). This thesis will investigate the effects of reinforcing wood

connections in double shear loading with Carbon FRP.

2.

Background

2.1. Engineered Wood

Engineered wood is manufactured by binding wood fibers, particles, or veneers together

with an adhesive. Engineered wood is generally stronger and more consistent than pure

wood. The thickness and type of engineered wood can vary, depending on the desired

parameters. The result is a stronger, stiffer wood product that can span longer distances

and withstand more load than pure wood of the same dimensions. Engineered wood is also

less susceptible to moisture damage and imperfections than pure wood. Glue laminated

wood (glulam) is a type of engineered wood in which veneers of pure wood are bonded

together with an adhesive. The first patents for glulam appeared in Switzerland and

Germany in 1900. The first structure built with glulam was a laboratory built in Madison,

Wisconsin, which still stands. Since its first use, the cost of glulam has dropped, allowing it

to become a widely used and affordable material. One such type of engineered wood is

Laminated Veneer Lumber (LVL).

2.2. FRP

Fiber Reinforced Plastic or Polymer is a relatively new material when compared to timber,

concrete and steel. It began to emerge in the 1950's when material and production costs

were low, allowing for economically feasible production of FRP. FRP was researched heavily

and began to be used more widely towards the end of World War II due to its resistance to

corrosion, strength to weight ratio, low maintenance and life cycle cost. After World War II,

FRP became more common in the automobile and aerospace industry. Much research and

application of FRP was then completed by the aerospace industry during the cold war.

In the mid 1960s, the ship industry began to use FRP for ship construction. FRP was more

advantageous than steel in some applications due to its resistance to corrosion and strength

to weight ratio, though it was susceptible to sunlight damage. In the 1970s, the price of FRP

materials and manufacturing dropped to a price that allowed the automobile and sporting

goods industries to use FRP in their manufactured products.

In the 1980s Dr Urs Maier from the Swiss national laboratory began researching the

bonding of FRP to concrete beams and decks and used FRP to wrap concrete columns. Soon

after, Japanese engineers, who deal largely with seismic loads, began to use FRP

commercially. FRP works well with concrete in seismic areas because it can be placed in

areas where the concrete may undergo large tensile stresses in a seismic event and prevent

the structure from failing, since concrete alone has very little tensile strength.

While research of FRP composite structures is popular, "a rational design model must be

based on sound mechanics which not only precisely reflects the concerned failure

mechanism but also predicts the capacity with reasonable accuracy" in order for the

material to become more integrated into common construction practices (Chen 2003).

Others have suggested that the US construction industry is more conservative than that of

Japan's and is therefore less willing to experiment with FRP, since FRP has a tendency to

fracture in a brittle manner (EdgeFRP).

2.3. History of Wood Reinforcement

Although engineered wood allows for a stronger material than pure wood, the material still

often fails at connections. Detailing for pure wood and glulam connections are defined

under the National Design Specifications (NDS) for Wood set by the American Wood

Council. Often, wood dowels or steel bolts are used to connect members. Depending on the

connection used, failure at the connection can occur at much lower loads than the rest of the

beam or column could endure, therefore underutilizing the strength of the wood. Better

understanding and engineering of wood connections is needed to better utilize emerging

wood products and increase the applications of timber design.

2.3.1.Steel As Reinforcement

In the 1950's, 60's, and 70's much research was done to measure the effects of reinforcing

wood with steel. Wood was reinforced with steel rods, steel plates, and steel wire adhered

to wood with epoxy resins. The majority of this researched showed measured improvement

in the performance of the steel reinforced member. However, the increase in cost was often

great, and therefore very few of the schemes researched were ever put into practice.

However, this research led to the commercial use of plywood reinforced with steel plates.

This arrangement is still used today in truck bodies, railway cars, heavy duty shelving, and

elevators. One particular application consists of balsa wood as a core, sandwiched between

aluminum. The balsa/aluminum composite was used on the exterior of jets during and after

World War II.

2.3.2.FRP As Reinforcement

In addition to steel reinforcement, engineered wood can also be strengthened with the use

of Fiber Reinforced Polymers or Fiber Reinforced Plastics (FRP). FRP reinforcement of

wood materials has been used in multiple academic investigations including thin FRP as

external reinforcement for tensile loads, internal reinforcement for shear loads, and at

connections for additional connection strength and ductility. Many tests have taken place

since the 1960's investigating the effect of FRP on wood design. In the 1960's, FRP was often

made with fiberglass strands. Currently, there is more of an interest in FRP consisting of

Carbon fibers, though fiberglass is still used.

Economics is the driving factor that

determines whether FRP reinforced wood products become commercially feasible (Bulleit

1984). The addition of FRP into the manufacturing process adds time and labor costs.

Additionally, reinforcement material itself can be expensive. The composite materials that

contain high-grade wood tend to be less viable commercially. If the wood substrate is made

of poorly graded wood material, such as plywood, the composite as a whole becomes

cheaper and more available to industry. Hence, many shipping and transportation

industries use plywood and steel composites.

It is important to keep in mind that one of the key advantages to using timber in place of

other construction materials is its superior affordability and sustainability. Including FRP

in the wood structure will likely deplete its affordability and sustainability features.

However, if the increase in strength of the composite allows for less material or less cost,

then the FRP may actually further enhance the affordability and sustainable aspects of the

structure. This thesis will revisit the strength gain vs. cost increase issue, but will not assess

the increase in environmental impact.

2.4. Past Research of FRP Reinforcement of Wood

FRP reinforcement research is wide and varied. Past research topics include the accuracy of

a strength model to predict the effects of thin FRP reinforcement on the tension face of

wood (Triantafillou 1992), carbon FRP rods as glued-in reinforcement (Micelli 2005), and

the effects of the thickness of FRP reinforcement used in bolted connections (Windorski 3).

Triantafillou found that a strength model was satisfactory, therefore setting forth a means

of predicting bending behavior of FRP reinforced wood members. Yet another use of FRP

has been in the inclusion of carbon rods within the wood.

Micelli, et al. investigated using carbon FRP rods as glued-in reinforcement of glulam beams

and as glued-in connectors for glulam timber head joints that should transfer flexural

moment between two adjacent beams and found that the addition of the FRP rods increased

the ultimate strength of the wood members from 26 to 82% depending on the amount of

rods used. Micelli also mentioned that the installation of the rods was 'fast and easy',

suggesting that the labor cost could be relatively affordable.

Daniel Windorski et al. investigated bolted wood connections with three thicknesses of FRP

against an unreinforced control group. Windorski found that adding FRP increased the

strength of the bolted connections. He found that the three layers of FRP increased strength

by 33% on average. He also found that the first layer of FRP had the greatest increase in

strength. Additionally, the FRP changed the failure mode from a brittle wood split, to a more

ductile failure. Windorski investigated both perpendicular to grain and parallel to grain

loading. See figure 1 for these schemes.

Figure 1: Parallel and Perpendicular to grain loading

3.

Testing Procedure

Testing was designed to examine the influence that FRP reinforcement has on a bolted

wood connection's yield strength, ultimate strength, and failure mode. Connections were

modeled as three wood members bolted together. The scope was limited to parallel to grain

double shear loading with unidirectional FRP reinforcement oriented so carbon fibers were

aligned with the grain. The loading was parallel to the grain and carbon fiber of the

members as portrayed in the left image of figure 1.

Sixteen samples were made. Each consisted of three 1 34" X 7 %" x 12" LVL members bolted

together as seen in figure 2. Lumber dimensions are nominal.

,

"

.........

........

...........

:- ::.........................

....

. ...

. ..........

...........................

.............

..............................................................................................

..........

Eight of the samples were reinforced with FRP. Eight were not reinforced. The ones that

were reinforced with FRP were reinforced such that each face undergoing shear load had

FRP attached. The outer members had FRP reinforcement only on the interior face. The

middle member had FRP placed on each side of the member. See figure 2.

Figure 2: Member Geometry and FRP Placement

In order to examine the effects of FRP reinforcement on a variety of connection scenarios,

three types of connections were designed. The first connection consists of one 3/8"

diameter bolt going through the center of all three wood members. The second connection

consists of two

" diameter bolts spaced two inches apart, centered about the midspan of

the connection such that the bolts are an equal distance from the loaded edge of the sample.

The third connection consists of one %" diameter bolt centered about all three wood

members. The calculations for the bolt designs correspond with the desired failure modes

and are discussed in Section 6.

4.

Sample Assembly

Materials used in the samples were chosen based on strength, availability and cost.

Laminated Veneer Lumber (LVL) was chosen as the wood material due to its wide

availability, relative low cost, and high strength. The largest size commercially available was

used. Each specimen consisted of three 12" long pieces cut from 12'long boards.

The FRP used consisted of Sikawrap Hex 230C and Sikadur 300. Sikawrap Hex 230C is a

uniaxial carbon fiber fabric. Biaxial carbon fiber fabrics are available, but are more

expensive. Sikadur 300 consists of two liquid parts that are mixed on site to create the

epoxy that adheres the carbon fibers to the substrate.

The two parts of Sikdur 300 were mixed on site and applied to the appropriate sides of the

12" long LVL members. As described above, the middle board of each sample had FRP

applied to both sides, and the outside boards of each sample had FRP applied only to the

sides facing the interior board. A thin layer of FRP was applied to the appropriate side. Next,

an approximately 11" X 6

" square of Sikawrap Hex 230 C was laid on top of the epoxy.

Next, a resin roller was used to imbed the carbon fibers into the epoxy. The resin roller is

ribbed to allow for epoxy to seep through the fabric while the carbon fibers are being rolled

into the epoxy. See figure 3.

Figure 3: FRP application

5.

Material Selection

The American Wood Council (AWC) is the preeminent authority on wood building in the

United States. The AWC establishes the National Design Specifications (NDS) that are widely

used as standards for building. The NDS dictates the design of timber structures, including

beam and column dimensions, connection details, and wood type selections.

To select the wood members for the analysis, a survey was conducted of a number of local

lumber yards. It was determined that the most widely available type of glulam was

laminated veneer lumber (LVL). In order to perform tests on the strongest glulam available,

the largest commercially available board was purchased. Sixty feet of 1

" X7

" LVL was

purchased.

Once the wood type and size was determined, the FRP material was determined. The FRP

used was also chosen to be one that was commercially available. Sika Corporation is one of

the largest distributors of FRP and therefore was used. Sika offers FRP in both laminate and

fabric form. The laminates are available in carbon and fiberglass. Only fabric FRP was

considered since it is easier to drill through. Laminates are better used for exterior

applications when dealing with concrete or timber that has already shown signs of

underperformance. Carbon laminates are often used on tension surfaces of concrete that

has begun to show signs of cracking beyond a reasonable amount.

Carbon fibers were chosen over fiberglass fibers because of their superior strength. Glass

fibers are more ductile, but for the purpose of strengthening the wood connection, the

superior strength of carbon fibers was more important. Sikawrap Hex 230C was chosen.

6. Analysis and Predictions

6.1. Failure Modes

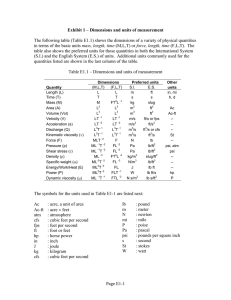

For connections in double shear, the NDS defines four types of failure; Im,Is, IlIs, and IV.

Failure Imindicates a crushing of the wood in the middle member. Failure Is indicates a

crushing of the wood of each of the side members. Failure IlIs indicates a yield of the dowel,

in this case a steel bolt, and a local crushing of the wood at the points of inflection of the

steel bolt. In failure III, the dowel stays straight in the middle member and bends when it

meets the side members. Finally, failure IV indicates a yielding of the dowel in the middle

member. The dowel stays straight in the side members and bends in the middle member,

with local crushing of the wood near the points of inflection. See figure 4 below.

Mode I,

Mode IIJ,

Mode IV

Figure 4: Double Shear Failure Modes

6.2. Failure Mode Calculations

The calculations used to design and predict the behavior of the non-FRP reinforced

specimens were taken from the NDS 2005 edition. It was believed that the FRP

reinforcement could change the failure mode of a connection that would typically fail by

wood crushing, to fail by bolt yield due to the increased strength of the wood/FRP

composite. Therefore, the unreinforced samples were designed such that a fraction would

fail by wood crushing and a fraction would fail by bolt yield. The reinforced samples were

designed to mimic the dimensions of the unreinforced samples in order to effectively

compare results.

The first failure modes to be considered were Is and Im.In these failure modes, the bolt can

withstand a larger load than the wood before yielding, and therefore wood crushing dictates

the failure of the sample. Modes Is and Imare distinct due to which members fail first, the

side pieces or the middle piece. In this experiment, the middle piece will fail first because it

has identical properties as the side pieces. Assuming the load is originally evenly distributed

amongst the side pieces, middle piece, and the bolt, the side pieces will have twice the area

of material resisting the load as the middle piece and therefore will not crush first. For the

side pieces to crush first, they would have to be significantly thinner than the middle piece,

or be made of a significantly weaker material. Therefore, failure mode Im was investigated,

and failure mode Is was not. For similar reasons, only failure mode IV was investigated and

failure mode IIls was not.

To predict the load at which the sample will yield, the allowable connection capacity in

pounds, Z, is calculated.

Z = f'*A

where f = yield stress of material to yield, and A = area of material carrying load.

Each yield mode has a quantity Z associated with it. The allowable connection capacity for

each yield mode is calculated and the yield mode with the lowest value for Z dictates the

design.

For each connection design, the wood dimensions, wood properties, and dowel type were

consistent. Steel bolts were chosen for the dowel type due to their strength, low cost, and

ease of installation.

For the steel to fail first in the unreinforced connections, the value for Z IV would have to be

the lowest value of the Z calculations for that section. The calculations for the various Z

values are shown in figure 5.

Mode i (NDS equation L&a):

Mode , (NDS equation 113-4)

Mode Il. (NDS equation lL3-9):

z2kD4F. 4

(2 + R4R4

Mode IV(ND equation 113-10)

g - 2&?

2FF

ia3(1 + R)j

mfrn design vahan for a ingle-atener eennemina(Zit taken as th

smallest value from al appliable yield limit oquation4h lb

whereZ

4

* - \+R

(1 + RJ

RI *R+)

k,

+2

(+ + 2t )DO

2 2F,(2 + R)D

H,

P.t

D - fastener diameter, in.

, dowel bearing length in main membr. in.

I, dowel bearing length in "id member, in.

dowel bearing strength of main member psi

F,

F. - dowel bearing strength of side member, psi

F- = bending yield strength of fostener, psi

,=coefcient specified in NDS Tabe 11,d.1B for reducing connection yield

capacity to a refeene design value

Figure 5: Z calculations

A spreadsheet was created to calculate allowable Z values for each failure mode. Results are

listed in table 1 and table 2.

Calculations for Im Failure Mode

Variables

D

0.5

1.75

in

in

Fem

1s

Fes

5600

psi

1.75

in

5600

Fyb

psi

psi

Rdfor Im,Is

45000

4

Rd For III,, IV

3.2

Re

k3

1

1.304767527

Im

Z=

1225

lbs

is

Ills

IV

Z=

Z=

Z=

2450

1332

1432

lbs

lbs

lbs

lm

Control

1225 lbs

Table 1: Calculations for Failure Mode Im

Calculations for IV failure mode

Variables

D

im

Fem

is

Fes

Fyb

Rdfor Im,Is

Rd for Ills, IV

Re

0.375

1.75

5600

in

in

psi

1.75

in

5600

45000

4

3.2

psi

psi

1

k3

1.176688715

Im

Z=

Z=

919

Is

1838

lbs

lbs

III,

Z=

901

lbs

IV

Z=

806

lbs

Control

806

lbs

Table 2: Calculations for Failure Mode IV

It is noted that the only parameters of the wood material used in the calculations were

specific gravity and the dimensions of each member. It was determined that failure mode IV

would be observed if the bolt diameter was 0.42" or less. Therefore, a

3/8

(0.375") diameter

bolt was used for three of the eight unreinforced samples.

Similarly, it was found that a bolt diameter of 0.43" or greater would lead to failure mode Im.

A bolt diameter of 0.5" was chosen. To achieve the total diameter, two %" diameter bolts

were used, with appropriate spacing, for three of the eight unreinforced samples.

For the remaining two unreinforced samples, a

" diameter bolt was used. This was chosen

under the assumption that it would demonstrate a higher load capacity, and would allow for

a comparison of unreinforced to reinforced samples under a greater load, still within

realistic connection scenario limits.

There are a variety of academic papers that propose mathematical models to predict the

effects of FRP reinforcement. However, the vast majority of these papers have been focused

on the use of FRP with concrete, not wood. Of the smaller number of papers that focus on

FRP with wood, none deal specifically with carbon fibers and LVL wood. Therefore, the

response of the FRP reinforced samples was not predicted.

7. Data

7.1. Experimental Data

For all graphs below, D = the diameter of the bolts used in the connection, 'Reinforced'

refers to samples reinforced with FRP, and 'Unreinforced' refers to samples with no FRP

reinforcement.

D= 0.375", Unreinforced

40M

200

OA

001

Figure 6: Load vs. Displacement, D = 0.375", Unreinforced

D = 0.375", Unreinforced

Ultimate Strength (lbs)

Yield Strength (lbs)

Yield Mode

Sample 1

5,691

Sample 2

5,152

Sample 3

4,766

Sample 1

2,640

Sample 2

2,370

Sample 3

2,400

Sample 1

Mode IV

Sample 2

Mode IV

Sample 3

Mode IV

Table 3: Data Summary, D = 0.375", Unreinforced

D= 0.375", Reinforced

s00

:v;=

4000

2000

1000 t-

0

0.2

0.4

0.6

0.8

1

Displacenent Qn)

Figure 7: Load vs. Displacement, D = 0.375", Reinforced

D = 0.375", Reinforced

Ultimate Strength (lbs)

Yield Strength (lbs)

Yield Mode

Sample 1

6,180

Sample 2

7,611

Sample 3

6,955

Sample 1

3,290

Sample 2

3,840

Sample 3

3,580

Sample 1

Mode IV

Sample 2

Mode IV

Sample 3

Mode IV

Table 4: Data Summary, D = 0.375", Reinforced

1.2

D=.5", Unreinforced

gooo

amo

7=O

5OCO

3=L

2000

2000

0

0.2

0A

0.6

0.8

1

nahe...ftg.a)

Figure 8: Load vs. Displacement, D = 0.5", Unreinforced

D = 0.5", Unreinforced

Ultimate Strength (lbs)

Yield Strength (lbs)

Yield Mode

Sample 1

7,848

Sample 2

6,945

Sample 3

8,353

Sample 1

3,300

Sample 2

3,040

Sample 3

3,633

Sample 1

Mode Im

Sample 2

Mode Im

Sample 3

Mode Im

Table 5: Data Summary, D = 0.5", Unreinforced

1.2

1A

D = 0.5", Reinforced

Chant Area.

120c0

10000

soo0

2000

0.2

Q4

04

0.8

1

hOKanemet 1n)

Figure 9: Load vs. Displacement, D=o.5", Reinforced

D = 0.5", Reinforced

Ultimate Strength (lbs)

Yield Strength (lbs)

Yield Mode

Sample 1

12,797

Sample 2

10,151

Sample 3

11,772

Sample 1

3,155

Sample 2

3,410

Sample 3

3,530

Sample 1

Mode IV

Sample 2

Mode IV

Sample 3

Mode IV

Table 6: Data Summary, D = 0.5", Reinforced

1.2

IA

D=0.75", Unreinforced

10000

tam

7000

son

4000

3000

2000

1000

0.05

0.1

0.15

0.2

ObpiaoemAi

025

n

Figure 10: Load vs. Displacement, D = 0.75", Unreinforced

D = 0.75", Unreinforced

Sample 1

7,694

Sample 2

8,601

Sample 1

6,330

Sample 2

7,240

Sample 1

Mode Im

Sample 2

Mode Im

Ultimate Strength (lbs)

Yield Strength (lbs)

Yield Mode

Table 7: Data Summary, D=0.75", Unreinforced

0.3

0J35

-BM

D

= 0.75", Reinforced

uNo0

100W t

~

---.

-

________________

.....

MWuo

00""

am0

Amo

2000

o

0.05

0.25

a.02

o0essMent

M

Figure 11: Load vs. Displacement, D=0.75", Reinforced

D = 0.75", Reinforced

Sample 1

9,370

Sample 2

9,803

Sample 1

6,960

Sample 2

7,710

Sample 1

Mode Im

Sample 2

Mode Im

Ultimate Strength (lbs)

Yield Strength (lbs)

Yield

Mode

Table 8: Data Summary, D=0.75", Reinforced

7.2. Cost Data

Costs

Sikadur 300 Epoxy

0.7

$/SF

Sikawrap Hex 230C

5.65

$/SF

LVL Wood

3.5

$/ft

Table 9: Cost Data

8. Data Analysis

8.1. Strength Analysis

For each type of sample, the ultimate strength and yield strength was averaged. The

corresponding reinforced and unreinforced samples were compared using the following

equation:

Ultimate Strength % increase = (PUR-PUU)/PUU

Yield Strength % increase = (PYR-PyU)/PYU

PUR

= average ultimate strength of reinforced samples

Puu = average ultimate strength of unreinforced samples

PYR

= average yield strength of reinforced samples

Pyu = average yield strength of unreinforced samples

The results are summarized below.

D = 0.375"

Average ultimate strength (lbs)

6,915

Average yield strength (lbs)

3,570

Ultimate strength increase

32.91%

Yield strength increase

44.53 %

Table 10: Data Analysis, D=0.375"

D = 0.5"

Average ultimate strength (Ibsj

11,b73

Average yield strength (lbs)

3,365

Table 11: Data Analysis, D=0.5"

D = 0.75"

Average ultimate strength (lbs)

8,148

Average yield strength (lbs)

6,785

Average ultimate strength (lbs)

9,587

Average yield strength (lbs)

7,3351

8.2. Cost Analysis

Based on the cost data shown in section 7.1, the wood cost per sample and FRP cost per

sample is calculated below.

Wood cost per sample = 3'/sample x 3.5 $/ft = $ 10.5/sample

FRP cost per reinforced sample = 0.5 SF/ face x 4 faces x (5.65 $/SF for Carbon Fiber + 0.7

$/SF for Sikadur 300) = $12.70/sample

9. Discussion and Results

9.1. Ultimate Strength

The most significant increase in ultimate strength due to FRP reinforcement

occurred in the 0.5" diameter bolt samples. These samples were designed so that the

minimum available bolt diameter that would achieve failure mode Imwas used.

9.2.Yield Strength

The most significant increase in yield strength due to FRP reinforcement occurred in

the 0.375" diameter bolt samples. The 0.375" diameter samples were designed so that the

unreinforced sample would yield in mode IV. When designing the 0.375" diameter sample, it

was assumed that the FRP reinforcement would not have a large impact on the outcome of

the yield strength since the bolt is the first member to yield. The FRP reinforcement should

only strengthen the wood substrate and not impact the yield strength of the bolt. However,

the experimental data shows that the FRP reinforcement does in fact increase the yield

strength of the sample connection.

As stated in section 6.2, the NDS calculation method only calls for the specific gravity

and dimensions of the wood members to determine the failure mode, which ultimately

determines the yield strength. Since the strengthening of the wood with FRP resulted in a

higher yield strength, it seems that the unreinforced yield mode was not only due to the bolt

yielding, but also due to wood crushing. It seems as though the NDS method may

oversimplify the actual behavior of the connection.

9.3.Yield mode

The FRP reinforcement changed the yield mode of the 0.5" bolt diameter samples.

The change in yield mode is not surprising. It suggests that the FRP reinforcement added

enough strength to the wood material to overcome the yield strength of the bolt.

9.4. Comparison of ultimate strength, yield strength and yield mode changes

The FRP reinforcement had a significant effect on the 0.375" bolt diameter samples. For

these samples, both the ultimate strength and yield strength increased by more than 30%

with the addition of FRP reinforcement. However, by increasing the bolt diameter by 0.125"

to 0.5", an even greater increase in ultimate strength was achieved and the yield mode also

changed, though the yield strength stayed similar (since the wood strength stayed the

same). In this case, it would be much cheaper to increase the bolt diameter (which would

add less than a dollar to the connection cost) than to add FRP reinforcement, which would

add $12.70 to the connection cost.

In the 0.5" diameter bolt samples, the FRP reinforcement did not change the yield strength

by much (less than 2%), but it did significantly change the ultimate strength and changed

the yield mode. In this case, unlike the case of the 0.375" bolt diameter, an increase in bolt

diameter by even 0.25" could not achieve the same increase in strength as the FRP. In fact,

with an increased bolt diameter and additional FRP, the connection could not achieve the

same strength. This implies that the FRP reinforcement can contribute strength to a wood

connection that cannot be realized by simply adding bolt diameter.

From the samples tested in this analysis, it is shown that FRP reinforcement is best used in

wood connections designed to fail in mode IV, and using a bolt diameter as close to the

calculated diameter as possible. If the connection is overdesigned with significant extra bolt

diameter than is needed, then the connection may fail at a lower load than if less bolt

diameter and FRP is used.

The costs analyzed in this thesis do not account for the addition of labor in applying the FRP

reinforcement. For a more detailed analysis that would include this cost, more research

would have to be done. While the labor needed does not require complicated machinery or

training, it does add an additional step to the building sequence and could therefore add

significant costs.

10. Conclusions

If used intelligently, steel bolts and FRP reinforcement can be combined to achieve greater

ultimate strengths than steel bolts alone in glulam double shear connections. The yield

strength changes most significantly if members are designed to fail in Mode IV. A cheaper

way to increase the yield strength of these connections is to add to the steel bolt diameter,

so the yield mode changes to wood crushing.

For connections designed to yield in Mode Im,if the bolt diameter is close to the lower limit

for such a yield mode, FRP reinforcement can achieve ultimate strengths approximately

45% greater. Typically, connections are designed for yield strength, not ultimate strength.

Therefore, the addition of FRP to these types of connections should not be used to increase

the design strength, but should be used in designs where the structure may be vulnerable to

loads that are infeasible to design for with a wood structure. For example, if there is a small

family home designed in a seismic area, or an area subject to natural disasters, it may be too

expensive to do a thorough engineering of the design such that the structure would

withstand any possible load. However, by adding FRP to the connections, the ultimate

strength of the structure could be greatly increased, therefore allowing for a much safer

structure in the event of an earthquake or natural disaster. The FRP reinforcement should

not be included in the design strength, but could add a relatively inexpensive layer of

security to the structure. The cost would be on the order of $13 per connection.

For connections that are designed with excessive bolt diameter and are designed to fail in

mode Im,the addition of FRP does not add a significant amount to the ultimate strength,

yield strength or change the yield mode.

Of course, more research would be needed to better understand the effects of FRP on

wooden connections. FRP is an ever evolving technology that has been well implemented in

the aircraft and ship industries. As FRP technologies evolve, and the cost continues to drop,

it can be further integrated into the civil structural engineering industry.

11. References

Bulleit, William M. "Reinforcement of Wood Materials: A Review." Wood and FiberScience

16.3 (1984): 391-97. Print.

Chen, J.F., and

J. G. Teng. "Fibre-reinforced

Polymer Composites in Construction." Editorial.

Constructionand Building Materials Sept. 2003: 363-64. Web.

Edge Structural Composites. FRP 101: A Guidefor Composite Strengthening.Point Richmond:

Edge Structural Composites. Web.

FiRP Panel Reinforced Glued Laminated Wood Beams. Tuulatin: Western Wood Structures,

2010. Print.

Gilham, Paul C., and Thomas Williamson. "New Opportunities for Fiber Reinforced GluedLaminated Beams." Structure Magazine April (2007): 57-59. Print.

Micelli, Francesco, Vincenza Scialpi, and Antonio La Tegola. "Flexural Reinforcement of

Glulam Timber Beams and Joints with Carbon Fiber-Reinforced Polymer Rods."

Journalof Compositesfor Construction 9.4 (2005): 337-47. Web.

Triantafillou, T., and N. Deskovic. "Prestressed FRP Sheets as External Reinforcement of

Wood Members." Journal of Structural Engineering.ASCE. 118.5 (1992): 1270-284.

Print.

Windorski, Daniel, Lawrence Soltis, and Robert Ross. "Effect of Fiberglass Reinforcement on

the Behavior of Bolted Wood Connections." Wood Design Focus 8.3 (1997): 19-24.

Web.