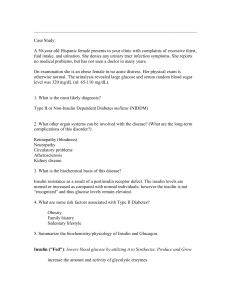

The Development of a Minimally Invasive ...

advertisement