(

advertisement

(

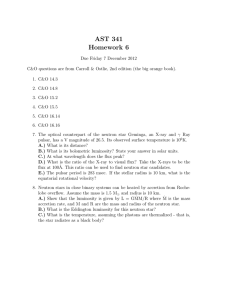

MIT-334-33

Reactor Technology

Standard TID 4500

IN-PILE LOOP IRRADIATION STUDIES

OF

ORGANIC COOLANT MATERIALS

PROGRESS REPORT

JANUARY 1,

1965 - SEPTEMBER 30,

D. T. Morgan, Project Supervisor

Report prepared by:

Contributors:

1965

Project Engineer

W. N. Bley,

T. H. Timmins, Research Assistant

DEPARTMENT OF NUCLEAR ENGINEERING

MASSACHUSETTS INSTITUTE OF TECHNOLOGY

CAMBRIDGE, MASSACHUSETTS 02139

(M.I.T. Project No. DSR 9819)

Work Performed Under Contract No.

with the

AT(38-1)-334

Savannah River Operations Office

U. S. ATOMIC ENERGY COMMISSION

Issued:

November 1, 1965

(MITNE-66)

ii

LEGAL NOTICE

This report was prepared as an account of Government

sponsored work. Neither the United States, nor the Commission, nor any person acting on behalf of the Commission:

A. Makes any warranty or representation, express or

implied, with respect to the accuracy, completeness, or

usefulness of the information contained in this report, or

that the use of any information, apparatus, method, or

process disclosed in this report may not infringe privately

owned rights; or

B. Assumes any liabilities with respect to the use of,

or for damages resulting from the use of information, apparatus, method, or process disclosed in this report.

As used in the above, "person acting on behalf of the

Commission" includes any employee or contractor of the Commission to the extent that such employee or contractor prepares, handles or distributes, or provides access to any

information, pursuant to his employment or contract with

the Commission.

.............

iii

DISTRIBUTION

This report is being distributed under the category

"Reactor Technology", TID 4500. Additional copies may be

obtained from USAEC Division of Technical Information

Extension (DTIE), P.O. Box 62, Oak Ridge, Tennessee.

Previous related reports on this project:

MITNE-4

(IDO 11,101)

MITNE- 7

(IDO 11,102)

MITNE-9

MITNE- 12

(IDO 11,103)

MITNE-21

MITNE- 22

(IDO 11,104)

MITNE-29

(IDO 11,106)

(IDQ 11,107)

MITNE-39

MITNE- 41

MITNE- 48

MITNE-55

MITNE-59

MITNE-63

(IDO 11,105)

(SRi-85)

(SRO-87)

(MIT-334-11)

(MIT-334-12)

(MIT-334-23)

iv

T ABLE

OF CONTENTS

Page

1.0

2.0

Summary

Loop Operations and Experimental Radiolysis

Results for This Period

3.0

4.0

Summary of Previous Irradiation Results

In-Pile Dosimetry

5.0

6.0

Heat Transfer and Friction Factor Results

Summary of Property Measurements for Run 14

7.0

Travel and Reports Issued

References

1

4

11

17

23

29

34

35

V

LIST OF TABLES

Page

1.1

2.1

3.1

3.2

4.1

4.2

6.1

6.2

Summary of Operating Conditions and Results

for Runs 13 and 14 Based on Pre-Irradiation

Dosimetry Measurements

Results of Steady-State Run 14 Based on

Pre-Irradiation Dosimetry Measurements

Summary of Results for Steady-State Loop

Irradiations

Summary of Results for Transient Loop

Irradiations

Summary of Results from Calorimeter

Measurements

Summary of Fast Neutron Dose Rates from

Foil Activation Measurements

Average Molecular Weight of Run 14 High Boiler

Summary of Average Molecular Weight for SteadyState Loop Irradiations Through Run 14

2

9

12

13

18

20

29

vi

LIST OF FIGURES

Page

2.1

2.2

3.1

3.2

4.1

4.2

5.1

5.2

5.3

5.4

6.1

6.2

6.3

Cross Section of Reactor Core Showing Fuel

and Control Rod Positions

Total Terphenyl Concentration as Function of

Absorbed Dose for Run 13

Effect of Tcmperature on Irradiation of

Terphenyl Coolants in M.I.T. Loop Irradiations

Pyrolysis of Terphenyl Coolants

Calculated Fast Neutron Dose Rate in Santowax WR

Using Foil Activation Data, Fuel Position 20

Neutron Energy Spectrum Used for Fast Neutron

Dose Rate Calculations from Foil Activation

Data

All M.I.T. Irradiated Organic Coolant Heat

Transfer Data

Friction Factor and Heat Transfer Factor for

Irradiated Santowax WR, Upstream Half of

Test Heater 7

Friction Factor Data for TH7,Selected Santowax

WR Data and Water Data

Colburn Analogy for M.I.T. Irradiated Santowax

OMP, Heat Transfer Data

Density Measurements for Run 14

Viscosity Measurements for Run 14

Average Molecular Weight of High Boiler as

Function of High Boiler Concentration

5

7

15

16

21

22

24

25

27

28

30

31

33

CIIAPTER 1

SUIMIMARY

Irradiation of Santowax WR in the MITR in a new fuel

position with a fast neutron fraction of 0.05-0.06 was initiated on May 10, 1965 as Transient Run 13. This run was

continued until July 19, 1965 when the terphenyl concentration had decreased from 92% to a level of 84% as desired for

Run 14. Steady-State Run 14 was started on July 19 and continued to September 27, 1965 with distillation processing

and recycle of the coolant. The operating conditions and the

preliminary G*(-omp) values from these runs are summarized

in Table 1.1. At the end of Run 14, a tritium dilution for

the circulating organic mass was carried out.

A reevaluation of previous loop data was carried out

and G values calculated for individual terphenyl isomers as

well as the total terphenyl and high boiler. These results

are summarized in this report and will be described in detail

in a topical report on the Santowax WR irradiat.i&Is which will

be issued late in 1965 (to be assigned the number MIT-334-34).

The new G values are slightly different in some cases than

those reported in MIT-334-12 (Q1).

Heat transfer and friction factor measurements using a

new test heater were performed. All previous data as well

as the new data were compared with the Dittus-Boelter and

Colburn relations. The heat transfer data agreed with either

correlation within +10%; the friction factor data agreed

with the Colburn relation within +10%. A report describing

these results in detail was issued in September, 1965 (1.2).

Additional heat transfer measurements were made at the end

of Run 14 but the results are not yet available.

Calorimeter and foil activation measurements were carried

out in the new experimental facility to establish the dose

rate. The preliminary values (see folnote of Table 1.1)

for the total dose rate and fast neutron fraction are (one

Table 1.1

Summary of Operation Conditions and Results for Runs }3 and 14

Based on Pre-Irradiation Dosimetry Measurements k)

Irradiation Temperature

Loop Pressure

572'F

Fast Neutron Fractionl

Average Dose Rate in Total Coolant Mass(l)

0.056

0.0068 watts/gm

G*(-omp)

Run 13 (First Order Kinetics)

Run 14

0.196 molecules/100 ev

P-100 psig

0.192 molecules/100 ev

Terphenyl Condentration

92->84%

84.0->83.5%

Run 13 (Transient Run)

Run 14 (Steady-State Run)

(1)These values are based on pre-irradiation calorimeter and foil

activation measurements in Fuel Position 20. Post-irradiation

calorimeter measurements are planned in the spring of 1966 at

the completion of the irradiations in Fuel Position 20. Slight

changes (<5%) in these values may occur when the additional

measurements are available and included in the data evaluation.

Eli

IIIIIIIIJIMM

IIIII

Jill'

III

3

standard deviation uncertainty limits):

3

FT = 20.4 + o.4 watt-cm

2

f

-

lM-gm

= 0.056 + 0.007

Construction of a new in-pile section (In-Pile Section

No. 4) was started during this period. This new in-pile section is identical to the one now being used (In-Pile Section

No. 3) and is being constructed in the MITR machine shop.

Visits were made to the AECL Chalk River Laboratories for

technical discussions on organic coolants and to Atomics

International for discussion of the future experimental program of the M.I.T. Organic Coolant Project. An experimental

program covering the next two years was agreed on by AI and

M.I.T. and approved by the AEC.

CHAPTER 2

Loop Operations and Experimental Radiolysis

Results .or This Period

All previous irradiations in the M.I.T. In-Pile Loop

were carried out in the central fuel position of the reactor

where the fast neutron fraction was 37-40%. As discussed

in the previous progress report (1.1), it appeared desirable

to perform irradiations at a significantly lower fast neutron

fraction in the same irradiation facility and with the same

loop equipment to provide a direct measurement of the fast

neutron effect or Gn/G . Furthermore, the use of steadystate runs would provide more accurate total G values than

is possible in transient irradiations thus providing a significantly more accurate determination of Gn/G than has

previously been possible.

To accomplish this purpose, plans were made to perform

several steady-state runs in Fuel Position 20 (see Figure 2.1)

near the outside edge of the core where the fast neutron fraction should be significantly less than in the central fuel

position (Fuel Position 1). To minimize the fast neutron

fraction in Fuel Position 20, it was desirable to (1) eliminate the use of any fuel in this fuel position thereby eliminating the production of fast neutrons near the in-pile capsule and (2) to include a cadmium converter to convert thermal

neutrons to gamma rays by the (n,7) reaction thereby increasing the gamma ray dose.

Consequently, a new irradiation facility and in-pile

section were designed and procured. The irradiation facility

consists of an aluminum sample assembly containing no uranium

but with an integral cadmium sleeve as a replacement for the

8 or 10-plate fuel element used in prev'ious irradiations.

The in-pile section fits inside this sample assembly and is

surrounded by the cadmium sleeve. The new in-pile section

(In-Pile Section No. 3), while similar to In-Pile Sections

5

1211 BEAM PORT

SHIM

SAFETY

RODS

FINE

CONTROL

ROD

FIG. 2.1 CROSS SECTION OF REACTOR CORE

AND CONTROL ROD POSITIONS

SHOWING

FUEL

...........

I-

No. 1 and 2, has been modified to increase the in-pile volume

from approximately 205 cm3 to 285 cm' and to provide more

reliable heaters and thermocouples. A central monitor tube

which extends from the top of the reactor shield down into

the center of the in-pile section has also been added so that

foils and other measuring devices having a diameter less than

0.3 inches can be inserted during an irradiation into a region

surrounded by the circulating coolant in the core. The monitor tube outside the thimble as used in all other in-pile

sections is also included.

The new sample assembly with integral cadmium sleeve was

inserted into Fuel Position 20 on February 28, 1965 with a

stainless steel thimble inserted in place of the in-pile

section. Calorimeter and foil activation experiments were

carried out in this thimble during the period March - May,

1965 (see Section 4.0). These measurements indicated a fast

neutron fraction of about 5-6%. The new in-pile section was

inserted in place of the stainless steel thimble on May 1,

1965. The loop was charged with Santowax WR and Transient

Run No. 13 started on May 10, 1965. The purpose of Run 13

was to degrade the coolant from its initial terphenyl concentration of '92% down to -84% as desired for steady-state

Run 14. The operating conditions for this run were 5720F

and 14100 psig. A concentration of 84% terphenyl was reached

and steady-state Run 14 started on July 19, 1965 at a temperature of 572 F and "100 psig. Run 14 was continued until

September 27, 1965 when sufficient terphenyl had been degraded

to provide a one standard deviation uncertainty in the total

terphenyl G value of about +5% and Run 14 was ended.

The results of Run 13 are presented in Figure 2.2 in

terms of total terphenyl concentration as a function of absorbed dose. The reaction rate constant for the total terphenyl disappearance was calculated based on first, second,

and third-order kinetics. The calculated values based on the

pre-irradiation dosimetry measurements (see footnote of

Table 1.1) and their one standard deviation uncertainty limits

are:

1.00

I

I

I

I

0.95[0

0.90

H

0.851

z

w

0-

0.80K

-J

AVG. EXPERIMENTAL VALUE OF AT LEAST

4 CHROMATOGRAPHY RUNS

w 0.750.70

FIG. 2.2

I

1.0

I

I

I

2.0

3.0

4.0

TOTAL ABSORBED DOSE, r, WATT HOURS/GM

TOTAL TERPHENYL CONCENTRATION

AS FUNCTION

5.0

6.0

OF ABSORBED DOSE FOR RUN 13

8

kR(First Order) = G*(-omp)

G*(-omp)

kR(Second Order)

= (1.69 + 0.20) x 10-2

w

-hr

= 0.196 + 0.023 molecules degraded.

ev rd

G*~op)_100

= 1.93 + 0.19 x 10-2 wa-shr

G*(CAvg = 0.878) = 11.65 kRCAvg = 0.198 Molecules

100 ev

g s

kR(Third Order) = (2,.20 + 0.22) x 102 watt-hr

G*(CAvg

=

0.878)

=

11.65 kAvg

=

0.198 molecules

The operating conditions were:

T = 572 0 F, P E 100 psig, fN = 0.056, Avg Dose Rate = 0.0068 watts

gm

The kinetics for the individual isomers will be reported

at a later date. It should be noted that the above results

are directly dependent on the loop mass. A tritium dilution

was carried out at the end of Run 14 for another loop mass

determination but the results are not yet available; the

numbers quoted above may therefore change slightly when the

results of the mass determination are available. Any change

should be less than 5% however since the mass used in these

calculations is based on previous tritium dilutions.

The results of steady-state Run 14 are presented in

Table 2.1 including operating conditions and G values for the

terphenyl isomers. It will be noted that-the concentration

change over the run is small so that the run is, in fact;- a

steady-state run. The statistical uncertainty is also excellent, the percentage uncertainty (one statistical deviation) being +5% for the total terphenyl G value. For this

run, to obtain good statistical accuracy, 140 separate analyses were made on the samples and returns used in the run.

Three additional steady-state runs are planned for

Fuel Position 20 (fN = 0.056). At the end of these runs, the

irradiation capsule will be moved back to Fuel Position 1 and

Table 2.1

Results of Steady-State Run 14 Based on Pre-Irradiation Dosimetry Measurements(l)

Irradiation Temperature = 572 0F

Type of Distillation - Quaterphenyls Not Recycled

Density = 0.897 gms/cm 3

Total Terphenyl Degraded = 534 grams

Total Loop Circulating Mass = 5230 grams

Fast Neutron Fraction = 0.056

Total Average Dose Rate = 0.0068 watts/gm

Total

Initial Loop Concentration, wt %

Final Loop Concentration, wt %

m-

15.4

63.6

5.0

84.0

10.9

14.6

63.9

5.0

11.2

0.136

+0.004

0.034

G(-), molecules/00 ev

-*(-1i) = G(-i)/C

HB

pmp

o-0

0.222

+.007

(')See footnote of Table 1.1.

Error limits are one standard deviation.

0.1115

0.010

83.5

0.161

+0004

+0.001

+0.008

0.20

+0.02

0.192

+0.009

0.181

+0.007

D

10

irradiations will be continued at the higher fast neutron

fraction of about 40%. Construction on In-Pile Section No. 4

was initiated during this reporting period for use in this

change as well as a back-up in case of failure of the present

in-pile section (No. 3) before the irradiations in Fuel

Position 20 are completed. In-Pile Section No. 4 will be

identical to In-Pile Section No. 3,

11

CHAPTER 3

SUrV4ARY OF PREVIOUS IRRADIATION RESULTS

During this period, the results of previous loop irradiations of Santowax WR in Position 1 of the MITR were reevaluated and the G values calculated for the disappearance

of the individual terphenyl isomers as well as for the total

terphenyl disappearance and HB generation. The new values are

slightly different in some cases than those reported in

MIT-334-12 (1.1). The G value for any pure component, G(-i)

or G(i), is defined as the molecules of that component destroyed or produced per 100 ev of energy absorbed from fast

neutron and gamma interactions in the total coolant. The G

value for

molecules

of energy

11 it was

high boiler production, G(4-HB), is defined as the

of terphenyl degraded to high boiler per 100 ev

absorbed in the total coolant. In Runs 8, 10, and

found that the statistical uncertainty was larger

than desired due to the relatively large scatter of the concentration data resulting from poor reproducibility of the

chromatographic column used for these analyses. The samples

from these runs were therefore reanalyzed and more precise

results were obtained.

The complete results are summarized in Table 3.1 for

the steady-state runs and in Table 3.2 for the transient

runs. For the steady-state runs, both G(i) and G*(i) values

are reported for each of the terphenyl isomers and the total

terphenyl; only the G(i) values are reported for high boiler

generation.

The G*(i) values are defined as:

G*(i) = 2i).

(3.1)

is the concentration of component i in the coolant.

For the transient runs, only G*(i) values are reported based

on use of first-order kinetics for the degradation. The G*

values sorvenas a useful normalization factor for comparison

where C

of the low and high temperature runs made at a given terphenyl

Table 3.1

Summary of Results for Steady-State LOOP Irradiations**

Mterial

Santowax

Temperature in

Irradiation Zone

0

0F

C

300

0.163 321

610

0.115

0.0102

0.136

+0.004

+0.0011

+0.004

22.0

56.6

4.8

9.6

0.34

(30.8)

(14.4)

+0.02

0.200

+0.009

(30.3)

(16.2)

750

399

53.5

Santowax

OMP

0.034

+0.001

83.3

750

750

399

399

60.5

69.5

T.5

44.6

2.5

43.4

3.3

7.1

0.155

+0.003

0.23

+0.003

0.020

+0.004

+0.01

+0.003

0.003

0.287

+0.009

0.029

+0.002

0.154

+0.008

0.015

+0.002

+0.008

0.0963

+0.0006

0.087

0.192

+0.009

0.264

+0.008

0.222

0.181

0.20

0.056

+0.009

0.26

+0.01

+0.007

0.256

+0.008

+0.02

0.41

0.40

0.40

0.015

0.37

+0.04

0 40

+0.02

0.36

+0.02

+0.02

+0.02

0.34

+0.02

0.39

+0.03

G*(-m)

0.28

+0.01

0.43

+0.08

0.60

+0.09

Run IDate of

Wno

Run

14

7/19/65

lC

11

+0:04

0.40

+0.04

5

9/27/65

5/24/62

8/30/62

8/25/64

9/25/64

1/20/64

3/10/64

10/2/63

0.26

0.014

0.245

o.63

1.00

0.59

0.42

0.40

+0.01

+0.04

0.46

+.04

0.37

3B

11/27/63

2/26/63

+0.005

+0.04

0.79

+0.04

+0.03

0.53

+0.002

0.085

+0.009

0.282

+0.006

+0.03

0.53

+0.01

0.31

+0.02

0.41

+0.001

0.085

+0.003

0.54

+0.02

0.45

+0.02

0.35

+0.04

0.40

2

6

4/18/63

3/12/64

4/12/64

4/20/64

5/8/64

6.1

35.3

18.6

49.5

4.0

(15.2)

(15.3)

(14.8) +0.03

+0.005

0.106

+0.009

0.186

0.22

+0.01

0.27

750

399

73.7

18.2

51.1

4.4

(11.5)

Santowax

WR

780

416

61.6

8.2

50.2

3.1

24.9

13.5

0.53

+0.03

0.090

+0.006

0.41

+0.03

Santowax

Satoax

800

427

80.03

51.5

11.3

36.9

3.0

(26.9)

(21.6)

-0.91

0.1

+

0.269

029

+0.009

o.61

069.3

+0.02

Santowax

80

(

1.06

+o.o4

0.35

+0.01

+0.03

.

G*(~o)

o.067

Santowax

4

0.173

O*(~omP)

+0.003

o.048

15.7

W

00

.0157

Fast

Neutron

Fraction

fm

G*(P)

+0.01

0.32

034

.6.7

32.4

G(~HB)

o.161

61.9

54.8

I

+0.008

06

+0.005

11.0

371

Q(-n)

5.

5.8

5.0

18.3

700

Santowax

Santowax

321

G(-m~

fl(-omn~

63.8

37.6

32.3

tl(-o'I

T.Th

15.0

6.0

83.7

G*(i) = G( i)/Ci

G(i), molecules/100 ev

572

7

Santowax

OMP

Santowax

WR

Santowax

Average Loop Concentrations, wtlt

HB*

p

(Bottoms)

m

o

omp

0.02

0.64

0.30

+0.01

0.33

+0.02

0.45

+0.03

o.56

+0.03

+0.03

+0.06

0.04

0.58

0.05

0.53

+0.04

0.34

0.15

0.034

+0.013

0.032

0.47

+0.04

o.86

+0.06

1.10

+0.07

0.81

+o.06

+0.001

+0.03

0.77

.7

1. 76

1.6

+0.06

-2.2336

+0.08

i~.5

+0.06

0.014

+0.002

0.015

0.006

0.074

+0.013

0.01

0.70

+0.03

1.62

+0.06

2.18

+0.08

1.42

+0.06

1.1

+0.4

1.0677(

F+0.04

7

1.9

+0.3

+0.04

0.40

0.04

o.4o

+0.04

12/4/63

12/23/63

6/18/64

7/20/64

0.40

.086

+0.04

0.40

+0.04

*HB refers to distillation where the quaterphenyl were not recycled.

Bottoms refers to distillation where about 75% of the quaterphenyls were carried over with the terphenyls and LIB and therefore recharged to the loop.

**Error limits are one standard deviation except for fast neutron fraction which is approximately two standard deviations.

10

7/21/64

8/25/64

Table 3.2

Summarm of Results for Transient Loop Irradiations*

Temperature in

Irradiation Zone

Material

Santowax

WR

Santowax

WR

Santowax

OMP

Santowax

0F

0C

425

218

572

300

6lo

321

G*(i) molecules/100 ev

Concentration Range, wt%

omp

69-858

91.8-83.8

66.6-+-39.6

0

m

p

-

-

~

41.2-+w25.1

18-.+10 4

321

100.1+- 59.6

10.7-+6.3

64.8-+37.4

24.6-v16.2

OMP

OH?

Santowax

Santowax

750

399

65. -41.

69-,>,3.1

38.54-+4.

20.6-+v13.8

750

399

90.4--063.0

10.4-+-a6.3

53.0+-37.0

27.0o+19.7

WR

750

399

78-+45

Santowax

WR

78o

416

68+v55

m

p

0.26

-

No.

N

+0.04

0.056

-

0.25

0.25

+0. 04

0.30

+0.05

+0.04

0.34

+0.09

+0.13

0.46

+0.07

+0.25

0.63

+0.27

0.58

+0.05

0.97~~

+0.10

Run iDate of

Run

N

0.40

~

+0.08

+0.02

610

Santowax

0

0.19

--6.7-+--4.1

1omp

Fast

Neutron

Fraction

02

033

o.2W

02

+0.015

13

0.37

1B

+0.21

+0.04

0.45

+0.07

+.41

+0.04

+0.101

3A

8

5/12/64

6/12/64

37 2B

0.7 2

2A

0.40

+0.04

+0.46J

+0.04-

18/9/61

10/5/61

10/5/61

1/3/62

1/14/63

2/15/63

12/4/62

1/10/63,

7/25/63

9/26/63

+0.0

+0.09

1/1/64

1/18/64

5/lo/65

7/19/65

*Error limits are one standard deviation except for fast neutror fraction which is approximately two standard deviations.

(A

14

concentration regardless of whether first or second-order

radiolysis and pyrolysis occurs.

In Figure 3.1, the G*(-omp) values are plotted for those

runs with similar total terphenyl concentrations. A large

increase in the G*(-omp) value with temperature above an

irradiation temperature of about 7000F is apparent. Our

present interpretation of this result is based on assuming

separability of the radiolysis and pyrolysis. The radiolysis

rate is extrapolated from low temperature measurements where

pyrolysis is negligible to higher temperatures using a constant activation energy of 1 kilocalorie/mole. This extrapolated rate is then subtracted from the total degradation

rate to give the pyrolysis rate. In Figure 3.2, the pyrolysis rate constant calculated in this fashion (assuming

first-order kinetics for pyrolysis) is given using the M.I.T.

data presented in Table 3.1; data from Euratom are also presented for comparison. It is apparent that the data from

M.I.T. and Euratom provide a consistent picture when analyzed

in this fashion supporting the proposed model for the total

degradation rate including both radiolysis and pyrolysis.

Additional data are required however before any definitive

conclusion can be stated and data from the M.I.T. loop as

well as other sources will be interpreted in terms of this

model as the data become available.

No detailed analysis of the data has been presented here

since a topical report on the Santowax WR irradiations through

Run 11 is in preparation and will be issued at a later date

(to be assigned the number MIT-33-3 11).

15

ERROR

250

LIMITS ARE 2o

300

400

350

*C

I

I

A SANTOWAX WR,25-31% BOTTOMS

1.8 |--

0

0 SANTOWAX

A

WR, 10-17% BOTTOMS

SANTOWAX OMP,

33% BOTTOMS

0

(f)

1.6 I-

(D

z

w z

w

0

0

C)

0

0

1.4|--

1.2

z

0

0-

0

a.

0

O

0

0

1.0 F--

z

0.8 |(f) 0L

w

-i

0.6 |-

-i

0

0'

0

0.4 F-

0.2 E-

0.01

40 0

I

I

500

600

IRRADIATION

FIGURE 3.1

700

800 *F

TEMPERATURE

EFFECT OF TEMPERATURE ON IRRADIATION OF

TERPHENYL COOLANTS IN M.I.T. LOOP IRRADIATIONS

.....................

u

16

5

7

S0

I UNIRRADIATED TERPHENYL OM- 2

II MIT IRRADIATED SANTOWAX WR

(27-31% BOTTOMS, 0.020 w/g)

III EURATOM IRRADIATED OM - 2

O MIT - 17 % BOTTOMS

AMIT - 27 -31 % BOTTOMS

O MIT - 12 -15% BOTTOMS

MIT - 25 % BOTTOMS

* EURATOM - BLO 2 (0.040 w/g)

0 EURATOM - BLO3 (0.015 w/g)

* EURATOM - UNIRRADIATED OM -2

2

z

z

ERROR LIMITS ARE 2 oI

0

u

w

51

cf)

*

0

21

a::

0W

it

10

-4

H-

n- u

5

0 0

0

o

L0ON

0

I

cxq

0 0

00

I

0uto

0 0

I

LoO0

2

1.40

FIGURE 3.2

1.45

EFFECTIVE

PYROLYSIS

1.50

TEMPERATURE

OF TERPHENYL

1.55

1.60

I/T,*K~ x 103

COOLAN T S

0

0

00

o0L

n-.

1+

CHAPTER 4

IN-PILE DOSIMETRY

During this period, several calorimetric dose rate

measurements were made in the M.I.T. Reactor to determine the

pre-irradiation dose rate and fast neutron fraction in Fuel

Position 20. These runs and the measured dose rates for

each individual run are summarized in Table 4.1. These

measurements will be repeated at the conclusion of irradiations in Position 20 so that an estimate of any dose rate

variation during the irradiation period can be made.

The fast neutron fraction in Fuel Position 20 is difficult to determine with any precision due to the small neutron dose rate relative to the gamma dose rate in this position and the fact that the fast neutron dose rate is basically

determined as the difference between the total and gamma dose

rates. This difficulty is particularly obvious at the edge

of the core and in the reflector region where the uncertainty in the measured fast neutron dose rate is as large as

the quantity itself. To alleviate this difficulty and to

obtain the best possible fast neutron dose rate integrated

over the in-pile capsule volume, the results of the calorimeter

measurenc's have been combined with the foil activation

results. The fast neutron dose rate from calorimeter measurements at positions where the experimental uncertainty is

a minimum was used as a normalization basis. The normalized

fast neutron dose rate calculated from foil activation results was then used to extend the fast neutron dose rate to

positions where the calorimetric measurements of the fast

neutron dose rate are less accurate.

Using this procedure, the final estimate for the gamma

and fast neutron dose rates integrated over the in-pile

volume are (one standard deviation uncertainty):

F

=

2'M

19.30 + 0.25 watt-cm

-g

Table 4.1

Summary of Results from Calorimeter Measurements

Calorimeter

Series No.

Core

Position

Dates of

Measurement

I

-----

Fuel Loading

23

in 23

3/3-4/65

20

I--.-.----------.

XIII

3/16-18/65

No

Cd

No

SS

20

+1.8

SW

27.4

19.0

1-

4 ----------

9

XIV

4/6-9/65

20

Same as XII

XV

4/28-29/65

20

xv'

5/25-26/65

1

1

0.094

0.055

22.8

All

t

0.053

+0.039

18.0

SW

3

0.20

+o.6

+1.2

Al

Less PS

SW

I

+0.06

29.0

Al

Less PS,

Fuel in 20

Lined Sample Assembly

Fuel in 21

Thimble

Same as XII

0.26

30.5

Less PE,

4

fN

I

+2.0

Fuel in 21 and 24

SS Thimble

XII

watt-cm 3

MW-gm

All***

No Fuel in 23

Cd Lined Sample Assembly

Fast

Neutron

Fraction

Mr.

~------~

1/19-20/65

XI

Absorbers

Used in

Data

Analysis

20.9

21.9

I

I

o.o68

All

21.0

Same as XII except

Aluminum Thimble

*

*

*

10 Plate New Fuel

Element

Aluminum Thimble

**

**

**

*This series was not made at all axial positions in the core and thus cannot be used to

directly evaluate FT and fn- This series did include the axial positions -6 inches,

0 inches, and +6 inches relative to the core midplane and is used with the results from

Series XII, XIII, and XIV in determining a best estimate of the fast neutron dose rate

at these three positions.

**This series was made to evaluate the possible effect of thermocouple size on the measurements in the low thermal conductivity absorbers using a new method of inserting

thermocouples in the absorbers. Unfortunately, poor thermal contact between the thermocouple and absorber invalidated the measurements and no conclusions could be made.

This experiment will be repeated at a later date using more carefully constructed calorimeters.

***Beryllium, aluminum, carbon, polyethylene, polystyrene, and Santowax OMP absorbers.

19

F

= 1.15 + 0.20

MWt-cm

FT = 20.45 + 0.36

wt- cm

fN = 0.056 + 0.007

These values have been used in evaluating the G values for

Runs 13 and 14 as presented in Section 2.0.

Three foil activation measurements were completed during

this period. The calculated values of FN and fN using these

data are summarized in Table 4.2. In Figure 4.1, the axial

variation of the calculated neutron dose rate in Santowax WR

is presented for Series 29, 30 side, and 30 center. The neutron energy spectrum used for these calculations is illustrated in Figure 4.2 with the positions of the detector

energies denoted. The spectrum is based on assumption of a

l/E spectrum from the Co5 9 resonance (120

Mev, a shape of O(E) = pEq from 0.711 Mev

a measured fast spectrum above 2.81 Mev.

culated from the foil activation data are

ev) to 0.711

to 2.81 Mev, and

The FN values cal-

en-the eder-of'

sligitly less than values obtained from the calorimeter measurements. This discrepancy is believed due to the lack of detectors between the Co 59 resonance of 120 ev and the lowest

threshold detector of 2.9 Mev now used, where a large percentage of the deposited energy by fast neutrons is derived.

The neutron spectrum in this energy region must therefore be

faired for the calculation of FN with a resulting large

uncertainty. Additional resonance and threshold detectors

are now being developed for use in this region so that the

spectrum may be better defined.

Table 4.2

Summary of Past Neutron Dose Rates from Foil Activation Measurements

Calculated

Fuel Position

Numbarv

Date of

watt-cm

3

Foil Activation

Series No.

Measureftent

29

March 1965

20

No fuel in 20

Cd Lined Sample

Assembly

No fuel in 21

SS Thimble

1.15

0.053

June 1965

20

No ful1 in 20

1.12

0.052

1.06

0.o48

30 side

In-Pile Section

No fuel in 21

30 Side in Side

Monitor Tube

30 Center in Center

Monitor Tube

30 center

31 side

31 center

September 29,

Fuel Loading

1965

20

Same as 30 Side and

30 Center

data not

yet analyzed

0

0.005

0.004

S0.003

0.002

0.001

-II

-6

0

AXIAL DISTANCE

6

11

15

FROM CORE CENTER, INCHES

20

25

FIG. 4.1 CALCULATED FAST NEUTRON DOSE RATE IN SANTOWAX WR USING FOIL ACTIVATION DATA,

FUEL POSITION 20

22

(n

a, I 0r

z

0

c-

w

0

w

(I)

N

z

0

w

104

102

104

ENERGY

106

,

eV

FIG. 4.2 NEUTRON ENERGY SPECTRUM USED FOR FAST NEUTRON

DOSE RATE CALCULATIONS FROM FOIL ACTIVATION

DATA - RUN 29

CHAPTER 5

HEAT TRANSFER AND FRICTION FACTOR RESULTS

Heat transfer data have been taken using an out-of-pile

test heater since the beginning of loop operation in August,

1961. Also, as described in the previous progress report, a

new test heater (THT) was installed with provision for pressure drop (or friction factor) measurements as well as heat

transfer measurements. During this period, friction factor

measurements and additional heat transfer measurements were

made using out-of-pile loop operation and the new test

heater THT.

A report (1.2) was issued in September, 1965

summarizing and analyzing the new friction factor and heat

transfer data as well as all previous heat transfer data

obtained with the M.I.T. Loop and establishing the best

correlations for both the heat transfer coefficient and the

friction factor.

In Figure 5.1, a comparison of all M.I.T. data taken

up to Run 14 (466 data points) are presented on a plot of

Nu/Pr *4 vs Re and compared with the Dittus-Boelter correlation,

NuB

o4 = 0.023 Re0.8

Nu/rB

RB'

with all properties evaluated at the bulk temperature.

(5.1)

The

data fall within +10% of this correlation over the Reynolds

number range covered in the experiments of 7 x 103 to 1.5 x

1050

A Colburn type correlation has been used for correlation

of both heat transfer and friction factor data,

j*

= StPro. 6 = 0.023 Re-0.2 =

(5.2)

In several measurements on Santowax WR, simultaneous heat

transfer and friction factor measurements were made using

test heater TH7. These results are presented in Figure 5.2

and compared with the Colburn relation with good agreement.

400

-

300-

0

Nu/Pr0.4 0.023

Re0.8

0

± 10%

*

200

150-

a100

z- 0

~80

-

0

Ts 0

0

50 /o

40

ORGANIC,

SANTOWAX

I

OMP

-e

&1~

30

-

15

4

5

6 7 8 910

1

1.5

ALL M.I.T.,IRRADIATED

TEST

HEATEF

USED

OMP

TH5

TH6

0

2

OMP

TH6

o

v

3

5

II

x

12

13

WR

WR

WR

WR

WR

TH6

TH6

TH6

TH7

TH7

-

20

FIG. 5.1

0

M.1.T.

IRRADIATION

RUN No.

111111

1

1

5 6 7 8910

4

3

2

Reynolds No., Re.

1

1.5

ORGANIC COOLANT, HEAT TRANSFER DATA

25

10-I

I

i

i

I

I

I

I

I

I

-

%I-

0

IL<

f = 0 023

z

8

0

Reo-.20

U-

o

RUN 12

a

RUN 13

10-2

III

2F

0

St Pr

2/ 3

=0.023Re-.

20

0

0

|I

I

1.5

FIG. 5.2

I

I

I

4

I

5

I

6

3

2

REYNOLDS NO., ReB

I

I

8 105

I

1.5

FRICTION FACTOR AND HEAT TRANSFER

FACTOR FOR IRRADIATED SANTOWAX WR,

UPSTRE AM HALF OF TEST HEATER 7

2

26

Additional measurements on both Santowax WR and distilled

water were made in which only the friction factor was measured.

In Figure 5.3, the friction factor data measured for Santowax

WR and for distilled water with test heater THT are presented

and compared with the Colburn relation with excellent agreement. In Figure 5.4, the heat transfer data for Santowax OMP

are compared with the C olburn relation, again with excellent

agreement.

In summary, the heat transfer data and friction factor

data obtained in the M.I.T. Organic Coolant Project can be

represented within +10% by the following standard correlations

over a Reynolds number range of 10 to 105:

Dittus-Boelter Equation

NuB = 0.023 ReO'8 Pr0. 4

(5.3)

or

Colburn Equation

StPr.

=

0.23 Re 0 2

where f =

1A2P

L

pVT

(5.4a)

(5.4b)

0.05

0.04

0

0.03

UL

z

9 0.02

L

0.01

4

FIG, 5.3

6

8

104

3

2

1.5

REYNOLDS NO.,

4

6

8

105

1.5

2

Re B

FRICTION FACTOR DATA FOR TH7, SELECTED

DATA AND WATER DATA

SANTOWAX

WR

t~3

28

0.01

(0

c

.. 0.005

C

0

0.004

0.003

0.002-

6

FIG. 5.4

I

I

0.001

8

104

1.5

5

4

3

2

REYNOLDS NO., ReB

6

8

COLBURN ANALOGY FOR M.I.T., IRRADIATED

SANTOWAX OMP, HEAT TRANSFER DATA

105

.4-

--

CHAPTER 6

SUMMARY OF PROPERTY MEASUREMENTS FOR RUN 14

During Run 14, the density, viscosity and number average

molecular weight of three samples, 14L-4, 8, and 12, were

measured.

In Figures 6.1 and 6.2, the density and viscosity

results respectively are presented for these three samples

representative of the beginning, middle, and end of Run 14.

From Figure 6.1, the density appears to decrease by 1.0 to

1.5% depending on temperature during Run 14. The viscosity

from all three samples is essentially the same, however, as

is evident from Figure 6.2.

In Table 6.1, the average molecular weight of the bottoms

from Samples 14L-4, 8, and 12 are presented; the average value

is 449. In Table 6.2 and Figure 6.3, a summary is given of

previous measurements of the average molecular weight of the

bottoms for steady-state runs. Additional data are required

before any definitive conclusions can be drawn. It will be

noticed however that the average molecular weight appears to

increase with %HB at a given irradiation temperature in all

cases. Also, the molecular weight appears to decrease as

irradiation temperature increases at a given HB content.

Table 6.1

Average Molecular Weight of Run 14 High Boiler

(quaterphenyls not recycled)

Sample No.

Average Molecular Weight

14L-4

14L-8

14L-12

444

450

452

Average

449

.. .........

30

1.00

-

0.98

0.96

0.94

0.92

C-)

0.90

0.88

0.86-

0.84-

0.82

0.80

0.78 .

400

450

500

700

650

550

600

TEMPERATURE, *F

FIG. 6.1 DENSITY MEASUREMENTS

750

FOR RUN 14

800

1.0

I

0.9* -

I

|I

1.10

|

1.20

31

0 14L -4

-

0.8

I

A

14L-8

+ 14L -12

0.7*

0.6 -

0.5

w

c'n

0

a_

z

0.4 k-

0.3 10

C-)

0.2 I-

0.1

L

0.70

I

0.80

FIG. 6.2

|I

0.90

|I

1.00

I/ T x 103

VISCOSITY

1.30

OR-I

MEASUREMENTS

FOR RUN 14

Table 6.2

Summary of Average Molecular Weight for

Steady-State Loop Irradiations Through Run 14

Run

No.

Irradiation

Temperature, OF

% HB

Average Molecular

Weight of HB

Quaterphenyls

Recycled

11

14

1C

610

9.6

416

No

572

610

11.0

32.3

449

690

No

No

5

700

30.8

702

Yes

7

6

3

750

750

750

11.5

15.2

30.3

599

644

666

Yes

Yes

Yes

2

750

32.4

580

No

4

78o

24.9

658

No

10

800

17.2

540

Yes

9

800

26.9

633

Yes

U)

R)

33

720

I

I

cc:

w 6801-J

m-6 40F+

0

600-

w

/

5601--

/

w

-J

0

w

w

520H-

480H-

0 572 -610 *F, QUATERPHEN YLS

NOT RECYCL ED

o

440|-

+ 7500F, QUATERPHENYLS

RECYCLED

bO800F, QUATERPHENYLS

z

RECYCLED

400 0

FIG. 6.3

5I

I

I

20

15

10

% HB IN COOLANT

I

I

25

I

30

I

35

AVERAGE MOLECULAR WEIGHT OF HIGH BOILER AS

FUNCTION OF HIGH BOILER CONCENTRATION

. ........

34

CHAPTER 7

TRAVEL AND REPORTS ISSUED

In June, 1965 E. A. Mason and T. H. Timmins of M.I.T.

visited the Chalk River Laboratories of AECL for two days and

participated in technical discussions concerning the organic

coolant work being carried out at these laboratories and at

M.I.T.

On August 5 and 6 1965 D. T. Morgan, W. N. Bley, and

T. H. Timmins visited Atomics International at Canoga Park,

California to discuss the experimental program planned for the

M.I.T. In-Pile Loop for the next two years, considering the

requirements of the HWOCR Program and the capabilities of the

M.I.T. Loop. An experimental program which satisfied the

HWOCR requirements was agreed on by both Atomics International

s4pd M.I.T. and submitted to the AEC where approval was granted

to the program.

A report describing and analyzing the friction factor

and heat transfer measurements performed at M.I.T. on organic

coolants was issued in September, 1965 (1.2). A topical

report (to be assigned the number MIT-334-34) describing all

results on Santowax WR up to Run 13 is in preparation and

should be completed during the next quarter.

REFERENCES

1.1

1.2

Mason, E. A., "In-Pile Loop Irradiation Studies of

Organic Coolant Materials," Progress Report, October 1

December 31, 1964, MIT-334-12, Department of Nuclear

Engineering, M.I.T., February 1, 1965.

Swan, A. H., and E. A. Mason, "Friction Factor and Heat

Transfer Correlation for Irradiated Organic Coolants,"

MIT-334-23, Department of Nuclear Engineering, M.I.T.,

September, 1965.

-

M.I.T. REPORT DISTRIBUTION LIST

AEC Contract AT(38-1)-334

ADDRESSEES

COPIES

Idaho Operations Office, P.O. Box 2108, Idaho

Falls, Idaho, Att: Dir. of Nucl. Tech. Div.

Canoga Park Area Office, P.O. Box 591, Canoga

Park, Calif., Att: Chief, Power Systems Br.

Chicago Operations Office, 9800 S. Cass Ave.,

Argonne, Ill., Att: Dir. of Reactor Engr. Div.

New York Operations Office, 376 Hudson St., N.Y.,

N.Y. 10014, Att: Dir. of Reactor Div.

Savannah River Operations Office, P.O. Box A,

Aiken, S. Carolina

Att: Dir., HWOCR Div.

J. H. Kruth

USAEC Technical Representative, USAEC, Whiteshell

Branch, Pinawa, Manitoba, Canada

Brussels Office, USAEC, US Mission to the European

Communities, 23 Avenue des Arts, Brussels, Belgium

USAEC, Washington 25, D.C.

Att: Mr. Angelo Giambusso, Div. of Reactor

Development

Att: Chief, High Temp. Reactors Br., Div. of

Reactor Development

Att: Clitef, Water Reactors Br., Div. of Reactor

Development

Att: A. N. Tardiff, Div. of Reactor Development

Atomics International, P.O. Box 309, Canoga Park, Calif.

Att:

Att:

Att:

C. A. Trilling

R. T. Keen

Combustion Engineering, Inc., Windsor, Conn.

Att: R. J. Rickert

Dr. C. W. J. Wende, E. I. du Pont de Nemours,

Explosives Dept., AED, Wilmington, Delaware 19898

Dr. W. M. Campbell, Dir., Chem. and Met. Div.,

Chalk River Proj., AECL, Chalk River, Ontario,

Canada

Dr. R. F. S. Robertson, AECL, Whiteshell Branch,

Pinawa, Manitoba, Canada

Dr. H. Hannaert Chemistry Department, Euratom CCR,

Ispra (VareseS, Italy

1

1

1

1

6

2

2

2

1

1

2

1

4

1

4

1

3

3

4

ADDRESSEES

COPIES

Babcock and Wilcox Co., Lynchburg, Virginia

Atomic Energy Div., Att: W. M. Vannoy

USAEC Div. of Tech. Information Ext., P.O. Box 62,

Oak Ridge, Tenn. (for standard TID-4500 dist.)

Dr. W. G. Purns, Atomic Energy Research Establishment,

Radiation Chemistry Building 146, Harwell, Didcot,

Berks., United Kingdom

Mr. P. A. Houllier, Laboratoire Central de Recherches

Progil, 10 #'uaidu Commerce (Boite Postale 105),

Lyon-Vaise, France

Mr. P. Leveque, Chef du Service de Physico-Chimie

Appliquee, CEA Centre D'Etudes Nucleaires de Sac~lay,

Boite Postale No. 2, Gif-sur-Yvette (Seine-et-Oise),

France

Dr. E. Proksch, Reactorzentrum Seibersdorf,

Lenaugasse 10, Wien VIII, Austria

Mr. J. R. Puig, CEA Centre D'Etudes Nucleaires de

Saclay, Boite Postale No. 2, Gif-sur-Yvette (Seineet-Ose), France

1

1

1

1

1