Document 11230546

advertisement

I If D E X.

page.

Introduction

1.

MaterialA

1.

Ore

Flux

Character, Preparation,

Fuel

Sampling,

Analysis. 1 - 8.

Description

of Blast Furnace

9.

9.

Blower

Calculation of Charge

11.

Description

14.

of Run

-

Data Sheets -

- 20.

16

21.

Clean Up -

22.

Analysis of Products - --

-

Gas Analysis

Account of Stock

-

Theoretical Balance Sheet for materials

of one fyritic Charge

Calculation of Blast. -

23.

- 24 - 26 a.

- 2',30.

Thermal Balance

38.

Summary

43.

-

37.

1

INTRODUCTI~N.

The subject of this thesis ia pyritic smelting

tha Tnstitute b~~st furnace of a mixture af copper-nickel

and

the

cuprlferouB

Institute

pyr1 ta •

blast

furna.ce,

a reducing atmosphere.

conditions.

the sulphide of

matte

raduc lng emel ting

1n

18,%of coke _1s used which furnishes

In pyritic smelting, no coke or only a Bm~

amount 1s used, and this

oxidizing

With the ordinary

in

causes the smelting to taka place under

The oxidation of the iron and sulphnr of

iron and the formation of the slag, furnish the

whOle or the greater part of the heat necessary.

nf tha process, it is necessary

For the success

to have an abundant supply of

air at the right pressure and a sufficient

~uant1ty of silica

to slag off the iron which 13 not required for the desired grade

of matt9.

The matte concentration

ia affected by the amount of

alT' furnished, by the quantity of ailiciapresent

added.The

slag c~mpo81tion under given conditions

constant.

An increasa of silica

tion, but causes the formation

a. riss

and by the cOke

ia always

will not change this composiof a larger quantity of slag and

1n the grade nf the me.tte. \.

MATERIALS.

The or~ smelted consisted

nickel matte and aupriferous

of equal parts of coppsr-

pyrite.

Matte. The matte used was a mixture of four lots of coppsr matte

and one lot of nickel matte prOduced at the Institute

in labora-

x

tory :runs and in a thee is run of 1.908.

The fi va lots

'of matte

were

sap9.rately

brOken

by

s19ve to remove the finss"

han~

BS

to

only the oversize

This was sampled by fractional

weight of each lot

30 mm. B.nd screwed

S91sction,

on 8 mm.

was to be used.

one tenth part by

being reserved as sample.

The samples were

combined and reduced to 1/4 inch In the Sturtevant

rOll-jaw

.

cnlsher. Tha combined sample was then halved 1n the Jones samplar and the reserved portion put through the Hendrlck-Bolthoff

sample grinder .to pass's 30 mesh

sieve, then SPlit-shoveled

down

to 485 grams and this ground on the bucking plate to pass a

..

t,

100 mesh :screen. The matte was found to ba magnetic,

meta~11c iron particl~a from the machines

hence the

could not be r~moved

,wlth a magn.et.

The ma.tte

was analyzed

for

,C:U,N!,

Fe, Pb,

S,

CaO,

The sample for analysis was traat8d with a solution

of bromide in HN03 (Sp.Gr.l.42).

After action ceased, concen-

trated HO/was added, and the SOlution boiled until no more substance wa.s dissolved.

Na

2

The residue was then filtered, fused with

C0 8nd added to the main SOllltion.

3

evaporated

~

*

to dryness,

dehydrated,

The sOlution W~6 then

H~/and water ware added,

and the silica filtered off, washed, ignited, and weighed.

x Foot-note from 1st. p~e:-Bradford and C. A. Gibbons, Jr.

Thesis

No. 341 by A. H.

3

H2 S was passed 1ntc the slightly

a.cid fl1tre.t~,

of .copper and lead wars precipitated

sulphides

precipitate

was dissolved

in H N ~and

zed. The copper was weighed as

the

and filtered.

The

th?- SOlution electrolY-

Cu and the lead as PbO.2

The filtrate wasevaporatsd

nearly to dryness

with

H S 04,watsr was added, and the SOlution passed through a Jones

2

The iron was det.armined by ti trat1ng wi th K lJ[n04 '

solution was eV8,po:hat~d to about 250 q.;<;.,

rednctor.

AJ:tA!'.titra~ingnthe

g.od th'S nickel

weighed

precipi ta.ted by the dimsthy~gJ.YOi:ime.

i4N.404Nt ~.

as C8 H

A frash sample was taken forthedeterm1nat1on

CaO

method end

and Al 2 03. It was put into SOlution

Cn. and Pb were separated

of aluminum andiron

prsc1.pitatlt)n,

S.s shown,

thrown down

filtered,

ignited

of

as a~ove, 5102

and the combined hydroxides

by

means of a d~ubla ammonia

and weighed.

As soma nickel

carried down its amnunt has to be determined.

This was done

by fusine; the ignited precipitate

is

with ~HS04' taking up with

wat~r, precipitating with dimethylglyoxime,

ducting

,

the wsight of the previously

and weighing. De-

determined

oxides of iron

and nickel gave the A12 03 •

The ca.lcium wa.s preclp1 t:3.ted in the filtrate

cinm,b~late~he

precipitate

was di9801ved in H ~.S04 ~d

a.s cal-

titrat-

ed hot wi th:XMnO 4,-

Sulphur was determined in ~ne s~~ple by the Fresenius

method

of fusing with Na2 C03and K N 03 and in another by the

,

Gla.ser method of fusing

.

.with N8. 0

2

a,

4

The metta

of iron.

The analysis

9.54

ton,

Pb

Fe

2.35

55.32

..

Pyr!~~.

gav~ the fOllowing

:Ni

Cu

%

was found to contain some magnetic

S

25.94

.42

The pyrit~

used

CaO

SiO~. 0#

Al-O

G .tJ

~

.46

.45

came from the

pyrite

with

.63

Total

100

4.89

screening.

removad-:by

selection

on the flcor.

rOll-Jaw

crusher,

and ground

in the

the amalls

, finer

ore

in half

thrl)ugh

a lOO-mesh sieve.

sample

iron

was romoved with

by hand

by fractional

from it when

in the sturtevant

Jones

grinder.

to 210 grams and this

The metal2ic

copper-

than 8 mm. were

by means of the

HendrickTBclthoff

sp~1t-shove19d

C~Ple-

was broken

pieces

The sample was crushed

cut

mine at

was halved

sampled by taking

was-then

th9 machines

as gangue.It

The coarse

and one half

Eustis

The ora was a massive

some quartz

to pass ~ 30 rom. screen,

spread

results:

'

PTovince of Quebec, Canada.

b9~ring

oxide

sampler

The pUlp

amount bucked

from the wear of

a magnet.

The pyri ta was analyzed for S i02' F~," Al~ 03 . S, and

Cu. The SiO

,combined

oxides

of irl)n p..nd aluminum

a.nd S

2

were ds.termined in one sample, as fOllowd:

A samp~9 of about

1n 20 c.c.

of a frshly-m~da

5/10 gram. ef pyrite

mixture

of three

was dissolved

vO~lmas HN03

(Sp.gr.l.42) ..and ons volume of Hel (Sp. gr. 1.20). When dieIntegrat1.on was c('mplata 50. c. of sod.ium carbonate

wers added.

50.c.

The whole was evaporated

Hel and dehydrated.

The residue

sOlution

to dryness,treated

wae moistened

with

with

5

lo.c. HC1, _100 c.c. of hot water were ~ddad, the whole heated

to boiling and the silica fl1tsTad off, washed, and ignited

and weighed.

A teat with HF showed that the 1ne01uble residue

was silica..

The ~11trata

we,a treat9d with bromine water to oxidize

oxides of iron and a.luminum ware precip-

the iron. The combined

itated

into an _8xces3

pouring the hot filtrate

by

filtering off the

hydroxides.

and re-prec1pitated

1'hey wers re-dissolvedin

with-ammonia.. This-second

filtrate

the washing ware added to the first filtrate.

was ignl tad anct weighed

determined

as

of ammoni~,

Fe2~3'

and

The precipitate

0t -Sulphur

9.nd A12

as Ba 504 by precipitating

Hel

was

in the hot

with Ba C12

filtrate.

Iron was determined from the second sample ofpyr1te

by

dissOlving

in the sa.me mixture

chloric acid as above,

ttm

carbonate,

of nitr1cac1d

and hydro-

filtering, fusing the residue with -aOdi-

adding water and suphurlc acid (cone.), evap-

orat~d until fumes are given off, passing through a.Jonas reductor and titrating with K~no4.

Copper was determined

third sample of pyrite. -It was dissolved

1zed with ammonia., ~ada slightlY

as above, no~tral-

a.cid with hydroch:toric acid,

.-hea.ted to b~11ing a.nd hydrogen sulphide

pa.ssed. in.

itated copper sulphide was filtered off, dissolved

acid and electrolyzed.

The following

S

eu

....•

~%

40.62

45.'11

81°2

,-

1.25

~"

,

10.12

Al20~

-

The precip-

1n nitric

are the results

analysis.

Fe

in the

. .. .........

'-

2.07

-

Total

to,'

.,...

99.17

~f the

6

The fluxes used were limestone and quartz.

L1mest~ne.The

was sampled,

limestone used was a very pure white marble.

It

crushed, and ground to about 30-meah 1n the sama

way as'the pyrite. ~he sample wag split-shoveled to 300 grams ,

and then bucked through

8

lOO-mesh screen. All metallic iron

present was ~emoved with a magnet.

The analysis was carried

out in about the same way as in the Spathic

ure, common in the InstItute

The analya1s

CaO

"

54.16

Iron Ore Proceed-

raboratories.

was as fOllOws:

MgO

FeO

8102

1.13

.35

.21 43.89

C(;)2

99.74

# Calculated.

Quartz ..The ~uartz was the same used 1n the thesis of Messrs.

Bradford and Gibbons, Jr., in 1908. The1t analysis gave:

%

~i02

FeO

A1203

Tota.l

96~'61

1.50

0.49

98.60

For use 1n the smelt the quartz was broken up by hand

.to pa.ss through

a. 30 mm. screen.

Fuel. The fuel used was Everett

bins. A sufficient

The fin(:)s ware not rt:3moved.

coke taken from the Instmtute

quantity was put aside for tha run and samp-

led by reservinga;p1ece

from every fourth shovelful.

le was broken by hand, then crushed

as thf; py!'lte. It wa.s split-shoveled

this

amnunt bucked. through

8.

The samp-

and ground in the same way

down to 100 grams and

100-mesh screen.

The fOllowing

7

is "approximate"

a~~1y;~1$ of the coke.

FixedcCarbon

Matter •••• ; •••••••.

6.76

Ash ••.••••••••••••••••••••••

16•22

%

%

(Undried Sample) •••00.92

%

Volatile

Moisture

I

The aBhg~ve,

A1203 MgO

r:f

Ie;

'6.39

%

••••••••••••••• 77.02

~2.~3

8i02

upon analYsis,

,

Al:?6~ .tBO~

Fe2<?3

35.10

32.10

In the subjoined

15. 75

Tota.l

. A1k s

4 .38

3. 75

Table I a.re assembled

100.00

the results

the'above analyses.

Si02. Fe

Maienals

Mot/e. oii3

of

-

hO h?zq C,O

MiO A~~

OH'"

55.32

(! ()z

o!Js

0

~g1

S

Cq Ni

Pb.

tJ':!2

25'.9'1 9. 5'~ 2,.3S'

.

.'i1J.lll

IO.lt

.

Pyritl!

,"

I

Lim~.ste

0.2/

«ifortz:. 96.61

ao/(@

A$h

32./0

2.07

"-

o.af)

.1/3.89

/.13

6Jf./b

'IS;1/ 1.2S

t

1.60

•

35'./0

For convenience

-

0._-

____

'.37

~-

, ,

.

h.

_.

0/19

__

$03

•

3.76< '1.38

2..53 /5".75"

in calculating

the slag the percentage

of magnesia and alumina' were changed ~nto equivalent

a~es of lime and added to tne

AIKs

percent-

CaO cOlumn. This was dona as

fOllOws.

Mol. Wt. of CaO,

. x ,'1 A1 0''= Equi valent

2 3 ..

MOl. Wt. OfA1 -.O

.....-2

3

%

of Ca.o

8

MO!.!_~

_?lt. of CaO x ,'t MgO

trOl. wt:"Ofggo

=

Equi valent

%

of CaO.

Table No. I .1a thus c.h:mged'a.s given below in Table

NO.

II •

S

au

Ni

0.71

25.94

9.54

2.35

52.22

1.13

45.11

1.~5

1.50

0.27

0.35

55.73

32.10 · 31.5~

18.53

Materials

81°2

FeO

Matte

0.63

71.12

Pyri te

10.12

Q,uartz

96.61

'CaO

.

,

Limestone

Coke Ash

0.21

1.50

)~)b

0.42

9

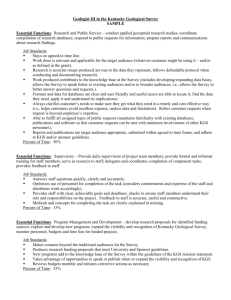

DESCRIPTION

The blaat

OF THE BLAST FURNACE.

furna.ce of the laboratory

is similar

to the

Arizona capper blast fu~nace. It cone1ats of a water-jacketad

bo11ar shell r&st1ng on four cast iron COlumns. The working

height 1s 46" and the distance from the bottom to the level

of the

tuyerss

is

14".

a ie-meter

The

at

the top

of the furna.ce

is 23-1/4" and at the bottom 17-1/2",

There are

seven

tuyeres -- four 1-3/8" and three

2" in diametar. The bustle pipe is 6" in dlamster. This ie

shown in the drawing.

The crucible was put in the furnace as f~llOws: the

bott~m

pl8,t'9 was placed

ture of

3

and clamped •. Then a mix-

parts coke, 1-1/2 part ashes and 1 part fire clay,

was introduced

into place.

tuyer'3S

in pos1 tion

through

cha.rgiI?g door

the

a.nd tamped firmly

The fu~naca was filled up to the leval of the

w1i:h thIs

ll19.terial

firmly

tamped down. Then

the plats

which closed the br~ast of the fl~nace was rem~ved and the

central p~rt of the compact brasque dug out leaving the cruai.ble. wi th the crose

eecti"n

THE

ahown in the

drawing.

BLOWER.

The blowar which supplied the air to the furnace is

a Root No. 1/2. It has a rated ca~ac1ty of 487 c\lbic fe~t of

•

1 .•

free air per minute. running at a rats of 325 R. P.M. The

bla.st

main is 6" in diameter.

lC

The vOlume of air furnished to the furnace was measured w1th a

Pitot

tub~ and two U-tube manometers , giving

respectivelY the static and velocity pressure heeds.

P

I TOT

TUBE. S

I,

I

22-

k

2.

!

Slots are in each

s,"de dlametrt"cally

"

K------- 2.1..

2.

Fit at A IN'dh standard

Sca.le -

rull

Size.

if" elhow.

opposite.

APPARATUS.

for

BLAST

Connected

to Static

MEASUREMENTS

Tube.

Conn~cted to Static

Cl

I)

9

Tube.

0

2.0

I.S

1.0

D.S"

Connected to

9

o

O.S

Velocity

StQtJc

Pressure.

Pressure.

e

Velocity

Tube.

CA!.,CULPTION

t~~ smelt

It wa.s decided

mntte

and pyri

O~P CHARGE.

a m1xtt1.re af equa.l pa.rts of

ta .9.nd to pruduc~

e. mette

wi th 30,:1 copper

e.nd

n1ckel •

.Starting

~ha mixture

contains 5.40 Kgs. Cu, 1.17 Kgs. N1 end .21 Kgs.

Tctal = 6.78 Kgs.

Pb.

Kgs. matte and 50 Kgs. pyr1 t~.

wi th 50

Cu, Ni, Pb.

These

6.78 Kg~. =

Hance

~(?'8.__ x 100 ;:: 22.8

3~~ of Wt. nf m~tte,

Kgs. 1s the

~.rt.

~f

matte

t.o

be

prcduced par 100 Kga. ore.

New 'S.40 KgB. copper

1.17

0.21

=

6.76 KgB.

CU2S

2.13

"

Ni3S2

"

"

Pb S

"

N1

-

"

Pb

- 0.24

- 9.13

Tota.l

Matte.

Th~ FeS in tho mette will be

22.60 - 9.13 = 13.47 Kgs.

'ro snPPly

th~ FeO nacessa:ry

£'r 1"

12 Kgs. coke per 100 kge.

me tte

A ft)rm~r

one showed th~t

run,

l

this

13.4'7 x

simila.r

in cl1.e,rf:l,cter to th{-) prf.lsent

an addition

of 12 Kgs. coks to 100 Kgs.

~f ore would supplement the heat generated

ien of iroD and sulphur

thitJ

FeO ~ ll.03

-peS-"

.

end pyr1 tEt werf; us ad.

-- hc?nce the

same

by

Xgs.

the c~mbuat-

&.mcunt of fuel

time.

The slag chosen had the f~llowing

S1 02' 36.8

1;

FaO, 51.2

%;

CaO,12.o1.

compos1t1cn:

It 11es within the

range ~f pyritic slag.

The tabla N~. III

ShOW8

that the proposed charge

12

contains 62.29 Kgs. FeO.

Frcm this

totBl "ri11 have to be deducted

FeO gC'ing

1.ntc\ the matte.

82.29

- 11.03 = 51.26 . Kgs. FeD to be fluxed.

equals 36.~ x

51.2

The Silica necessary fer this FeO

=

the number of Kgs.

36.84

Kgs.

Tabla Ne. III shows t~t

Rance,

51.26

to be Bupp:..ied

Si O

2

The quartz

thera is 6.00 Kgs. s11ic~ prAsent.

used conte.lna

ThaI"ef:'('~re quartz

the.t

equals 36.84

95.531

has

- 6.00

30.84

30.84 x 100

= 313• {ggs,

95.53

T~ find the CaO n~c8s8ary the silica w~a used as

thl9 basis

c-f calcnlation.

As sh~.~.n byta,ble

Ne. IT] there

a~e now present 37.20 Kgs. of 8100.

CaO necessary for this 1s

OJ

x 37 .20~ 12.14

_1~_

36.8

Kgs.

Ther8 ~r~ already prosent 1.37 Kgs. CaD.

rence the CaO to be supplied 1a

12.14

- 1.37

= 10.77

Kp-"s.

Th9 11mAstcn~ contains .3~1FeO. Ae this 1s equ1v~1~nt

to---x

12

51.2

5.5.73 -

d

.35 /-,-:FeO

=

4 CaO, there.

• 08

/.1

V

.08.=.55.65)1. CaO available

in

1s

the

lim€;ston€l.

R9nce, the 11m~stcn9 necessary to furnish the CaD is

10. 77

5:cr.es-

x 100== 19.36

Kga.

Kgs.

8102 t

ava11ab16

to bo o...dded

==

13

TAB LF

0,:,'

~

~

~

~

;

,

N

~.

~

,

~l l''i~

"~

~t::)

K O.

::

~

~

.......

~ ...

~

~

~

'"

~

~

~

~

~

..........

~

w

"-

~

~

6'-.

~

~

~

~

lo..:)

~

C\

N

~t

~

"N

......

~

~

......

~

'()

~

:....

~

~

~

~

~

~

......

\:}

....,:

'-)

.

~

~

~

~

~

~

~

~

~

~

~

~

~

"~

..

S\

~

~

~

~

~

CJ

;-..

~

c.....

~

N

~

':'

N

~

c:::i

t::)

~c:s

.ry.

N

.....

......

".~

>-

~

~

~

~

I::::.

~

~

~

~

N

tIJ

N

G'-

......

e'i

~

~

~

.~

~

~

~

N

......

b.

~

II..:l

~

~

N

c....

-Q...

~

~C)

~

<.r{

~

N

~

'.a

~

~

<%}'

~

.~

~~

*

!'i-

~

~

*

~

*

~

~

~

~

.......

~

~

~

"N

~

~

~

~

~

~

.~

"

<

l\J

~

~

~

~

"

~

~

~

~,

v,

"1

~

<

' ..

."i-

~

......

~

N

V;

~

~

a....

~

~~

~

~tJ..

......

......

~

~

--.0

~

C;'-

CS".

~

~

~

<:.tJ

~~

"~

"\

.....

j

N

~

~

I

''.~"

~

~

~

~

~

~

0)

~

~

~

~

,".

~

N

~

......

l- ~

~

~

:0...

~

N

~

~

~

~

~

~

~

~~

~

~

~

~

~

T 1J •

I

"

~

~

~

~

N

~

~

~

~

~

~

~

~,...

()

~

~

14

DESCRIPTION

rrhf:' fn:rne.ca

OF RUN AND DATA SHERTS.

bIO?'!"

was

in che.rg9 consisted

idual

and

ch€t,rge8

the

ing in charges

were the same

blest

tng fUAj~n.

The furnace,

was lighted,

later,

and. a gentle

ble ..st turned

the charccal

~nd coke

1-3/A"

tuyares

Charges

The indiv-

weI'EJ fad are

date sheets.

those

used

furna.ce

a tuyere

for

in

The blowthA

was inserted

'lre.rtf'

burming

freelY.

the

reducin charge,

in the t~p-hcle

'Then

furna.ce

E',.rd the

labora-

a normel

en. This was kept 'going

Ws!,'e ins art6d

until

the

run

four

a while

pyri t1c cl1a.rg-e. tJow the

~ere pu t. In ~n d t-Jhe

ttlteI"oS

~

matte.

filled with ,the blowing

l1nti 1 it got hot ene-ugh fer

th-,'.~,

~ng ~ 2 'f

9,5

charccal,

1Ai(.ct

in ~thlch t.hey

and feeder's

p

d,

kindling

(n~d51

fr:r blct1, 1ng in the

AM • The blowing

fine coppar

scm$

weigher

shown in th~

tory'

lnd

n e..t 8.45

pp...per,

~f

c~ke, coppaT slag

j

regu 1aT pyr it.10

cf 100 Kgs. cf ore and flux with 8 Kgs. of coke

fed.

DUl':fng the ~tln the f~1lcw1ng

eratn:re

of Je.ckat

water

at

r~e.ds wa~e taken:

1n:..,(:t C'.:.nd outlet,

and vel~ci~y

.h~eds cf th~ b~ast,

cubic font)

in the air, barometric

Ie temp~re.tura,

at

th~:. tempera.ture

and

,.na.tar 'Nas mea.81Jrt~d at

flew

during

tC"inE'4d frt:m

e. ha.lf

evary

8.1~r: m~'de during

m~i6tDr&

intervals

minute.

51ag

th~

part.

run.

Chilled

ot~_tic

(Gra1nG rer

prEssure,

0':'

the

temp-

etmospher-

e2,ag. The Jp-.ck-

by weighing

t.he CVf;r-

alE4..g semplE'S were

1'wo flt".e gfia ana.lyses

Gb-

were

15

'Phe fUrni\Ce

fluidi

worked vary well,

ty and th0 sam!

n. vs'!':y 18.re~~ amcpnt

formed

"1'8.S

1n the furnace

we:r(i black

mf.'lst 'cf

W8,S

the

the

the

case

produced.

sla.g shewed grea.t

wi th the

mp..tte of '"hlcll

An artificial

bosh

e,s shown by the. dral},71ng, the

time"

but

th~

blast

WEtS

tuyaree

penetrated

th~

walJ. accretion without difficulty.

The run le.stad

materials

till

2.15

p. M.

fed was 230 Kgs.,elag;

Kge., pyrite;

139.9 Kgs., quartz;

~nd 84.1 Kge. , coke.

The total

e.mc.unt

236.8 Kgs., matte;

72.1 Kgs.,

of

216.9

11meBt~n6;

16

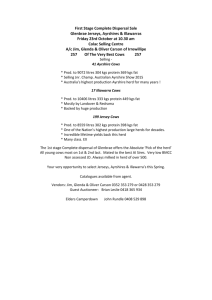

WEIGHER.

Titne.

w.

Chqr~e

Ore.

Slag.

Mettte. Pyrite.

No.

Flu x.

Quartz

3b

SO

..J

If

9. If)

J.f

If'.

1,20

S-

I~.

'1,tfJ

/:;

~.:.

33, 33,

21.3 I ~. 8

JO,on

1

~

33. 33.0

2-\.3 J?,f6

. lo~) 7 g'

/,b 4:7

20

d

~o

(J

(j

I//?r~

CI"

It

(

,

t,

:}'}cO

JJeO

')...1 t.J , l ~f

1. r

:3(0

33:0

::2/0

("2 ~g

:2.[ ~3

/~Jb

\

~1..3 I~'~.r

(,

0

.33,() 33cO

~',

:3~to. 3JO

I /,45"

} ~ . If-

1:<'Ll-3

/3 fl.

~

/00

~

tI ~(55 1°

J 1.15 I,

-

t ure.

J

2-

,

Signa

Limest!

J

)

8.11- ~~

r

Coke.

/2 c; '1 J~/

.

6 J ~_,~ 1~,<1

J~.J

].3

_;f'

!D

v

eo

\of

\.

~eI

PI

/>~

r;..,~c:..r

r~~

,

¥ .-S?

c.t!,~]Rii-

r

1C,f1

J'

~'''.I~

wr

17

:FEED£R

I

1.

t/

/'

~

- 0.31

~/O. J

S- 3

6 !l,'b(If

7 I,

~ I~~C/

ff 1/

v{~S5

9

/1,3

10

9.~S-

l~

:./

/'2.0

If.

"

/z,. Z3

/1-

12,'1-3

/.3

/"Z15

/e

Cot¥

fA/:

G

1

t ,

,"

I.

Cot

I,

,r

/

,,

t.

,.

'

I'

I

,/

,3

2~o

1/

II

I,

w~

r

I' C ~ 7411]

Z"Z

0

cU-

2J '",

4-

..

,

/,{/

11.;:/(

y-

."

'-

(f:~

~

I"Z.°f

Wr

, £., .I1!;)'

,?~~

,

(}wo~~

t'WtA:.4 J

~

II.sS-

18

TAPPER.

ASS/~TANT

Time

~

S'totj

o/:~~

J"; S

' 3~

fO,'OS

{;,t(r

,st

/O.(CJ

, . If

.j ,

It) J '"

'If

I

'11

it)

/~,''i'l

I~:J{?

-

1~:.J.r

1/; /

II;

f-

~fL

II,' 3/

1/'. j t

,

..

0

/J. 1/6

J.'!~

,.rr;

,.elf

CJ 7r

· 6 tJ

{,7tJ

...

/..2 .' .z 21~,'.J2

lll,'tf If

/:;:JJ"

/:

-

f~j

. CtJ

/ p

/ /.;{

7

_/:J

(rx.. j,\rs

~

) ~. a r

0

J,.Jr

.(fer

12..~/

tt.()

/J~ I

bJ:

..

f

~:;.

~I

t.~

ff!.'()

I(

qJ:'r

7.(/ 1(.

/).rJ

1;"/

1

,r;~

9) C{ 0

/2.'0

I!)..

,tf:J/.()

f/. j.'

$f.tJ°

,

t.rl(

II

I

2. j

/2,,1/

I

"

r'

~r,()

'I

"

'1. (/

61-d

'1

6{.(

/1

'f

6%,1

fIe ~2/(. / t I

/.2. /

~f. dO

6(.0

6f.(J

1

P 3. J"

1tJ 1(;

7~.;

1/

0

6r:7

1()./cl~

t rC.29

(

• IP 7...

I'vl(

'/

67'7

/2,)

,

II

(tJj]

?,2.~d

..&

If

()

It/

o.

II

IJ.~/ 6/.j

).(, / ct,tJ

6 $0)-

.(,1

'I

tI

/,j..(

. ~ 2-

'I

()

'/). t! d

7;,'dJ-

70S7. err

U/fo

6'Jj.

rer , 6 i

,vi

'J~

7-1' r .• (p I

. (''210/1

-.,/

/.2./

,(,2,

If

6f~

12,/

()

'1J~ TJ

7.

"76""

c3.7

()

,S1

" 'J/~

()

[)

1)q,

fj~P

11,'1/7

t 'f

/.2; 0-0 '.7/

/2./

rf lt~o

' ;-1

l(J"

(l

--0

,3Z

I

If'/"

6J. ~

5.~

~~.r

,/;, 10

( 'jJ II; 0 3

•

(if

C.J.f

)p.'1(1J

d

'.

I ()::L?

~f

71~

1"b:t

"

71.

:L

':17

6, P;-

jo ~'Ib

l~. S()

5/°

(PI

(,'/0 {/

•~6~ ~:l. (P~'6

0

r.I((

/1../

1).6

1.7-~1

I 'l-. 0

?'f IJ~ ~

7().I

/ ;2. (

/p. C/

/:2.(

b!,f)

1)./

&6'7

I,

'/

'I

r/

f'

"

r

19

TAPPER.

Time.

TQP' Plug.

~/QPsed

of Tuye,. es. Slag Note~.

Appea.ra.nc~

Time.

2. d.

I.

4.

s.

6.

Si9nature.

Remarks.

7.

r~~

'<:$ • J-f a

,ne

ir/14-l

~.c.:.

ft. ,4. /If.

~

,-

~~J~

/ I- .:z

9,$0

9.S-~

I().

0 1-

/(). 04

9',16-

Hlh,~,

1'1..

r~~

r

/0.7>3

J 0. J

IIJ.'f.}-

lo.f''?

1~

~~~

>T

/1).

/1 tJ:!:.

1/. /L(

/ I. 2lf'

tJ;;;Z;

lo.s7

I ~

dt di

11,°'1

/

/1.

I

I J-

It

,r

'r

I

,, ,.

ILJt) ... If - 31:-

2

hit. M ~

II 3'

I

II. If 6

/2.cI"])

j:J.""

/1. ~ 2

.12.32It.

c./\{

./'l.S';

1./0

/1.2'

II. /19

"

' l/7

/2.dl

I

I

..,, .,,

..

',

,

.

/2.17

/

'

/2.2-3

(

M

/~.

13

I

t(

11..,0I 2. S"/.-

/

f.lf

,

')./;

I

,

1.1~

1/31

/

((

,'

/. tS'

2-

II

II

r

I

,

I'

..

.

0 •

In

f'

I'

,t

"

dJl,

dA 4

,,

,.

•

Ir

,-

,.

-

"

.,

I,

f-

'

.

..

,~

,,

..

.,

.'

"

.,

\0 •

,,

"

"

.

~

,,

II

t

.

(

~

..

.. .. ., ..

I •

h

..

.

~~.

~~

,.

..

"

41

I

.

..

\

7

" ~~

,

',

. "

I I

.

'

~

. . ..

"

..

..

If

...

"

~

h

..

tJ3 w , 'L.A

r1l

Il. u

"

~

.

Ii,

h

M M-

..

,(

,.

J,

~

,

I'

"

I.

1.2S

- I.

"

..

~r

,,

.,

",. ,,

,' ,,

/

JJ. di

~

•

',

'4 •

..

I I

.

,

,,

• I

.-r/

20

SLAGMAN.

Tilne .

J

3/0,9 HY9rom.

No.

9.50

/

O.C2

2

8qro/n.

Read/119. Pressure.

~ q .«)'~'.

71,ick - Qu-.te.. \Nqrrn

R. L. 73EA /£8

3 q. SO

29.~<&

H 6t - 7J1()r~ f/~

R. L, _ 73t~A If S

10.13

+-

10.20

cF

"

10.210

7

''1S

9

"

I D .4--tJ

'0

"

If] 6T

Ii

/1.1Jl)

/2

If. 2. 'I

.Ll.'!: (,

12.

t1)J

. /2(1;

~fO

~

..

~

t

,-:3

41(

/.1{

If'

/"'1

-l~

#J

"

"

r,

.

.,

-

t

I J..t/y

2.3

2'1

I'

I.)D

..2 ~--

"

J. :1,.)-

2~

I"

7

.,

t

7710. ff-c.

,,

0

.,

.,

..

..

"

"

If

.

~HY /'r;d-

,

.,

..

"

, «

~(

rlJW~

re. ' ~

t13W~

~"

f

M-

1'~

, ..

~

/t.b7n:/' C

Z;r/:J.;/~

''

7~

"

('

,,

.

'f

,

\

"

f

f •

I '

,,

• I

II!Lo°e.

I(!J

D

1/ lfD

"

'

'r

«

I'

"

'-

~

.f

I'

flu,oJ

frs

..

,-

...

,

.f

"

tfJrr

g." ~

id-

I •

f f

_ 212.

2i

"

It'

.L2..3 l

,.S" 3

,-

, f

/1

2

,.

.,

f

9.1

7

.,

I~

12.,1

13

'.

66i

'k

~ 12.Ft'

.

,

, I

:ll(, If

W-=-.J_?"'- _/-6 .....

II. '3 ~

S-O

,.

11J.!J3

/ '.D 3

:~/-'-::IH

St"9nQ t vre.

4/.3

'-J tJ.

Ill. , () 3

. Rema.rks.

f

I'

II 'fo

/4,30

t'

-t!:.f O'c./~c f rowe ri...,!!n

I'

,

....!......

h.3~

fOP"CIE

r

cJ

tf.

f,

"

die"

,

~

~

f

.

21

CJ~AN

UP.

The products of the smelt were divided into pyritic

slag,

matte,

pyritic

matte,

preliminary

final slag and oddA and ends. Towards

And

prelimine,ry

the end of the pra-

I1mlnary run~ the pots were kept in the order in which

they' were filled,

slag

so a.s te keep separa.te

a.nd matt frc,m the

pyritic

when COld by the difference

The preliminary

end

the pT€tlimine.ry

to distinguish

and

in appearance

them

of the slag.

also the final slag were black in

cOlor, vitreous in lustre while the pyritic slag wes black

but was dull

and non-vi treC'u5.

Al~. the roatte

produced

after that which had been fed ~1th the blowing

in charges

",'

~.'e..s cons idered

be pyri tic

t(l

me.tte.

The odds e.nd ends

included the crnst forming the. bOsh or wall accretion,

the matte-soaked

portion of the crucible, and the mat~r-

1al drawn from the furnace

the unburned

It

ina~y

WJlS

decided

last

tap

not to se.mple and e.na.lyze

matte,aE,be1ng

sqnalin

1t probablY

excepting

...

excepting

took up frt"m the

the

pra:!.im-

to the matte

the

was assumed tc

amount

blowing

added

in

of cnpper

Rlag.

ware broken by hand t" abc:ut egg-size

products

th~n sampled.

weight

run, 1ts compos1 tion

h9:ve :remained nncha.nged.

other

the

coke ~lh1ch 'lITae picked out by hand.

dU.r1ng the prelimin.ary

.that

aftt~r

by

fract1?nal

All

and

selection. A hod of each was

preserved as a sample, and a hodful crushed, ground, and

bucked to pa.ss a lOO-mesh screen 1n the same way as was

done w 1th th~ samples

of

,or6

fOl'

the smelt.

Analys.!~_E!

PrcduE.!:!.

of the

The prOducts

22

:run were ena.l-

yzed :for their copper, nickel, and sulphur contents.

'In additiC'n,

the

there

W!/re

detE-trmined,

iran .. in the chilled

in the pyritic

sample of the pyrlti'c

me.tte,

slag:

the

I

FeO,.Si0

CaO, MgO, and A1 0 ' The methods of analysis

2 3

2

were similar to thode used with the raw materi~le of the

smelt. Some difficulty was experienced

ccpper

electrolytica.lly

in determining

in the pyritic

the

slag and. in the

cdds and ends. Tha ~esult6 ware checked by the method of

ttration with potassium

iodat~ (KI03)dev1aed by G. S.

Jamieson, L. H. tevy, and H. I. Welle a.~d published in

the

jC'ul'na.l of .the American Chemical

Society,

1908, Vol.

T, Page 760.

PRODUCTS.

Materials

Matte

Slag

Odds & Ends

Materials

TAB!,E

S

Fe

8.73

1.95

26.25

0.76

O.~96

2.75

0.28

0.00 . 1.48

1.59

0.29

S

FeO

~..

NO. IV.

58.65

2.51

8102

CaO

~

,

Pyritic Slag

Chilled Sample

--

MgO

A1203_

\

2.57

28.80

37.35

18.34

0.86

4.61

-

23

GAS

C02&~S02

ANALYSIS.

N

CO

0

I

19.6%

0.6%

1.a%'

78.0%

II

20.6~(fIf

0.4%

3.4%

75.6%

No. I'

802

0.35%

No.

II

0.15,%

24

ACCOUNT OF STOCK,

Th~ blcwlng in charges contained 20 Kgs. of matte,

th~ ana-lye is ()f ~h~ch was n~t known. For this

reason,

e..

complete acc~unt of the copper is nnt possible •

. The first

m9.tte mixture

w~.s assumed.

20 KgB.

and foul

to conte-.in

~ther products.

of me,t ta' produced

slag

used

E:2~11copper

resulted.

from the

in the blowing in and

not ecc~unted

for.

in

The balance sheet was made, using this

~ assnmpt1r.n.

The balance sheet of sulphur wes calculated onlY

forthe pyritic nln.

25

BALANCE SHEET OF MATERIALS.

-

NO VI.

rrA'RT.R

Materials

Wt.1n

Fed

Kgs.

Matte

Fyri te

Matte

Copper

%

216.8

216.8

.

lO V.L--

:tl1ckcl

..A

legs

Total

9.54

1.25-

20.68

2.70

CSU.7":J

0.67

2.22

.

wt. kg.

ci

I'"

o~rTotal

c

/0

~oo

--Z. Dff -. b. O~

10.54

20~(

Mix

330.0

Foul SlRg

8.6a

I

I

Quartz

139.9

Lime!1tone

:

84.1'

160.6

Coke

.

I

Total

1168.2

25.60

#

i

as it was decided

This analy~is unknown

5.09

. i

just before

the

run to add the matte mixture.

!,ABLE NO. VII.

Wt. in

Materials

Produced

Copper

%:'

Kgs.

Kgs

.

20.0

Prelim.Matte

18.89

1.90#

"

.

73~'80

0.76

1.95

7.62

255.6

0.28

0.72

2.81

134.4.

1~59

2.14

8.36

-Odds

.....,

~,

,

--" .....

#

Si~ce

the

a complete

eu

%

10 of

KgA

'ota]

88.65

1.95

4.22

0.06

0.15

3.15

0.29

0.39

8.20

.-':.'.

88.24

Total

Nickel

7.41

~Yr1t1c' Slag 256.0

Prelim &: Fin •

Slag

& Ends

I

'--:.

21.6.,.,4 "a~ 73

Matte

.

% cC"f

'Tota:!:

-

.

.

1---

in the matte

account

\

4.?6

25.60

.

used when blowing.

of the eu is not po~sible.

in is

notknown

*", ..-, •.

26.

:RALA1~CE SHEET OF SULPHUR.

TABLE NO. VIII.

I

"

twlaterials

Charged.

Weig;ht

%

Su1'Phur.

wt.Kgs.

25.94

56.24

Kga.

~atte

216.8

..

Pyrite

216.8

45.11

J

Goke

52.6

7" of total.

~

---.-..

36.50

.,~,---"._-------._

--,

0.14

•

63.46

97.80

~.+ ...............

-

d

0.04

0.07

-rotal

486.2

---

TABLE NO.

rMaterials' .

~roduced •

~att'e

154.11

100.00

---

,.

IX.

Sulphur.

Weight

. Kga.

216.4

%

wt.

Kgs. ,

%

of total

-.......... -

26.25

56.'SO

84.49

-..

Pyri tic

Odds

Total

Slag

& linda

256.0

2.75

7.04

10.50

134 •.

4

2.51

3.37

5.01

67.21

100.00

606.8

27

CALCULATION

OF THEORETICAL

FORO~~

BALANCE SHEET OF MATERIALS

PYRITIC CHARGE.

There are three methods of calculating

a Theor8tical

Balance Sheet of Mat~r1al. They are baaed on, (1) total

materials;

'~matsI'1ale

(2) definite weight 'cf me.tte produced;

of

9.

(3)

single cha.rge.

The irregularities

in ths running of the furnace dur-

ing blowing in and blowing out make it difficult to oht~in reliable data fo~ these two periods and also to de.fine the limits ~fthe

fOT m~{1ng a definite

(tf calculation.

The same hOlds good

run proper.

of matte produced, the basis

am~unt

In the third method, these errors are

avoided, as the calculation3

are based upon data taken

while the furnace 1s running normelly.

chosen fer making a theoretical

It was the~fore

balence sheet of material.

_Since the hea.t requirE.\d to smelt

the charge

depends

largely upon the form in the elements ara chemically

com-

b1n~d, it is necessary to calculate a rational analYsis

Of the materials, cha~ged.

Matte.

.

iron

Frc:m the analysis

This- is done

as

fOllOWS

=

o:r the ma:tl:1eit is known that

the

is pre8e~t as FeS, FeD, Fe304aDd the remainder is

assumed to exist as metallic iron. The amount of oxygen

present is assumed to be the per cent not avountad

1n the chemical analysis. With these assumpt1ens,

amounts cf FeS, FeO, Fs 04and Fe

3

fCl1cws=

for

the

were calculated as

28

Iron present is FeS.

This 1s feund by ca.lculating the sulphur necessary

un1 te with

Ct2

s,

N~

the

Cu,' r-r1,

andPb

present

to

to form

r

s~

and 'P~S I~d

assuming

the rema.i ning

S to

exist as FaS.

, Total sulphur present = 25.94,1

,S as CU2S

N13Saand

=

Pbs

3.34%

S to form FeS 1s 25.94 - 3.34 ::;22.601

F~ &quival~nt to this Sulphur as FeS

~}'

x 22.60 == 39.46.%

FeS present equals 62.08%

The amount ofFaO

,1s

present 1s determined

in the:'~.rat10 40 to the

..

30

silica.

by

present,

assuming it

that

i8,

tha.t

it ia 1n the f~orm of slag pelJ.ets.

Silica present equals

.6~~

FeG present equals 40

30

,x. v=.8

4~

p

to .65% iren and .19t Oxygen.

This 1s equivalent

The remainder

6~

of the iron

exists

as 'Fe304and metallic

Fe.

The amonnt of "oxygen in t.he Fe304 is obta.ined by subtracting from lO~~ the total percentage

a.na.lys 1s (95

.1~7 )

This

:.,.70,1: a.s the

leaves

and the percent

amount

as found by

oxygen in the FeO( .19%> •

of oxygen

combined

with

iron in the form of Fe 0 •

3 4

Fe 'in Fe304 that

,1s equivalent

to

4.70,'1 0 = 12.34%

•

This gives 17.041 of Fe 04 •

3

,The remaining iron is the ,metallic iron and its

c~nt is found

by

subtracting

from the tot~l Fe, the

amount present as FeS, FeO, and Fe 0

3 4

•

per

29

Total Fe equals

55.32%

Metallic Fe equals 55.32 - (39.46

The Ala Oa,Ca

0

12 .34 )

.65

and S1 02 a.re assumed

=:

to exist

2 .87%

in

that form.

Elri.!~.The pyrite contains 1.251

exist as CU2S'

the

eu

which is assumed to

~he ram~1n1ng S is conBider~d to be in

form of FeS a.nd FeSc:)

, the a.mount of each qei ng ca,lcuIJ

lat~d as fOllows:

S as FeSand

Fe S~:::

.,., tota.l

S - S

,

CU2S•

8.S

Total S equals 4;5.11%•.,

S as C'l2 S equa.ls.

32%.

S as FeS and FeS2

=

Fe as Fee and FeSa

Now

1.at X :::

;t

= 44.79%

45.11 - .32

= total

Fes,

•

Fe :;::40.62%.

then ~

X=-% S a.s FeS.

88

= ,"/Fe~,-G

" Y

Also

the

.~ FeS

-t-

"

64

12v

-,,-'

.1 FeS 2

= %

Y -=

%

Fe ..,...

S as Fe S 2

%

S a.s

•

FeS

and FeSa.

(1)

=

S as FeS and FeS 2

(2) X -r

r ::::40.62

From equations

.:!,FaS

,e:!.

=-

FeS2=

=

+

44.79

64

120

y

= 85.41

(1) and (2)

:::.. 4.51%

X

Y

=

80.90%

assumed to

.83;~ unaccounted

for

ed to be water of crystallIzation

cate.

32 X

88

The A1203' a.nd Sf 02a~9

The remaining

44.79

exIst

in

that

by a.nalysis

form.

is

assum-

in the aluminum sili-

30

Qua?tzt'he

form.

Si~

, FeO and AJe

ca

a.re assumed

to exist

in that

The rem~ining 1.40% unaccounted for by the analysis

1s designated

in the table

~ro. XII as X.

1s assumed tc

It

be slag-forming material.

!'imesto~.

The CaO, MgOt FeO,

a.nd Si02

are

as obtained by analysis. The 44,15% unaccounted

re corded

for is

assumed to be CO •

. 2

The proximate analysis

Coke.

77 .02% fixed

ba.sed on dry coke gave

ca.rbon and 16.22,% ash.

The sulphur

in the

latter probably exists as 503 (.6~~).,The S03 is VOlatile

at the furnace temperature leaving 15.61% of Blag-forming.

The 6.7~~ unaccounted for is the VOlatile mat-

mat8Tiel.

ter in the coke.

of coke,as

The moisture accompanying

obtained

Calculation

by

analysis,

is

the 7.91 KgB.

.73 KgB •.

of Blast.

There are two methods of c8.1cule.tion of the blast,

using the

flue gas analysis

end

one

the am~unt of carbon per

...

charge, the other

by

means of Pitot tube measurements

velocity hea.o.and

static pressure head.

of

Method Ueing Gas An~lYsiB.

I

The VOlume of flue gas is first calculated

ing the total weight of carbon in ons charge

'of c'a.rbon

Average

CO2,

( as

CO and C02

3

) in I-m-=- of

by

by divid-

the ~e1ght

ga.s.

Gas Analysis.

19.85;1;

CO, 2.60,4;

8°2,.2.5,1;

0,.50%;

N,76.80;(.

31.

3

C in

1 m

In flue

of flue

=

gas

(;I

of C02 In flue

% eo

gas

x (Wt. of C in 1 mS of CO or C02

gas)

under

ste~n-

ds.rd conci t~ons) •

Wt.

of C in

C

1 m 3 of CO or

"""""

CO2 under

(.1985

gas::::;

fl'l't9

Carbon ant~rl ng gas frcm coke

..

"

"

"

Total carbon In gas

..

"

"

..

C

=

6.09

__ -= 63.58 m3

.026)

=

12

44

introduced

ondi t1

.54

x

one:=. 54Kg.

=

.12 Kg.

(See TabIe XI I • )

6.09 Kgs.

T

1.54

x 5.64

:=

1.54Kgs.

at

I

7.,63 Kgs.

::::;

oOC

mm.

and 760

•

.12

It was e,ssumad that all the ni trogen

was that

C

from coke -r- C from limestone.

=:

Volume of flue gas per charge

= ~~

=

limestone

,

standard

in the flue gases

by the blast.

VOlunle cf N' ::::

.~N in flue gas x volume of flue gas.

=

VOlume of N

.768

x

63.58

3

m •

:: 48.83

VOlume of air _ VOlume of N

N in air x 100.

- ~

of N 1n air _

Vt;')lumeof a.ir to

t!!

79.2.~ by vOlume.

3

furnish

48.83 m

N equals

3

~~~_x

(9.2

100 :::61.65

3

'Nt. of 1 m

"61.t3S""

..

dry

..

m

air at

"

"

0

dry air a.t 0 and 760 mm.

0° a.nd 780 nun.

"If

"

"

"

=:

1.293 Kgs.

,:::::

79.71

"

Condl t1 ons at

time of run.

Atmospheric temp. -

'e90

F

.=

20~5

C

Barometric pressure = 29.90

approx. standard.

3

0

61.65

m dry air at 0 and 760 nun.::: 293.5

tt

= 66.28 m 3 dry air at 20~5 C and 760 273

mm.

x 61.65 '

The moisture acccmpanying

this air is calculated as

. fOllows:

Hygrometer

readings

gp..ve

;3.6 grains

wa.ter to cubic

foot air •

.. 3

3.6 grains par cubic foot equals 8.27 grams per m

VOl. of blaat x Kgs. H20 per m

in bIe.at per charge

"

"

"

"

•

86 •2~ x 8.27

1000

_

=.55

Kge.

3

H20.

Method using Pitot Tube measurements.

The vOlume of the .blast.was calcule.ted from the Pitot

tube measurements

as fOllows:

Vol. of air

croas

section

furnace

=

pe+harge

of pipe

) i.X)

(Vel. per Sec.)

of one charge

(

x

(A.of

in passing

through

in seconds).

The veloci ty 1s calculated

where h 1a the velocity

VaJ..Oc i ty

head

==.61"

Water is 772 x

by the

formula. V =

V2

gh

head in terms of air.

.:wa.ter.

as heavy as air at 0° and 780 mm.

Therafc-re velocity

=

head

.61 x 772 = 470.9" a.ir

39.24' air.

==

"(

,

I

Substituting

in the formula

~--

V::

-

V 54 xl~.2 .~~~; = 52.08'

per sec.

Area af cross section of blast main

=

.195 sq. ft.

Rate of charging equals one charge in 21 minutes or 1,260 sec.

Static

pressnre

head == 8 .97" w~ter ~ 1/4 lb.

Therefore Vol. of a.ir .par charge

=

per sq.

inch.

:::: 52.08 x .196 x 1260

12A65 en .ft. a.lr at 26'.5 and 1/4 lb.

33

o

cu. ft. air at 20.5

12865

364

m3

"

..

..

..

"

II

3

and 1/4 lb. -

0

364 m at 20.5 ~1/4#

0

ai r at 0

344"

a.nd 760 mm.

NOTE.There

is a gre~t difference

the vOllmes of air

between

'obta~ned by the two methods. This is due either to

of the Pitot tubas

gas samples or to the lack of calibration

or to both.

The vOlume calculated

was used 1n the calculations

Pitot tube measurements,

faulty

from the gas analysis

, and not that obtained

as the gas analysis

from the

had to enter

the "calculation of the heat balance.

The materials

are distributed

under the heads of Matte,

Sla.g and Gas. The copper,

nickel,

a.ndlead

as entering the matte,the

small amounts

matte

figured

in t~e slag are

\

a.SSUIntllO.

ar~. all

to exist there as matte -particles'.

of

The weight

produced from one charge was calculated

from the

weight of copper in the charge and the per cent of copper

in the'matte produced.

The.weights

of iron and sulphur

entoring the matte were calculated

frcm the analysis

m~.tte fo~ed.

notentsrlng

All

solid

substances

were assumed to form slag and the remaining

of the

the matte

vOlatile

and

combustible matter to enter the gas.

Wt. matte

produced per charge - wt. eu ner charge x 100

- nu1iil:matte-'-•

Wt. Cu per charge

=

3.55 Kgs.

1Cu in me.ttet=8.73%.

34

Matte produced, per charge;

The sulphur is

x 100 == 40.67 KgB.

~..!~~_

8.-(3

assigned as follows:

The Cu

S ,Ni. S

, Pbs, and FaS (amounting to

2

:5 2

27.82 Kgs) ~ were assigned to the matte. Thess conta1nad

9.20 Kgs. sulphur. The sulphur in the matte produc~d is

25~25% (by analysis). Therefore, the 40.67 Kgs. of m~tte

contain

10.88 Kgs. sulphur.

furnished

==

10.68 - 9.20

This 1s equ1va1e~t

The amount of S still to be

::= 1.48 Kgs.

to 3.87 Kgs. FeS which must be fur-

n1~hed -by the FeS2 ."

The remaining sulphur is 3.asign~d to the

gas.

The iron 1a assigned as fo~lows:

The total.iron

entering the mate as indicated above

equals 16.30 Kgs.

The matte prOduced

magnetic

dete:rm1nad

Total

both metallic

iron and

oxide of iron. The am~unt of the latter was not

but is

to correspond

estimated

wt. of sulphides

The weight

contains

=

31.29 Kgs.

Fe and Fea 04= 40.87-

Wt. 0 in ma.tte

_

This. is equivalent

Wt. metallic Fe

to 3,~ of oxygen.

.03 x 40.87

31.29

=

= 9.38 Kgs.

1.22 Kgs.

to 4.42 Kgs. Fe3 O~ •

= 9.38

- 4.42 == 4.96 Kgs.

The Fe3 04 ia assumed to be supplied

matte cha.rged. The remainder

by

the

of the la.tter

F9304

in the

Fe 3°4 1s assumed

to be reduced to FeO and 0 and to enter the slag ~nd gas

35

respectively. The metallic iron (4.96Kgs.) is assumed to c

come from the FeS2• Of the FeS2J 8.63 Kge •. (4.96 Kgs~

aR Fe and 3.Q7 Kgs. asFeS ) enter the matte,.

The Fe

(5.30 Kgs) is assigned to the slag and remaining S (I~.74

Kgg.)

to the gas.

The assignment of the remaining materials requires

no'comment

~xcept that of the 1.76 Kge. of 0 from the

blast which is assigned to the slag. It~is the 0 required

to oxidize the metallic

iron from the matte charged and

the iron which enters theslag from the FeS2.

38

THEBMAL BALANCE.

The figures used for heats ofiformation,

specific heats,

etc. are~tho5e ~iven by J.W.Richards in his ~Metallurgical

Calculations".

Those marked "approx~. do not apply directly

to the materials

in this case. Eut since determinations

specific heats, heats of fusion, etc. on thedifferent

erials were not. practicable,

of

mat-

figures were selected which

seemed to apply most nearly to each case.

Heat Generated.

(I)

Oxidation

C .to CO2

e burned to CO2

=

(8100 Cal. per Kgs. of C)

(Vol. of gasX~

CO2 X Wt. C in

m3 CO2) ~ ( Wt.

C

in

CO2

1

from lmste)

~3. 58 x .1985 x •.54 = 6.83 Kgs.

6.83 - 1.54 =5.29 Egs.

5.29 x 8100 = 44,'93 Cal.

(2) Oxidation

C to CO. (2430 Cal. per Kg. C.)

C burned to CO

=

Total C in. coke - C burned to C02.

6.09 -5.29 = .80 Kg.

~80 x 2430

(3) Oxidation

% S02

in

=

1944 Cal.

S to 802 (2164 Oal. per Kg. S )

3

gas x m3 of gas =.m of 802 • (Gas analysis)

Wt. of 1 m

:3

H x Density of 502 x

.a...

:3

= Wt. S in 1 m

802"

of ~2.

3

.0025 x 63.58 =.159 mof

50

2

.159 (.0896 x 32 x 32 ) = .22? Egs. S burned.

This does not agree

the theoretical

wyt~ theo!

S assigned to gas in

balance sheet. The difference

is .assumed

39

to have been distilled

off as free

sulphur •

•227'x .2164 = 491 Calf

(4) Oxidation

of Fe to FeO. (1173 Cal. per Kg. Fe.)

5.30 = 6:25 KgB. (See

wt. Fe oxidized = .95

Table No. XII)

6.25 x 1173

=

7331 Cal.

(5) Heat ot Formation

of Matte.

All copper and iron ex1stas

sulphides

The:.heat of union of FeS andCu2S

=

43.59 x 150

i8 unknown.

of Slag. (150 Cal. per Kg. approx.)

(6) Heat of Formation

Wt. slag made

in the ore.

45.59 Kge.

=

$53~ Cal.

o

(7) Sensible Heat in Blast at roam temp. (20.5) (Sp.

Heat .25 approx.

)

Vol. x Spa Ht., x Temp. = 66,.28 x .3036 x 20.5. =

413 Calf

(8)

Sens1bleHeat

in Charge at

room

o

temp. (20.5)

(sp. Heat = .25 approx.)

Wt. xSp. Ht. x Temp.

=

107.91 x .25 x 20.5

=

553 Cal.

HEAT ABSORBED.

(a) Reduction

of Fe304 to FeO. (1023 Calf per Kg. FeO. )

Wt. FeO from

Fe 304") = 1.llKgs.

1.11 x1023 =ll35'Cal.

(b) Reduction

FeS2 to Fe (428 Cal. p~r Kg. Fe Approx.

)

....

The heat of reduction

Since it probably

of FeSs! to

Fe is not kn.own.,.

is not much larger than FeS to

Fe,

49

the latter figure is used.

wt.

Fe from FeS2 =

constituents.

10.26 Kgs. (See distribution-of

matte

page 34.)

10.26 x 428 = 4391 Ca1.

(c) Decomposition

#

(1026 Cal. per Kg. C02)

of Limestone.

.R Figure for CaC63 to CO2 used since the amount of

MgC03 is small.

Wt. CO2 from

=

CaC03

5.64 Kgs.

5.64 x 1026 = 5787 Cal.

_

(d) Heat

in Slag

0

( Temp.• = 1130

C. )

o

Hea t in melted

a t l~OO =: 300 ..,Ca1. per Kg. (approx.)

slag

43 .59 x 300 = 130'(.'"

Cal.

o

TQ

heat .from 1100

0

to. 1130 C. (Sp. Ht.

= .27 approx.)

43~59 x .27 x 30 = 355 Cal.

=

Total Reat = i3cf'1' + S53)

(el Heat in Matte.

U4.3Q CaJl..

o

(Temp. = 1130 C )

0'

Heat in melted matte at 1000

=

,

200Cal.(approx.)

40.67 x '200 = 8134 Ca1.

o

To heat

from 1000

0

to 1130

40.67 x .285 x 130

Total Heat

=

=

(Sp. Ht .. = .285 approx.)

1507 Ca1.

8134 +,1507 = 9641 Ca1.

0

I

(f) Heat in Gasei.

( 212 ~ = 100

0

C.l

(1) CO + N + 0 = 79.90% •

( These gases have same specific heat.)

.7990 x 63.58 = 50.80 m3

3

Sp.Ht.

per m = (. 303 + .00002 7t )

Heat = 50.80 x 100 (.~03 + .000027 x 100 ) =

1553 CAL.

41

=

(2) Vol. of C02 = .1985 x 63.58

l2.62m3•

:3

Sp. lit. per m = (.37 + .00022t).

=

Heat

12.62 x 100 ( .37 + .00022

x 100 ) _..

495 Cal.

of 002 = .0025

:3

(3) .Vol.

Sp. Ht. per m

Heat

=

:3

.16 m.

x 63.58;:::

.

=(.36 + .0003t.>.

.16 x 100 ( .36 + .0003 x 100 ) = 6 Cal.

(4) Wt. evaporated

= .73 +.2'7 + .55 = 1. 55 Kgs~

o

Heat of Vaporization

1;55 x 606.5

=

=

at 0

606.5 Cal. per Kg.

940 Cal.

Sp. Ht. of Gas per Kg.

=

(.42 + .000188t ).

Heat = 1.55 x ,100 (.•42 + .000188 x 100) =

68 Cal.

= 1553

Total Heat in gases

+ 68 =.3162 cal.

(g) Heat in cooling wat~~.

Temp~ of Feed Water

=

o

12.1 C.

'0.

Temp. of Overflow = 92.1

c.

Rate of Flow = 14 Kgs. per minute~ .

"

"

"=147

Kgs. per charge.

147 x( 92.1 - 12.1 ) = 11,613 Cal.

+ 495 + .6 + 940

42

XIII.

THERM~AL BALANCE

FOR ONE CHARGE.

~-Credit, Kg. Calories.

Debit, Kg. Calories.

~urn1ng

C to CO2

_ 44,793

Burning C to CO'- -

~urning S to

802

1,944

~91

-

Reduction Fe304 to FeO - 1,135

Reduction

FeS2 to Fe - -.4,391

Decomposition

of CaCo3 - 5,.787

Burning Fe to FeO -

7,331

Heat

Formation

6,538

Heat in Matte

- - - - - 9,641

Sensible Heat in Blast 413

Heat in Gases

3,l6~

Sensible Heat .in c~a~

Heqt in.Cooling Water

..

Formation

of Slag -

of Matte(?)

62,063

in Slag - - - ... - .~13,430

11,613

49,159

Radiation{by Difference)12.90~

62,063

43

SUM1~ARY•

The sulphur a~1mlnat1on obtained in this run was

par cant of the sulphur present,

ed. If the analys1sof"

instead of 79.64% as expect-

the flue gas 1s ,correct about 9.8%

of the sulphur eliminated

sulphur'vapor

56.38

was driven off in the ~orm of

and not as sulphur dioxide. The sample of gas

must have been faulty,

as the conce,ntrat1on

1.6 into 1 -- gives a greater

falls belOw the calculated

The thermal balance

pyritic effect although it

concentration

shOWS

thatthe

heat. in the furnace was furnished

the oxidation'of

obta.ined,

by

of 4.4 into 1.

larger

part of the

the coke and not

by

the iron and sulphur as should have been

the case.

The Slag formed contained

32.37

% FeO

instead of the

.calculated 51.~~, the s1l1ca contents was 41.98% instead

of the calculated

36,08%. The percentage

of lime ran much

higher "than was intended. These facts show that sufficient

silica was present but thatthe

therefore

Assuming

iron was not oxidized

and

coUld not ent'3r the slag but went into the matte.

the air supply to be sufficient,

"prevente~ the desired pytl~1c

, A decrEtase

the coke must have

effect.

in the ampl.mt of coke

..

fore correct the smaltingconditions.

used WOUld thare-