n. TECllNOLOOV LlBRARY. By

advertisement

~!SS. I~STITUH

OF

TECllNOLOOV

25 lUL 1907

LlBRARY.

STATIOHA:tY

TESTS

OF

A

\lIIITE

STEAl.f

AUTOlrOBILE.

By O. G. Fales and G.

n.

Norton.

FOnEWORD.

The \1!'itars wish to aoknowledge thoir

variouc Professors

also

to the

at the In3titute who in many ways aided the work,

to the W"ni

t e Cornpa.'t'ly

who furnished

eopecially

obligation

the oar and equipnent,

to Hr. A. K. Miller tmder whose personal

'Work '\Vasdone, and to whom they are indebted

fornation and advice.

supervision

and

the

for much va.luable il1-

ILLITSTRATIOl!S.

Boilel. of Car.

Page 2.

Engine and Thernostat.

Page 4.

Writer Circulation

System.

Page 6.

Engine as Arranged for Tenting.

Page 8. Cut

General Arrangement

v.

of Car.

Par;(3 10. Cut I.

Countershaft

and Driving Belts.

Pages 11 and 12.

Auxiliary

Fuel Tank.

Page 13. Cut IV.

Pyroneter

Details.

Page 14.

Cut \~.

Cuts II. and III.

C01~TElITS •

Object of Thesis.

Page 1.

Description

of the Car.

Pages

Description

2 to 9 inclusive.

of Testing Plant.

Pages 10 to 19 inclusive.

Description

of Tests.

Pages 20 to 23 inclusive.

Precision

of Tests.

PageD 24 to 31 inclusive.

Tableo of Results.

Pages g2 to 66 inclusive.

Tables of Summaries.

Pages C7 to 76 inclusive.

Conclusion.

Page 77.

I

OBJECT OF THESIS.

The object

of this

a..'rJ.d

economy of the povter plant

various

thesio

was to deternine

of a rnli te Stea!l Automobile under

cond.itions of o:pt3rntion.

Inasmuch

8.S

a road tent

was decided to nuke the tests

can be but roughly apy,roxiT.'k'1te,it

ntationary.

car \7an jacked up from the floor,

To do this

In other rBSJ?ect.s the testo

'\"Terecarried

Vlouldbe, the fuel and water cOl1s~tion

preasure

a regular

stock

and the pov:er ta.ken from tho rea.r

wheels, thus mcasurine the exact power availablo

necessary

the efficiency

for driving

out junt

B.S

any plant

being accurately

and tot!J?erature observa.tions

taJ~en.

the ca.r.

test

measured, and

FIG.

1

THE

WI-lITE

SHOWING ALSO THE BURNER, YAPORIZER,

WITH EXTERNAL

GENEHATOR

PILOT LIGHT AND GASOLENE

CASING REMOVED

W~TU

--~

I

FIG. 2 DIAGRAM OF GENERATOR CIRCULATION

CONNECTIONS

:3

The steam Generator or boiler of the ~~lite System consinto of

a aeries of horizontal

tube, the connections

spiral coils co~~e~ted

GO

as to form a aontinuous

being such that the water or steam on louvi1"1[j

any

coil is obliged to pass to the top before entering the next lower coil,

~hus preventing

the water in the top coil fron descending

by gravity,

and

render ing the circula tiol1 tl~roueh the boiler dependent upon the act ion of

the feed :pumps. A distinctive

feature is that tho cold water enters at

the top, and turning into steam as it passes down through the successive

coils., becomes highl~' superheated

at the bottom in the hottest part of

Another peculiar"!ty is the abcence of any resoryoir

the fire.

for steam or

'\Vater. On the '06 Car the coils are eleven in number and of tubing

3/B in. internal diameter.

!b2.

gasoline

Burner, shorn at (P) fig. 1, is a.dapted for the burning

vapor.

The gasoline,

therefore,

of

r.IUstbe first YD.:porizedby

heat or other means, and then mixed with air.

The main burner conoisto

of a cast iron grate (P) with slots for the mixture

to enter the oom-

'hustion chamber.

The gasol i11e conca from a large tank where it ia under :pressur e

to the ttTttconnection

in the lower pipe shown in fig. 1.

Here a portion

turns to the left to 3upply the pilot light (C) \'.'l:ich

i:3kept continually

burning,

ita offico beine to keep the vaporizer

main burner when required.

The tln.inportion

the !Jain burner, paosing main burner valve (J),

(0) hot, and ignite the

turns to the riVlt to surply

r7hich can be controlled

FIG 7 FRONT VIEW OF ENGINE

4

$)

A

A

~.~.

A

FIG.3

THERMOSTAT

--.

lie'

./

/

0

5

ei ther

from the seat

or from the ground,

and next

through

Wili~h it

is discharged

the vaporizer(O),.whioh

into

The thermostat

copp'3r rod. inside

ally

adjuoted

fitted

to close

with plain

trolled

all

oloses

in fig.

enclosed

at a tenperature

slide

by a hand lover

v~lves

asbestoo

a section

A front

and elevation

As operated

The engine

fig.

directly

is direct

rump (n) fig.

6, for p~~ing

and returninc

th.~ latter

ptU:1p3

,

time.

(S) and (T),

motion con-

by a foot

a

pedal,

r.tain a.re heavily

is

lagged

ohown in fig.

",i th

7, and

G.

on air-cooled

of the tests

into

connected

air

cO:'lpound,

The (c:ngine is ball-bear-

the air

to all

the exhaust

as in fig.

and condensed

to the feed tank,

fig.

condenser

pipe

flO.S

removed

7.

pumps:- an air

the l':"ezsure in the gano line

6, for naintaining

cross

und in casen where u

the engine e.xl1austs into

exhausted

m1})2."'ly

It has also

7, controlled

view of the ensine

in fie.

link

of the oporator.

for a short

0.

it being gener-

vertical

fie.

of

in the steam main, and

moved by a Stephenson

sho\111in cut V, but for l)urposes

and the eneine

(Y),

after

conoists

in u two cylinder

and the oylindi:3rs and stean

oement.

It

BOOo}'.

and (11),

maxitltL':1of rower is necessary

3.

or f6.lls,

cut IV, which is always used in starting,

ing throughout,

a hollow grid,

of about

at the side

(10),

the thermostat

or opens the nain bur::er

of the steam rises

The engine

sir:rp1ine :le't.rice (9),

(e)

tube,

expannion

The Engine.

is cinply

is shown in detail

as the tenIHrature

through

the mixing tube (11:).

of a steel

'\Ihose differential

valye

thence

!lump (P)

ta.n1~; a. vacuum air

steam from the condenser

5; also

t\'10boiler

feed

the one shown at (T) beil1:: })rovided with a bY-r>ass

6

FIG.;)

,rATER

CIRCULATION

SYSTEM

p

FIG.4

WATER REGULATOR

7

autormtioally

controlled by otea.!!1

:o:'oGsu::oe,

and tl~G.toho\':11

at (S) wi th

a by-pans controlled by hand by means of the v~lve Cg) cut v.

'rhe throttle valve is controlled oy a small hand wheel lom~.ted

above the steering wheel.

The engine is conneoted to the rea~ axle by ahaft drivG i7hich

is provided 'with a olutch and one ohange gear, allowing the engine to

be run independently,

and also to allow of cha:~gins ratio of 8r~ed of

rear axle to that of engine.

ID1d force-foed

~

lubrication

The oilers are located on tho dash-board,

is obtained by means of a snaIl belt-driven

Fuel Supply. In ordinary operation

the fuel is kept rmder

:pressure in storage tank (h) out- IV, the caraoity of which io aoout fifteen

gallons.

The air pressure

is oontrolled by a foot pedal shown at (m) cut IV.

The tank is provided with three pet-cocks

The Feed Water Control.

fib. 5.

eivin£; rou:;hly tho ganoline

The water circulation

The water is taken from the feed ta.n.~ (28),

level.

systmn in nhoyrn in

through the main

suction (14), alone through pipes (27) und (28), through the lower feed

2

:pump controlled automaticc.lly, through the delivery (29) into pipe (14 ).

Then if :pressure is lO'7~erthan the regulator

to the generator(ahovm

io also provided

is net for, the water goes

at the right) throu{~h pi'pe (29a).

A hand pump (17a)

so that water ms~ be sup~lied to generator

~lcn

engine

is not running.

The adnission of the water to the eenerator

pressure rogula.tor (9) shown in detail in fig. 4.

is admitted against a dluphrc.gm at (n),

is controlled by

In thio, steam pressure

and in opposed. by the recistanoe

of

8

CUT

V

--

9

When tho steam pressure

the spring (G).

comes the resistance

on the diuphrar;n over-

of the spring, the vulve at (P) opens, nllo\."ing

t:::ewater to flow through the regulator

:lnd out at (0),

then back

through the pipe (28) fig. 5, to be pl..W:pedaround the circuit again.

2

into pipe (14 ) and has a by-pass

The other pump delivero

to the feed tank controlled

The vacuum pump (33)

by hand v~lve (28a).

takes water from the condenser

through ]?ipe (34) and delivers

feed tank through pipe (35).

Hence in operation

:lre supplied

becones

intermittently

exoessive,

it to

both fire and ~ater

require;

tllUS

if steam pressure

the water supply is stopped by the ~ater regulator,

and if the temperature

off the fire.

as conditions

(16)

exceeds the correct amount,

On the other hand,

the thermostat

shuts

if there is a large demand for stoan,

the firo and. water both come on and the increased

der..andis 8Up1)lied,

the system thus being self-regulating.

For the purlJoses of the test an auxiliary

on, connections

gasoline

(itt)

being made throueh globe valves

could be taken from oither tank through

to the burner.

tank (11') '\"las

:put

(1) and (i') so that

the main SUl)~ly valve

At first plug cocks were used but could not be made

tight, so the glooe valves had to be substituted.

The joints were all

teoted for leaks when und0r :pressure by using a lighted match, a method

somowhat

dangerous

but decidedly

mainta.ined an previously

hand air pl~

available.

(j)

effective.

Prescure

in main tank is

noted, by air pump on engine; there in also a

cut V, which io used to get pressure

A "Tn was substituted

is not

for the elboVl'at (K) cut IV und con-

n.ection made through a needle valve (1) to the auxiliary

that preosure

~hen po~er

could be kept in ei tIler or 1::oth tanks.

tank (hi) so

10

CUT

I.

11

12

CUT

III.

13

CUT

lYe

14

15

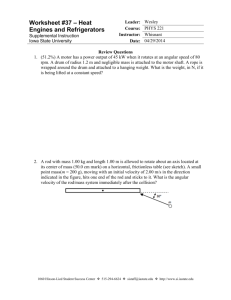

DESCRIPTION OF TESTING PLANT.

The general arrarigement of the apparatus

in 3ho\711by

cuts I, II, and III.

The automobile

itself wao a 1906 model Touring Car.

For

these tests it was raised from the floor by jacks placed under the rear

axle as shown on cut I.

From the inflated tires of the rear ,;,heelsdriving belto extended backward

to pulleys

(0) on counter-shaft

shown in cuts II and III.

To keep the correct tensions on the belts, and to take the atreso due to

the pull off the temporary hangers,

structed

the struts (d) cut II, were 'con-

to extend from the rear a.xle diroct to tho hangers

at the

height of the boxes.

On one end of the counter-shaft

a 5in. belt, an Edison-Type

cut III.

The power developed,by

water rheostat

baing

Compound,

driving by

was a large pulley,

12 Kilo-Wa.tt Generator

thia generator

was absorbed

3ho\'1non

by a

(11) cuts I a.nd II, the bank for lamps shown in cuto not

u:::;ed.

In order that no steam could e3cape and be lost, the oafety

valve in the steam main ~as removed and a blank plug substituted.

A 1500 lb. gage (11) cut V was used in place of tho 750 lb. gage with

which the car \vas originally

.

equipped.

in the steam main, clooe to the boiler;

of the boiler steam "Jere obtained.

Each car has a thernometer

well

thus the presst1~e and tenpcrature

As both of tho3e quantities

were

16

reduoed

in passing

the throttle,

one was introduoed between

with

0.

cut V.

thermometer

a speoial pipe in :place of the regular

the throttle and the stearn chest,

well shown at (0)

These gave the temperatures

provided

out V, and a gage ohov.rnat (p)

and :9reosuroo close to the steam

chest, and the pipe and fittings being ca~erully

lagged with asbestos,

no heat was lost by radiation.

At firct thermometers

was broken by exoessive

were used in these two wells, but one

vibration

was deemed adV'isable to substitute

.plaoes.

This apparatus

of the oar durinG testil~,

Thermal Junotion PYro~etors

was oonstructed

as follo\7o:-

selves l';"ere

of oopper and niokel \1ire brazed

of these junctions was plaoed

and so it

at thece

The jtU1ctio1l3 them-

together wi.th si1vel'. One

in eaoh well and the wires led through :pipe

to the cold junctions,

Tho temperatures

of the cold junotions

out VI,

from the external binding post on each of the oold jtU1ctions

WCTS

!'1.U1

one of which is ohorn at (q) cut

v.

clay insulators

"iere taken by thermometers.

to the double throw awi tch shown at (:::;).The niddle points

wero oonnected

through a 2100 ohm series resistance

wall galvanometer

ohovm at (u) cut VI.

during teste, whicl1 observations,

junotion temperatures

the ter.rperatures at these pointa,

Tb

cut V introduced

to tl1e suspended

Here deflections

~irror

were observed

cold

curve, eave means of oalculatir~

whioh appear in tables nnder colu::ms

and To •. For details of these caloulations

The temperature

of this 3ui toh

together with the oorresponding

and calibration

1/ireo (1')

see page 32.

of the exhaust steam \'Iastaken by thermometer

within the exhaust opening.

The feed water temperature

(v)

17

was taken by a thermometer

suspended

in the feed tank (f)

cut

v.

The feed water was '7eiehed in a barrel on a set of Fairbanks

scales which could be read to 1/2 lb.

The ~1ater wao pumped from thin

barrel through hose (x) cut V, by a small hand pump to the feed tank (f).

At beginning

and end of testa the water level was brought

'to the same point

in rin a~o1.U1dthe opening at the top of the tank.

110 trouble was experienced

vlith the driving belts at (b)

cut I, either from running off or slipping on the wheels, but as the tires

bagged tho belts considerably

.pulleys (0)

an excessive

was aocomplished

it '\7asfound necessary

crown to steady the rmmine

to give the small

of the belts.

This

by surrotU1ding each pulley ~1ith a strip of leather in the

center about 1 in. wide and 1/8 in. think.

the sn~ll pulleys occasionally,

At first the belts skidded on

but increaoed

tension and a liberal use

of belt dressing obviated the difficu lty here as well as in thd vertical

belt (b) cut III. Guides were also used uherc the belts a:pproached the

smll

pulleya.

The length of the struts (d) cut II could be adjusted

small limits by double wedges at (y) cut II.

cut II was attached

A revolution

within

counter at (z)

to the shaft and read during testo, frot! whi~h the

average speed, shown on the ta.bles, wac calculated.

THE ELECTnrCAL

C01HIECTIOlIS.

of the dyn~mo wan separately

anticipate

parallel

During all teots the shunt field

excited front the light r.lainsin order to

any excitation troubles.

A tell-tale

ill the shnnt field circuit,

light was placed

shown at (1) cut III.

in

The nhnnt

field rheostat wan placed on swit~h board and sho\~ at (R) cut I.

The generator

different

oomnutator

times from sparking,

gave a great deal of trouc,le at

causing the loos of several teoto, both

18

insulc.tion and brushes burnil1.g.

The mains 0.0 cut III

led froD the dynano alone; the wall

through two l50-awpere fuses sho,,:n at (F) cut I, through the line

switch (8)

cut I, a.nd the ammeter (A) to the \'iater rheootat

power was absorbed.

The a~eter

was a milli-voltmeter

(V!) ~;here the

used with a

l50-ampere shunt.

The \vater rheostat

brine.

The electrodes

was :::ade of an oil barrel

were two furnace grate bars.

filled

One of the leads

led to the bottom one, a wooden cleat beine placed above this

short cirouiting.

with

to ~revent

The upper grid eG) cut I. was sU3}lendedfrom the

frame work ohownand counterweighted,

so that by raising

it tho resistance

hence the cU'r'rent and load on car,

could be 8.1tored.

of the barrel,"

D.nel

lIo t-:-ou.t.lewas exper ienced from this

cepting once when the lover lead was corroded off.

cut I,

\7US

or 10V!erine

apparatus

ex-

The voltmeter

(V)

tapl)ed into the mains between the fuse and the main s'\7itch.

A diagram of electrical

connections will be shown on Page 19.

19

Stray Power

l/t-'/"ring.

Sh.

S.

B.

D ynOi77

0

I/I//"r/ny .

.f

20

DESCRIPTION OF TESTS.

In view of the diminutive

speed of rotation,

indicator

of tests.

cards;

size of the er~ine, and its high

it huo been found irrpracticable to take accurate

this, therefore,

was not attempted

Ao will be seen from the description

power measured was the actual power available

and on the whole, tl1e results

in the present

of the apparatus,

group

the

for driving tho car,

so obtained wore of more practical

value

for so b0ing.

In preparing

for a test the pilot light (C) fig. 1, was first

ignited and allowed to burn for about three ~inutes,

fig. 1.

thus heating

the-

After ma.king aure by use of the hand pump that the

vaporizer

(0)

generator

was filled with 'Water, the main burner was turned on by opening

valve (J)

fig. 1.

When pressure

was observed

on the boiler gage (n)

cut V, u cock in the steam main was opened, allowing

out of the pipo3.

the water to blow

When steam appeared here, the cock wan closed,

the

throttle valve opened, and the slide \"alveo of the ep.gine moved by

mauns of the reversing

lever, until, all water being thus blown out of the

engine, it started turning over, the car then being ready to start. The

whole operation

of getting under way did not take over five to seven

minutes.

The engine was next run free, (on the neutral)

tine, and then tho rear wheels and generator

were thrown in wi th no load.

After a few minutes the speed und load ~ere grawlally

the desired point.

This :point being reaohed,

for a ahort

increased

the \1holo apparatus

up to

was

21

kept running under load conditions

readings.

for a half hour before taking any

Thus the testa proper Vlere started. a.bout one hour

lighting UP.

after

The fuel for this hour of runnilig came from the regular

tank (11), and was not measured.

On starting readings the water was brought to a leyel in the

rim of the feed tank, the reference

mark being a downward projecting

metal point, the exact time being taken in minutes and seconds.

Before lighting up a supply of gasoline was weigl1ed and introduced

into the auxiliary

tho souroe of fuel supply

tank (hI) out IV.

\'lUS

After 1eveline ~ater,

shifted from the main tank (11) to the aux-

iliary tank (h') by opcming valve (i I) and closing (i) at sane operation.

This too}: v.bout five seconds, and tho gasoline was tined fron the

third second.

The fuel und water SU}):rlyhaYing thus been started, the reading

of the oounter followed on the next full minuto.

Thon followed

in regu-

lar order the readings of am."neter,boiler ter.tperature, steam chest temperature,

pressure

exhaust tOlilperature and feed VIater temperature,

on fuel tank.

oiling apparatus,

end air

These observe.tion3, together wi tll load adjustmontn,

and weiehing and supplying feed water, constituted

IJan's duties; the other oporated

the er:gine, read the voltmeter

one

o,nd

boiler and steam chest :pressures, and kept the tine.

At the end of the test the fuel supply from the auxiliary

tank was shut off and tine noted.

ivnediately,

weighed.

Tho o.p:paratuswas then shut clown

water leveled up again in feed tank, and supply burrel

Thon the gasolil1e re~inillg

in the auxiliary

tank \'Jasdrawn

out through a spout on the botton fitted with globe valve, and weiehed.

22

The differer.co

of tho weighings before

The extreme flexibili

test ing much more difficult

stat

opened the burner

explained,

necessary

fall

all

ready

explained

frequently

attendance

was also

oc~urred

For the first

but

in boiler

it

~ressure

instruments;

voltmeter

'\VOl':>

to disturb

as often

at

test

all

After

thin

three

minutes

correspond

by !fOhn's

This gave the same result

ar.u:leter every minute,

variationfJ

of the feed water

the equilibriun

readings

of the

it

was

control

syster-.

loo.cis,

constant

were taxen at five

the frequent

great

readings

and. 3tearn chest

ninute

fluctuations

of sono of the

and

every r.linute in the succeeding

tests

The ammeter readings

Law", and a reading

reading,

uas found for

of the anneter

and interpolated

as 7t"ould have beon obtained

and consequently

in reaQ.in~s vlera, to a large

so 1011g a time was opent in each test

were taken

to road then any oftener.

of the water barrel

to each voltmeter

uhich

The subsequent

tllt1.s neoecGi tatint;

an it was inpossible

the resistance

in voltage

pressures

be seen from the tables.

every 3rd minute,

an before

150 pounds or more.

a littlo.

for more froquent

\7ere taken

YEhenthe thertlo-

the engine.

uoco!'din.~ly the boiler

readings

accurate

as every minute on the high

then scen that

called

instantly

The effect

on the lOfT loadS,

and regulation

intervals,

alrIost

the throttle

was more eradual.

These fluctuations

alld less

rose

plant.

on tl1() main fire

in speed and rioe

to check by. closing

in pressure

as will

J~hus turning

increase

gave amount used.

ty of the '.':'hite System rendered

pressure

Tllis caused a ~rked

test

than ::-ith an ordinary

valve,

the boiler

and after

the

each

cOLiputed to

in the tc.blcs.

by reaiing

inaccuracie'o

extent,

elininated.

obtainine

unifoTn

the

due to the

!nasrn.t0h ns

cond.itions,

a

22

leneth

of tezt

of warming up,

of 45 minutes,

is believed

tU1forezeen accidents,

in these

cases

together

ytith a rrelininary

to ha.ve been sufficient.

several

of the tests

check runs were alrrays nade.

half

hour

On account

were nhortenedj

of

hoy,'ever,

24

PRECISIOU

.9l:

TESTS.

The product of the voltneter

a.ctual :power output of the generator.

amotU1t of the car power

friction,

power.

VIas

absorbed

a.nd ammeter readings

gave the

In addi tioll to tllis a conoiderable

in belt losses, counter';'chaft

lleating looses in the arnatt~e and series field, n.~d stray

To aocurately

account for these losses, data fo~ a set of

stray power ourves were determined

and armature voltage.

The generator

furnished

under different

oonditions

The method :puroued was as follows:was cOl1nected up us a motor, tho current beir£

from the lieht mains.

A oo.r was jacked up so that the driving

belta (b) ran on the front wheels and the whole belting

by the motor.

The stray power measurenonts

ing and friction

slight friotion

of speed

losses in the apparatus,

system Vlas run

thus taken inoluded all beltthe only error being very

losses in the front wheels ~hich ran very easily in

ball bearings.

The eleotrical

on Page 1.9.

connections

One wire of the light ciroui t is cOll.'1ectedto binding post

(L) on starting box (8 B); in running,

is at the right.

ammeter

other light cirouit wire.

fiold(Sh).

the handle of this sta.rting box

The lead then goes from binding post (A) throue;h the

(I), series resistance

connection

for the stra.y power tests are shown

CRl), series field and armature, to the

From the binding :post (F) on startine box

ia made through the serios reoistance

(nC)

to the shunt

w

Tho othor end of shunt field io connected

outside of the armature.

Thus the armture

to the lieht mains

current could be measured

25

exclusi ve of that e;oing through tho shtmt field •. The voltmeter

gave the drop in potential

around the armature;

uhich, taken together

with the arma.ture current, gave the groao :power used.

pOfler ilas obta.ined by subtraoting

(E)

The stray

fron thio the heat ing loss of the

series field fi.'1d

a.rmature.

.

In "'obtaining

data for anyone

curve the resistanoe

in the

shlmt field was made a certain oonsta.nt 8.nount. Thus the armature

voltage was proportional

to the sreed, or tho ratio of arr.lB.ture

voltage

to speed '7.asa constant.

In a motor the arnature voltage is equal to

the voltage arormdthe

armature minus the drop in potential

to the product of the resistance

of the arr.m.turetines the current

In a dynamo the armature voltage is equal to the ~

through it.

of these two.

resistance

equivala.nt

When the maohine is compounded,

of the series field io reckoned

The series resistance

in the armature

0.0

was this one, the

in with that of the arma.tUre.

circuit wo.s changed so us to nake

the motor run over wide. ranges of speed in the several teots.

sucoessi va op.eed, as determined

voltage,

by a magneto,

and speed of oOlmter-shaft

At oach

readings of current,

wero taken every 30 seconds after

these values had become conotantj and the values given in the tables

for anyone

:point are the meuns of ten succesoi ve readings.

\TIlen

points were taken over the roquired range of sp~eed8, the resistance

in

the sh~~t field was char~ed and data for another ourve ~ere taken.

Thus elata for fOUT curves wero obt.ained; but inasmuoh as the belt losoes

were much greater

than those within the generator

itself, the variation

\'lithchange of speed was much greater than any due to chunge in arma-

26

ture voltage.

coincided,

For this reason the curves fit low speeds practically

and at the higher crpeeds came'so close together that it

was thought best to plot but two.

Since during the car tests there were changes

and adhesiveness

in the tension

of the belts, a series of stray power teots '\1asrnn

after the completion of the tests in order to detect any change in

belt losses which might have occurred; but the results of those latter

tests show no changes at high speeds and very little at the lower sreeds.

The following

computation

for

ffilY

is a sample of the method used illmaking a

one point:-

Data:E, the voltage around the a.rmature = 61.42 volts.

I, the current in armature == 9 amperes.

Speed (connter-shaft)

Resistance

= 422 r. p. m.

of artlature -plus resistance

of series field

= .473 ohma.

Computation:I x E

=

553 watts.

Thin ia the gross power

From this subtract the power absorbed

field,

supplied to machine.

in heating

arnature D.nd series

equal to the square of tho current tines the sum of the re-

,.,

siotances of the a.rmature and series field; (I)"'"x R=

stray po~er = I x E - r2 n= 553 - 43

Va ( the armature voltage)

61.42 - 4.26

= 57.16

=

=

43 Viatts.

510 ~attD.

E - I TI=61.42 - 9.00 x .'173 =

volts.

Therefore:-

V

Sa

0.1354.

27

28

Eaoh curve is plotted

'Poweras ordinateo,

for a oonstant ratio

tables).

with. stray

and the corresponding speed as abscissae.

The use of the curves isw

and current

V

of ~

£ollowo:-

The terninal

vol tago

of the gene-rator are known, (averages of colunms I and E on

Va = E plus I Uj hence ratio ~

in determined.

Then a. value

for the s~ray power is found correnponding to the average speed of

the counter-shaft,

if neccsaa-ry.

heating loss,

nnd tl1e ratio

~

interpola.ted

The sum of load delivered,

ioequal

betveen the curves

J~heatray rower, and the

to the out-put of the car.

Precioion of stray po~er:the readings are surely accurate

Ao all

to r.rithin 1 7~' and hence the stray

power refJul ts are probably good to within 2

most is only equal to 25

% of

inotrumento were calibrated

%.

The stray power at

the car power, so tho percentage

due to the error in stray power cannot be overl.O

The scaleD on r;hich the water burrel

accurate

to 1/2 Ib; therefore

ing at Dtart

Ul1d

c!':.dof a test

used in the tests

water was slightly

the greatest

was 1 lb.

%.

waG weiGhed were

possible

error

in weigh-

The average amount of water

was 117 Ibsj hence the error due to weiehing of feed

less than 1

%.

The a.rea of li:pped ol'ening in the

feed tank (f) on cut V was 16 sq. i11.

The levelo could certainly

determined '\'!ithin 1/4 of an inch of each other,

possiblo

error

00

be

that the greatest

errOT from this source was 4 'ou. in. of water, or .145 of a lb.,

which was well within tho error of the test.

Tho scales on which the gasoline was \'leir;hed ~O!'e gl"8.duated.

possible

to 1/4 of an ounce; hence the rnaxiIIlUl:1

error due to weighing

29

was 1/2 an 01ll1ce. The averar;e

hence the Teroentage

believed

adhering

amOl.U1t

of gnooline used wan 11.82 Ibs;

error due to weigl1ing alone was .38<%.

that some gasoline YTas lost in evaporation

1\3

in pouring

it rras

and by

to the sides of the Vieighir.gvessel, testo \10re made to de-

termine the c.rn.ount

of this 10s3 by ';7oiehi11(;

up nome gasoline,

pouri!:g

about 20 Ibs. (the usual amotUlt) into the auxiliary tank, drawing it

>

off, and weighing again. Tl1io oporation repeated sever~l tines gave a

constant

10130

of about 1.5 ounces, so that this ar.1ountis subtracted

from the apparent amonnt used, thus eliminating

oouroe.

The maxi~~

ceed 0.5

%.

~robable

tIle error from this

error of fuel neasl~enent

In tho first teet tho gasoline was meaoured

graduate,

the Bcales not being available,

error in fuel measurement

were correoted according

80

especially

thermometers,

in a quart

in this teet the

is probably as great as 1

All anmeters, voltmeters,

were carefully oalibrated

and

did not ex-

%.

pyrometero,

and gages

for these tests, and all readings

to theoe ca.librations, hence the error in this

'direction is regarded n negligible.

The variouo instrument

as close no changing cond.itions ~ouldwa.rrnnt,

to this cause is also negligible.

0

I

were read

so that the error clue

30

STRt\Y

Ea

Ia

Speed

POWER

I E

~.

.IaTIa+q

s.

p.

Va.

S

Va

I

91.86

83.32

76.00

68.10

61.12

51.05

43.04

11.52

; 10.74

1p.12

~.55

9.00

8.50

7.92

654

602

536

478

422

3e1

298

Curve No.

1.

1060

895

768

650

553

433

341

63

I

55

48

43

43

34

30

997

840

720

607

510

399

311

86.41

78.30

71.15

63.58

57.1G

47.02

28.29

921

764

G44

500

385

296

192

88.23

80.42

71.99

61.25

51.58

43.07

30.60

824

728

567

465

323

245

93.02

• 1695

84.91

.1715

72.62

.1718

63.01

.lC84

48.89

.1642

30.26

.1611

sum = l.00G5

r.t~~:tJ.

l67 Z

.1322

.1:303

.1326

.1333

.1354

.1302

.1286

.9£2G

sum

rnea1J.=-..13J8

=

Curve No. 2.

93.17

84.94

76.22

65.13

55.13

46.40

33.58

10.43

9.54

8.93

8.18

7.49

7.04

6.25

576

514

476

402

340 .

291

207

972

810

682

532

413

320

211

Curve

97.30

. ?8.97

76.32

G6.51

52~03

42.23

98.53

87.85

79.54

71.32

60.GO

45.25

9.06

8.57

7.81

7.38

6.62

6.26

8.55

7.98

7.50

7.14

6.63

5.88

548

495

4t')t'\

~~

374

298

244

523

467

422

379

326

239

51

43

38

32

27

24

17

58

35

29

26

21

19

Curve

lIo• 4.

842

702

597

508

402

35

30

27

24

21

16

2G6

=

110• 3.

763

506

491

-344

264

88~

.1532

.1564

.1513

.1532

.1516

.147G

.1476

1.0609

Sl.L"n

mean = .1516

= ..

II

1

807

672

570

484

381

250

94.48

84.07

75.98

67.94

57.46

42.47

sum

.__

=

rJ.eD.11.

• 1804

.1798

.1843

.1792

.1763

.177'7

1.0777

=--l'l~

31

STRAY

POVlER DATA.

The fo11ov:ing set of data wus ta.kon after the cOr.1I'lotion

of all of the tests on tll0 car.

ascertain

what ch~~e,

The obj ect of doing this was to

if any, had taken ~laoe in the friction

belt losses" due to adjustnents

and

of the a~paratus.

~.

.s•. P.

Ea.

1a

Speed

IE

IaRa.-ts

92.,05

11.07

10.35

9.89

9.16

7.83

853

588

1018

864

728

563

318

46

40

37

Sl

691

532

23

295

83.76

73.68

60.35

40.73

515

413

273

972

828

Va.

Va

S

87.80

70.88

69.97

56.92

37.79

.1346

.1358

.1358

.lS77

.1385

StL~ =.6824

mean -.1365

Ao shown by the

fo11o\i"ing

compara t i ve columns

in stray power was negligible.

S. P.

s.

970

830

972

828

691

532

295

690

505

275

P.

Diff.

2

-2

1

27 "

20

the

chanGe

I

I

1'0

L

t

"

I

t

~

+

I~ ~

i

I

I

u

U)

~l

~

t

-+-

I

t

I

1

t

1

1

I

~.,

I

I

t

i

i~

~-

t

t

i

I

~ t-

r ...,.

I

I

r--'I

f

i

i

T

J-I

I

i~

I

I

~'t.

I

l

ft

~T

I

,..

en

~

1:

Wc2<9l

2

32

EXPLANATION

The following

tests.

2!

TABLES.

tables are oopies of the 10g13 obtained

on the

The oolu.'?l1s

oontain the follor:ine data::Tine:"I:-

This oolumn oontains

the tine intervals

in ninutes.

This colUDn oontains

the ammeter reading

13 ,

ohov:ing the cu!'rent delivered

E:-

(uncorrected)

by the dynamo.

This oolumn oontains

(lU1corrected) showing the potential

the reading

of the voltmeter,

acrosu the terminals

Pb:-

Tlds ooltunn shows the boiler

p s:-

This oolur.u1ahows the uncorrected

gage at t11e engine, close to the high pressure

of the dynano.

gage readings

(tmcorrected).

readingo

of the

13team cheat.

Tb:-!-'Thi3 ooltttm in the first t\10 teots contains

the temper-

atures (in degrees centigra.de) of: the stean ao it left the boiler;

teots 3 - 13 inclusive have two sub-coltL~s

the general head

To.

(e) and

(0)

tmder

In these testo the tempera.ture was obtained

the ther~al junction pyrometers,

actual galvanometer

headed

by

and tho values in column (g) are tIle

30ale deflections,

arc the oorres!,onding neold junctiontt

va.lues the temperatures

the

and the values in column (e)

temperatures.

From t}lese two

are worked out by the aid of a. oalibration

curve

of tho apparatus.

Ts:-

This oolumn containo

temperature

data for the steam

in the throttle pipe olooe to the atea.n chest; the sub-columns

and (c) as explained above, are T-,yrooeter readings

temperatures

are oomputed.

(g)

from which the

33

At the bottom of each of these columns \ViII be found the corresponding

average temperature

as obtained

fro~ tlle average pyroneter

ree.dings.

Tho colu.'TI!ls

Tf and Te record the temperatures

of the feed

water and of the exhaust atea.'nin. desrees Centierade.

The averages

the calibrations

of all these columns al'e correot.ed aooording

of the various

to

instruments.

Then below, on the lowel' part of the log, are found oo~e a.dditional data relating

to each areoial teat, such as ttVlattsdelivered",

tained by multiplyine

averages

of columns I and E:

"Heat loss"

ob:a

"stray pOVlertl, gotten from stray power curves aD before mentioned

detail.

The value

of average

which is easily obtained

hour.

of air kept on the gasoline

Following

boiler

apeed of the car in niles per

air pressurett

means tLe average prescure

fuel tanks (h) and (11').

each test io8. page of computationo

efficiencies.

in

apoed of counter-sha.ft is given, from

the probable

The value of "Average

r2n;

of engine and

In those latter c01:Iputations the heatine

va.lue

of 18,770 B. T. Uta. ~or lb. 10 given to the ga.soline. this value

having been determined

Bomb in the Institute

gravity

of .701.

by a serieo of careful tests r.-iththe.Mahler

Heat Laboratory.

The saj'i1:ple

showed a specifio

The values for the specific heat of superheated

steam at the varioua pressures

were obtained from Bureoon's

Tablea.

34

TEST NO. I.

I

Tins

Sta.rt

5

10

15

20

25

SO

35

40

45

50

55

60

65

'23.2

23.5

23.4

23.5

23.3

23.0

24.0

25.1

21'.L_

25.0

25.3

26.0

25.7

26.8

SUI:1S

339.5

24.25

Averages

Cor. Av. I 25.45

Watts delivered

n

heat laos

It

stray

E

Ph

100

107

108

105

103

100

102

108

112

106

107

108

400

380

640

410

260

170

190

270

630

400

430

370

105

107

1478

105.6

10G.3

180

260

4990

356

516

I

T

Ps

Tr

100

11.4

12.0

1n.O

12.3

13.3

13.4

13.2

13.2

13.2

13.0

-417

417

13.5

420

13.3

419

305

310

311

313

313

312

312

314

314

420

420

5461

420.1

4~0.1

314

311

4276

305.4

305.4

95

85

90

87

100

100

100

95

95

95

93

13.3

105

102

13~3

1342

181.4

95.9 12.96

95.9 12.8

T h

s

280

282

414

424

424

417

423

424

285

422

'l

e

130

133

135

169

161

161.3

164.0

161.7

160.2

163.3

164.4

163.7

162.8

160.3

2190.7

156.5

155.7

Average speed = 750

II

air presoure = 49.4 1bo.

2710

307

power 1330

Total power 4347 Watts::

5.83 H.P.

Wa.ter ussd in 66.0 minuteo-138.5 Iho.

»

tI

tI

60

tI

=126.0 u

Gasoline used in 66.0 minutes:

II

n

II

60

n

11.64 lbs. water evaporated per lb. of gasoline.

tt

per Horse Power IJGr hour.

21.60 u

1.86 "

gasoline"

It

It

It

It

=

11.901bs.

10.83 II

35

TEST NO.1.

Data,for Engine and Boiler Test.

H. P.

=

5.83.

1

Water per R.P. per hour

Dir.tensions

of Engine 3&5'tx~.tf

Pb= 51~_ 1bs. per sq. in.

Ps.95.9 n

n

»

»

!b= 788°F.

Cp at 516 lbs.

Ta= 582oF.

Cr at 96 Ibs.

Computation

A

=

=

.69.

U. due to auperhea.t

Cp(Tat~.-Tsat.>

by Ene.

1322 B. T. tI. received

=

21.6 Ibs.

.558

t-:.

B. T.

-

B. T. U. :per II.P. min.

=

for Engine Tect.

at Py:_ 111~48

6

=

Ga.soline II It

tt

It

1.50 u

Actual evap. per lb. bauoline = 11.G4 Ibs.

l3226~ 21.6

=

=

=

.558(582-335)=

138 B. T. U.

476. Eff~= 4~~~~~B

=

8.9n;fo

Computation for Boiler Teat •

tf -=

.{ at Pb :, 1226

6 =....@.g!

(

788-1(3)

.69

=

224 B. T. U.

1450 B. T. U. delivered by Boiler.

Eff. of Boiler

=

Eff. of Plant

=

Equiv.

=

(14fiO - 23)x 11.64

8S.~

18770

8.92 x 88.5

7.89%

=

evap. rer lb. gasoline fro~ and at 2120F

=

(1450 - 23)x 11.64 ---------17.31bs.

985.6

36

TEST

I

Tine

start

E

Ph

45.8

102

150

130

51.0

108

52.0

108

2

4

160

6

..8

10

12

120

110

160

150

160

200

230

120

300

160

2150

165

325

14

16

18

20

22

108

49.6

50.2

!Q1.

533

248.6

49.72 106.6

52.22 107.3

24

StL'"nS

Averages

Av.

COT.

Watto delivered

n

tt

no.

2.

P

s

124

120

126

135

130

130

140

145

135

145

138

135

135

1738

134

.134

T

T

b

Tf'

T

s

e

15.0

429.3

329.3

IG3.8

15.0

428.8

332.0

160.3

14.8

411.8

328.4

157. !

15.2

407.0

326.2

157.2

14.4

74.40

14.9

14.7

401.0

2077.9

415.6

415.6

326.3

1642.2

328.4

328.4

15'7.0

7n5.7

159.1

158.3

J

Average speed : 784

It

air preGsure

44.5 lbs.

5600

=

heat loss

1290

stray power 1450

T-ota1 power 8340 Watta.= II.ISH.P.

Water used in 90.0

It

It

If

10.12

15.20

60

minutes =8~.0 1bs.

tt

=170 • 0

tI

Gasoline used in 25.0ninutos=

tt

tt

It

lbs. water evaporated per lb. of gasoline.

It

It

'Per Horse powor per hour.

1.50 1bs. gasoline per H. P. :per hour.

60

It

=

7.00 lbs.

16.8

tt

37

no.

TEST

Data for Engine and Boiler Test.

H. P. = 11.83

Pb

Pooa

---

325 Ibs.

134

Tb

=

7790 F.

Ts

=

Water per H.P. per hour a 15.2 lbo.

Gasoline""

"

"

• 1.50"

Actual evap. ~er lb. gasoline =10.12 Ibs.

per sq. in.

"

"

tf

If

On at

ci> at

6230 F.

./

Comp~tation

A at

Pa

=

6.

325 1bs.=

134 1bs.=

.69

.593

for Engine Test.

6 ~

1193

=

593 (623-36S)

140.5 B. T.

u.

150

1343 B. T. U. received by Eng.

B. T. U. ~er H.P. min.

a

1343x15.2

60

Computation

=

340: Efr.:

=

33000

12.47%

~40x778

for Boiler Test.

6

1213

=(779-428) .69

=

242 B.T. U.

242

1455 B. T. U. delivered by Boiler

=

(1455-27)x 10.12 18770

Eff. of Plant : 0.5~

Efr.of Boiler

Equiv. evap. per lb. gaooline

77.0

%

(from and at) M(145n-27)x

965.8

10.12

=

14.93 1bo.

38

TEST NO.3.

Time

start

1

2

4

5

6

7

8

9

10

11

12

13'

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

I

I

50.8

-

-

-

55.0

I

E

, I

102

-

-

--

105

-- --- - _/-

51.0

---

100

-

--,

-54.0 100--

--

52.2

-56.0

-

--

--

--

104

-105

--~

gSO

270

120

400

230

140

150

180

100

320

320

110

360

240

60

420

250

90

270

330

260

30

320

360

'SO

410

380

120

260

330

240

120

250

300

140

150

240

30

37

- 38

~

- 719.

- 7990

Sum (76.0 tlean 53.71 102.7 205

36

Cor.

57.0

103

56.31,103.4

365

148

-

--

g

15.0

0

23.60 152~6

I

j

I

22~351

20.4

1156.6

I

145

155

-

15.4

23.35 ,58.3

22.40

20.7

156.3

15.3

23.50

56.7

22.35

20.7

155.3

15.2

23.90

54.7

22.40

20.8

157.0

14.7

24.10

53.3

14.3

24.05

53.7

21.80

-

165

148

150

--

145

140

--

170

-

150

148

-

21.2

162.2

22.37

21.2

162.2

-

-

-

-

143

-

155

- -- 150

153

165

2428

151.8

151.8

89.9

14.8

14.6

-

125.0

164.30 329.3 111.87

22.35

80.8

23.47 54.9

T=4170C-782oF T=3650C=689 F

949. 4

158.2

157.3

-

Average speed = 817

Watts delivered

5830

"

air pressure =48 Ibs.

"

heat loss

1500

tt

stray power 1800

Total power 9I3'OWatts = 12.23 H.P.

Water used in 39.6 nin.=110.0 1ba. Gasoline used in 39.83 min=11.35 Iba.

tt

""

60

"= 116.4 1ba. "

tt

"60

":17.10"

Water per 1b.gasoline= 9.73 Water per li.P. hour-13.6 Ibs.

Gasoline per H. p. hour = 1.4 Ibs.

39

TEST NO•

.,v.

Data for Engine and Boiler Test.

H. P. : 12.23

Pb

Po

=

=

Water per H.P. per hour

If

It

Gasoline It It

= lS.60lbo.

=

1.40 If

Actual eve.p.per lb. gaooline =9.73 Ibs.

365 Ibs. lior sq. in.

tt

It

It

152 It

at 365 1bs. • .69

If

= .598

~ at 152

Tb = 782~ F.

689 F.

Ts

C

=

Computation for Engine Teot.

6 =

,;(at P~= 1194

6s=~

598 (689-367)

=

193 B. T. U.

1387 B. T. U. reoeivod by Eng.

B •••

T

U.

=

P' mln •• _1_38_7_x_1_3_.6_

314

per H••

60

Efr.

=

13. 5J~

Computation for Boiler Test.

A

at ~ _~ 1216

..6

.6 -=-(782-4-37) .G9

=

240 B. T. tT •

240

T456

B. T. U. delivered by Boiler

Efr. of Doiler =(1456i~~~~ 9.73 = 74.1%

Eff. of Plant II'.~O.O%

Equiv. evap. per lb. gasoline (from and at)8(1456-26)x

965.8

9.73 =14.4 lbs.

40

TEST

E

I

Ti ne

pt

no.

4

-Ps

T:r

Tb

g

I

st art

1

:3

3

4

5

0

7

78.0

-

11

1

2

1S

14

15

16

17

18

19

20

21

22

:3

24

25

26

27

2B

29

30

31

32

33

34

35

36

-

78.8

-

------

--

--

-

---

--

--

70.0

-

--

8

9

10

91

--

82.8

78

85

--

86

-

--

77.0

--

----

76.0

82.0

Sum 544.6

Me an 77.80

Co r. 80.80

-----

88

82

-

..!2.

596

85.1

85.8

240

150

280

210

10

10

10

20

40

20

20

30

40

40

40

40

----

50.

60

60

60

60

50

40

40

40

--

40

40

860

37

197

175

-

Tn

Te __

g

0

-

19

J

-

-

42.6

12.0

9.50

38.5

10.80

18.8

101.

o

10.5 10.00

S8.0

10.95

18.8

100.

o

13.0 10.10

37.7

10.95

19.0

100~

11.0 10.35

37.5

'10.90

19.5

100

176

-

177

-

160

-

187

-

185

-

195

195

195

197

200

200

195

190

195

195

193

-

1°'}

193

192

192

192

180

188

187

185

180

194

196

'-U

i

9.0

9.95

9.3

-

189

171

11.1

10.9

37.8

10.85

19.4-

--

19.6

133.9

19.1

10.30

232.0

72.75

9.98,

12.13

38.3

T=l950C=S8SoF

5482 7'B:O 49:90

Average sreed = 714

" air pressure

=

v9

100

600

100

100

47.2 lbs.

15.lliI.P.

Ibs.

Gasoline used in 43.0 min.-18.16

1ba.

1bo.

"

tt

tt

60

tt

=24.75 Ibs.

Water per H. P. hour-19.45 1bs.

H. p. hour.

1.63 Ibs.

r

four pressures

I

13.2

Watts delivered

6940

tt

heat loss

3090

n

stray ~ower 1310

Total ~ower 11340=Watta

Water used in 43.33 mi~•• 213.5

n

n

n 60

min.=290.0

Water per lb. gasoline = 11.96

Caso1ine per

First

0

not averaged

in.

41

TEST 1m.

4.

Data for Engine and Boil{~ Test.

H. p.

=

15.24

Gasoline

Pb

=

=

Tb

= 406

= 403

Pa

To

Water per R.P. per hour.

197 Ibs. per sq. in.

171

"

0

It

On at 197 lbs.

Cp at 171 Ibs.

=

1.64

It,

for Engine Test.

=

=

=

B. T. U. per H.P. min ••

1214x19.45

= 394

Eff.

60

Computation

Pb•

19.45 lbs.

.600

at'Pa

1194

~

623 (403-369)

:6 .~

1214 B. T. U. received by Eng.

A. at

=

"

Actual evap. per lb. gasoline =11.D6lbs.

F.

F.

Computation

A

tI

" "

"

0

tt

=

20

B.T.U.

10.74%

for Boiler Tect.

1198

=

Eff. of Boiler

.

Eff. of Plant

=

119ax11.96

18770

=

76.~

8.20%

Equiv. evar. per lb. gaso1ine.(from

and at)

=

l198xll.96

905.8

=

14 8 'b

•

-

s.

42

TEST

Tine

I

E

Pb

Ps

no.

5.

Tr

Tb

g

sta.rt

1

2

3

4

5

6

37.0

103

-

80

105

39.4

100

220

135

41.0

102

7

8

9

37.5

92

49.5

97

10

11

12

13

14

15

28.5

94

29.5

94

16

17

18

19

20.

31.7

31.8

35.3

30.9

34.0

32.3

37.9

36.2

:37.9

37.5

39.0

35.1

36.5

37.5

101

99

110

---

400

300

300

430

110

260

220

450

290

360

160

560

-

.38.3

109

400

108

36

40.4

37

3S

39

40

42.8

104

110

.98

109

96

III

290

450

330

400

200

525

105

115

110

26

27

28

29

30

31

32

33

34

35

41

38.1

40.7

45.8

41.4

96

I

13.5

22.00

41.4

18.10

16.7

123.0

13.0

20.50

42.8

20.35

16.8

147.8

12.3

20.00

43.0

20.70

17.2

153.3

13.4-

22.00

43.0

20.65

17.3

157.8

14.0

23.00

44.0

20.85

17.1

154.8

16.2

23.10

44.4

20.80

17.5

157.2

100

100

90

115

95

94

100

90

110

100

I

41.8

120

103

98

115

108

113

112.

111

100

104

24

Te

c

120

105

22

23

22.20

Ts

g

135

475

220

640

210

390

230

650

210

500

290

450

310

320

21

13.0

c

95

95

105

(over)

43

TEST

NO.5.

(continued)

I

I

Tine

E

.I

I.

Pb

Ps

350

500

340

400 .

140

425

105

Tr

Tb

c

44.6

g

, 42.0

46.3

42.0

40.4

35.1

40~3.

43.4

49.7

47.3

33.2

35.9

42

43

44

45

46

47

48

49

50

51

52

29.3

.53

54

55

56

57

sUm

39.0

38.6

39.4

40.0

l6G6.4

Mean 37.87

Cor.I 39.67

98

108

98

106

92

106

89

102

97

101

109

89

102

101

103

lQE...

4390

lQ2.l

102.8

390

210

310

450

.270

300

190

280

300

i'6'475

336

496

r

Watts delivered

It

heat loss

"

stray power

Total power

12.0 23.00

I

Ts

1

Te

c

~

20.70

17.6

155.0

156.2

115105

13.0 22.30

45.3

20.60

17.8

13.5 22.70

45.7

21.30

18.2

105

115

.

160.2

105

l

18.4

20.70

46.3

12.0 22.00

191.4

3198 1~5~9 242~80 482.1 204.75

17.4

.20.47

~}2.21

43.92

13.3

106.6

107

13.1

T-S800C=2720F T=332oC=630oF

...!Q.2

4050

735

ll'l.Q.

6255

Average

tt

speed

air

=

159.7

1524.0

152.4

151.0

814

preo3Ure::

50 Ibo.

Watts - 8.40 H. P.

Water used in 63.5 0111.:166.0 Ibs. Gasoline-used

tt

If

If 60

u ~156.9"

"

It"

in 62.5 nin.= 14.18 1bo.

eo

It

= 13.61 It

Water per lb. gasoline:

11.53 1bs. Water per li.P. hour

Gasoline per H. P. hour

1.62 Ibs.

=

=

18.66 Ibs.

44

TEST

liD.

5.

Data for Engine and Bailor Tent.

=

II. P.

Pb

Ps

=

=

=

Water per R.P. per hour

18.66 lbs.

Gasoline If 11

It

It

= 1.62 'tl

Actual evap. por lb. gasoline =11.53 Ibs.

8.40

496 Ibs. per sq. in.

107 "

It

tt

tI

Tb : 727oF.

Cp

cp

Ts = 630<7.

Computation

=

.6 =

A at Po

=

at 496 lbs.

.69

at 107 Ibs.= .567

for Engine Test.

=

=

1186.3

~

(630-343 .567

162.7

1349.0 B. T. U. received by Engine.

B. T. U. per .R.P. min.

= _1_34_9_7_,,1_8_._66_

= 412:

Eff. ='16.12

60

Computation

J.. at Pb

,6

Eff.

=

1225

=

.l1l

1462 B. T.' U. dolivered

_(1402-24)x

%

for Boiler Teat.

-6 -=

of Boiler

1627 B. T. U•

11.53

(727-470).69

=

177 B. T. U.

by Boiler.

=

84.7

%

10770

Eff. of Plant

Equiv.

=

8.57

%

evap. per lb. gasoline

(from and at)

=

(1402-21) 11.53

9G5.6

=

10.5 lbs.

45

Time

UO. 6.

PR

Tr

I

I

E

I

Ph

I

91

109

90

109

38.4

32.0

36.9

33.0

36.1

35.1

36.5

38.6

34.4

38.5

35.4

36.4

35.4

3

92

106

96

105

102

106

'112

100

III

102

105

101

37.5 107

35.8 102

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

38.8

110

36.0

20

39.9

34.6

37.1

34.9

33.7

35.1

33.7

102

113

99

106

100

460

270

480

220

370

250

310'

420

300

510

300

510

130

100

112

105

105

110

110

100

100

120

100

120

100

115

290

500

360

95

110

95

115

100

115

110

115

110

115

98

98

90

115

95

110

36.0

102

29

30

3G.8

33.2

41.0

104

94

580

380

400

380

390

370

200

350

180

290

300

150

31

37.2

32

38.0

110

100

.!Qg

338.0

102.4

103.1

380

200

260

11410

346

506

21

22

23

24

25

26

27

28

96

100

96

Sum 1184~O

Yean 35.91

37.51

-

40.2

19.45

15.0

149.0

10.5

24.0

41.0

19.30

15.0

152.3

11.0

23.85

41.2

19.45

15.4

15S.0

12.3

23.90

42

19.40

15.8

152.3

10.a

24.20

42.7

19.50

16.0

153.3

11.0

24.10

43.2

19.80

16.3

154.0

--

3323 67.3

107 .11.2

11.0

=

"

60

II

-13 C•2

914.9

152.5 ,

93.5

251.3 116.90

144.40

15.6

42.8 19.48

20.07

T=411oC=7780P. T=3160C=6000F.

Average speed • 758

tt

air pressure

=

46.7 lbs.

7.92 It.P.

Water used in 33.25 Din~~75.5 lbs.

It

Te

0

24.45

3867

Watts delivered

665

tt

heat loss

1380

"

stray pO\7er

Total power 5912 Watts

tt

g

0

12.0

110

200

550

300

I

Ts

Tb

g

star t 31.0

1 37.2

2

30.7

Cor.

TEST

:r

Gasoline used in 22.92 ~in. • 7.13 Ibo.

If

II

If

60

Water per lb. gasoline. 10.31 Ibn. Water !Jer H. P. hour

Gasoline per H. P.

hour

1.67 Iba.

=

If

=

-13 • 21

17.2 lbs.

tt

46

TEST lTO. 6.

Data for

-

II. P.

==

506 lbe.

107 tt

Tb

=

"'8

=

77SoF•

600oF •

Water :per R.P .. :per hour

17.2 lb3.

It

tt

Gasoline tt It

1.67 tI

Aotual eve.p_pC!' lb. gasoline

10.:31 Ibe.

=

:por sq. in.

tt

It

tt

Cp at 506 Ibo.

at 107 1bs.

cp

Computation

A

at Ps ~

6

B

•

m

J. ••

for

~~ine

--= •69

• 567

Teat.

6

1186

=

Test.

==

7.92

Pb

Pa

rp

Engine and Boiler

=

(600-342)

.567 - 135 B. T. U.

135

1321 B. T. U. reoeived

U :per II••P

.

-tlln.

by Engine.

=

132lx17.2

-----

Computation

379-_

Eff. -

11.1B

60

for Boiler

Test.

122G

6.= (77B-170) .69

212

1438 B. !. U. delivered

=

Efr.

of Boiler

Eff.

of Plant

=

evap.

per

Equiv.

(1438-20) x 10.31

18770

10

=

212 B. T. U.

by Boiler.

=

78.0

%

B.71%

lb.

gasolhle

(from and at)

_ (143B-20}xlO.3l

965.8

-

•

15.1 1bo.

47

I

Tine

E

Pb

TEST

no.

Pa

Tf

I

star t 64.5

1

2

"

OJ

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

. 37

38

39

40

41

42

43

44

45

46

47

48

,

60.3

62.4

60.0

64.2

66.3

70.6

57.6

60.5

65.2

62.3

68.8

66.0

72.7

69.7

66.0

-

67.6

67.5

72.2

65.2

63.3

70.3

74.3

78.0

60.3

71.7

78.0

74.6

62.2'

66.0

78.3

62.7

72.0

66.3

59.7

C8.0

81.7

73.2

64.0

67.2

73.4

75.0

85.6

80.2

72.0

76.5

76.5

77.0

93

87

90

86

92

95

98

80

84

90

86

95

39

98

94

87

310

200

200

170

250

325

310

150

200

210

140

260

440

350

260

140

89

87

93

84

31

90

95

97

75

89

94

90

75

80

95

76

87

80

72

80

96

86

75

80

86

85

97

91

80

325

370

290

250

130

300

325

450

200

390

-

e5

85

86

150

7.

Tb

e

-1

Ts

Te

14.0

19.90

c

46.0

20.60

c

20.6

138.0

14.0

21.95

47.6

21.20

21.2

136.1

14.3

22.90

48.4

20.40

20.4

139.7

14.2

21.75

48.0

19.60

19.6

~ 132.8

13.8

21.00

47.3

10.30

19.3

127.0

12.6

21.40

47.0

18.60

18.0

125.0

12.0

22.30

46.4

18.50

18.5

124. '

12.3

22.00

45.3

18.30

18.3

12.3

22.00

45.5

17.50

17.!5

g

...

145

. 140

145

138

150

140

130

140

150

1.10

155

160

175

155

-

-

140

155

160

155

120

150

145

140

145

150

-

I

-

300

325

300

150

325

250

120

100

350

180

150

150

290

325

370

260

290

160

225 i

,

100 II

I

--

145

160

-

140

160

142

145

165

165

160

140

140

160

175

170

110

150

165

140

130.'

48

TEST

no.

7•

. ( cont inued)

I

I

84.2

82.4

73.0

73.8

69.3

E

94

92

79

80

75

54

55

82.0

86

76.3

56

57

87.7

80

92

93

88

76

Time

49

50

51.

52

53

90.0

58 79.2'

59 68.3

60 71.0 ~

Sufl 4 254~1 5198

86.6

Mean 70.90

B7.3

Cor. 73.7

Pb

360

410

Ps

165

165

-

280

150

130

300

125

325

160

-

350

100

110

100

14340

252

412

160

g

c

g

12.0

T8

Tb

Tf

46.9

20.00

19.45

Te

-C

I

I

121.0

17.5

.

I

-

-

10.S

7210 141.8

150 12.8

132 12.6

18.85

234.05

21.28

46.2

514.6

46.8

T-3750C=7070F

Watto delivered

It

heat loss

It

stray !l0';Ter

I

Average

6434

D570

1J.iQ.

It

17.60

218.50

19.86

104.0

1407.7

127.97

127.5

17.4

208.9

18.1

T=324oC~615<7.

speed

=

7D4

air pressure

==

49 1ba.

Total power 10344 Watts =13.87 H. P.

Water used in 64 min.=207~0

It

It

"

60 min.=194.1

Ibs.

"

Gasoline used in 63.3 nine =21.22 1bs.

It

»It

60

It

=20.10 »

Water per lb. gasoline :9.581bs. ~ater per H. p. hour =13.97 1bs.

Gasoline per H. p. hour =1.44 1bs.

B. T. U. par nin.:

49

TEST NO.7.

Data for Engine and Boiler Test.

=

H. P.

Pb

P :3

=

=

Water per R.P. par hour

13.87

Gaoolinett

412 lbs. per sq. in.

132 u

"

"

"

Tb -

707°F.

'Is -

615°F.

at P

(, 8

:

=

It

=

13.97 lbo.

=

It

1.44 Ibs.

Aotual evap. per.lb. gasoline

=

Cp at 412 1bs.

Cp at 132 lbs.

Computation

A

u

=

=

9.581bs.

.69

.580

for Engine Teot.

6

1191

=(615-357).580

=

150 B. T. U.

150

1341 B. T. U. reoeived by Engine.

E. T. U. per H.P. min.

=

l340x13.97

=

Eff.:

312:

13.58

%

60

Computation

for Boiler Tect.

1220

6 = (707-452) .69

176

1396 B. T. U. delivered by Boiler.

Efr. of Boiler

Eff. of Plant

=

=

(1396-23)x9.58

18770

9.54

=

70.2

=

176 B. T. U.

%

%

Equiv. evap. por lb. gasoline

(from and at)

=

(1396-23)x

965.8

9.58

=

13.6 1bo.

50

TEST 110.

I

Tine

I

E

P'h

I

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

10

20

21

22

23

24

25

26

~7

28

29

30

31

32

33

34

35

30

37

38

39

40

41

42

43

44

Tr

3e.O

38.8

38.0

38.4

3G.8

41.5

40.3

35.7

3"7.0

23.7

39.6

88.5

40.9

39.4

38.0.

39.2

40.4

46.0

45.5

46.3

50.0

39.8

39.0

87.5

39.3

41.8

48.0

39.3

41.5

44.7

42.2

44.3

46.2

40.0

47.1

43.0

49.3

39.9

51.8

41.8

47.2

46.0

47.1

45.1

Sum

1879.7

Mean

41.77

Cor.

4S.67

97

103

105

101

102

95

107

104

92

III

92

108

97

103

99

95

98

101

102

101

103

113

106

104

100

90

96

100

90

95

105

99

104

104

90

108

96

110

89

114

92

104

92

94

....!?lL

4499

100.

100.7

250

360

290

310

340

400

460

520

200

625

200

560

230

530

370

290

aoo

290

320

240

400

400

340

350

270

200

360

350

410

190

240

250

340

370

190

400

230

600

200

580

200

340

300

420

200

15115

336

496

235

230

Ta

Tb

g

star t 35.8

1

2

3

Pa

8.

0