Identification and Optimization of a Liquid Medium for the Colletotricum graminico/a

advertisement

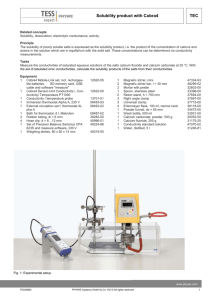

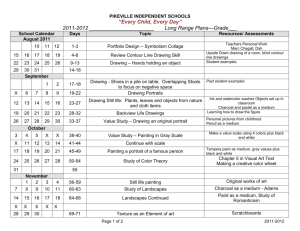

Identification and Optimization of a Liquid Medium for the Culture of Colletotricum graminico/a An Honors Thesis (HONRS 499) by Jennifer L. Minter Thesis Advisor Dr. James Mitchell Ball State University Muncie, Indiana May 2004 Expected Date of Graduation May 8, 2004 Abstract Crude carbon compounds were evaluated in several stages to determine the optimal liquid-culture medium for conidial production in Colletotrichum graminicola. Among those tested, use of unfiltered V8 medium resulted in optimum conidiation. % v/v of this medium was evaluated along with pH and conductivity using a central composite design to optimize conidiation in C. graminicola. The predicted titer using this model was 4.78x10 7 conidia/mL, using a medium consisting of 40.14% v/v V8, with a pH of6.16 and a conductivity of28.03mS. Acknowledgements • I would like to thank Dr. James Mitchell for his tireless help throughout the entire process. He trained me on technique, provided all of the materials, and assisted me with many experiments. He also helped me sort through the results of each individual experiment and edited my drafts of the written paper. • I would also like to thank Dr. David LeBlanc for providing me with a few critical numbers for my statistical analysis. Also, his course on statistics in biology made it possible for me to analyze my data. Table of Contents Introduction and Rationale 1 Identification and optimization of a liquid medium 4 for the culture of Colletotrichum graminicola Appendix A 10 AppendixB 12 Appendix C 19 Appendix D 24 Appendix E 31 Appendix F 43 Introduction and Rationale A major problem for farmers has always been weeds, which has been dealt with in several ways throughout human history. In the past, farmers relied entirely on manual weeding. Many farmers, particularly in less-developed regions, rely on this technique today. However, with the recent increase in the size of farms, manual weeding quickly became impractical. The current strategy for these farmers is usually herbicides. Although they are often the only recourse, herbicides pose environmental concern. Most do not rapidly degrade in the environment and thus persist long after the weeds have been killed. They have been detected in our surface waters [1, 11], the waters that Muncie and many communities largely rely on for drinking water. An alternative to chemical herbicides is the use ofbioherbicides. Bioherbicides are organisms, usually fungi, which naturally infect the unwanted weed in the wild. Most fungi are host-specific, meaning that they only infect certain plants and leave others largely alone. A farmer can apply the organism to his weeds in order to infect and kill the plants without harming his crops. Typically, when a fungal bioherbicide is applied with the same application technologies as chemical herbicides [19], it infects and kills the weed host within 1-2 weeks. After death ofthe weed host, the bioherbicide organism naturally dies back to its usual numbers in the environment because its food source is depleted. In contrast to chemical herbicides, the use of fungal bioherbicides does not result in any toxic substance that could accumulate in the environment or appear as surface or groundwater contaminants. 1 One weed that poses major problems for farmers is johnsongrass [Sorghum halepense (L.) Pers.]' It is an exotic grass native to the Mediterranean region which has established itself in warm regions of all major agricultural areas of the world [13]. It has been reported as one of the world's ten worst weeds [10]. Johnsongrass reduces crop yields in com [2, 12, 16], soybeans [23], and cotton [IS]. It also hosts insect and disease pests of grain sorghum [9, 13], and interbreeds with grain sorghum [13]. Numerous chemical herbicides have been developed and tested for efficacy against johnsongrass [8, 18]. Several fungal bioherbicides have also been proposed for the control ofjohnsongrass [5,6, 14, 15,24]. One of these is Colletotrichum graminicola (Ces.) Wils., which causes anthracnose [14], a plant disease. This organism has also been proposed as a means to control barnyard grass [Echinochloa crus-gallI], a common weed problem in rice [26]. Only three fungal bioherbicides have been registered for use in North America [17,20]. One of the three fungal bioherbicides was Collego, which contained a different species of Colletotrichum; C. gloeosporioides [3, 20]. These fungi infect by using spores, a dormant product of fungal reproduction, which germinate on the plant and infect it. Low-cost methods for producing infective spores must be used in order for a profit to be maintained. Submerged-culture fermentations are currently considered to be the most economical method of production [7]. In this method, the fungus grows and produces spores in a liquid medium. This study aimed to develop an optimized submerged-culture medium for the sporulation of Collelolricum graminicola. Over the course of four months, many media were tested. To begin, basic liquids were tried, such as the brine juice in canned vegetables, V8, sugar solutions, coffee, and 2 tea. Based on the results of that experiment, V8 juice, com syrup, and canned pea brine were selected for further testing. Subsequent experiments tested various concentrations of those media and also tested several additives to the basic media, including the ingredients in Collego medium that were effective for the other species of Colletotrichum. The results eliminated com syrup and pea brine from the possibilities. After determining that unfiltered V8 led to more spores than filtered V8, this medium was used in the final experiment. The final experiment made use of a statistical tool in the JMP4 software which predicted the optimum conditions for the best sporulation of the fungus. The conditions tested were V8 concentration, pH, and conductivity. Optimal sporulation was predicted at 40.14% V8 by volume with a pH of 6.16 and a conductivity of28.03mS. The predicted amount of spores with these conditions was 47.8 million spores per milliliter. The results indicate a very promising spore production in this medium, but more research would be necessary to determine the effect the spores produced in. this medium would have on the johnsongrass plant. 3 Identification and optimization of a liquid medium for the culture of Colletotrichum graminicola Jennifer L. Minter Honors Thesis Credit (HONRS 499) Department of Biology, Ball State University, Muncie, IN 47306, USA May 2004 Abstract Crude carbon compounds were evaluated in several stages to determine the optimal liquid-culture medium for conidial production in Colletotrichum graminicola. Among those tested, use of unfiltered V8 medium resulted in optimum conidiation. Percent v/v of this medium was evaluated along with pH and conductivity using a central comfosite design to optimize conidiation in C. graminicoia. The predicted titer using this model was 4.78xlO conidialmL, using a medium consisting of40.14% v/v V8, with a pH of6.16 and a conductivity of28.03mS. Several fungal bioherbicides have been proposed for the control of johnsongrass [5,6, Introduction 14, 15,24]. One of these is Colletotrichum graminicola (Ces.) Wits., which causes Johnsongrass [Sorghum halepense (L.) Pers.] is an exotic grass native to the Mediterranean anthracnose [14]. This organism has also been region which has established itself in warm proposed as a means to control barnyard grass regions of all major agricultural areas of the [Echinochloa crus-galli], a common weed world [13]. It has been reported as one of the problem in rice [26]. world's ten worst weeds [10]. Johnsongrass Only three fungal bioherbicides have been reduces crop yields in com [2, 12, 16], soybeans registered for use in North America [17, 20]. [23], and cotton [15]. It also hosts insect and One of the three fungal bioherbicides was disease pests of grain sorghum [9, 13], and Collego, which contained a different species of hybridizes with grain sorghum [13]. This Colletotrichum; C. gloeosporioides [3, 20]. perennial grass propagates by seeds and Low-cost methods for producing infective spores rhizomes, with propagation by rhizomes leading must be used in order for a profit to be to the most detrimental effects on crop yields maintained. Submerged-culture fermentations [16]. are currently considered to be the most Numerous herbicides have been developed economical method of production [7]. This and tested for efficacy against johnsongrass [8, study aimed to develop an optimized submerged18]. Although they are often the only recourse culture medium for the sporulation of for farmers, herbicides pose environmental Colletotrichum graminicola. concern because many do not rapidly degrade and have been detected in surface waters [1, 11]. An alternative to chemical herbicides is the Materials and Methods use ofbioherbicides. Typically, when a fungal Organism bioherbicide is applied as inundative inoculum with the same application technologies as Single-spore isolates of C. graminico/a were collected at chemical herbicides [19], it infects and kills the locations in Arkansas and Texas. Stock cultures were weed host within 1-2 weeks. After death of the maintained on both potato-dextrose agar slants under mineral oil and glycerol-skim milk at -BO°C. The inoculum conidia weed host, the bioherbicide organism is naturally were produced on Torula yeast agar (fA). The TA medium reduced in numbers to background levels. In contained: 15g. Torutein-IO (Provesta, Hutchinson, MN), contrast to chemical herbicides, the use of fungal ISg M-I 00 (Grain Processing Corporation, Muscatine, IA), bioherbicides does not result in any toxic l.Og. K2 HPO., O,5g. MgSO. x 711,0, and ISg. agar (Difco, Detroit, MI) per liter of deionized water. For each substance that could accumulate in the experiment, 5 plates ofTA medium were inoculated and environment or appear as surface or groundwater incubated on a laboratory bench for 7 days at 22-24°C under contaminants. fluorescent lights (I : I, Gro-Lux: Cool White) adjusted to a 14-hour photoperiod. The TA medium plates were 4 produced oval conidia. The com syrup produced falcate conidia, similar to the inoculum conidia, so it was also selected for further study. Raw data from this experiment are shown in appendix aseptically scraped with sterile cotton swabs and conidia were suspended in 10mL sterile deionized water. Submerged culture A. Liquid culture experiments were conducted using 2S0-mL Erlenmeyer flasks, each containing SOmL medium. An appropriate volume of inoculum was introduced to the autoclaved (IS-minute liquid cycle) media, resulting in an initial spore concentration of2xl04 conidialmL. Cultures were incubated at 22-24°C on a rotary shaker at 220rpm. Flasks were manually shaken daily to remove aerial mycelial growth on the flask wall. Conidia were counted with a hemacytometer under the microscope after 6 days of culture unless indicated otherwise. T A medium in liquid form was evaluated (100 and 33% v/v) along with dilutions of Pea and filtered V8 (5, 10, 15,20, and 30% v/v). This experiment was conducted in quadruplicate. Greatest numbers were again observed in V8 and Pea; TA and com syrup were dropped from further consideration. Raw data and analysis of this experiment are shown in appendix B. The additive ingredients of Collego, a medium developed for a different species of Colletolrichum, were tested with this organism using selected carbon sources, and CaC03 was tested for it's efficacy as an additive. The experiment was performed with 8 replicates per treatment. It was noted during counting that some of the treatments exhibited evidence of conidial germination. There was no significant difference between 30% filtered V8 and 30% filtered V8 with Collego additives (Table 2). These two treatments were significantly different from all Pea treatments and all treatments with the CaC03 additive (p<0.05) and were selected for further testing. Raw data and analysis of this experiment are shown in appendix C. Thus far, aU experiments had been conducted using filtered V8. Comparisons were made between the effects of filtered versus unfiltered V8 in both plain media and media augmented with Collego additives at 15 and 30% v/v concentrations. This experiment was performed with 8 replicates per treatment. Because of the earlier observation of conidial germination on day 6 of culture, daily counts were also performed to determine the optimal harvesting period for this organism. Conidial counts leveled out around day 5 for all Media and experimental design Crude carbon sources shown in Table I were evaluated for sporulation ofthe fungus. Canned vegetables, including V8 juice unless indicated otherwise, were filtered through four layers of grade 40 cheesecloth and the filtrate (brine) was used in the experiment. Coffee was prepared on a Mr. Coffee automatic-drip coffeemaker using the amount recommended by the manufacturer. Tea was prepared by placing 3 tea bags in I L boiling water for 20min. Dilutions of concentrated media were made using deionized water. Later experiments tested TA liquid medium, which was prepared similarly to the solid medium with the omission of the agar. COLLEGO medium was also evaluated, which was prepared from the following ingredients: Sg. KN03, 2.Sg. K2HP04, 1.2Sg MgS04 x 7H1 0, 109 sucrose (Difco, Detroit, MI),O.Olg FeCh, 75mL V8 juice, and 42SmL deionized water. This basic formulation contains 15% V8 v/v; alterations of the formula were tested using 30% V8 v/v and 15% Pea v/v. Thirty percent V8 and I S% Pea were also tested using 3gfL. CaCo, as an additive. When adjustments of pH were required, 50% NaOH and 1: I 0 and I: 100 dilutions were used to increase pH and concentrated HCI and I: 10 dilution were used to decrease pH. Results Nineteen carbon sources were evaluated for conidia production and shape (Table J). Sporulation was observed in all concentrations of com syrup, V8, and Pea. Greatest numbers were observed in V8 and Pea, but both media atIon 0 fC o11etolrichurn graminicoia T a ble 1: Cru de carb on sources eva uatedfior SPOlrul' Type (concenDrcttion) Canned vegetable brine (5, 10, and 15% v/v) i ! Specific ingredient V8 juice', sliced earrotsb, butter beansb, mustard greensb, golden hominy", whole kernel golden com (no saltt, sliced Irish potatoesb, cut yamsb, leaf spinichb, pinto beansb, green shelled blackeye peasb, cut beetsb, peas!, green beansb and cut okra' Com (Karo dark)g, Molasses· Syrups (0.2,0.5, and 1% w/v) Coffee and Tea Guatemalan blend eoffeed , regular teae (l0, 30, and 100% v/v) •Campbell Soup Co. (Cambden, NJ) "Alliance World Coffees (MunCIe, IN) eLipton (Englewood Cliffs, NJ) ~arsh Supermarkets, LLC (Indianapolis, IN) C Bruce Foods Corporation (New Iberia, LA) 'DelMonte Foods (San Francisco, CAl gEPC Int. (Englewood Cliffs, NJ) "B&G Foods (Roseland, NJ) 5 treatments (Figure I), so flasks were counted at day 5 instead of day 6 from this point forward. Conidia counts were significantly higher for three ofthe unfiltered treatments (V8 30 and 15% v/vand 30% v/v V8 with Collego additives) than for the fourth unfiltered treatment and all filtered treatments (Table 3). Unfiltered plain V8 was selected for use in the final optimization experiment. Raw data and analysis of this experiment are shown in appendix D. Table 3: Colletotrichum graminicola conidia production in crude filtered or unfiltered media with or without Collego additives Medium and Concentration Table 2: Colletotrichum graminico/a conidia production in crude liquid media with selected additives Medium 30% v/v filtered V8 with 3gIL CaC03 COLLEGO . 15% v/v Pea with • Collego additives . 15% v/v Pea with • 3g1LCaC0 3 15% v/v Pea 30% v/v filtered V8 with Collego additives 30% v/v filtered V8 Mean loglll conidialmL 3.38 c 3.52 3.62 bc bc 3.72 bc 4.11 5.27 b a 5.82 a ! Mean LoglO conidia/mL 3.79 d 15% v/v filtered V8 with Collego additives 15% v/v unfiltered V8 with Collego additives 30% v/v filtered V8 with Collego additives 30% v/v unfiltered V8 with Collego additives 15% v/v filtered V8 15% v/v unfiltered V8 30% v/v filtered V8 30% v/v unfiltered V8 5.51 bed 4.76 cd 5.94 abc 5.15 6.16 4.66 6.69 bed ab bcd a Figure 1: Co//etotrichum graminico/a conidia production in selected liquid media B -g - 7 - - -.......... --~----.- ....... --- - _ .........._ - - .!! :26 c o (.) 5 o "C"" C) ,34 3 +-------~------~------~------~------~----~ o 25 50 75 100 125 150 Hours post-innoculation -- 30% Col Filt 30% VB Filt -- 30% Col Untilt -- 30% VB Unfilt 15% Col Filt -+- 15% VB Filt 6 .t+-. - 15% Col Untilt! 15% VB Untilt Conductivity adjustments were made with KCI ranging from 0% w/v to 0.02% w/v. Results of this standardization are shown in appendix E. The value was 0.97. Conidial concentration results for V8 versus pH a V8 versus conductivity are shown in Figure 2. Optimal sporulation was predicted at 40.14% v/v V8 with a pH of6.16 and a conductivity of28.03mS. The predicted spore titer with these conditions was 4.78x10 7 conidiaimL. Raw data and analysis of this experiment are shown in appendixF. An orthogonal CCD in the JMP4 software was utilized to optimize conidia production with the following variables: unfiltered V8 concentrations, pH, and conductivity. Prior to conducting the experiment, pH and conductivity were standardized over a wide range of V8 concentrations pre- and post- autoclave in order to predict starting pH and conductivity from desired post-autoclave pH and conductivity. r Figure 2: Contour plots of pH and conductivity interaction with % v/v V8 to affect spore yield of Colletotrichum graminicola Discussion .. ~ dtr":--,-,-,~ '~~~~ .... "". ,,~ Fungi differ by species in optimal medium for sporulation. As seen in this study, the Collego medium, optimal for Colletotrichum gioeosporioidies, is not the optimal medium for C. graminicola. The orthogonal CCD predicted a spore titer of 4.78x10 7 conidialmL with 40.14% v/v V8, a pH of6.16 and a conductivity of28.03mS. This titer would be reached after 5 days of incubation at 22-24°C. It is possible that other factors not considered in this study could affect conidia production, and if considered, lead to a greater spore titer. However, the titer predicted by the orthogonal CCD model is satisfactory and further extensive testing would only be necessary if it were determined that a higher initial titer would be required for economical production. It must be remembered that the overall goal of this study is to develop a liquid-culture medium that has the potential to be used in the future to produce conidia for use as a bioherbicide against johnsongrass. As noted earlier, conidia shape in V8 is oval, not falcate as is produced on solid media. This has been observed by others [4,22] and the effects on spore germination have been studied [4]. It was found that oval conidia germinated similarly to falcate conidia and had the additional advantage of having less strict requirements of surface hydrophobicity. Further tests would need to be done to confirm that finding with this medium and to determine the virulence of the conidia produced by this medium on the johnsongrass plant. 10910 conidi~L \6.94 .,I ; - ," BI ~" !' ~, . ,.' .'L jOt' \7.14~.-, " -I , 'f '<1) , ' 94'" , " 13 58 7 14.Mitchell J (1993) Potential of Colletotrichum graminicola and Gloeocercospora sorghi as biological herbicides for control of Johnson grass. Plant Pathol I: 31-36 15.Mitchell J, Njalamimba-Bertsh M, Bradford N, Birdsong J (2003) Development ofa submerged-liquid sporulation medium for the johnsongrass bioherbicide Gloeocercospora sorghi. J Ind Microbiol Biotechnol 30:599605 16.Mitskas M Tsolis C, Eleftherohorinos I (2003) Interference between com and johnsongrass (Sorghum halepense) from seed or rhizomes. Weed Sci 51:540-545 17.Mortensen K (1988) The potential of an endemic fungus, Colletotrichum gloeosporioides, for the biological control of round-leaved mallow (Malva pusilla) and velvetleaf (Abutilon theophrasti). Weed Sci 36:473-478 18.Orr J, Mitich L, Roncoroni E (1995) Postemergence herbicide controls johsongrass, other weeds in field com. Cal Agr 49:33-38 19.5mith R Jr (1982) Integration of microbial herbicides with existing pest management programs. In: Charudattan R, Walker L (eds) Biological Control of weeds with plant pathogens. Wiley, New York, pp 189-206 20.Templeton G (1982) Status of weed control with plant pathogens. In: Charudattan R, Walker L (eds) Biological control of weeds with plant pathogens. Wiley, New York, pp 29-44 21. Templeton, G (1986) Mycoherbicide research and the University of Arkansas--past, present, and future. Weed Sci 34 (Suppl. 1): 35-37 22.Thomas, M Frederiksen, R (1995) Dynamisc of oval and falcate conidium production of Colletotrichum graminicola from sorghum Mycologia 87:87-89 23.Williams C, Hayes R (1984) Johnsongrass (Sorghum halepense) competition in soybeans (Glycine max). Weed Sci 32:498-501 24.Winder R, Van Dyke C (1990) The pathogenicity, virulence, and biocontrol Potential of two Bipolaris species on johnsongrass (Sorghum halepense) Weed Sci 38:89-94 25.Wood M, Murray D, Banks J, Verhalen L, Westennan R, Anderson K (2002) Johnsongrass (sorghum halepense) density effects on cotton (Gossypium hirsutum) harvest and economic value. Weed Tech 16:495-501 26. Yang Y -K, Kim S-O, Chung H-S, Lee Y-H (2000) Use of Colletotrichum graminicola References l.Battaglin W, Thunnan E, KalkhoffS, Porter S (2003) Herbicides and transfonnation products in surface waters of the midwestern United States. J Am Water Res Ass 39:743-757 2Bendixen L (1986) Com (Zea mays) yield in relationship to johnsongrass (Sorghum halepense) population. Weed Sci 34:449-451 3.Bowers, R (1986) Commerialization of Collego---an industiralist's view. Weed Sci. 34(Suppl. 1):24-25 4.Chaky J, Anderson K, Moss M, Vaillancort L (200 I) Surface hydrophobicity and surface rigidity induce spore gennination in Colletotrichum graminicola. Phytopathology 91:558-564 5.Chandramohan S, Chardattan R, sonoda R, Singh M (2001) Field evaluation of a fungal pathogen mixture for the control of seven weedy grasses. Weed Sci 50:204-213 6.Chiang M-Y, Van Dyke C, Chilton W (1989) Four foliar fungi for controlling seedling johnsongrass (Sorghum halepense). Weed Sci 37:802-809 7.Churchill B (1982) Mass production of microorganisms for biological control. In: Charudattan R, Walker L (eds) Biological control of weeds with plant pathogens. Wiley, New York, pp 139-156 8.Ferrell J, Earl H, Vencill W (2003) The effect of selected herbicides on C02 assimilation, cholorophyll fluorescence, and stomatal conductance injohnsongrass (Sorghum halepense L.) Weed Sci 51:28-31 9.Forrester N, Geenup L, Tuart L (1975) Seasonal abundance of sorghum midge. Cotton Newslett 17:8-12 10.Holm L, Pluknett D, Pancho J, Herberger J (1977) Sorghum halepense (L.) Pers. In: The world's worst weeds: distribution and biology. University Press of Hawaii, Honolulu, pp 54-61 II.Kalkhoff S, Lee K, Porter S, Terrio P, Thunnan E (2003) Herbicides and herbicide degradation products in upper Midwest agricultural streams during august base-flow conditions. J Env Qual 32:1025-1036 12.Kiniry J (1994) Radiation-use efficiency and grain yield of maize competing with johnsongrass. Agron J 86:554-557 13.McWhorter C (1989) History, biology, and control of johnsongrass. Rev Weed Sci 4:85121 8 KAOOI to control barnyard grass. Plant dis 84:55-59 9 Appendix A: Carbon Source Screening Table 4: Conidiation in crude media and observations Flask Number 1 2 3 4 5 6 7 8 9 10 11 12 13 i i 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 Flask Contents Beets 5% Beets 10% Beets 15% Blackeye Peas 5% Blackeye Peas 10% Blackeye Peas 15% Hominy 5% Hominy 10% Hominy 15% Potatoes 5% Potatoes 10% Potatoes 15% Carrots 5% Carrots 10% Carrots 15% Spinach 5% Spinach 10% Spinach 15% Peas 5% Peas 10% Peas 15% Butter Beans 5% Butter Beans 10% Butter Beans 15% V85% V81O% V815% Mustard Greens 5% Mustard Greens 10% Mustard Greens 15% Okra 5% Okra 10% Okra 15% Pinto Beans 5% Pinto Beans 10% Pinto Beans 15% Com 5% Conidia Present Observations - - I + Very few, mix of oval and falcate - + + + + Mix of oval and falcate, few Many, most oval Many, most oval Very few, all falcate - + + ++ Many, most falcate, some oval Many, mix of oval and falcate Very many, mix of oval and falcate - + + oval conidia Many, all oval + Many, all oval + Very few 10 • Flask i Number 38 39 ! 40 41 42 .43 44 45 ,46 147 48 149 50 , 51 ,52 53 54 55 56 57 ! , Flask Contents Corn 10% Corn 15% Green Beans 5% Green Beans 10% Green Beans 15% Yams 5% Yams 10% Yams 15% Corn Syrup 0.2% Corn Syrup 0.5% Corn Syrup 1% Molasses 0.2% Molasses 0.5% Molasses 1% Coffee 10% Coffee 30% Coffee 100% Tea 10% Tea 30% Tea 100% Conidia Present Observations + + oval conidia Many ~ all oval - i - + + + + + + - oval and falcate conidia Little v(,:getative biomass All falcate Little vegetative biomass Many, all oval - - - - Table 5: Conidia counts in selected crude media Flask Number 46 47 ! 48 i 49 ! 50 25 ! 26 27 • 31 132 33 19 20 21 ! Flask Contents Corn Syrup 0.2% Corn Syrup 0.5% Corn Syrup 1% Molasses 0.2% Molasses 0.5% V85% V81O% V815% Okra 5% Okra 10% Okra 15% Peas 5% Peas 10% Peas 15% Log1o Conidia/mL 4.19 4.03 4.43 4.29 4.75 4.49 4.89 5.36 4.21 3.22 4.55 4.88 5.05 5.30 ! i 11 Appendix B: V8, Corn Syrup, Pea, and TA Table 6: Explanation of Abbreviations Medium Abbrev. 0.2 CI Com Syrup (% w/v 0.5 I 1.0 I 1.5 C2 I C3 I C4 I I 2.0 C5 5 PI M I1 I P2 P3 P4 30 P5 5 VI I l V8 (% v/v) 10 I 15 I 20 V2 I V3 I V4 I I 30 V5 Table 7: Raw data of conidia COWlts in selected concentrations ofV8, Corn Syrup, Pea, andTA Flask Number 1 2 3 4 5 cr 8 9 10 I 11 12 13 14 15 I 16 . 17 18 19 20 21 22 23 24 25 26 27 .28 29 30 i 31 32 Flask Conte P1 P1 P1 P1 P2 P2 P2 P2 P3 P3 P3 P3 P4 P4 P4 P4 P5 P5 P5 P5 V1 V1 V1 V1 V2 V2 V2 V2 V3 V3 V3 V3 LO~lO conidialmL 0 4.38 4.22 3.52 4.81 4.53 4.52 4.24 0 4.84 4.94 5.76 5.23 5.83 5.19 4.81 5.82 5.67 5.1 5.63 3.82 0 3.22 3.92 4.29 4.67 4.78 4.14 5.19 5.24 4.65 4.46 12 TA (% Vi 100 I 3 Tl I 1 Flask Number 33 34 35 36 37 38 39 40 41 42 • 43 144 i 45 46 i 47 r-----48 49 ~ 50 • 51 52 53 54 55 56 57 58 59 60 .61 62 63 .64 65 66 67 68 i ~ ... Flask Contents Loglo conidialmL V4 V4 V4 4.58 5.61 5.19 V4 4.3 V5 V5 V5 V5 C1 5.73 5.87 6.15 C1 C1 C1 C2 C2 C2 C2 C3 C3 C3 C3 C4 C4 C4 C4 C5 C5 C5 C5 T1 T1 T1 T1 T2 T2 T2 T2 i ! 5.89 4.22 4.14 4.22 4.19 4.19 4.05 3.82 4.25 4.18 4.11 3.75 3.89 4.25 3.59 4.12 i 3.89 4 3.52 3.35 3.74 0 0 0 3.65 0 3.35 3.05 0 13 Conoentration Medium Summary of For categories in No Selector Group Cl C2 C3 C4 C5 PI P2 P3 P4 P5 Tl T2 VI V2 V3 V4 V5 Count Mean Median Std[)ev Min Max Skewness 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4.1925 4.0775 3.9825 3.9625 3.6525 3.83 4.525 3.885 5.265 5.555 0.9125 1.6 2.74 4.47 4.885 4.92 5.91 4.205 4.12 4 4.005 3.63 3.87 4.525 4.89 5.21 5.65 0 1.525 3.52 4.48 4.92 4.885 5.88 0.0377492 0.191028 0.198221 0.289525 0.281351 2.05423 0.232737 2.62259 0.421545 0.314166 1.825 1.85158 1.85264 0.304083 0.389401 0.591326 0.175119 4.14 3.82 3.75 3.59 3.35 0 4.24 0 4.81 5.1 0 0 0 4.14 4.46 4.3 5.73 4.22 4.25 4.18 4.25 4 4.38 4.81 5.76 5.83 5.82 3.65 3.35 3.92 4.78 5.24 5.61 6.15 -0.737887 -0.581849 -0.177076 -0.386925 0.218205 -1.04588 -6.66134e-15 -1.06691 0.440355 -0.914134 1.1547 0.0130972 -1.06277 -0.0544547 -0.108418 0.131349 0.567641 There is no one transformation that will make all data sets normally distributed. Thus, the Kruskal-Wallis test must be used. Data values were converted to ranks and ANOVA was used to statistically evaluate the transformed data. 4 It It 1 2 : 3 C 0 n .. c 0 4.58 0 -0.75 n 0 0.75 "t I -0.75 0 n It 5 V 5.4 "n 5.1 n c <:; .. 4.8 t r 4.5 n "ti I 0 -0.75 n 0 I -0.75 "n 0.75 I 0 0.75 nsoor4ts , p 6.1 4 : : C C 0 i I nscores nscores 4 4.6 r 4.20 i I 4.8 n t "t 0 0 n 4.33 n t r a 5.0 .. 0 n t t I C 0 e 5.2 : C n 2 It 3 4.65 C 6.0 3 0 n e 5.9 n t r a 5.8 ...'" n t 2 , r a t t 0 i nsooreS 0 0.75 0 n -0.75 0 nsoores 14 0.75 0 n -0.75 0 nscores 0.75 P 2 C 4.80 4.65 0 C 3.75 4.5O c e c "n t 1.25 r r i 0.75 5.8 C 5.6 I -0.75 n T 1 5.4 5.2 ..c 1.50 t O.75 -0.75 n I 0 -8.75 n C 2 C 3 0 n C 4.0 e n t 0 I i 0.15 0 3.9 r a C 4.0 "n .. c e c 3.8 t t r r Q t n iii 0 8.75 n 3.6 3.90 3.75 3.69 3.45 t -0.15 iii n:s:cores 0.75 0.75 4.0 3.9 3.8 0 n I I -0.75 0 nsCOf"b 15 I -iii. 75 nsconts n CI 0 i I -8.75 n C 5 n I 8 4.1 t nscores: 4.2 8.75 t a t 4.14 0 C Moores n -0.75 nscores n i 0 8 n c r C 0.75 n . 4.16 -8.75 t 0 4.1 0 4.18 Q C 4 0 4.2 C 0 1.:5Iil I I 0.75 4.28 n ..c nscor•• e t 2.25 r 4.22 0 n t C a t nseores n c 3.00 0 I 8.75 T 2 n 8 t 0 I O.75 n r I 0 8 nsOOres 2.25 a i C n n t C 1 8.75 3.88 0 t r 0 n n a I -0.75 I C 0 e I 8 ns:cOr4ts n c 5.00 t 8 0 nsoores: p 5 5.25 a j I 0 -0.75 5.:5Iil n a t t C . 2.50 t 4.35 5.75 0 n a P 4 n n e n t 5.88 0 n c P 3 I 0.75 5.00 B ~~BB~ 3.75 C 0 n c e n t r a t 2.50 i 0 n 1.25 Cl C2 C3 C4 C5 PI P2 P3 P4 P5 Tl T2 VI V2 Mecliut"l'l Analysis of Variance For No Selector Source df Sums of Squares Mean Square F-ratio 10 51 07 80937 21290 4851 20147 80937 1331 95.1176 850.91 13.993 Canst Mdm Error Total Rank: Concentration 16 Prob ~ 0.0001 0.0001 V3 V4 V5 Summary of For categories in No Seleotor Group C1 C2 C3 C4 C5 P1 P2 P3 P4 P5 T1 T2 V1 V2 V3 V4 V5 SE SE SE Rank: Conoentration MediuM Count M.an Median StdD_ Min Max 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 32 28.375 23.875 25.25 16.5 23.25 43.125 42.625 56.625 59.5 7.375 7.375 14.25 40.625 50.25 49.75 65.75 32.75 28.25 23.75 24.25 15.25 23.75 43.5 51.5 56 60.5 4.5 6.75 14.75 43 50.5 50 66.S 2.61406 7.81425 5.2341 9.52628 5.49242 17.1002 5.54339 25.9916 6.42099 4.65475 5.75 3.47311 8.5098 9.0312 7.5 8.77021 2.62996 28.5 19.5 18 15 11.5 4.5 36 4.5 49.5 53 4.5 4.5 4.5 28.5 42 40 62 34 37.5 30 37.5 24 41 49.5 63 65 64 16 11.5 23 48 58 59 68 "((k(N+ 1))/12) "((17(69))/12) 9.89 MSD = Qa=o.05, k=l7, df-= ro (SE) MSD 4.792 (9.89) MSD =47.4 Table 8: Media and their mean ranks, with results of the Kruskal-Wallis test Medium Tl T2 VI C5 . PI C3 ! C4 C2 C] V2 P3 P2 V4 • V3 i P4 i P5 i V5 Mean Rank 7.375 7.375 14.25 16.5 23.25 23.875 25.25 28.375 32 40.625 42.625 43.125 5 50.25 56.625 59.5 65.75 c c be be abc abc abc abc abc abc abc abc abc abc ab ab a I 17 Table 9: Media and condia concentrations with results of the Kruskal-Wallis test Medium Com Syrup (%w/v) 0.2 0.5 1.0 1.5 I 2.0 i Pea (% v/v) 5 10 15 20 30 V8 (%v/v) 5 10 15 20 30 TA (% v/v) 33 100 Mean IOglO conidia/mL 4.19 4.08 3.98 3.96 3.65 abc abc abc abc bc 3.03 4.53 3.89 5.27 5.56 abc abc abc ab ab 2.74 4.47 4.89 4.92 5.91 be abc abc abc a 0.91 1.60 e e 18 Appendix C: Collego and CaC03 Table 10: Explanation of abbreviations Medium and Concentration ! 30% v/v filtered V8 • 30% v/v filtered V8 with Collego additives 30% v/v filtered V8 with 3g/L CaC03 15% v/v Pea 15% v/v Pea with Collego additives 15% v/v Pea with 3g/L CaC03 Collego as originally formulated Abbreviation V8 "(1 "'''llego V8-Ca P P-collego P-Ca COLLEGO ! Table 11: Conductivity and pH ofV8 and Pea media with and without Collego additives orC aC03 Medium i V8 V8-collego V8-Ca P P-collego P-Ca COLLEGO Conductivity (mS) preautoclave 5.33 18.38 5.38 0.699 14.70 0.730 16.69 Conductivity (mS) postautoclave 5.57 19.24 5.66 0.731 15.19 0.763 17.12 pH preautoclave pH postautoclave 4.13 6.58 6.25 6.85 7.49 7.47 7.01 4.28 6.41 5.96 6.65 7.03 7.41 6.52 Table 12: Raw data of conidia counts in V8 and Pea with and without Collego additives orCaC03 Flask Number Flask Contents Log1o conidia/mL 1 5.812913 V8 2 6.068186 V8 3 V8 5.740363 V8 6.089905 .4 ·5 V8 5.716003 6 V8 5.414973 1 •7 ·8 9 10 11 12 13 V8 V8 V8-collego V8-collego V8-collego V8-collego V8-collego 5.585461 6.164353 5.278754 5.290035 5.389166 5.243038 5.09691 19 Flask Number Flask Contents LoglO conidialmL I 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 V8-collego V8-collego V8-collego V8-Ca V8-Ca V8-Ca V8-Ca V8-Ca V8-Ca V8-Ca V8-Ca COLLEGO COLLEGO COLLEGO COLLEGO COLLEGO COLLEGO COLLEGO COLLEGO P P P P P P P P P-collego P-collego P-collego P-collego P-collego P-collego P-collego P-collego 5.361728 5.585461 4.954243 2.745075 2.745075 3.222716 i 36 37 38 39 40 41 i 42 43 44 45 46 47 48 49 i 50 51 52 53 54 55 56 ! ! P-Ca P-Ca P-Ca P-Ca P-Ca P-Ca P-Ca P-Ca 3.045323 3.647383 4.954243 3.647383 3.045323 3.522444 3.045323 3.745075 3.045323 3.444045 3.69897 3.920645 3.745075 4.58995 3.69897 4.235528 4.222716 3.69897 4.557507 3.58995 4.324282 3.920645 3.444045 3.69897 13.69897 3.522444 2.745075 3.920645 4.025306 3.58995 3.647383 3.786041 3.948902 3.647383 3.974972 3.444045 3.69897 20 I i i i Summary of For oategories in No Seleotor Group COLLEGO P P-Ca P-collego va va-Ca Va-collego Log Conidia/mL Medium a Mean 3.52085 4.11473 3.71721 3.6221'31 5.8241'32 3.38157 5.27492 Median 3.511'371 4.22912 3.67318 3.59897 5.77664 3.1341'32 5.28439 StdOey 1'3.327386 1'3.398776 1'3.170586 1'3.41'37687 0.264348 1'3.724589 0.191'3039 Min 3.1'34532 3.58995 3.4441'34 2.7451'37 5.41497 2.74507 4.95424 COLLEGO P P-Ca P-oollego va Count a 8 8 a 8 8 Max 3.921'365 4.58995 3.97497 4.1'32531 6.16435 4.95424 5.58545 6 5 L o 9 C o n i d a I 4 m L 3 Medium 21 va-Co va-oollego c 4.50 0 L L 3.8 P E G 0 L 3.0 4.23 0 9 L C 0 9 n i C d 0 n i 4.90 0 3.4 3.2 3.75 CI I d rn i CI I -9.75 I rn L I 9 L I 9.75 I 0 I -0.75 nscor • • I 0.75 nscores p 3.875 I I . C CI L 0 0 0 L 3.3 0 9 3.625 n i d i 3.6 9 3.759 <;I C 3.<;1 0 0 P C 3.0 0 n 3.599 i Q d I rn I -9.75 L I I 13 0.75 Q I I I I -0.75 0 0.75 rn L nsoc,..•• n.cor•• V 8 V 8 Q L L 0 '" d i 4.9 0 9 5.8 C n i 4.5 c 6.0 C 3.5 0 i 5.<:1 d 3.0 Q a / ....... / rn L -0.75 0 0.75 L 5.55 "I 0 .. I :5.48 9 0 L 5.25 "9 C 5.10 "n i d i I CI I m -8.75 I I 13 9.75 nsoor• • nsoor • • V 8 I -9.75 0 I 0.75 L 22 2 S21argest I S smallest (0.72)2 I (0.18)2 Fmax 16 Fcritical with k=7, df=7 = 11.8 F max Fmax There is evidence of skew in the data sets and the variances are not all equal. However, since sample sizes are the same, ANOVA can still be used with these rather modest deviations from normality and equal variance. Analysis of Variance For No S.leoctor Source Const Mdm Error Total HSD HSD HSD df 1 6 49 55 Log Conidia/mL Sums of Squares 991.561 43.9835 7.67083 51.1:i544 I"IeGIn Square 991.561 7.33059 0.156548 F-ratio 6333.9 46.827 Prob S 0.0001 S 0.0001 Q (1=0.05, k=7, df=49 v'(MSE/ni) 4.389 v'(0.156548/8) 0.614 Table 13: Media and condia concentrations with results of the ANOVA test Medium 30% v/v filtered V8 with 3gIL CaC03 COLLEGO 15% v/v Pea with Collego additives 15% v/v Pea with 3gIL CaC03 15% v/v Pea 30% v/v filtered V8 with Collego additives 30% v/v filtered V8 Mean logllJ conidialmL 3.38 e 3.52 3.62 be be 3.72 be 4.11 5.27 b a 5.82 a 23 Appendix D: Filtered versus Unfiltered V8 Table 14: Explanation of Abbreviations Medium and Concentration 15% v/v filtered V8 with Collego additives • 15% v/v unfiltered V8 with Collego additives • 30% v/v filtered V8 with Collego additives 30% v/v unfiltered V8 with Collego additives 15% v/v filtered V8 15% v/v unfiltered V8 30% v/v filtered V8 30% v/v unfiltered V8 Abbreviation Co115F Co115U Col30F Col30U V 15F V 15U V30F V30U I i Table 15: Conductivity and pH of selected concentrations of filtered and unfiltered V8 with and without Collego additives Medium Col15F • Col15U Col30F Col30U V 15F • V 15U V 30F V30U Conductivity (mS) preautoclave 11.95 11.85 13.19 13.05 1.93 1.96 3.97 3.89 Conductivity (mS) postautoclave 16.53 16.50 18.63 18.38 2.76 2.73 5.67 5.56 pH preautoclave pH postautoclave 6.98 7.01 6.51 6.55 4.27 4.20 4.39 4.23 6.39 6.56 6.28 6.33 3.96 3.48 3.95 3.93 i Table 16: Raw data of conidia counts at selected times post-innoculation Hours post-innoculation Medium Col30F Col30U Col15F Col15U V30F V30U V15F V15U 43 4.346352974 4.46834733 4.434568904 4.84509804 4.086359831 4.460897843 4.357934847 4.086359831 I 78 102 4.801404 6.318063 4.620136 5.607455 4.206826 6.763428 4.83123 6.403121 5.217484 6.201397 4.40824 5.667453 4.85187 6.829304 5.875061 6.537819 24 136 5.45 i 6.03 4.24 i 5.71 • 4.86 • 6.67 5.92 6.63 Table 17: Raw data of conidia counts in selected concentrations of filtered and unfilteredV8 with and without Collego additives i Flask Number Flask Contents Log1o conidialmL 1 2 3 4 5 6 7 8 9 10 Col30F Col30F Col30F Col30F Col30F Col30F Col30F Col30F Col30U Col30U Col30U Col30U Col30U Col30U Col30U Col30U Col15F Col15F Col15F Col15F Col15F Col15F Col15F Col15F Col15U Col15U Col15U Col15U Col15U Col15U Col15U Col15U V30F V30F V30F V30F V30F V30F V30F V30F 4.72 4.55 4.64 4.73 4.68 4.75 4.56 5.45 5.90 5.85 5.90 5.87 6.30 6.00 5.64 6.03 3.05 3.65 4.19 3.22 4.03 3.95 4.03 4.24 5.27 5.35 5.42 5.98 5.72 5.08 5.51 5.71 3.35 6.15 4.60 3.70 4.18 4.37 6.10 4.86 11 i 12 .13 14 15 16 17 118 19 , 20 21 22 23 24 25 26 , 27 28 29 30 31 32 33 , 34 ! 35 36 37 38 39 40 ! I I I i I ! ! i 25 Flask Number 41 42 43 44 45 46 47 48 49 • 50 51 • 52 53 54 55 56 ·57 58 59 160 61 62 63 64 i Summary of For categories in No Selector &-oup Col15F Col15U Col38F CoI38U V15F V15U V38F V38U Flask Contents L0210 conidialmL V30U V30U V30U V30U V30U V30U V30U V30U V15F V15F V15F V15F V15F V15F V15F V15F V15U V15U V15U V15U V15U V15U V15U V15U 6.51 6.58 6.72 6.82 6.72 6.69 6.80 6.67 5.66 5.37 5.63 5.47 4.61 5.34 3.22 5.92 6.37 6.37 5.95 6.22 6.09 5.66 6.06 6.53 ! I i Log.8 conidia/mL Hedium Count H_ Median StdDev Hin Max 8 8 8 8 8 8 8 8 3.79295 5.50678 4.76067 5.93745 5.15281 6.15714 4.66198 6.68841 3.9871 5.46756 4.70881 5.99173 5.42044 6.15192 4.48143 6.79429 8.446193 8.29001 8.287358 8.186876 8.868885 0.277716 1.9228 8.193273 3.84532 5.07918 4.55023 5.63849 3.22272 5.66276 3.34635 6.5892 4.23553 5.98453 5.44716 6.29667 5.91645 6.53148 6.15229 6.81823 26 6 L * 0 9 1 0 5 c 0 El n i d a I m L 4 Col15F Col15U Col30F V15F Col30U M&dium 27 V15U V30F V30U c 0 I 1 5 <..: 4.25 0 4.00 5 U 3.75 0 3.5e 9 I 0 I I F L 0 9 1 e L n i d 0 3.25 n -e.75 m 0 i Q e.75 I m nscores ....L 0 I 0 0 nscores I 3 0 U 5.25 L 6.15 L 0 9 1 0 5.00 c 4.75 0 6.00 9 I 0 5.85 c 0 0 n n i d i d i I -0.75 I C m 5.2 d I I GI 5.4 i GI 3 0 F 5.6 c c 0 5.8 -0.75 nscor_ I 0 0.75 Q I m L 28 5.70 I -0.75 nscor_ 0 0.75 V V 1 5 1 5 U : F 5.25 L L 0 0 9 9 1 0 0 0 n i d i 3.75 I m -0.75 L V o 0.75 nscores 0.75 ns:cor&s: V 5.00 3 0 U : 5.750 L 5.25 0 0 9 9 5.575 5.500 1 0 o -0.75 L F L 5.8 a I m a 3 0 5.0 c c n i d 5.2 1 0 4.50 5.4 1 0 4.50 c c 0 0 n i d n i d i 3.75 a I m a I m -0.75 L o 5.525 0.75 -0.75 L nscores o 0.75 ns:cores The 30% V8 with collego additives treatment has a large positive outlier that is not eliminated by data transformation. With such an extreme violation of normality, the Kruskal-Wallis test must be used. Data values were converted to ranks and ANOVA was used to statistically evaluate the transformed data. Analysis of Variance For No Selector Source Const Mdm Error Total df 1 7 56 63 Sums of Squares 67600 17032.2 4805.81 21839 Summary of For categor i es in No Selector Group Col15F Col15U Col38F Col38U V15F V15U V38F V38U Rank: Log 18 conidia/mL Count 8 8 8 8 8 8 8 8 Mean Square 67600 2433.17 85.8359 F-ratio 787.55 28.347 Rank: Log 18 conidia/mL Medium Mean 6.9375 32.125 19.875 42.75 25.9375 49.375 21.625 60.375 Median 7.75 30.5 19.5 41.5 29.5 50.5 14.5 60.5 StdDev 3.88622 7.33753 4.94072 5.80025 12.3879 6.84392 18.7688 2.55927 29 Min 1 24 14 34 2.5 36 4 55 Max 12 45 30 53 43 57 51 64 Prob 0.0001 ~ 0.0001 SE "«k(N+1)112) SE = "«8(65»/12) SE 6.58 MSD = Qa=O.05, k=8, df-= 00 (SE) MSD 4.286 (6.58) MSD=28.21 Table 18: Media and their mean ranks, with results of the Kruskal-Wallis test Treatment Col15F • Co130F V30F V l5F Col15U Co130U V 15U V30U Mean Rank 6.94 d 19.88 cd 21.63 bed 26.94 bcd 32.13 bed 42.75 abc ab 49.38 60.38 a I I Table 20: Mean conidia concentration for filtered and unfiltered V8, with or without Collego additives, and results of the Kruskal-Wallis test Medium and Concentration 15% v/v filtered V8 with CoUego additives 15% v/v unfiltered V8 with Collego additives I 30% v/v filtered V8 with Collego additives ! 30% v/v unfiltered V8 with • Collego additives 15% v/v filtered V8 15% v/v unfiltered V8 30% v/v filtered V8 30% v/v unfiltered V8 Mean Log1o conidialmL 3.79 d 5.51 bed 4.76 cd 5.94 abc 5.15 6.16 4.66 6.69 bed ab bed a I 30 Appendix E: pH and Conductivity Calibrations Table 21: Results of pH and conductivity calibrations for selected concentrations ofV8 0/0 Flask Number V8 i 1 2 3 4 5 6 7 8 9 10 .11 12 .13 ! 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 10 10 10 10 10 10 10 10 10 10 15 15 15 15 15 15 15 15 15 15 30 30 30 30 30 30 30 30 30 30 50 50 50 50 50 50 pH post- Grams Conductivity pH prepreautoclave autoclave KCI added autoclave(mS) 4.33 4.18 --2.83 2.77 --2.03 11.99 --6.94 8.76 --11.19 7.41 --1.87 0 -0.5 9.20 --15.99 I --1.5 tI2.7 --2 129.3 --4.15 4.22 --2.63 2.63 --2.00 2.01 --6.14 6.69 --7.23 9.86 --0 2.54 --0.5 10.36 --I 15.98 --23.4 1.5 --29.4 2 --4.11 4.09 --3.08 3.09 --2.01 2.01 --8.86 6.65 --9.98 7.05 --0 4.74 --0.5 11.74 ---I 18.35 -1.5 25.1 --2 31.0 ---4.03 4.02 -2.26 2.30 --3.08 3.22 --7.78 6.29 --9.07 6.84 --0 7.38 --- -- 31 Conductivity postautoclave( mS) --- I i -- -- -- 1.96 10.29 17.86 25.6 32.6 -----2.87 11.52 18.00 26.2 32.8 I ! I --- --- -5.32 12.97 20.5 27.9 34.5 -- -- ---- 8.15 i I % Flask Number V8 37 38 139 40 41 42 43 44 45 46 47 ~ 50 pH prepH post- Grams autoclave autoclave KCI added 0.5 -- IT 50 50 75 75 75 75 75 75 75 75 75 75 -- -- --- 3.94 2.94 2.27 6.60 9.42 3.91 2.96 2.22 5.84 7.18 -- -- -- --- --- -- ---- I 1.5 2 Conductivity preautoclave(mS) 14.17 21.0 26.6 33.0 -- I -- --- --- --0 0.5 I 1.5 12 32 --- 10.30 16.57 22.8 28.7 34.5 Conductivity postautoclave(mS) 15.80 22.9 29.5 36.1 ----- -11.18 18.1 25.0 32.2 37.5 Figure 3: Plotted pre-post autoclave differences vs. post-autoclave readings pH difference pre-post autoclave vs. pH post-autoclave for 10%V8 4 • 3.5 ~ y = 0.2469x2 1.7537x + 2.7225 R2 = 0.9392 3 ftS ~ -g 2.5 ftS 2 Q. e I 1.5 Q. CD CJ C e :s ~ J: Q. 0.5 o 6 2 -0.5 -1 pH post-autoclave 33 7 8 pH difference pre-post autoclave vs. pH post-autoclave for 15%V8 3 y = 0.2125x2 -1.5384x + 2.4157 R2 = 0.9346 2.5 -~'f----~--~ 6 -0.5· -1 pH post-autoclave 34 7 • ...........-----, 8 pH difference pre-post autoclave vs. pH post-autoclave for 30%V8 3.5 = 3 Y 0.1837~ -1.108x + 1.539. R2 0.9959 (» > CIS U 2.5 = .s ::::I CIS ( Ii 2 0 . Q. I (» 1.5 Q. (» CJ c ! :E ":J: 0.5 ,..- Q. 0 .. -0.5 ~-I- 4 2 --.. - -~.---"~- 5 .. -"- pH post-autoclave 35 6 7 $ pH difference pre-post autoclave vs. pH post-autoclave for 50%V8 2.5 y=0.1699x2-1.064x+ 1.5197 R2 = 0.9988 2 2 5 -0.5 pH post-autoclave 36 6 7 pH difference pre-post autoclave vs. pH post-autoclave for 75%V8 2.5 .. 2 y= 0.1555x -1.0415x + 1.6535. R2 = 0.993 CD > ca U S ; 2 1.5 u; oCo eCo I CD () c e :E"C J: Co 0.5 o --~·~~~···· ---~~~-................~-2 3 4 5 - - - - - - T - - ............. -0.5 pH post-autoclave 37 --~------~---6 7 .. conductivity difference pre-post autoclave vs. conductivity post-autoclave for 10% va 4 3.5 G) > ftI .. .. ..• (j 0 :::1 ftI en 3 2.5 0 Q. G) 2 Q. G) (J c 1.5 ! ~ "0 J: Q. 0.5 0 0 5 10 15 20 25 conductivity post-autoclave (mS) 38 30 35 conductivity difference pre-post autoclave vs. conductivity post-autoclave for 15% va 4 CD > 3.5 .!! u .s 3 ....C'O 8 Co 2.5 ::l I ...Co CD 2 CD u 1.5 c ... ~ =s CD ::J: Co 1 0.5 o +--------,------,r-----~------~------~------_,------~ o 5 10 15 20 25 30 35 conductivity post-autoclave (mS) 39 conductivity difference pre-post autoclave vs. conductivity post-autoclave for 30% va 4 GI > I'G U 3.5 --.. 0 3 := I'G 2.5 0 CI ...GIC- 2 GI Q c: 1.5 ... <D ~ "tJ J: C- 0.5 0, 0 5 10 15 20 25 conductivity post-autoclave (mS) 40 30 35 40 conductivity difference pre-post autoclave vs. conductivity post-autoclave for 50% va 3.5 Q) 3 > CIS -U 0 2.5 :::l CIS I /) 0 Q. 2 I ...Q. Q) Q) u 1.5 cQ) ... !E '0 ::I: • Q. 0.5 0 0 5 10 15 20 25 conductivity post-autoclave (mS) 41 30 35 40 conductivity difference pre-post autoclave vs. conductivity post-autoclave for 75% V8 4 3.5 uE ! o y =0.0946x - 0.1243 • R2 = 0.8847 • 3 :::::s (/) 2.5 o Co ! 2 Co CD U ec 1.5 ~ :s J: Co 0.5 O'~-----r-----'------'------r------'-----'-----~----~ o 5 10 15 20 25 conductivity post-autoclave (mS) 42 30 35 40 Appendix F: V8 Concentration, pH, and Conductivity Table 22: Adjustments in pH to achieve desired post-autoclave pH Desired pH 3 6.5 3 6.5 4.75 4.75 2.5 7 4.75 V8 concentration 18% ·18% 53% 53% 13% 58% 35.5% 135.5% 35 .5% 1 Adjusted pH pre-autoclave 2.713 7.9 2.86 8.28 4.65 5.95 2.42 9.78 5.17 I I I I i I Table 23: Adjustments in conductivity to achieve desired post-autoclave conductivity I V8 concentration 18% 18% 53% 53% 13% 58% ·35.5% 35.5% 35.5% Desired Conductivity (mS) 12 38 12 38 25 25 25 8.3 41.7 Adjusted Conductivity preautoclave (mS) 10.71 34 10.83 34.62 22.36 22.73 22.47 7.45 37.48 I I i Table 24: Target pH and conductivity, actual pH and conductivity, conidia concentration, and media color Flask Number .1 12 3 4 5 6 7 .8 9 110 V8% 18% 18% 18% 18% 53% 53% 53% 53% 13% 58% Target Actual pH Conductivity pH Conductivity LOgIO conidialmL 3 12 3.4 11.40 3.70 3 38 3.5 36.1 3.70 ]2 6.5 6.6 11.40 6.24 6.5 36.0 38 6.8 6.71 12 3 3.4 11.52 4.00 3 3.6 4.07 38 36.5 6.5 12 6.8 11.35 6.59 6.5 38 7.0 36.7 7.15 4.75 25 4.9 24.1 6.53 4.75 25 6.0 23.9 7.20 43 Medium I i color Tan i L orange D green i Brown I D green Orange D green Brown Olive~r. Brown I Flask V8% Number ·11 12 13 i 14 • 15 16 17 18 19 20 21 22 23 24 25 26 127 128 29 30 31 32 33 34 35 36 37 i 38 i 39 40 41 142 43 44 45 146 47 48 35.5% 35.5% 35.5% 35.5% 35.5% 35.5% 18% 18° 18% 18% 53% 53% 53% 53% 13% 58% 35.5% 35.5% 35.5% 35.5% 35.5% 35.5% 18% 18% 18% 18% 53% 53% 53% 53% 13% 58% 35.5% 35.5% 35.5% 35.5% 35.5% 35.5% Target Actual pH Conductivity pH Conductivity Flask Number 24.0 2.5 25 3.1 4.12 25 7.4 23.7 7.0 6.79 4.75 8.27 5.1 7.87 6.95 4.75 41.73 5.6 39.5 7.15 25 4.75 5.5 23.7 7.13 4.75 25 23.7 5.5 7.19 12 11.40 3 3.4 2.74 36.1 3 38 3.5 3.52 6.5 12 6.6 11.40 6.20 38 6.8 6.5 36.0 6.90 12 3 3.4 11.52 3.59 38 36.5 3 3.6 4.09 12 6.8 6.5 11.35 6.76 6.5 38 7.0 36.7 7.27 4.9 24.1 4.75 25 6.54 23.9 6.0 7.07 4.75 25 2.5 25 3.1 24.0 4.24 25 7.4 23.7 6.81 7.0 4.75 8.27 5.1 7.87 6.54 41.73 5.6 39.5 7.16 4.75 23.7 7.28 4.75 25 5.5 5.5 23.7 7.17 4.75 25 3.4 11.40 3.35 3 12 36.1 38 3.5 3.35 3 6.5 12 6.6 11.40 6.26 36.0 6.83 38 6.8 6.5 3 12 3.4 11.52 3.59 3.6 3 38 36.5 3.86 12 6.8 6.5 11.35 6.64 6.5 38 7.0 36.7 7.24 4.75 25 4.9 24.1 6.49 4.75 25 6.0 23.9 7.15 24.0 2.5 25 3.1 4.09 7.0 25 7.4 23.7 6.60 4.75 8.27 5.1 7.87 6.82 4.75 41.73 5.6 39.5 7.16 7.10 4.75 25 5.5 23.7 23.7 4.75 25 5.5 7.22 44 !V8% ! Orange Brown D green Brown Brown Brown I Tan I L orange i Olive gr. I Brown I D green I Orange D green Brown Olive gr. brown . Orange Brown D green Brown Brown I Brown i Tan I L orange I Olive gr. Brown ! D green Orange D green Brown Olive gr. : Brown • Orange Olive gr. i D green Brown J Brown Brown Figure 4: Orthagonal CCD analysis of data in table 24 IResponse log10 conldia/mL IWhole Model IActual by, Predicted Plot iii • 7- 1.1 I -..! • • JI ::::I • «13 6- ..J .E .!!! 5:2 t: ~ 4- .. ".- ~ 33 I I 4 5 7 6 log10 conidialmL Predicted P<.OOO1 RSq=0.97 RMSE=0.268 1Summary of Fit RSquare RSquare Adj Root Mean Square Error Mean of Response Observations (or Sum Wgts) 0.974558 0.968532 0.268049 5.892708 48 [ Analysis of Variance Source Model Error C. Total OF 9 38 47 Sum of Squares 104.58464 2.73031 107.31495 Mean Square 11.6205 0.0719 F Ratio 161.7324 Prob> F <.0001 ILack Of Fit Source Lack Of Fit Pure Error Total Error OF 5 33 38 Sum of Squares 1.8510273 0.8792833 2.7303107 Mean Square 0.370205 0.026645 IParameter Estimates Term Intercept V8(18,53)&RS pH(3,6.5)&RS conductivity (mS)(12,38)&RS V8( 18.53)*pH(3.6.5) V8(18.53)*conductlvlty (mS)(12,38) pH(3.6.5}*condUclivity (mS)(12.38) V8(18.53)"V8( 18,53) pH(3,6.5)*pH(3,6.5) conductivity (mS)(12,38)"conductivity (mS)( 12.38) 45 F Ratio 13.8940 Prob:> F <.0001 MaxRSq 0.9918 Estimate 6.7904008 0.2318244 2.1105324 0.112163 -0.013438 -0.000415 0.0774555 -0.416562 -1.320171 -0.373732 Std Error 0.090169 0.048815 0.058234 0.052671 0.057443 0.057178 0.060033 0.066175 0.073988 0.073176 t Ratio 75.31 4.75 36.24 2.13 -0.23 -0.01 1.29 -6.29 -17.84 -5.11 Prob>ltl <.0001 <.0001 <.0001 0.0398 0.8163 0.9942 0.2048 <.0001 <.0001 <.0001 IResponse lag10 conidia/mL IWhole Model IEffect Tests Source V8(18,53)&RS pH(3,6.5)&RS conductivity (mS)(12,38)&RS V8(18,53tpH(3,6.5) V8(18,53tconductivity (mS)(12 ,38) pH(3,6.5tconductivity (mS)(12,38) V8(18,53)"V8(18,53) pH(3,6.5)*pH(3,6.5) conductivity (mS)(12,38)*conductlvity (mS)(12,38) I Residual by Predicted Plot Nparm 1 1 1 1 1 1 1 1 1 OF 1 1 1 1 1 1 Sum of Squares F Ratio 1.620470 22.5534 94.376469 1313.516 0.325819 4.5347 0.003932 0.0547 0.000004 0.0001 0.119605 1.6646 2.847090 39.6253 22.875255 318.3739 1.874161 26.0843 0.75...,.----------------, iii .g 0.50- a:: 0.25- .~ ... . .. . -. .,- ...J E - Cii 0.00'§ c: 8-0 .25 o j-0.50- ,-r--r-i, -0. 75-+--.-,~"'-...,...---r---'r--.- 3 4 5 6 7 log10 conidia/mL Predicted I Response Surface Coef V8(18,53) pH(3,6.5) conductivity (mS)(12,38) V8(18,53) -0.416562 pH(3.6.5) conductivity (mS)(12,38) log1 0 conidialmL -0.013438 -0.000415 0.2318244 0.0774555 2.1105324 -1.320171 -0.373732 0.112163 ISolution Variable Critical Value V8(18,53) 40.140324 pH(3,6.5) 6.1564622 conductivity (mS)(12.38) 28.033043 Solution is a Maximum Predicted Value at Solution 7.6835364 46 Prob > F <.0001 <.0001 0.0398 0.8163 0.9942 0.2048 <.0001 <.0001 <.0001 Figure 5: Contour Profiler i Response log10 conidialmL [ Co ntour Profiler Current X Horiz Vert ® 0 o 0 Factor V8(18,53) I pH(3,6 .S) I €I conductivity (mS)(12,38) I Response log 10 conidialmL 1l ......_ _ _ _ _ _ _1J1 o I I I I I I Contour 35.5 5.25875 23.8531 25 Current Y 7281 7 2nS984 1 "'-- Lo It HI limit Lo Limn Hi Limit ---.Ir------,I I Response log10 conldiaJmL I Contour Profller Horiz Vert o o o Fador V8(18,53) 0 0 0 I pH(3,B.S) I I I I I conductivity (mS)( 12,38) I Response log10 conidi.a/mL ...... 0 _ _ _ _ _~ 'DI I I Contour Current X 35.5 5.25875 23.853125 Current Y 7.281 7.2n59841r----.'lIr---.:....~...,.1 Figure 6: Prediction profiter with maximized desirability I Response log10 conidialmL I Prediction Profiler 7.845 ,,~ . _. -_.----- -~ - '- .- 68.3536 2.74 . ~ Q) 0 .-' ....J E -- ------- ----- .... . -. ...... -- -.,._-_._- (D '0 <=0 u 0 ~ 9tL.-3 0 C. n~ V8(18,53) ......J pH(3.6.5) 47 21..1 n.o; ., W co <.0 ...... (]I Conductivity (mS) (12.3S) 0 De 51 rabll tty