Fracture Characterization from Seismic Sudhish Kumar Bakku

advertisement

Fracture Characterization from Seismic

Measurements in a Borehole

by

Sudhish Kumar Bakku

B.Tech., Indian Institute of Technology Roorkee (2007)

S.M., Massachusetts Institute of Technology (2010)

Submitted to the Department of Earth Atmospheric and Planetary

Sciences

in partial fulfillment of the requirements for the degree of

Doctor of Philosophy

at the

MASSACHUSETTS INSTITUTE OF TECHNOLOGY

February 2015

Massachusetts Institute of Technology 2015. All rights reserved.

Signature redacted

Author.......

..........................

Depart ent of Earth Atmospheric and Planetary Sciences

Nov 12, 2014

Signature redacted

Certified by.........

Signature

....................................

Michael Fehler

Senior Research Scientist

redacted

Thesis Supervisor

.........................

Robert van der Hilst

Schlumberger Professor of Earth Sciences

Head, Department of Earth Atmospheric and Planetary Sciences

A ccepted by ...

cmLC

0

%.11%w

LLo

Dedicated to my Loving Parents,

Udayasree and Sriramulu Bakku.

3

4

Fracture Characterization from Seismic Measurements in a

Borehole

by

Sudhish Kumar Bakku

Submitted to the Department of Earth Atmospheric and Planetary Sciences

on Nov 12, 2014, in partial fulfillment of the requirements for the degree of

Doctor of Philosophy

Abstract

Fracture characterization is important for optimal recovery of hydrocarbons. In this

thesis, we develop techniques to characterize natural and hydraulic fractures using

seismic measurements in a borehole.

We first develop methods to characterize a fracture intersecting an open borehole

by studying tubewave generation and attenuation at the fracture. By numerically

studying the dispersion relation for fluid pressure in the fracture, we show that the

tubewave measurements made in the transition regime from low to high frequency can

constrain fracture compliance, aperture and length, while measurements made in the

high-frequency regime can place a lower bound on fracture compliance. Analysis of

field data suggest a large compliance value (10- 0 m/Pa) for a meter-scale fracture and

supports scaling of fracture compliance and applicability of scattering based methods

for fracture characterization on a reservoir scale.

We next study Distributed Acoustic Sensing (DAS), a novel Fiber Optic (FO) cable based seismic acquisition technology. We relate DAS measurements to traditional

geophone measurements and make a comprehensive study of factors that influence

DAS measurements. Using a layered borehole model, we analytically compare the

sensitivity of DAS measurements to P- and S-wave incidence at arbitrary angles for

the cases when the FO cable is installed in the borehole fluid or when cemented outside

the casing. In addition, we study the azimuthal placement of the cable, the effect of

cable design, and the effect of environmental conditions on time-lapse measurements.

We show that DAS is a reliable tool for time-lapse monitoring.

Finally, we analyze time-lapse DAS Vertical Seismic Profiling (VSP) data collected during a multi-stage hydraulic fracture treatment of a well drilled into a tightgas sandstone reservoir. We develop a processing workflow to mitigate the unique

challenges posed by DAS data and propose methods for DAS depth calibration. We

observe systematic and long-lived (over 10 days) time-lapse changes in the amplitudes

of direct P-waves and nearly no phase changes due to stimulation. We argue that

the time-lapse changes cannot be explained by measurement factors alone and that

they may be correlated to the stimulated volume. Though the current geometry is

not ideal, DAS is promising for hydraulic fracture monitoring.

Thesis Supervisor: Michael Fehler

Title: Senior Research Scientist

5

6

Acknowledgments

It gives me immense pleasure to recollect the many wonderful years I spent at MIT

and to thank all the amazing people who have been part of this journey and influenced

my life in their special ways. Along with it is a fear that I may forget mentioning

someone dear. My gratitudes to everyone that I mention here and others whom I

mistakenly miss. Seven years is a long time and there are countless people to thank

and anecdotes to share. I am sure I will not do justice to all.

My journey at MIT started with me reluctantly (to save money on applications)

applying to MIT at the behest of my dedicated friends Saratchandra Palagummi

(Paul), Venkat Avadhanulu (Lulu), Vinod Vavilapalli (Potter) and Vijay Ganesh

(Haddu). That day has set into motion the events to follow. I am thankful to Prof.

Brian Evans for admitting me into his group as a Masters student even though I knew

nothing about Earth sciences. Embodying the spirit of MIT, Brian asked me to come

to the university and explore the research areas. That is a luxury very few have and

I feel blessed to be one such. MIT has transformed me as a person and a researcher:

I was given the freedom to explore many different projects, take inter-disciplinary

courses and encouraged to be inquisitive. It is humbling to be surrounded by very

smart people. There is so much to learn and so many interesting things happening

around, it is with heavy heart that I leave this wonderful place. My sincere thanks

to MIT and everyone who makes it such an amazing place.

Foremost, I thank my advisor Dr. Michael Fehler for his guidance and mentorship

over the last five years. After my masters, Mike was kind to take me on as a graduate

student even though I had little experience working on seismology. Mike has been

very patient and encouraging since then while I explored different ideas and faltered

at some badly. He is a terrific seismologist and I always left learning something new

after a discussion with him. He always had new ideas up his sleeve every time I hit a

dead end. His optimism and passion for science are contagious and I hope they stick

to me always. He is a caring advisor, concerned about the overall well being of all his

students and generously shared his wisdom both in science and personal life. Mike

is an inspiration for me with all the hard work he puts in, an efficient multi-tasker

atmany different roles. Amid all this, he still finds time for students. Thank you,

Mike, for being an amazing advisor and a mentor.

Prof. Alison Malcolm has been my academic advisor, teacher and a thesis committee member. She brought in a different perspective and always reminded me of

the need for focus and defining time-bound goals. Not only is she an amazing teacher

but also a caring mentor. I learned seismic imaging and presentation skills from her.

We shared a lot of funny moments during the communication course where she made

us watch ourselves speak. She was on my generals committee as well as my thesis

committee and generously guided me throughout all these years. Thank you, Alison.

I thank my thesis committee for all their guidance and keeping me on track. As a

Master's advisor and generals and thesis committee member, Prof. Brian Evans has

been a grounding presence and guiding force for me at MIT. Prof. Nafi Toks6z is a

great source of knowledge and wisdom. I consulted him on science, career decisions

and guidance at MIT. He is always very kind to make time for students despite his

7

busy schedule and health. To put things in perspective, he once reminded me that

there is an entire life to contribute and that a PhD is only the first step. Dr. Mark

Willis has been a mentor to me from my early days at MIT. He helped me navigate

through MIT and guided me in taking many tough decisions in life, both personal

and career wise. He spent many hours teaching me seismic processing and about life

in industry. He generously hosts the annual ERL alumni get together at his home in

Houston and introduces young students like me to many industry experts and thus

helps build our network. Prof. Taylor Perron very generously accepted to be on my

committee just a few months before my defense and was equally quick in catching up

and providing me valuable feedback. The committee has been extremely patient and

supportive during the last few months as I repeatedly missed deadlines. Thank you

all very much.

Dr. Daniel Burns is my unofficial second advisor. I spent long hours learning

borehole geophysics and lessons on life from him. He co-authored two of the chapters

in my thesis and I greatly benefited from his scientific insight. He is very approachable,

supportive and optimistic. During tough days, a chat with Dan would instantly lift

up my spirits. Another important person who influenced my stay at MIT is Prof.

Dale Morgan. Dale is a father figure and has been a great advisor and a good

friend. He always pushed me to strive for the best and think on a larger scale. Our

countless discussions on science, politics and religion were always challenging and

thought provoking. I regret not being able to make to any of his field trips. Thank

you Dale and Dan.

I would like to thank all my collaborators during my stay at MIT. Firstly, I thank

Samantha Grandhi for inviting me to Shell and helping me get access to DAS data.

It inspired a significant part of the thesis. Peter Wills was my mentor while I interned

at Shell and he guided me in understanding and processing the DAS data. Peter went

out of his way to help me with both technical aspects and dealing with bureaucracy.

In addition, Albena Mateeva and Kees Hornman at Shell provided valuable inputs to

the DAS chapters in the thesis. Numerous intense discussions with Drs. Mark Willis,

Doug Miller, Greg Duckworth, Arthur Cheng, Prof. Haruo Sato and Prof. Boris

Gurevich enhanced my understanding of DAS, borehole geophysics and the interpretation of the time-lapse DAS Data. I would also like to thank Shell International

E&P Inc. for providing me the DAS data set and Optasonse for providing support. I

learned a lot about fractures and fracture characterization during numerous conversations with Dr. Steve Brown, Dr. Xinding Fang and Dr. Yingcai Zheng. Xinding very

generously allowed me to use his finite difference code to run fracture simulations.

Yingcai is a very knowledgeable seismologist and gave excellent feedback. Dr. Zhenya

Zhu very patiently trained me on using the acoustics lab and helped with everything

related to the lab.

Dr.Yves Bernabe, Dr.Steve Hickman and Dr. Nick Beeler are extraordinary researchers I was fortunate enough to work with. I am thankful to them for guiding

me during my masters and beyond. I would also like to thank my mentors during my

summer internships Ricko Wardhana (BP) and Bilgin Atlundas (Schlumberger) for

helping me make the most out of the internships. I benefitted immensely from the

courses I took from Prof. Stephane Rondenay, Prof. Laurent Demanet, Prof. Robert

8

van der Hilst and Prof. Dale Morgan. Bill Rodi is a great resource at ERL, well

knowledgeable in inverse theory and extremely helpful. I regret not being able to get

the best out of him.

I would like to thank the extended Earth Resources Laboratory (ERL) family

for all the support during these past 7 years. I made long lasting friendships that

I will cherish for the rest of my life. Sue Turbak has been the bonding gel to keep

ERL together and meticulously took care of everyone's need. She has been a source

of support and a good friend. Natalie Counts has taken over Sue's responsibilities

over the past few months and is equally amazing. Anna Shaughnessy advised me on

many student body organizational aspects and helped me take career decisions. Terri

Macloon helped a lot on dealing with the financial issues of the student run TechGS.

I feel lucky to have known Mirna Slim, Ahmad Zamanian, Di Yang, Yulia Agramakova, Diego Concha, Gabi Melo Silva, Alan Richardson, Xinding Fang, Abdulaziz

AlMuhaidib, Brain Willemsen (fondly Lucas), Junlun Li, Hui Huang (mom), Nasruddin Nazerali, Xuefang Shang, Fixian Song, Kang Hyeun Ji, Alejandra Quintanilla,

Hussam Busfar,Bongani Mashele, Fred Pearce, Sami Alsaadan, Scott Burdick, Yang

Zang, Xin, Tim Sayer, Noa Bechor Ben Dov, Martina Coccia, Sedar Sahin, Piero Poli,

Thomas Gallot,Oleg Poliannikov, Tianrun Chen, Greg Ely, Jared Atkinson, Chunquan Yu, Chen Gu, Jing Liu, Haoyue Wang, Yuval Tal, Manuel Torres, Eva Golos,

Dylan Mikesell, Darrell Coles, Zhulin Yu, Lili Xu, Hua Wang, Elita, Peter Kang,

Xuan, Pierre Gouedard, Huajiang Yao, Haijiang Zhang, Berenice Froment, Elizabeth

Day, Saleh Al Nasser, Leonardo Zepada, Bing, and others. I thank Mirna, Di, Gabi,

Ahmad, Diego, Yulia , Aziz, Andrey, Nas, and Brain for the countless weekend outings and fun stuff we did together. The gym and swimming team included Di, Diego

and Ahmad. Diego very meticulously held it together for a very long time until Di

broke his hand and things fell apart. Alan has been a great resource for computing

and juicy gossip. He mercilessly extracted every little piece of information and I always dreaded hearing 'Any news?'. Brain and I almost froze to death to save a few

bucks, thanks to Alan. Ahmad and Nas were my companions during the all night

thesis writing sessions. The postdocs at ERL were a wise lot. It was always fun to

grab a beer with them and occasional lunches. I never figured out on which side of

the grad-postdoc divide Scott Burdick stood. But I forgive him since he beats Nate

in biking. There were many visiting researchers, post-docs and students at ERL who

made it even more fun to be around. Jonathan Kane has been both part of ERL

(alumni) and Shell. He was very kind in introducing me to people at Shell and also

facilitating the process of my internship and employment with Shell.

I had the pleasure of friendship with Dan Chavas, Mike Sori, Stephen Messenger,

Ben Mandler, Arthur Olive, Marie Giron, Elena Steponaitis, Erin Shea, Ruel Jerry

while working on EGSAC. We had great times together, especially the Long Pond

Trip. I should probably stop here. What happens at Long Pond stays at Long

Pond. Others from EAPS who have been good friends are Sonia M T. Sanchez,

Alex Evans, Frank Centinello, Sharon Newman, Hendrik Lenferink, Yodit Tewelde,

Aron Schwanberg, Ben Black and many more. Having stayed for seven years, I

was fortunate enough to be kicked around many offices and thus befriend many. My

journey started with my faithful friend Nathaniel Dixon who stayed at MIT almost as

9

long as I did. I am thankful to him for helping me acclimatize to American culture and

for adopting me into his family. The next dose of american culture (Texan?) came

from the chatty Beatrice Parker, bayesian Ahmad Zamanian and caving Clarion.

Otherwise, the office space has been pretty much international (Chinese) with the

likes of Xinding Fang, Di Yang, Hua Wang, Andrey Shabelansky, Bongani Mashele

and Jing. I was the sole customer for all Xinding's discounted movie tickets. Hua

sometimes read us Mormon bible. Di pumped up muscles staring at posters and

empty protein bottles. My philosophical discussions with Andrey and Bongani were

endless (probably useless). Meanwhile, Gabi was conveniently lost in her heavy metal.

EAPS is blessed with amazing staff. Vicki McKenna and Carol Sprague at the

EAPS headquarters always looked out for me and were extremely helpful. It always

feels like home talking to Roberta Allard and she goes out of her way to help everyone.

Linda Mienke tirelessly deals with all our software and hardware issues. I am thankful

to all of them. David Keazer, the wise janitor, is a good friend to all of us night owls.

Many thanks to David for taking every opportunity to remind me of my increasing

weight and pushing me to get out of MIT!

I want to thank my amazing roommates Sumeet Kumar, Vivek Raghunathan,

Abishek Kashinath, and Karthik Kumar for the wonderful times together. All the

stupid things we did together remain memorable stories. How easy is it to set your

house on fire on a cold winter night? Many thanks to my dear friends Kushal Kedia,

Raghavendra Hosur, Harshad Kasture, Sahil Sahni, Sriram Emani, Sarvee Diwan,

Chaithanya Misal, Harish Sundaresh, Vikrant Vaze, Nikhil Galagali, Ankur Sinha,

Kavyakamal Manyapu, Suman Bose and others. You made me feel at home and

part of a huge family. Other friends who made my stay in Boston wonderful are

Naresh Kosaraju, Yanni, John Mangones, Tricia Chan, Dely Gisagra, Jon Labrecque,

and Marylin. I am very thankful to all my friends from college who are my support

network: Sarat, Vinod, Avadhanulu, Ganesh, Madhur Johri, Naresh, Karthik, Dinesh,

Srikant, Bharat, Naveen, Sujith, Mubeen and all others in India. I really enjoy the

annual re-union trips that we take.

The most fortunate thing to happen to me during my stay at MIT is my fiancee

Sara (Sarada Sivaraman). Her dedicated friendship and unconditional love kept me

motivated in the darkest of the times. She always has a way to keep my spirits up and

cheer me up with riddles. She worked as hard, kept me company for long hours- and

made sure that I was well fed with delicious home made food. She is my English coach,

personal proof reader, partner-in-crime and party planner. Her company made my

life much easier and enjoyable. Sara, thank you for being there for me. I am looking

forward to the wonderful journey ahead together.

My parents deserve the greatest thanks for making me the person I am today. I

cannot thank them enough for all the sacrifices, selfless love and support. I like to

recollect how my father used to enthusiastically narrate to me the big-bang theory

for the millionth time. He was always eager to answer my curiosity with the best of

his knowledge and tirelessly fought many chicken or egg first debates. My father is

an inspiration for me to keep learning and has been my guide and mentor in life. My

mother always magically knows what I want even before I say it. Her love and care

are unparalleled. Both my parents encouraged me to shoot for the best and imbibed

10

in me the spirit to put in my best regardless of the results. It gives immense strength

to know that they are always there for me to fall back on to. I am blessed to have

such amazing parents. Thank you, amma and nanna! I am lucky to have my younger

brother Ranjith, a life long friend and accomplice. He has endured the worst of me

and has seen all the dark sides not known to the world. My cousin Satish has always

been my philosophical buddy. I thank all my other cousins, uncles and aunts for the

faith in me and supporting me through out. I miss spending Sankranti with everyone.

My grandmother Muvvala Gangamma is the Dark Knight who toiled hard raising me

and my brother. I am indebted to her for my life.

Finally, I thank ENI, MIT Energy Initiative, and Total S.A. for financially supporting me during the course of the PhD.

11

12

Contents

1

2

Introduction

29

1.1

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

29

1.2

Thesis Outline and Contributions . . . . . . . . . . . . . . . . . . . .

34

Fracture Compliance Estimation using Borehole Tubewaves

39

2.1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

39

2.1.1

Fracture Compliance . . . . . . . . . . . . . . . . . . . . . . .

41

Theorertical Formulation . . . . . . . . . . . . . . . . . . . . . . . . .

43

2.2.1

Tube-wave generation in a borehole . . . . . . . . . . . . . . .

43

2.2.2

Tubewave attenuation in a borehole . . . . . . . . . . . . . . .

50

2.2.3

Effect of dynamic tortuosity and permeability

. . . . . . . . .

53

Field Data Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . .

56

2.3.1

Overview

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

56

2.3.2

Field example . . . . . . . . . . . . . . . . . . . . . . . . . . .

58

2.2

2.3

3

2.4

Discussion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..

2.5

Conclusions

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

61

2.6

Figures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

62

59

Distributed Acoustic Sensing for Vertical Seismic Profiling

71

3.1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

71

3.2

Distributed Acoustic Sensing . . . . . . . . . . . . . . . . . . . . . . .

74

13

3.2.2

Coherent Optical Time Domain Reflectometry

75

3.2.3

Lim itations

.

.

75

79

Comparison to Geophones . . . . . . . . . . . . . .

80

3.3.1

Broad-side sensitivity . . . . . . . . . . . . .

83

3.3.2

Effect of gauge length

. . . . . . . . . . . .

.

.

.

. . . . . . . . . . . . . . . . . .

3.4

Strain and temperature effects on DAS measurements

86

3.5

Effect of borehole on DAS VSP measurements

89

.

84

Layered Borehole Model . . . . . . . . . . .

90

3.5.2

FO Cable in the borehole fluid . . . . . . . .

93

3.5.3

FO Cable cemented outside the casing

. . .

96

Effect of cable design on DAS VSP measurements .

98

3.6.1

Coupling in fluid . . . . . . . . . . . . . . .

100

3.6.2

Coupling in solid . . . . . . . . . . . . . . .

104

3.7

Considerations for Time-lapse DAS VSP . . . . . .

106

3.8

Conclusions . . . . . . . . . . . . . . . . . . . . . .

110

3.9

Figures . . . . . . . . . . . . . . . . . . . . . . . . .

114

.

.

.

.

.

.

.

.

.

3.5.1

3.6

Time-lapse Monitoring of Hydraulic Fracturing using DAS

129

Introduction . . . . . . . . . . . . . . . . . . . . . . .

129

4.2

Hydraulic Fracturing . . . . . . . . . . . . . . . . . .

132

4.3

Field Experiment

. . . . . . . . . . . . . . . . . . . .

133

4.3.1

Field Geology . . . . . . . . . . . . . . . . . .

133

4.3.2

Well Completion and Stimulation Parameters

135

4.3.3

Seismic Acquisition

. .. . . . . . . . . . . .

135

4.3.4

Temperature Monitoring using DTS . . . . . .

137

DAS Challenges . . . . . . . . . . . . . . . . . . . . .

137

D C bias . . . . . . . . . . . . . . . . . . . . .

138

.

.

.

.

.

.

4.4

.

4.1

4.4.1

.

4

Scattering mechanisms . . . . . . . . . . . .

.

3.3

3.2.1

14

4.5

4.6

Spikes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

140

4.4.3

Depth Calibration

. . . . . . . . . . . . . . . . . . . . . . . .

141

Data Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

145

4.5.1

Pre-processing . . . . . . . . . . . . . . . . . . . . . . . . . . .

145

4.5.2

Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

148

4.5.3

Background model

. . . . . . . . . . . . . . . . . . . . . . . .

150

Time-lapse Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . .

152

4.6.1

Time-lapse Attributes

153

4.6.2

Analysis on direct P-wave

4.6.3

Analysis on up-going P-waves

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

154

. . . . . . . . . . . . . . . . . .

158

Interpretation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

159

4.7.1

Measurement system factors

. . . . . . . . . . . . . . . . . .

160

4.7.2

Formation changes

. . . . . . . . . . . . . . . . . . . . . . . .

163

4.8

Conclusions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

170

4.9

Figures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

174

4.7

5

4.4.2

Conclusions and Future Work

197

5.1

Summary of conclusions

. . . . . . . . . . . . . . . . . . . . . . . . .

197

5.2

Future directions

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

200

A Tube-wave generation and attenuation at a finite fracture

205

A.1

Tube-wave Generation

. . . . . . . . . . . . . . . . . . . . . . . . . .

205

A.2

Tube-wave Attenuation . . . . . . . . . . . . . . . . . . . . . . . . . .

207

B Layered Borehole Model

B.1 Displacement Potentials

209

. . . . . . . . . . . . . . . . . . . . . . . . .

209

B.2

Displacement-Stress Matrix

. . . . . . . . . . . . . . . . . . . . . . .

210

B.3

Displacement-stress vector for incident waves . . . . . . . . . . . . . .

215

15

C Reflection and Transmission Coefficients for Strain

217

References

219

16

List of Figures

2-1

Diagram showing tube-wave generation at a fracture intersecting a

borehole. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2

62

Propagation velocity for fluid pressure in the radial direction in a fracture, w

/

Re{}, is plotted against frequency for different values of

compliance and aperture. The solid lines represent varying compliance

when fracture aperture is 0.5 mm. The dotted lines represent varying

fracture aperture when fracture compliance is 10-9 m/Pa. The propagation velocity is obtained by numerically solving Tang's dispersion

relation using: af=1500 m/s, a=5800 m/s, f=3300 m/s, pf=1000

kg/m 3 , p = 2700 kg/m, v=10- 6 m 2 /s. The fluid properties correspond

to water. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3

62

Attenuation factor Im{(} for fluid pressure in a fracture is plotted

against frequency for different values of compliance and aperture. The

solid lines represent varying compliance when fracture aperture is 0.5

mm. The dotted lines represent varying fracture aperture when fracture compliance is 10-9 m/Pa. The parameters for this study are the

same as in Figure 2-2.

. . . . . . . . . . . . . . . . . . . . . . . . . .

17

63

2-4

Tube to P-wave pressure amplitude ratio is plotted against frequency

for a 0.5-mm-wide fracture with a fracture compliance of 10-

m/Pa,

intersecting a 15 cm diameter borehole. The formation and fluid properties are the same as in Figure 2-2. . . . . . . . . . . . . . . . . . . .

2-5

63

Tube to P-wave pressure amplitude ratio plotted against frequency for

different fracture compliance values, taking LO = 0.5 mm, while other

parameters are kept constant. Note that the amplitude ratio decreases

with decreasing compliance and the transition regime is independent

of compliance. The parameters for this study are the same as in Figure

2-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-6

64

Tube to P-wave pressure amplitude ratios are plotted against frequency

for different values of aperture, taking Z = 10- 9 m/Pa, while other

parameters are kept constant. Note that the transition regime moves

towards higher frequencies with decreasing aperture. Also, amplitude

ratio decreases with decreasing aperture. Medium parameters are the

same as in Figure 2-4.

2-7

. . . . . . . . . . . . . . . . . . . . . . . . . .

64

Tube to P-wave pressure amplitude ratios plotted against frequency

for different kinematic viscosity values, taking Z = 10

9

m/Pa and

LO = 0.5 mm, while other parameters are kept const-ant. Note that

the transition regime moves towards higher frequencies with increasing

viscosity. The parameters other than viscosity are the same as in Figure

2-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-8

65

Tube to P-wave pressure amplitude ratio is plotted against frequency

for fractures of different fracture lengths, taking Z

=

10- 9 m/Pa and

LO = 0.5 mm, while other parameters are kept constant.

All other

parameters are the same as in Figure 2-4 . . . . . . . . . . . . . . . .

18

65

2-9

Schematic showing attenuation of tubewave at a fracture intersecting

a borehole. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

66

2-10 Transmission coefficient is plotted against frequency assuming a fracture compliance of 10

9

Pa/m and an aperture of 0.5 mm. The pa-

rameters for this study are the same as in Figure 2-4. . . . . . . . . .

66

2-11 Transmission coefficient is plotted against frequency for different fracture compliance values, taking LO = 0.5 mm, while other parameters

are kept constant.

Note that the transmission coefficient increases

with decreasing compliance and the transition regime is independent

of compliance. The parameters for this study are the same as in Figure

2-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

67

2-12 Transmission coefficients are plotted against frequency for different values of aperture, taking Z = 10-' m/Pa, while other parameters are

kept constant. Note that the transition regime moves towards higher

frequencies with decreasing aperture. Also, transmission coefficient increases with decreasing aperture. Medium parameters are the same as

in 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

67

2-13 Transmission coefficient is plotted against frequency for different kinematic viscosity values, taking Z = 10

9

m/Pa and LO

=

0.5 mm, while

other parameters are kept constant. Note that the transition regime

moves towards higher frequencies with increasing viscosity.

The pa-

rameters other than viscosity are the same as in 2-4 . . . . . . . . . .

68

2-14 Transmission coefficient is plotted against frequency for fractures of

different sizes, taking Z = 10-

9

m/Pa and LO = 0.5 mm, while other

parameters are the same as in 2-4. . . . . . . . . . . . . . . . . . . . .

19

68

2-15 Amplitude ratio contours are plotted in the aperture, compliance parameter space for a frequency of 150 Hz. The parameters for the study

are the same as in Figure 2-2 and correspond to the field study at the

Mirror Lake borehole discussed in the field example section. Amplitude ratios estimated from the field data lie between 10 and 15. This

suggests that the lower bound on the compliance lies between 3 x 10-10

m/Pa and 10- 9 m/Pa (indicated by the black dotted lines) when fracture aperture is assumed to be lower than 1 mm.

3-1

. . . . . . . . . . .

69

A schematic description of the various components of the DAS system.

The phase-lag between the beat signals (S1+S2) formed from two scattering points in the fiber in the unstrained (blue) and strained (red)

state is proportional to the strain in that section of the fiber occurred

between the two sampling times ...

3-2

. . . . . . .... . . . . . . . .

.

Three different implementations of COTDR are shown: (a) Dual-Pulse

system (b) Single-Pulse system (c) Single-Pulse with Local Oscillator.

3-3

114

115

Sensitivity of a vertical component geophone and DAS as a function of

angle of incidence from z-axis. Dotted lines indicates negative polarity. 116

3-5

Averaging strain over a gauge-length is equivalent to applying a sinc

filter in the frequency domain. The amplitude response of the filter is

shown as a function of the wave-length. . . . . . . . . . . . . . . . . .

3-6

117

Borehole reception pattern for P- and SV-wave incidence on an open

borehole. The amplitude ratio of fluid pressure at borehole center (I A 1)

to the stress due to incident P-wave (JajOc,), away from the borehole,

is plotted against the incidence angle J for different frequencies and for

both hard (Berea Sandstone) and soft (Pierre Shale) formations. Note

differing amplitude scales for each plot. . . . . . . . . . . . . . . . . .

20

117

3-7

Amplitude ratio of pressure at the wall of an open borehole (Pb(r - rb))

to that at borehole center (Pb(r = 0)) is plotted against the azimuth

0 of the receiver for different frequencies and for P- and SV-wave incidence (6

=

450) in hard (Berea Sandstone) and soft (Pierre Shale)

formations. Azimuth is 1800 in the direction of the wave incidence.

3-8

.

118

Borehole reception pattern for P- and SV-wave incidence on a cased

borehole. The amplitude ratio of fluid pressure at borehole center (I P1)

to the stress due to incident P-wave (-I

u

I), away from the borehole,

is plotted against the incidence angle 3 for different frequencies and for

both hard (Berea Sandstone) and soft (Pierre Shale) formations. Note

differing amplitude scales for each plot. . . . . . . . . . . . . . . . . .

3-9

119

Axial strain sensitivity for DAS buried in an infinite homogenous elastic

solid. The amplitude ratio of strain in the z-direction (I Ec,) to the total

strain due to incident P-wave (JI

cI)

is plotted against the incidence

angle 3 for different frequencies and for P- and SV-wave incidence in

(a) hard (Berea Sandstone) and (b) soft (Pierre Shale) formations. The

maximum sensitivity for SV-wave incidence is proportional to

..

120

3-10 Axial strain sensitivity for DAS installed in the cement outside casing.

The amplitude ratio of strain in the z-direction at the casing-cement interface (Icz|) to the strain due to the incident P-wave (I cjI) is plotted

against the incidence angle 3 for different frequencies and for P- and

SV-wave incidence in hard (Berea Sandstone) and soft (Pierre Shale)

form ations.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21

121

3-11 Ratio of the strain Ic,,(0) 1at the casing-cement boundary for arbitrary

azimuth to that at zero azimuth lzc (9 = 00) is plotted against the

azimuth 0 of the receiver for different frequencies and for P- and SVwave incidence (6 = 450) in hard (Berea Sandstone) and soft (Pierre

Shale) formations. Azimuth is 1800 in the direction of the wave incidence. 122

3-12 A schematic diagram of a typical FO cable cross section. A typical FO

cable has multiple optical fibers packaged inside metal or plastic jackets. 123

3-13 A schematic diagram of the modeled FO cable cross section.

. . . . .

123

3-14 Strain sensitivity of two-layered cable installed in borehole fluid is plotted against angle of incidence for both P-wave (solid lines) and SV-wave

(dotted lines) incidence at 100 Hz. Sensitivity is shown for open and

cased boreholes in hard (Berea Sandstone) and soft (Pierre Shale) form ations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

124

3-15 Strain sensitivity of three-layered cable installed in borehole fluid is

plotted against angle of incidence for both P-wave (solid lines) and

SV-wave (dotted lines) incidence at 100 Hz. Sensitivity is shown for

open and cased boreholes in hard (Berea Sandstone) and soft (Pierre

Shale) form ations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

125

3-16 Strain sensitivity of two-layered cable installed in cement is plotted

against angle of incidence for both P-wave (solid lines) and SV-wave

(dotted lines) incidence at 100 Hz. Sensitivity is shown for hard (Berea

Sandstone) and soft (Pierre Shale) formations. . . . . . . . . . . . . . 126

3-17 Strain sensitivity of three-layered cable installed in cement is plotted

against angle of incidence for both P-wave (solid lines) and SV-wave

(dotted lines) incidence at 100 Hz. Sensitivity is shown for hard (Berea

Sandstone) and soft (Pierre Shale) formations. . . . . . . . . . . . . .

22

126

3-18 Percentage change in strain sensitivity (A#/#Ej,,) for a cable installed

in borehole fluid as the elastic properties of the Teflon layer are varied

from the reference properties E = 3.06 GPa and v = 0.317.

The

change in sensitivity is the same for both P, SV-wave incidence at any

arbitrary angle of incidence.

. . . . . . . . . . . . . . . . . . . . . . .

127

outside the casing as the elastic properties of the Teflon layer are varied

from the reference properties E

=

3.06 GPa and v

=

0.317.

-

3-19 Percentage change in strain sensitivity (A#/#Ejx,) for a cable cemented

The

change in sensitivity is shown for P-wave incidence in Berea Sandstone

at 6 = 00, 0 = 00 and frequency 100 Hz. . . . . . . . . . . . . . . . . .

127

3-20 Percentage change in strain sensitivity (A#/#Ecj) for a cable cemented

outside the casing as the elastic properties of the Teflon layer are varied

from the reference properties E = 3.06 GPa and v = 0.317.

The

change in sensitivity is shown for SV-wave incidence Berea Sandstone

at 6 = 450, 0 = 0' and frequency 100 Hz. . . . . . . . . . . . . . . . .

128

3-21 Percentage change in strain sensitivity as the cement properties are

varied. Both P-wave velocity and S-wave velocity of the cement are

simultaneously perturbed as a percentage of the reference cement prop-

erties (a = 2823 m/s and 3 =1792 m/s). . . . . . . . . . . . . . . . .

4-1

Stratigraphic sequence at the El Paso Natural Gas Company Wagon

Wheel No. 1 well located in the Pinedale Anticline.

4-2

128

. . . . . . . . .

174

A schematic diagram of well completion and the FO cable placement.

A scaled diagram of plug locations for all the stages is shown in the

inset of the stimulated zone. . . . . . . . . . . . . . . . . . . . . . . .

4-3

4-4

175

Fluid and proppant placed in the formation during the stimulation of

each of the stages . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

176

Plan-view of the well and the source locations A, B and C. . . . . . .

176

23

4-5

Uncorrelated and correlated sweeps before, during and after stimulation of stage 9 for source at location B.

4-6

. . . . . . . . . . . . . . . . 177

Uncorrelated trace recorded at channel 403 in the sweep shown in Figure 4-5e. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

4-7

DC bias (one number per trace) for each shot-gather (vibroseis sweep)

is plotted against the time of day when the sweep was collected and

the channel number. DC bias is related to the activity in the well and

depends on the phase of stimulation: A) Pre-stimulation B) Fracture

initiation C) Stimulation D) Post-stimulation. . . . . . . . . . . . . . 178

4-8

Integrated DC bias qualitatively follows the temperature measured in

the well using DTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-9

179

Spikes in the field and lab data are plotted aligned at the peak. When

normalized by the peak amplitude spikes in the field and lab fall on

the sam e curve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

180

4-10 Shot-gathers showing (a) Tubewave generation during the perforation

shot for stage 9. (b) Tubewave reflection at stage 9 plug (c) Tubewave

reflection at the surface . . . . . . . . . . . . . . . . . . . . . . . . . .

181

4-11 DC bias is plotted for a sweep after stimulation of stage 9. Jump in

DC bias can be observed at the bottom perforation (channel 432).

.

181

4-12 a) Channels corresponding to plugs/perforations at each stage as identified from tube-wave reflections and DC bias changes. b) Calibration

plot for DAS channels. Red dots are the receiver depths estimated in

the field. Blue dots are the depths of the same channels after associating with a plug/perforation depth. Red crosses represent the depth

of the same channels after assigning depth from the best-fit line to the

blue dots. The slope of the best-fit line implied a channel spacing of

8.19 m eters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24

182

4-13 Data processing workflow for time-lapse analysis of DAS data. . ..

.18 182

4-14 Data at various stages of the processing workflow in the order from (a)

to (f). Note the different time scale on correlated data and uncorrelated

data. The color scale on the correlated stacks is saturated to bring out

the reflections that are lower in amplitude (;

direct P-wave (-

0.05) compared to the

1). We did not apply any amplitude gain control.

.

183

4-15 Pre-processed stacks before the stimulation operations started in the

well and serve as baseline. Stacks corresponding to sources at the three

source locations are shown . . . . . . . . . . . . . . . . . . . . . . . .

184

4-16 Wave-field separation using median filter. The red line in the figures

denotes the arrival time of the direct P-wave.

. . . . . . . . . . . . .

185

4-17 Up- and down-going P-wave traces at channel 350 for baseline data

collected from source location B shown in Figure 4-16 . . . . . . . . .

186

4-18 Individual traces of the aligned down-going P-wave (a) before and (b)

after removal of remaining phases. The traces are taken from baseline

stack collected from source location B shown in Figure 4-16 . . . . . .

186

4-19 The spectrum of down-going P-wave as a function of depth (channel)

for the traces shown in Figure 4-18b . . . . . . . . . . . . . . . . . . .

187

4-20 Medium P-, S-wave velocities and P-wave quality factor are plotted

against the channel number (increasing depth). The plots for velocity

show velocity estimates from data at all the three source positions. The

Q factor

plots show the mean Q-value obtained from the data collected

at the three source positions with the error bars denoting the standard

deviation between the measurements. The stage numbers are labeled

in the figures. The horizontal black lines denote the plug locations. All

the four plots are to the same scale. . . . . . . . . . . . . . . . . . . .

25

188

4-21 Timeline of well operations and illustration of local and global timelapse attributes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-22 Time-lapse changes between repeated stacks during stage 12.

189

The

changes are due to noise as no well operations occurred between the

two stacks. The vertical black line identifies the location of the plug/

bottom perforation.

The dashed horizontal line represents the first

break time of the down-going P-wave.

. . . . . . . . . . . . . . . . .

189

4-23 Changes in the direct P-wave before and after: plug placement, and

perforation operation of stage 16. The vertical black line identifies the

location of the plug/ bottom perforation. The dashed horizontal line

represents the first break time of the down-going P-wave.

. . . . . .

190

4-24 Local time-lapse attributes for stage 16. The vertical black line identifies the channel at which the plug/ bottom perforation is placed for

stage 16. The dashed horizontal line represents the first break time of

the down-going P-wave.

. . . . . . . . . . . . . . . . . . . . . . . . .

191

4-25 Changes in traces at channels above and below the plug of stage 16:

before and after stimulation. . . . . . . . . . . . . . . . . . . . . . . .

4-26 Summary of the local time-lapse attributes for all the stages.

192

The

black asterisk in the figures represent the bottom perforation location

for that stage. In figure (b), the red vertical line denotes the location

of the bottom perforation.

. . . . . . . . . . . . . . . . . . . . . . . .

193

4-27 Summary of the global time-lapse attributes for all the stages. The

black asterisk in the figures represent the bottom perforation location

for that stage while the red represents the same for the previous stage. 194

4-29 Stimulated volume modeled as a low velocity layer sandwiched between

background layers.

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

195

. .

196

4-30 Extent of the amplified zone and the amplification in each stage.

26

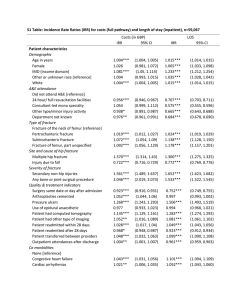

List of Tables

4.1

Effect of Measurement system factors on time-lapse changes

. . . . .

164

4.2

Summary of conclusions from models for formation changes . . . . . .

173

27

28

Chapter 1

Introduction

1.1

Overview

In this thesis, I focus on developing techniques to characterize fractures, both natural and hydraulic, from borehole seismic measurements. Fractures are macroscopic

planar discontinuities in the subsurface that are caused by stresses that exceed the

rupture strength of the rock or by physical diagenesis (Nelson, 2001). Fracture networks play a dominant role in governing the fluid-flow in the subsurface over reservoir

scales, especially in low permeability formations such as carbonates, shales, coalbed

methane and tight sandstones.

Naturally fractured reservoirs are present all over

the world, in all types of formations and contribute significantly to hydrocarbon production. Carbonate reservoirs alone, which are characterized by extensive fracture

networks, constitute about 60% of the world's oil and 40% of world's gas reserves. The

hydrocarbon storage and permeability structure of naturally fractured reservoirs are

markedly different from reservoirs governed by matrix permeability and the knowledge of fracture density, orientation, spacing and morphology is important for optimal

development and production of these resources (Aguilera, 1995; Nelson, 2001). On

the other hand, unconventional resources like shales, coalbed methane and tight-gas

29

sandstones have very low matrix permeability (microdarcy to nanodarcy) and are

hydraulically fractured for economic recovery of hydrocarbons. Advances in horizontal drilling and hydraulic fracturing not only made these resources viable but also

competitive.

As a result of the recent shale gas revolution, the United States has

transitioned from being a net importer of gas (1.5 trillion cubic feet, Tcf, in 2012)

to net exporter of gas by 2018 and estimates are that exports will be as large as

5.8 Tcf in 2040 (EIA, 2014). Increased development of tight oil resources in Eagle

Ford, Bakken and Permian basin formations is leading to increased U.S. crude production that started from 2012 and is expected to continue to increase to a peak

production of 9.6 million barrels per day by 2019 (EIA, 2014). On the global scale,

shale gas contributes to 32% (22,882 Tcf) of the total estimated natural gas resources

and Shale/tight oil contributes to 10% (3357 billion barrels) of the global crude oil

reserves (Kuuskraa et al., 2013).

However, the recovery factor for tight oil is less

than 5% and for shale gas, on an average, is only about 20%. Tapping these huge

reserves definitely needs improved technology. Monitoring is crucial to enhance our

understanding of hydraulic fracturing and provides critical feedback for improving

the hydraulic stimulation design.

Fractures range in scale from as small as micro-cracks at centimeter scale to joints

on the order of meters to faults on the scale of 10's of meters to kilometers. Similarly,

the techniques to characterize fractures vary based on the scale of observation. On

a reservoir scale surface seismic techniques are used; on an intermediate scale Vertical Seismic Profiling (VSP) and cross-well studies are made; and for near borehole

studies well logs are used (Long et al., 1996). Televiewer and Formation micro scanner are the common well logs for identifying and determining the orientation of the

fractures intersecting the borehole (Long et al., 1996; Zoback, 2010). However, they

do not provide information about the extent of the fracture away from the borehole

or a reliable estimate of the fluid transmissivity of the fracture, which is the prime

30

motivation for fracture characterization.

Sometimes packer tests are performed in

isolated intervals to determine the transmissivity in that section of the well. These

tests are time consuming and are not regularly used.

The signature of fractures in the seismic wave field depends on the size of the

fractures compared to the wavelength of the incident wave field. When the fractures

or cracks are much smaller than the seismic wavelength, the wave field responds to the

effective medium properties of the formation with cracks. Various authors (Kuster

& Toksdz, 1974; O'Connell & Budiansky, 1974; Hudson, 1981, 1991; Liu et al., 2000;

Kachanov, 1992) related the crack density of penny shaped cracks to the elastic

properties of the effective medium and thus the propagation velocity of elastic waves.

When the micro-cracks are preferentially oriented, the effective medium properties

are anisotropic (Hudson, 1981; Schoenberg & Douma, 1988; Schoenberg & Sayers,

1995).

It is common in nature to find preferred orientation of cracks comprising a

fracture set (Long et al., 1996). In addition, given the stress state, fractures oriented

perpendicular to the minimum principal stress direction are more likely to be open

and more active (Boness & Zoback, 2006). Various surface seismic studies have used

Amplitude Variation with Offset and Azimuth (Rfiger, 1998; Hall & Kendall, 2003;

Liu et al., 2010) to infer the anisotropy in the medium and thus the preferred crack

orientation and crack density. Other studies have relied on shear wave splitting (Majer

et al., 1988; Crampin & Lovell, 1991; Winterstein & Meadows, 1991; Gaiser et al.,

2001, 2002; Shen et al., 2002). However, preferred orientation and crack density are

not sufficient to estimate the permeability of the formation.

Moreover, the cracks

characterized by effective medium methods are small in size and do not contribute

significantly to the fluid flow.

Fractures that are comparable to the seismic wavelength (on the order of 10s of

meters) are large enough to be connected over reservoir scales and are major contributors to fluid flow. The seismic wave field is scattered from such large discrete

31

fracture networks. Based on the observations from various numerical studies, several scattering based methods (Willis et al., 2006; Burns et al., 2007; Grandi, 2008;

X. Fang, Fehler, et al., 2013; Zheng et al., 2013) have been proposed to estimate the

preferred orientation of the fracture network, fracture dimension and spacing. Several

studies show that the scattering amplitude from fractures is proportional to fracture

compliance (Blum et al., 2011; X. Fang, Shang, & Fehler, 2013).

Fractures are rough surfaces that are in contact with each other through asperities

(Brown & Scholz, 1985). The flow through a fracture is controlled by inter-linked microscopic features such as aperture distribution, tortuosity, roughness of the fracture

surface and the actual contact area (Walsh, 1981; Brown, 1987; Thompson & Brown,

1991; Zimmerman & Bodvarsson, 1996; Hakami & Larsson, 1996). The same microscopic details control the mechanical properties of the fracture and thus the fracture

compliance (Brown & Scholz, 1986; Tsang ,& Witherspoon, 1983; Renshaw, 1995;

Liu, 2005).

Laboratory experiments (Pyrak-Nolte, 1996; Pyrak-Nolte & Morris,

2000) showed that fracture compliance and transmissivity are positively correlated.

Thus, fracture compliance is a key link between seismic measurements and the fracture transmissivity (Brown & Fang, 2012). However, fracture compliances estimated

from ultrasonic experiments in the laboratory are too small to observe any scattering in the field. Worthington and Lubbe (2007) argue that fracture compliance may

scale with fracture size and thus reservoir scale fractures have observable scattering

effects. However, field measurements of fracture compliance are limited. I address

this in chapter 2 by developing models to estimate fracture compliance in the field.

I studied tubewave generation and attenuation at a fracture intersecting a borehole

to estimate the fracture compliance as well as the fracture size and aperture. These

models can be used to characterize both natural and man-made fractures that intersect a borehole. Using published field data, I show that fracture compliances of

fractures intersecting a shallow borehole have sufficient compliance to cause seismic

32

scattering in the frequency range used for seismic observations.

In chapter 4, I shift the focus on to monitoring hydraulic fracturing.

We are

interested in estimating the Stimulated Reservoir Volume (SRV) (Mayerhofer et al.,

2010) within which the permeability has been increased due to hydraulic fracturing.

The two popular methods for estimating SRV are monitoring microseismicity and

tilt-meter measurements on the surface after stimulation (Warpinski et al., 2004).

Tilt-meter measurements only provide the surface deformation due to stimulation.

Though useful they are not ideal to estimate the extent of stimulated volume. Numerous microseismic studies have been made to understand the hydraulic fracturing

process (Rutledge & Phillips, 2003; Warpinski, 2009; Maxwell, Rutledge, et al., 2010;

Warpinski et al., 2012). It is now well understood that the extent of the microseismic cloud is not necessarily confined to the newly stimulated volume (Maxwell et al.,

2009; Maxwell, Underhill, et al., 2010). Pore pressures communicating over large distances and poroelasticity may cause seismic activity at pre-existing faults (Warpinski

et al., 2004). Alternatively, the stimulated volume is probed using active source methods and studying shear wave shadowing, shear wave splitting and P-wave amplitude

changes in the stimulated zone (Stewart et al., 1981; Turpening & Blackway, 1984;

Wills et al., 1992; Meadows & Winterstein, 1994; Baird et al., 2013). Until recently,

both active source methods and passive microseismic monitoring required a neighboring monitoring well to house the seismic sensors. With the advent of Distributed

Acoustic Sensing (DAS) we can make seismic measurements in the same well that is

treated. This is a game changer for monitoring efforts. I devote chapter 3 to studying

DAS system for VSP measurements and quantifying the effect of various factors on

time-lapse DAS measurements.

In chapter 4, time-lapse DAS VSP data collected

during a multi-stage hydrofracturing operation were analyzed.

33

1.2

Thesis Outline and Contributions

The major contributions of this thesis can be summarized as below.

* Two methods are developed to estimate fracture compliance, fracture aperture

and fracture size in-situ by using tubewaves in a borehole. These methods are

applied to field data to show that fractures in the field have large compliance

values and that fracture compliance scales with fracture size. This has broad

implications for using seismic scattering-based methods to characterize fractures

on a reservoir scale.

.. Significant progress is made on the theoretical understanding of Distributed

Acoustic Sensing (DAS), a new seismic acquisition system and its relation to

geophone measurements. The effect of various factors in a borehole environment on DAS measurements is analytically studied. This study provides solid

foundation for use of DAS for reservoir monitoring.

* Time-lapse DAS VSP data collected during a multi-stage hydrofracturing operation are analyzed. Challenges in interpreting and processing this novel data

are addressed.

DAS is shown to be a reliable tool for monitoring hydraulic

fracturing provided acquisition geometry is chosen carefully.

This thesis is organized into five chapters. Chapter 1 discusses the context of

the thesis and prepares ground for the subsequent chapters. In chapter 2, we study

borehole tubewaves for fracture characterization and discuss the question of scaling

of fracture compliance. In chapter 3, we study Distributed Acoustic Sensing (DAS),

a novel seismic acquisition technique which has huge implications for in-well timelapse measurements and fracture characterization.

Chapter 4 is a field-study of a

multi-stage hydraulic fracturing job in a tight-gas sandstone reservoir using DAS in a

treatment well. Chapter 5 summarizes the contributions by the thesis and discusses

34

specific problems for future study. Chapters 2, 3, and 4 are stand alone chapters and

the reader may skip to the chapter of interest.

In chapter 2, we study tubewaves in a borehole and use them to characterize the

fractures that intersect a borehole. We describe two models, one for tubewave generation and the other for tubewave attenuation at a fracture intersecting a borehole,

that can be used to estimate fracture compliance, as well as, fracture aperture and

lateral extent. In the tubewave generation model, we consider tubewave excitation in

the borehole when a P-wave is incident on the fracture. The amplitude ratio of the

pressure due to the tubewave to that of the incident P-wave is a function of fracture

compliance, aperture, and length. Similarly, the attenuation of a tubewave in the

borehole as it crosses a fracture intersecting the borehole is also a function of fracture

properties. Numerically solving the dispersion relation in the fracture, we study tubewave generation and the attenuation coefficient at arbitrary frequencies. We observe

that measuring amplitude ratios or attenuation near a transition frequency can help

constrain the fracture properties. The transition frequency corresponds to the regime

where the viscous skin depth in the fracture is comparable to its aperture. Measurements in the high frequency limit can place a lower bound on fracture compliance and

lateral extent. We evaluate the applicability of the tubewave generation model to a

previously published VSP dataset and find that compliance values of the order 10-10

to 10-

m/Pa are likely in the field. These observations support scaling of fracture

compliance with fracture size and applicability of fracture scattering based techniques

to characterize fractured reservoirs.

In chapter 3, we change gears and study Distributed Acoustic Sensing (DAS), a

Fiber Optic (FO) cable based seismic acquisition technology which is gaining importance for Vertical Seismic Profiling (VSP) surveys, especially for time-lapse monitoring of reservoirs. DAS is a nascent technology and the current chapter contributes

towards the development of DAS for VSP. We first describe the technique in detail

35

for readers not acquainted with DAS. We show that DAS measurements are identical

to differential geophone measurements and compare the advantages and limitations

between DAS and geophones. We systematically study various factors that influence

DAS measurements including: gauge-length, strain in the cable and the background

temperature. We then present the borehole effects on DAS measurements for the cases

when the DAS cable is installed in the borehole fluid and when the cable is cemented

outside the casing. We followed the approach by Peng et al. (1993, 1994) to study P

and S plane-wave incidence on a borehole in both hard and soft formations, and show

the relation between the incident wave-field to DAS measurements. We show that the

sensitivity of DAS is markedly different based on how it is installed. We argue that

borehole effects are not important for frequencies below 300 Hz and are important for

frequencies above 500 Hz. We also studied the effect of cable design and formation

coupling on DAS measurements and show that cable design is important when DAS

is coupled through borehole fluid and not so important when cemented outside the

casing. Finally, we study the effect of temperature, pressure and cement properties

on time-lapse measurements and show that they do not contribute significantly. This

makes DAS a reliable tool for time-lapse monitoring.

In chapter 4, we describe a novel active-source seismic experiment with DAS in a

treatment well and study time-lapse changes due to hydraulic fracturing. The advent

of Distributed Acoustic Sensing (DAS) has allowed us to monitor changes from within

the treatment well itself. DAS offers distinct advantages over geophones but it also

poses unique challenges, including receiver depth uncertainty and low signal-to-noise

ratio. We describe the pre-processing needed before further time-lapse analysis of the

VSP. We focus on two key steps - depth calibration and noise removal. Large spike

noise, most likely from the DAS acquisition system, appears to be a major source of

noise in the raw DAS data, but can be removed with careful processing. Other sources

of noise include temperature fluctuations in the well and optical noise. We show that

36

excellent quality DAS VSP data can be obtained in a hydrofrac treatment well. We

observe systematic time-lapse changes in the amplitudes of direct P-waves: increased

amplitudes above the lowest perforation for each stage and decreased amplitudes

below.

These strong time-lapse changes appear to be long-lived, at least over a

period of 10 days. The time-lapse phase changes are small and hard to interpret.

We show that these time-lapse changes are not related to temperature and pressure

fluctuations between the time-lapse surveys.

We believe that the amplification in

the stimulated zone is related to formation changes and the attenuation is probably

related to coupling changes between the FO cable and cement. Though the acquisition

geometry of the field experiment was not ideal, DAS is promising for hydraulic fracture

monitoring.

37

38

Chapter 2

Fracture Compliance Estimation

using Borehole Tubewaves

2.1

Introduction

Naturally occurring fracture networks account for significant fluid flow in many petroleum

reservoirs, especially in carbonate reservoirs and other less porous formations. Fracture networks also play an important role in the economic recovery of geothermal

energy and for C02 sequestration.

To model flow in fractured reservoirs, we need

to know fracture network properties such as the dominant orientation of the fractures, fracture spacing, and fracture fluid transmissivity.

Direct measurement of

some fracture properties is possible in boreholes. Borehole televiewer and formation

micro-imager (FMI) logs are the most popular tools for characterizing fractures that

intersect boreholes. These logs provide the orientation and spacing of those fractures

intersecting the borehole. However, from these data, it is hard to differentiate between fractures with high or low fluid transmissivity and it is not possible to estimate

the lateral extent of the fractures.

Some of the fracture like features seen in the

logs could be drilling induced and thus not extend far from the borehole. Pressure

39

transient tests can give an estimate of fluid transmissivity of fractures, but these are

macroscopic measurements averaging over a large conducting region.

On a reservoir scale, seismic methods are at the forefront for detecting and analyzing fractures networks. The scale of a fracture relative to the seismic wavelength

determines the nature of the fracture signature in the wavefield (X. Fang, Fehler, et

al., 2013). Microfractures or cracks that are much smaller than the seismic wavelength

are known to cause velocity anisotropy. Considerable research has been done to characterize microfractures through effective medium theories (e.g., Peacock & Hudson,

1990; Kachanov, 1992). It is common to apply methods like amplitude variation with

offset and azimuth (AVOA) to characterize the velocity anisotropy that can be interpreted to characterize the preferred orientation of the fractures. It is not possible to

independently estimate the fracture spacing and fracture transmissivity using AVOA

analysis. The focus now is increasingly on detecting large discrete fractures that have

a larger impact on fluid flow. These macrofractures have lateral extent comparable

to the wavelength of the incident wavefield (tens of meters) and the spacing between

these fractures or fracture zones may be on the order of a wavelength. Such fractures

can scatter the seismic wavefield (Willis et al., 2006; Burns et al., 2007). They are

treated as distinct features rather than as an effective medium. Descriptive distributions of such networks are usually referred to as discrete fracture networks and can

be used to stochastically model fluid flow in reservoirs. Willis et al. (2006), Burns et

al. (2007), Grandi (2008) and X. Fang, Fehler, et al. (2013) develop scattering-based

methods to determine fracture orientation and spacing from seismic reflection data.

Scattered wave signals are a function of fracture compliance. Grandi (2008) numerically simulates scattering from a parallel set of discrete fractures and shows that the

amplitude of the scattered wavefield increases with increasing fracture compliance.

40

2.1.1

Fracture Compliance

Fracture compliance is the inverse of fracture specific stiffness (Pyrak-Nolte et al.,

1990) and is defined as the displacement across the fracture surfaces when a unit

stress is applied across the fracture. Laboratory studies suggest that fracture compliance and fracture fluid transmissivity are influenced by the same microscopic features

of the fracture, i.e., aperture distribution, actual contact area, fractal dimension of

the fracture surfaces and that these are inter-related (Pyrak-Nolte & Morris, 2000).

Therefore fracture compliance may be a key link to estimate fracture fluid transmissivity from scattered energy (Brown & Fang, 2012). Measuring the fracture compliance

in a borehole, we may be able to assign fracture compliance and thus, fracture transmissivity, to regions away from borehole based on relative scattered energy measured

on surface seismic data. In addition, estimating fracture compliance in a borehole

may be useful for monitoring the efficiency of hydraulic fracturing. Therefore it is

important to understand the range of compliance values that can be expected in the

subsurface.

Estimates of fracture compliance vary over orders of magnitude from laboratory

to the field. Worthington and Lubbe (2007) suggest that fracture compliance scales

with fracture size, which would explain the small compliance value measured in the

lab and the scattering effects seen at field seismic wavelength scales (Pyrak-Nolte et

al., 1990; Lubbe, 2005). However, compliance measurements in the field are limited

and are mostly based on effective medium methods by assuming some fracture density. In this chapter, we develop models that estimate fracture compliance, aperture,

and size in the field by studying 1) tube-wave generation and 2) tube-wave attenuation at a fracture intersecting a borehole. When an external wavefield is incident

on a fluid-filled fracture intersecting a borehole (e.g., VSP), it squeezes the fracture

and expels fluid into the borehole, generating a tubewave in the borehole. The amplitude of the tube-wave is proportional to the amount of fluid exchanged between

41

the fracture and the borehole. The fluid exchange, in turn, depends on the compliance and fluid transmissivity of the fracture. The amplitude ratio of the pressure

due to the incident wavefield measured in the borehole fluid to the pressure due to

the tube-wave generated at the fracture can be diagnostic of fracture compliance and

fracture transmissivity. Similarly, when a borehole tube-wave that is generated elsewhere propagates across a fracture, part of its energy is spent in pushing the fluid into

the conducting fracture. This energy loss depends on the amount of fluid exchanged,

and the attenuation coefficient is a function of the fracture properties.

Tubewave generation at a fracture was first studied by Beydoun et al. (1985).

However, Beydoun does not consider fracture compliance.

Later, Hardin, Cheng,

Paillet, and Mendelson (1987) formulate fracture closure as a function of fracture

compliance.

Beydoun and Hardin assume Darcy flow in the fracture, which is a

low-frequency approximation to the dispersion relation in the fracture (Tang, 1990).

Cicerone and Toks6z (1995) and Ionov (2007) study tube-wave generation by taking

the high-frequency approximation solution to the dispersion relation in the fracture.

Though Ionov (2007) does not consider fracture compliance, Cicerone and Toks6z

(1995) attempt to include fracture compliance indirectly by allowing displacement to

be discontinuous at the fracture top and bottom surfaces.

Attenuation of tubewaves across a fracture was studied by Mathieu (1984), Hornby

et al. (1989), Tang and Cheng (1993),Kostek, Johnson, and Randall (1998),Kostek,

Johnson, Winkler, and Hornby (1998)and Mathieu (1984) assumed Darcy flow in

the fracture and studied attenuation of tubewaves across the fracture. However, the

assumption of Darcy flow is not valid for typical logging frequencies.

Hornby et

al. (1989) and Tang and Cheng (1993) solved the problem under a high-frequency

approximation, which is a valid assumption for acoustic logging (kHz range of frequencies) and fractures like those expected in-situ. Later, Kostek, Johnson, Winkler,

and Hornby (1998) extend the theory to include the elasticity of the formation. These

42

studies did not account for the fracture compliance that plays an important role in

the tubewave attenuation.

In this chapter, we develop models for tube-wave generation and attenuation that

account for fracture compliance and are valid over a broad range of frequencies (Hz

to kHz).

To study tube-wave generation and attenuation at arbitrary frequency,

we numerically solve for the dispersion relation in the fracture. We first describe the

models for an infinitely long fracture to understand the affects of fracture aperture and

fracture compliance. The models predict a low-frequency regime, a high-frequency

regime and a transition regime in which the viscous skin depth is comparable to the

fracture aperture. Based on these observations, we show that measurements in the

transition regime are required to infer fracture aperture and compliance. However,

we discuss how data collected in the high frequency regime can be used to place a

lower bound on fracture compliance. We then extend the models to the finite fracture

case and discuss the effect of the finite length of fracture. Finite fracture models are

described in the Appendices A.1 and A.2. Finally, we present a field data example to

argue that fracture compliance of the order of 10-' m/Pa are feasible in the field.

2.2

2.2.1

Theorertical Formulation

Tube-wave generation in a borehole

Following previous studies, we consider a horizontal fracture that is infinite in lateral

extent and intersecting a vertical borehole of radius R as shown in Figure 2-1. The

model is developed to study the tubewave generation in the borehole when a plane

P-wave is normally incident on the fracture. However, the results can be extended

to an arbitrary angle of incidence.

Fractures are discontinuities in the subsurface,

held open by asperities that resist the fracture closure.

For simplicity, we assume

the fracture to be a parallel plate with static aperture Lo and normal compliance,

43

Z. For now, we neglect the effect of roughness, tortuosity and actual contact area of

the fracture on the fluid motion in the fracture; however these will be discussed in

a later section. Fracture closure is proportional to the compliance and the applied

effective normal stress. Though fracture closure and applied stress are non-linearly

related (Pyrak-Nolte et al., 1990), fracture closure due to the perturbation in the

applied stress over a background litho-static stress due to an incident wavefield can

be considered locally linear (Schoenberg, 1980).

Therefore, the dynamic fracture

aperture L(t) at any location can be written as (Hardin et al., 1987)

L(t)

=

Lo + Z [p(t) - on(t)] ,

(2.1)

where LO is the static aperture, on(t) is the normal stress on the fracture face, and

p(t) is the perturbation in the fracture fluid pressure due to closure.

For a normally incident P-wave, Un(t) = coe-w, where o0 ,w are the stress amplitude and frequency of the incident wave. The incident wave perturbs the fracture

aperture and causes a pressure gradient in the fracture. For simplicity, fluid pressure

and flow in the fracture are averaged over the aperture and only their radial variation

away from the borehole is considered. We use cylindrical coordinates to accommodate

the axial symmetry of the problem. The net flow out of a volume element 27rrL(t)dr

between r and r + dr from the axis of the borehole, during a time increment dt, should

equal the change in volume of the element due to the perturbation in the aperture

and the change in the fluid volume due to compressibility of the fluid. Thus, we arrive

at the mass conservation equation in the fracture as

(q+ -) =

o(

r

-L + L7--,

d

(2.2)

at'

where -/ is the fluid compressibility and q is the radial flow per unit length away from

the borehole. Flow in the fracture can be related to the pressure gradient through

44

dynamic conductivity, C. Solving for the flow field of a viscous fluid in an infinitely

long rigid fracture, Tang (1990) showed that the flow averaged over the aperture at

any location could be related to the radial pressure gradient at that location as

-

1=-U

_ O iwLo a

a_

=-

Or

i

o

k2ajpf Or'

(2.3)

where cf is the acoustic velocity in the fluid, pf is the fluid density and i is the

imaginary unit. A bar over a symbol denotes that the quantity is in the frequency

domain.

The radial wavenumber of those specific modes that can exist in a rigid

fracture (zero fracture compliance) is represented by kr and is obtained by solving

the dispersion relation for the velocity field in an infinitely long, fluid filled fracture,

given by (Tang, 1990)

k tan (2o

S2+k

+

1?2

(

=2 1-

0,

iwv ,P

44.

f3

72+ kr =

=

(2.4a)

(2.4b)

,(2.4c)

where v is the kinematic viscosity of the fluid.

Given the small strains associated

with exploration seismic waves, and for the range of the fracture apertures and the

fracture compliances that are practical, fracture closure is small compared to the

fracture aperture.