Document 11236102

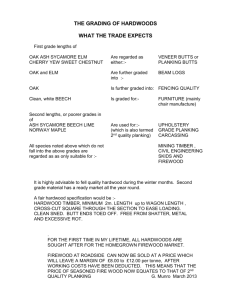

advertisement