The International Center for Research

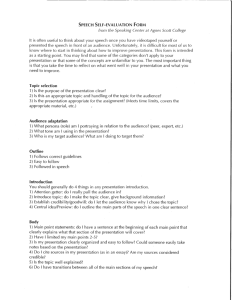

advertisement