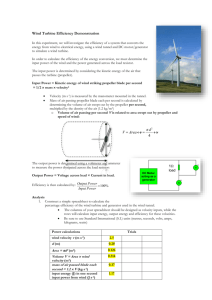

DESIGN WITH WIND of Technology SUBMITTED IN PARTIAL FULFILLMENT THE

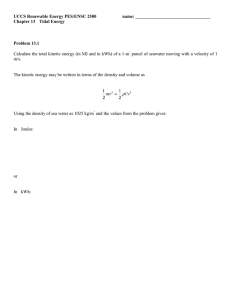

advertisement