Microprocessor Applications for Laboratory Learning

advertisement

Microprocessor Applications for Laboratory

Learning

by

David Earl Robison

Submitted to the Department of Electrical Engineering and

Computer Science

in partial fulfillment of the requirements for the degree of

Master of Engineering in Electrical Engineering and Computer

Science

at the

MASSACHUSETTS INSTITUTE OF TECHNOLOGY

May 2001

5S?

c

© David Earl Robison, MMI. All rights reserved.

The author hereby grants to MIT permission to reproduce and

distribute publicly paper and electronic copies of this th( iRASSACHUSETTS

document in whole or in part.

INSTITUTE

OFTEGHNOLQGY

JUL 11 2001

.IBRARIES

Author ..........................

Department of Electrical Engineering and Computer Science

May 23, 2001

Certified by...........

Steven B. Leeb

Associate Professor

Tbsis Supervisor

Accepted by ......

Arthur C. Smith

Chairman, Department Committee on Graduate Theses

BARKER.

2

Microprocessor Applications for Laboratory Learning

by

David Earl Robison

Submitted to the Department of Electrical Engineering and Computer Science

on May 23, 2001, in partial fulfillment of the

requirements for the degree of

Master of Engineering in Electrical Engineering and Computer Science

Abstract

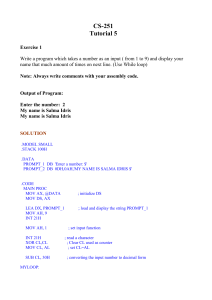

In this thesis, I designed, implemented, and verified a number of projects for

use in the Microprocessor Project Laboratory. I selected the development system

for the course, designing and building hardware components where necessary. I

also developed new project ideas, in addition to implementing and revising several projects used by the laboratory course in previous years. The finished set

of laboratory projects included microprocessor applications from several different fields: flourescent lamp technology, waveform generation, robotics, feedback

control, digital signal processing, and programmable logic.

Thesis Supervisor: Steven B. Leeb

Title: Associate Professor

3

4

Acknowledgments

I would like to thank my Lord and Savior, Jesus Christ. He has been my strength

when I was weak, my reason for pressing onward when I felt like giving up. In the

times that I have failed, His grace and forgiveness have brought me healing and

restoration.

I would like to thank my family, and all those people who have offered me

their love and support through all the hard times.

I would also like to thank Prof. Steve Leeb, for providing the ideas and support

necessary to complete this project.

And finally, I would like to thank Mr. David Grainger, and the Grainger

Foundation, as well as Dr. Emanuel Landsman, and the Landsman Foundation,

for the donations which have made this project possible.

5

6

Contents

1

Introduction

15

1.1

Design Considerations

. . . . . . . .

. . . . . . . . . . . . . . .

16

1.2

Main Tasks . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

17

1.3

Organization

. . . . . . . . . . . . .

. . . . . . . . . . . . . . .

17

2 A Library of Useful Hardware Tools

19

2.1

Choosing a Microprocessor . . . . . .

19

2.2

Microprocessor Accessories . . . . . .

20

2.3

R 31JP . . . . . . . . . . . . . . . . .

23

2.4

Interfacing the R31JP

. . . . . . . .

24

2.4.1

Power and Signal Connections

24

2.4.2

Robustness

. . . . . . . . . .

24

2.4.3

Additional Features . . . . . .

25

2.4.4

Daughter Card for the R31JP

26

2.5

Interfacing Peripherals . . . . . . . .

26

2.5.1

Memory-Mapped I/O Chips .

27

2.5.2

Telephone Keypad

. . . . . .

27

2.5.3

Liquid Crystal Display . . . .

30

2.5.4

Speaker

. . . . . . . . . . . . . . . . . . . . . . . . . .

3 Fluorescent Lamps

30

33

7

3.1

4

Theory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

33

3.1.1

Dynamics of a Fluorescent Bulb . . . . . . . . . . . . . . .

33

3.1.2

LC Ballast . . . . . . . . . . . . . . . . . . . . . . . . . . .

34

3.2

Hardware

3.3

An Interactive Fluorescent System

. . . . . . . . . . . . . . . . .

35

3.4

Motivation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

35

3.5

Implementation . . . . . . . . . . . . . . . . . . . . . . . . . . . .

36

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

35

Generating Waveforms

39

4.1

Motivation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

39

4.2

Hardware

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

40

4.3

Implementation . . . . . . . . . . . . . . . . . . . . . . . . . . . .

40

Techniques for Generating Waveforms . . . . . . . . . . . .

40

Telephone Dialing . . . . . . . . . . . . . . . . . . . . . . . . . . .

42

4.3.1

4.4

5 Motor and Robot Control

5.1

Motivation.

5.2

Hardware

5.3

43

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

43

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

44

5.2.1

Current for a DC Motor . . . . . . . . . . . . . . . . . . .

44

5.2.2

Robot Arms . . . . . . . . . . . . . . . . . . . . . . . . . .

45

Implementation . . . . . . . . . . . . . . . . . . . . . . . . . . . .

46

5.3.1

Voltage for a DC Motor

. . . . . . . . . . . . . . . . . . .

46

5.3.2

Creating a PWM Waveform . . . . . . . . . . . . . . . . .

47

5.3.3

Monitoring the Robot Keypad . . . . . . . . . . . . . . . .

49

5.3.4

Recording Robot Motion . . . . . . . . . . . . . . . . . . .

50

6 Feedback Control

53

6.1

Motivation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

53

6.2

Hardware

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

54

6.3

Implementation . . . . . . . . . . . . . . . . . . . . . . . . . . . .

54

8

7 Programmable Logic

57

7.1

M otivation ................

57

7.2

Hardware and Development Tools . . .

58

7.2.1

Hardware Description Language

58

7.2.2

Compilation and Synthesis Tools

59

7.2.3

Programmable Logic Devices

.

60

7.2.4

Device Programmer . . . . . . .

60

7.2.5

Conclusions . . . . . . . . . . .

60

Implementation . . . . . . . . . . . . .

61

7.3.1

Implementing Designs in VHDL

61

7.3.2

Design Projects . . . . . . . . .

66

7.3

8 Voice Recorder

85

8.1

Motivation . . . . . . . . . . .

85

8.2

Hardware

. . . . . . . . . . .

86

8.3

8.2.1

Microphone Circuitry

86

8.2.2

Speaker Circuitry . .

86

Implementation . . . . . . . .

86

8.3.1

Record and Playback .

86

8.3.2

Sampling Rate and the Nyquist Frequency

91

8.3.3

FIR Filters

. . . . . .

92

8.3.4

Filtering Strategy . . .

93

8.3.5

Filter Implementation

94

8.3.6

Timing Constraints . .

117

9 Conclusions

119

A Schematics

121

A.1 R31JP Daughter Card ...........................

121

A.2 Fluorescent Lamp Ballast

121

. . . . . . . . . . . . . . . . . . . . .

9

A.3 Keypad

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

121

A.4 Speaker

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

125

A.5 M emory-m apped I/O Devices . . . . . . . . . . . . . . . . . . . .

125

10

List of Figures

7-1

Schematic for XC9536 Square Wave Generator . . . . . . . . . . .

72

7-2

Schematic for XC9536 Pulse Width Modulator . . . . . . . . . . .

75

7-3

Schematic for XC9536 LED Driver

. . . . . . . . . . . . . . . . .

82

7-4

Schematic for XC9536 Parallel Output Port

8-1

Schematic for Microphone and ADC

. . . . . . . . . . . .

82

. . . . . . . . . . . . . . . .

87

A-1 R31JP Daughter Card . . . . . . . . . . . . . . . . . . . . . . . .

122

A-2 Interactive Ballast for a Fluroescent Lamp . . . . . . . . . . . . .

123

A-3 Schematic for Keypad and MM74C922

. . . . . . . . . . . . . . .

124

A-4 Schematic for DAC and Speaker . . . . . . . . . . . . . . . . . . .

125

A-5 Address Decoding For Memory-Mapped I/O . . . . . . . . . . . .

126

A-6 8254 Counter/Timer . . . . . . . . . . . . . . . . . . . . . . . . .

127

A-7 8255 Parallel Port . . . . . . . . . . . . . . . . . . . . . . . . . . .

128

A-8 AD558 digital-to-analog converter . . . . . . . . . . . . . . . . . .

129

A-9 ADC0848 Analog-to-Digital Converter

130

11

. . . . . . . . . . . . . . .

12

List of Tables

5.1

Achievable Ranges for Various PWM Generators . . . . . . . . . .

49

7.1

Available Pins on Programmable Devices . . . . . . . . . . . . . .

66

7.2

Programmable Logic Specifications

66

8.1

Maximum Sampling Rates for Various Filter Implementations

13

. . . . . . . . . . . . . . . . .

. .

117

14

Chapter 1

Introduction

The MIT Department of Electrical Engineering and Computer Science offers a

laboratory course entitled "Microprocessor Project Laboratory", better known as

"6.115". Before the spring of 2001, however, this class had not been offered for

more than a year.

Over the years, courses come and go. Certain fields of study which may have

been significant 10 years ago have now become obsolete, or have lost their importance. Not so with microprocessors. Microprocessors have become a vital feature

of today's electronic landscape. From jet airplanes to cars to microwaves to cell

phones, they have made possible many technologies, appliances, and features that

people take for granted every day. Therefore, at an institute like MIT, students

must be given the opportunity to learn about microprocessors, and be equipped

to take that technology to the next level.

My thesis project was to re-create and re-design the laboratory experiments

and equipment necessary to begin offering the "Microprocessor Project Laboratory" in the spring of 2001. Given several ideas for possible laboratory exercises,

my task was to revise, modify, and implement those ideas, integrating them into

a series of experiments and projects.

15

1.1

Design Considerations

It would be fairly easy for a microprocessor laboratory course to be taught as if it

were a user's manual, a guide for how to do various tasks. The class would teach

students how to use a microprocessor, how to program in assembly, how to wire

up chips and peripheral devices. But the challenge is to create a laboratory course

which teaches students to think critically about microprocessors, and forces them

to be creative, to find new ways to do things, and to stretch the technology to its

limit.

The first design requirement, therefore, was to create microprocessor experiments which force students to think critically about the problem, and explore the

various limitations of the system involved.

The second requirement was to expose students to a representative sampling

of major microprocessor applications over the course of the semester, including

digital user interfaces, feedback control, signal processing, waveform generation,

and robotics.

A laboratory course may be able to meet these first two requirements, but if

the class causes students to hate the subject material, it has somehow failed at

its objective. Our hope is that students would enjoy taking 6.115, and would be

excited about what they have learned. This hope is the third design requirement:

the microprocessor laboratory (and the experiments associated with it) should

build interest and enthusiasm in the subject.

Many of the lab experiments considered for 6.115 required additional hardware

and equipment. But in a large laboratory class like 6.115 (expected enrollment

was between 75 and 100 students), equipment sees a lot of wear and tear over

the course of a semester. Therefore, to avoid replacing equipment after every

term, any item approved for use in 6.115 had to be rugged, hard to break, and

dependable. It also needed to be cheaply bought or easily built, given the large

number of students expected in the course.

16

This becomes the fourth (and most practical) design requirement: laboratory

equipment must be easily attainable or easily manufactured in large quantities,

hard to damage, and easy to repair.

In brief summary, there were four ideas that governed the development of

microprocessor projects for 6.115:

" Encourage students to think

* Explore a variety of practical microprocessor applications

" Generate enthusiasm for the microprocessor system design

" Accomplish all of the above with cheap, rugged, and long-lasting equipment

1.2

Main Tasks

Ideas for lab exercises which met the design requirements stated above were subjected to a deeper investigation.

The three stages or tasks involved in these

investigations are as follows:

1. Design and build the necessary hardware and interfaces

2. Demonstrate the feasibility of the proposed lab exercise

3. Demonstrate the reliability of the system involved

These three tasks had to be satisfactorily completed before a laboratory exercise could be acceptable for use in 6.115.

1.3

Organization

This report is divided into chapters, each of which discusses lab exercises considered for use in 6.115. Within each chapter, the motivation for the lab exercise will

17

be described. That will be followed by a discussion of interesting features of the

hardware and interface. There will also be a summary about the feasibility and

reliability of the lab exercise's implementation, making note of key features in the

design.

Chapter 2 describes a basic set of hardware that is necessary or useful for a

laboratory class in microprocessor technology.

Chapter 3 discusses a lab exercise involving fluorescent lamp technology.

Chapter 4 discusses a lab exercise focused on generating analog waveforms.

Chapter 5 discusses a lab exercise about motors, and robot arm control.

Chapter 6 discusses a lab exercise in feedback control, including both a firstorder and a second-order system.

Chapter 7 discusses a lab exercise focused on programmable logic devices.

Chapter 8 discusses a lab exercise about voice recording and digital signal

processing.

Chapter 9 contains a conclusion and summary of all the work completed within

the scope of this thesis project.

18

Chapter 2

A Library of Useful Hardware

Tools

Before starting to think about the specific laboratory exercises for the 6.115 curriculum, it is necessary to put together a library of basic hardware and software,

starting with the microprocessor.

2.1

Choosing a Microprocessor

When teaching a laboratory class about microprocessors, the first problem is to

decide which microprocessor to use. One approach would be to use a whole collection of different microprocessors, giving students a broad perspective of the

possibilities. But, in the end, this would only be tedious-the students would be

required to master the specifications for all the different chips, and then spend

hours re-wiring their circuits each time they switch between processors. It would

also be prohibitively expensive. A much better approach is to use a single microprocessor, allowing the course to focus more on microprocessor applications and

less on particular microprocessor specifications.

Previously, Intel's 8051 was the microprocessor of choice for 6.115. It is an

19

old part, so it lacks many of the extra features present in more recent designs.

But the Intel 8051 is very popular: there are more 8051-family microprocessors in

deployment around the world than there are of any other microprocessor. Using

the 8051 in a teaching environment will prepare students for what they'll see in

industry. Its popularity also lends another advantage: it is well-tested, tried and

true. Its simplicity also makes it a good teaching tool; with fewer details and

features, the 8051 is easier to understand, and it allow a student to focus on

general microprocessor concepts, instead of being buried in the complexity of a

more advanced chip.

A more advanced version of the 8051, Intel's 80C251, was also considered for

use in 6.115. In the end, however, the additional features were outweighed by the

increased complexity, and the 8051 was chosen as the official microprocessor of

6.115.

2.2

Microprocessor Accessories

The minimum microprocessor setup involves a bit more than just the 8051 itself.

There are several items and peripherals which must be added to the system in

order to provide basic functionality. Here is a description of those requirements:

11.0592 MHz Crystal The 8051, at the very least, requires a clock input; thus,

an oscillator crystal is necessary. The frequency of the oscillator could be

in the range of 10-15 MHz. An 11.0592 MHz crystal is best suited for this

purpose, because it allows for easy serial communication with a PC.

MAX232, DB9 Connector If the 8051's serial port will be used to communicate with a PC, a MAX232 chip and a serial connector are necessary. The

8051 use TTL logic levels (0 and 5v), but the standard for serial communication is something very different. The MAX232 translates back and forth

between the different voltage levels. And the serial connector is necessary,

20

in order to connect a serial cable (DB9 connector) between a PC and the

8051 setup.

EEPROM Unless factory-burned 8051 chips are specially ordered for 6.115,

with the desired program permanently written into the internal ROM, there

needs to be an external memory chip to contain the programs written by

students.

For this purpose, an EEPROM-Electronically Erasable Pro-

grammable Read Only Memory-will do well, because it is easily erased

and re-programmed.

RAM The 8051 contains 128 or 256 bytes of internal random-access memory

(depending on the version). For some applications, this amount of memory is

suitable, but if more data storage space is needed, another external memory

chip is needed.

The EEPROM is not sufficient, because it is read-only;

therefore, it is necessary to add RAM-Random Access Memory.

74HCT573 The 8051 has an interesting configuration for accessing external

memory. The 8 bit data bus, and the lower 8 bits of the 16-bit address

bus, are multiplexed together onto the same 8 pins of the 8051. The 8051

requires the use of an external latch: the address bus is latched onto an

external chip at the beginning of a machine cycle, so that the data bus can

take control of the 8051 pins for the remainder of the cycle. To perform

this operation, an 8-bit latch is required, and the 74HCT573 fulfills these

requirements nicely.

This is the minimum set of accessories; before a student can begin to do meaningful work, or even test simple programs, each of these chips must be correctly

wired and connected to the 8051. As to how this would be accomplished, there

were three options to choose from:

. Ask the students wire and connect the chips.

21

* Design and build a printed circuit board to meet the needs of the class, with

all the necessary hardware mentioned above.

" Buy a printed circuit board which contains all the necessary hardware.

Simply requiring each of the students to wire their own system is the easiest

choice, from the professor's point of view. Each student would receive a lab kit for

connecting and wiring chips; it would be a simple matter to have them build the

minimum system in their lab kit. But consider the students' perspective: before

they begin to program their microprocessor, they must use 75-100 separate wires

to connect all the various buses, control signals, and power lines. This process is

tedious, and includes a high probability of error. A large portion of the students'

(and teaching assistants') time would be spent de-bugging the system. It would be

a week into the term before anyone could start any of the microprocessor projects.

With that in mind, giving the students a circuit board, with the 8051 and

the minimal hardware all included, appears to be a much better solution. One

possibility was to design and build such a system ourselves. It would have been

costly and time-consuming, but it may have been worth it in the long run.

But another option was to find and buy a ready-made 8051 development system. If such a system was commercially available, and if it closely matched the

requirements for 6.115, then it would be the best solution. A product was found

which met these specifications: Rigel Corporation [7] sells a circuit board, the

R31JP, which was nearly perfect for use in 6.115. The cost of the board (minus

an educational discount) was far less than the cost (in materials and man-hours)

of designing and building the system ourselves. The R31JP included all the necessary hardware mentioned above, and in addition, contained some additional

circuitry to help in interfacing other peripheral chips. So the R31JP became the

"official" 6.115 development system.

22

2.3

R31JP

The R31JP is a very useful development system- it contains a microprocessor and

enough peripheral components to get you started on some interesting projects.

Here are some of the features which make it attractive:

Dynamic memory space The R31JP contains an EEPROM chip and a RAM

chip. This memory can be set up in any number of configurations, using

a switch and a CPLD. In the default configuration, program memory and

data memory occupy the same continuous memory space. It is also possible,

while in this default configuration, to swap the locations of the RAM and

EEPROM within the memory space. This is very useful, because it allows

for the EEPROM to be programmed with a semi-permanent operating system program. This operating system will then allow the user to down-load

program files to the RAM, and then run them. This eliminates the trouble

of having to re-burn an EEPROM each time a little change is made in the

assembly code.

Serial Port The R31JP contains the necessary hardware for connecting to a personal computer. The appropriate DB9 connector is included on the R31JP

board, as well as the appropriate serial line driver chip (MAX232 or equivalent).

Memory-mapped I/O Space If both the serial port and external memory will

be used, there are only 12 available I/O pins left for interfacing to peripheral

chips and hardware. This is not quite enough. One advantageous feature

on the R31JP is the memory-mapped I/O space- it already has a block of

memory which is devoted to external I/O. If the 8051 reads or writes to an

address in the memory-mapped I/O space, the data bus is automatically

re-routed to external peripheral chips.

23

No Wiring Necessary All of this comes ready-made on printed circuit board,

saving students from the tedious task of having to connect and wire a dozen

different components.

2.4

Interfacing the R31JP

When adapting the R31JP for use in the microprocessor lab (6.115), there were

a few problems encountered.

2.4.1

Power and Signal Connections

The R31JP needs to connect the NUBUS lab kit, in some fashion. The R31JP

would be used to control the systems developed by the students, and the lab kit

would be used to build those systems, so there needs to be an interface between

them. Some sort of adapter is necessary, because the lab kit comes equipped

with two 50-pin IDC connectors, while the R31JP contains 2 rows of header pins.

There needs to be an adapter which can covert the header pins into an IDC

cable/connector.

The R31JP requires a regulated 5 volt power supply. The most convenient

option is to use the lab kit power supplies for the R31JP, rather than buying

another power supply just for that purpose. If the R31JP is connected to the lab

kit somehow, it should be a simple matter to include power in that connection,

so that the R31JP feeds directly off of the lab kit.

2.4.2

Robustness

The system being developed will be used by hundreds of students over the years.

There will be a lot of abuse, and everything that can go wrong with our equipment

will go wrong. To that end, it is important to make things robust.

24

When connecting the R31JP to the lab kit, a few things were added to make

things more robust:

Power Regulation The power on the R31JP is coming directly from the lab

kit. And if a student plugs in the power in the wrong way, the R31JP

will suffer severe damage. To prevent such a wiring mistake from causing

damage, a power regulator was added between the R31JP and the lab kit.

This power supply takes 12V as input, and regulates it down to +5V. It is

a very inefficient power supply, generating a significant amount of heat, but

it prevents wiring mistakes from destroying the R31JP.

Signal Buffering If all the important signals on the R31JP are connected to the

lab kit, it allows the user to back-drive these signals, possibly damaging the

chips on the R31JP, or perhaps stalling the microprocessor. To prevent this,

a little protection was added-the WR#, RD#, XIOSEL#, and RESET

signals were all buffered, to prevent any back-driving by peripheral chips.

2.4.3

Additional Features

At this point, it became clear that another printed circuit board-some sort of

daughter card for the R31JP-would be necessary to connect the R31JP and the

lab kit. Once the decision was made to add an extra circuit board to the system,

it was time to add any other features which might be useful within the scope of

6.115.

This was an excellent opportunity to add blinking lights. All the signals on

Port 1 of the 8051 were connected to buffers, which lit up a bank of LEDs, such

that the LED bank displayed the data on Port 1. This bank of LEDs would serve

as visual aid, and also as a quick debugging tool.

25

2.4.4

Daughter Card for the R31JP

All of the proposed features and additions to the R31JP were integrated into a

printed circuit board design (see Figure A-1). This board was designed to sit on

top of the R31JP, plugging into the header pins as a sort of daughter card. The

cable connectors on the daughter card allow for quick and simple interfacing with

the NUBUS lab kit.

2.5

Interfacing Peripherals

When using the R31JP, there are two ways to interface peripheral chips and

components.

* Use the 8051 I/O ports. This is the simplest and easiest way to connect

peripheral chips, because the 8051 can read and write to all the I/O bits

individually. However, there is only a small number of available I/O pins on

the 8051, so it is only possible to interface a few chips this way.

9 Use the Memory-mapped I/O space. On the R31JP, the addresses FE00h

through FEFFh (hexadecimal) are reserved for memory-mapped I/O. When

the 8051 reads or writes to one of these addresses, the two memory chips are

de-activated, and the XIOSEL# line is pulled low. The XIOSEL# signal

can be used to activate peripheral devices. By decoding the lower bits of

the address, and combining them with the XIOSEL# line, it is possible to

fit several chips (up to 256) into this memory-mapped I/O space. The 8051

would select between these different devices by specifying the address of a

particular device.

When interfacing chips in the memory-mapped I/O space, a 74LS138 logic

chip can be used to decode the addresses bus and create separate chip select lines

for each of the peripheral devices (see Figure A-5 for a schematic).

26

A library of useful devices was developed for use of 6.115.

Many of these

devices required additional design and modification, in order to interface them

with the lab kit and the R31JP. The following sections contains a description of

the library of hardware devices and peripherals that were assembled for the course.

2.5.1

Memory-Mapped I/O Chips

The following chips can all be interfaced into the 8051's memory mapped I/O

space, without too much difficulty. Detailed schematics are available in the Appendix A.

* AD558 Digital-to-Analog Converter

* ADC0804 Analog-to-Digital Converter

* ADC0848 Analog-to-Digital Converter

* 8254 Counter-Timer

* 8255 Parallel I/O port

2.5.2

Telephone Keypad

A telephone-style keypad was found, available in quantity for a reasonable price.

The keypad has 8 I/O lines (one for each row and column on the keypad), and

can be plugged into the lab kit by using 8 pins of a 16-pin DIP cable/connector.

The keypad functions as a matrix: there is a wire for each of the columns, and

a wire for each of the rows. When an individual key is pressed, the corresponding

column wire and row wire are shorted together.

It would be possible to simply connect the keypad directly to the 8051. However, for it to work properly, the 8051 must be continuously polling the keypad,

to see if any of the keys are being pressed. With this setup, the following code

could be used to read key presses:

27

For this code segment, assume the following connections:

Keypad column 1 <-> P1.0

Keypad column 2 <-> P1.1

Keypad column 3 <-> P1.2

Keypad column 4 <-> P1.3

Keypad row 1 <-> P1.4

Keypad row 2 <-> P1.5

Keypad row 3 <-> P1.6

Keypad row 4 <-> P1.7

10

;

;

;

;

;

Keypad Polling Routine

This routine checks to see if any of the

keys are being pressed. If there is a key

being pressed, the index associated with

that key is placed in the accumulator.

poll-keypad:

20

; RO will be a place holder-it will keep track

; of which key is being polled at any given

; time. When a key is pressed, RO will

; contain the index of that key.

mov RO, #00h

clr 00h

; 00h is set when a key is pressed

mov P1, #OFFh

clr P1.4

jnb P1.0, key-pressed

inc RO

jnb P1.1, key-pressed

inc RO

jnb P1.2, key-pressed

inc RO

jnb P1.3, key-pressed

inc RO

Setup Port 1 for input

Pull row 1 'low'

If any key in row 1 is being

pressed, the column row

will also be 'low'.

mov P1, #OFFh

clr P1.4

jnb P1.0, key-pressed

inc RO

jnb P1.1, key-pressed

inc RO

jnb P1.2, key-pressed

inc RO

jnb P1.3, key-pressed

inc RO

; Setup Port 1 for input

; Pull row 2 'low'

mov P1, #OFFh

clr P1.4

; Setup Port 1 for input

; Pull row 3 'low'

30

40

; If any key in row 2 is being

; pressed, the column row

; will also be 'low'.

28

50

jnb

inc

jnb

inc

jnb

inc

jnb

inc

P1.0,

RO

P1.1,

RO

P1.2,

RO

P1.3,

RO

key-pressed

key-pressed

; If any key in row 3 is being

; pressed, the column row

; will also be 'low'.

key-pressed

key-pressed

60

mov P1, #OFFh

cdr P1.4

jnb P1.0, key-pressed

inc RO

jnb P1.1, key-pressed

inc RO

jnb P1.2, key-pressed

inc RO

jnb P1.3, key-pressed

inc RO

ret

;

;

;

;

;

Setup Port 1 for input

Pull row 3 'low'

If any key in row 3 is being

pressed, the column row

will also be 'low'.

70

key-pressed:

; Since RO was incremented after each individual key

; was polled, RO will now contain an index associated

; with the key that was pressed.

mov A, RO

setb 00h

ret

Fortunately, there is an integrated circuit which will perform all this task

automatically. The MM74C922 polls the keypad, and can generate an interrupt

when there is a key press, signaling to the 8051 that there is data to be read.

In this configuration, the 8051 could connect to the MM74C922 through Port 1

or the memory-mapped I/O space. Appendix A includes a schematic, describing

how the system is connected (see Figure A-3). The driver code would be:

; Get Key Routine

; This routine retrieves data from the MM74C922 (keypad decoder).

getkey:

mov P1, #OFFh

cdr P3.4

mov A, P1

setb P3.4

ani A, #OFh

; Configure Port 1 for input

; Enable data output on MM74C922

; Read data

; Disable data output

; Clear the top 4 bits (unimportant data)

29

10

mov DPTR, #keytab

movc A, c A+DPTR ; Load appropriate data from key table

ret

keytab:

; This key table maps values onto the different keys.

; This particular version of the table maps values to

; the keys as follows:

20

1 2

4 5

7 8

0 0

db

db

db

db

db

db

db

db

db

db

db

db

db

db

db

db

2.5.3

3

6

9

0

A

B

C

D

01h

02h

03h

OAh

04h

05h

06h

OBh

07h

08h

09h

OCh

00h

00h

00h

ODh

30

40

Liquid Crystal Display

The Liquid Crystal Display can be connected to the 8051 using the 8255 parallel

port. The 8255 can be used to manipulate the control lines and the data bus on

the LCD.

2.5.4

Speaker

The 8051 microprocessor is capable of driving a speaker, and creating various

sound waveforms, with the help of the DAC and a LM386 amplifier. The LM386 is

designed specifically for use with a speaker or other audio devices. The speaker can

30

be connected to the LM386 as recommended in the first example of the LM386's

application notes. Appendix A contains a complete schematic of the system (see

Figure A-4).

31

32

Chapter 3

Fluorescent Lamps

One clever way to introduce students to relevant microprocessor issues-

physical

systems, real-time computation, interrupts, feedback-is to use a fluorescent lamp.

3.1

3.1.1

Theory

Dynamics of a Fluorescent Bulb

A fluorescent bulb is a valuable innovation-it consumes a fraction of the power

required for standard incandescent bulbs. However, to light up a fluorescent bulb,

it cannot be connected directly to an AC or DC power supply. The bulb requires

ballast.

The inside of a fluorescent bulb is a partial vacuum, filled with a small concentration of gas. When the bulb is not turned on, this gas tube could be modeled

as an open circuit, or an infinite resistance. To light the bulb, a very high voltage

(200-300V) must be applied across the tube, in order to ionize the gas inside.

Once the gas is ionized, current begins to flow, and energy is emitted from

the bulb in the form of light (photons).

But at this point, the electrical char-

acteristic of the bulb changes dramatically-from an infinite resistance to a very

small resistance, practically a short circuit. When in this state, the fluorescent

33

bulb becomes very unstable. The incremental resistance is actually negative-as

current flows through the gas, it causes the gas to be ionized even further, with

further decreases the resistance the gas chamber, causing even more current to

flow. This pattern could escalate until the fluorescent bulb explodes because of

excessive current and heat dissipation.

3.1.2

LC Ballast

In order to properly control a fluorescent bulb, a ballast is necessary. This ballast

must be able to provide a very high voltage to strike the bulb and ionize the gas.

But this ballast must also be able to limit the current flowing through the bulb,

after it has been struck and lit.

An resonant inductor-capacitor (LC) circuit is the perfect solution. The fluorescent bulb can be combined with an inductor and a capacitor, as shown in

Figure . When the bulb is off, its very high resistance causes the circuit to behave like a simple series-LC circuit. If we apply an AC voltage to the system, and

tune its frequency to the resonant frequency of the LC circuit, we can create a

very high voltage across the capacitor, and across the bulb. If all the parameters

are correct, this should cause the fluorescent bulb to be lit.

Then, once the bulb has been lit, the LC circuit limits the current through the

bulb. Because of the very small resistance across the bulb, the capacitor becomes

irrelevant, and the system behaves like an inductor and resistor in series.

This LC ballast is used to drive the fluorescent bulbs in most industrial systems.

34

3.2

Hardware

3.3

An Interactive Fluorescent System

As part of the course development for 6.115, a unique version of the LC ballast

was developed.

The full schematic of this fluorescent lamp LC ballast can be

found in Appendix A (see Figure A-2). When designing the lamp ballast, the goal

was to create an interactive lab station, allowing a student to control the inputs

to the system while observing the outputs. With the fluorescent lamp providing

a visual aid, this lab station has an appealing reward for all who are able to find

the resonant frequency.

The final product contained many attractive features:

* Socket for FT4 fluorescent bulbs

" Resonant LC circuit with removable inductor and capacitor

* Isolation for the high-voltage portion of the system

" Driver circuitry, converting a TTL low-current input into a high-voltage,

high-current signal to drive the LC circuit

" Input protection diodes, to prevent a user's wiring errors from damaging the

system.

* Scaled version of the bulb voltage, available as output to the user

3.4

Motivation

This fluorescent lamp lab station is very useful for studying resonant circuits

and fluorescent bulb dynamics. But it can also be made relevant to study of

microprocessors, and is worthy of inclusion in the 6.115 curriculum.

35

One of the biggest applications that microprocessors are used for is embedded control. Microprocessors are perfect for controlling systems which cannot

be trusted to run perfectly on their own. The fluorescent lamp is an excellent

example. Every fluorescent lamp comes equipped with an LC ballast. However,

depending on the manufacturing techniques, the resonant frequency of that ballast is not guaranteed to be very exact-it could be anywhere within a certain

range of frequencies. In order to successfully light the lamp, there must be some

mechanism which finds that resonant frequency.

That's where the microprocessor comes in: it can be used to sweep through

a range of frequencies, find the resonant frequency of the ballast, and ensure the

lamp is lit.

As a laboratory exercise, this design problem would force students to deal with

many important issues:

* Real-time programming and control

" Timing constraints

* Interrupts

* Closed-loop systems

3.5

Implementation

Here's how the system works: by generating a TTL square wave, the R31JP can

drive the lamp system, and attempt to light the bulb. However, the lamp will never

be lit if the microprocessor is blindly sweeping through a range of frequencies. The

microprocessor needs some sort of feedback.

To provide the necessary feedback to the microprocessor, the voltage across

the lamp can be rectified and converted into a trigger signal. The trigger signal

can be used to alert the microprocessor when the lamp voltage exceeds a certain

36

threshold. This should give the microprocessor all the information necessary for

finding the resonant frequency of the LC circuit and lighting the lamp.

37

38

Chapter 4

Generating Waveforms

4.1

Motivation

When driving the fluorescent lamp, students are forced to explore the issues of

microprocessor timing, as they try to create square waves at very specific frequencies. But an even more powerful method for teaching issues of timing and

real-time programming is to have students create a waveform generator.

When attempting to create high-frequency waveforms, students will discover

that they are held back by the speed of the microprocessor and the inefficiencies

of their code. Hopefully, in the course of completing this lab exercise, students

will learn how to write efficient code, and also come to understand the limitations

of the 8051 microprocessor.

An exercise in waveform-generation will also provide hands-on experience in

sound systems, since generating waveforms is the core function of any stereo system.

A laboratory exploring the generation of various waveforms will be a valuable

learning experience for the 6.115 students.

39

4.2

Hardware

By using the microprocessor together with a DAC (Digital-to-Analog Converter),

it is possible to create analog voltage waveforms. Of course, the quality of these

signals will be limited by quantization effects, due to time and magnitude quantization. But the quantization noise can be reduced by simply adding an analog

filter to the system.

In addition to the DAC, a speaker can be added to the system. (A schematic

for the speaker circuitry can be found in Figure A-4.)

Over the course of this

laboratory exercise, as students generate various analog signals, their work will be

more tangible if students are permitted to listen to the signals they create. With

a speaker incorporated into the system, it is possible to convert voltage waveforms

into sound waveforms. Students will then be able to observe their waveforms in

both the electrical form and the audio form.

The speaker will also be necessary for the telephone dialing exercise included

in this lab assignment.

4.3

4.3.1

Implementation

Techniques for Generating Waveforms

If done in the right manner, it is fairly simple to write 8051 assembly code which

generates a waveform.

The MOVC command allows data to be loaded from the program memory

space. The address used to access the code data is computed using the 16-bit

data pointer (DPTR) plus an 8-bit offset. This feature can be used to create

a circular buffer. The data pointer can be loaded with the first address of the

buffer; to access all of the data in the buffer sequentially, simply increment the

8-bit offset after each use of the MOVC command. When the offset is equal to

40

255, incrementing it will cause it to overflow and return to 0, essentially creating

a 256-byte circular buffer.

This circular buffer can be used to generate periodic waveforms, according to

the following procedure:

1. Convert one period of the desired waveform into 256 equally spaced data

points.

2. Convert each data point into an 8-bit number

3. Encode those 256 8-bit data points into a program, such that they will be

loaded into 256 sequential memory locations.

4. Using the MOVC command, the data pointer (DPTR), and an 8-bit offset,

create a program loop which will periodically read a data value from the

256-byte buffer, then write it out to the DAC, incrementing the offset after

each write.

As part of this lab exercise, students will be encouraged to generate waveforms

at arbitrary frequencies, and they will therefore be forced to see the limits of the

microprocessor and the code that they've written. There are two basic methods for

varying the frequency of one of these waveforms. The first method is to change the

frequency of the code loop which writes data out to the DAC. The other method

is to change how fast you increment through a period-instead of incrementing

the offset by one after each write, the offset can be incremented by some higher

number, such that the offset steps through the table more rapidly. With either

method, there are limitations. In the first case, the limitation is the speed of the

microprocessor. In the second case, the quality of the signal is compromised as

the frequency is increased.

41

4.4

Telephone Dialing

Once students have mastered the art of generating waveforms with a microprocessor, an interesting problem to tackle is the problem of creating telephone tones.

For a telephone to work properly, a depressed key must generate two distinct tones

at very specific frequencies.

To accomplish this task, it is possible to use a simple sine wave generating

program, with just a few modifications. However, it is important to be precisefor commercial dialing to work properly, the generated tones must be within 2%

of the specified frequencies. In order to meet these specifications, a 256-byte sine

table can be used, along with a 16-bit counter. The first 8 bits of the counter

will be used to look up a value in the table; the last 8 bits are retained to reduce

round-off error, and are used when incrementing the counter.

As for the problem of simultaneously generating two distinct frequencies, it

can be done by adding and scaling the two waveforms. Two separate counters

and increments are maintained, one for each of the desired frequencies. During

each program loop, both counters are incremented, and each is used to look up

a value in the sine table. Those two values are scaled and added to produce the

proper output value for the dual-tone waveform.

42

Chapter 5

Motor and Robot Control

Motivation

5.1

Motor control is a microprocessor application which cannot be overlooked. With

increasing regularity, microprocessors are being embedded in physical systems.

These microprocessors provide processing power and govern the actions of the

system.

When embedded in such a system, there are two basic ways that a microprocessor can communicate with the physical system around it:

Actuators The microprocessor can "talk" to the physical system by providing

commands, and controlling various actuators.

Sensors The microprocessor can "listen" to the physical system, and observe its

status, by reading the signals from various sensors.

The purpose of this lab exercise is to focus on the actuators, and how to drive

them using the microprocessor, in an open-loop fashion (the next lab will combine

both actuators and sensors to do a study in closed-loop feedback control). Most of

the emphasis of this exercise will be on DC motors. Though it may seem trivial,

there are actually several subtleties involved in driving DC motors.

43

The study of motors also provides a nice lead-in to a study in simple roboticsat the end of the lab, the students will experiment with the control of a simple

robot arm.

DC motor control, as well as robot arm control, are both very important topics

in the field of microprocessor systems. It is, therefore, an essential component of

the 6.115 curriculum.

5.2

5.2.1

Hardware

Current for a DC Motor

The first issue, when driving a DC motor, is the amount of current required. A

DC motor could quite easily consume around 1 A of current (the actual current

is dependent on the motor model and the torque applied to the drive shaft). A

motor cannot be directly run from the microprocessor, because the microprocessor

can only supply around 10 or 20 mA of current. A high-current buffer is neededsomething which will give the DC motor all the current that it needs. For 6.115,

the answer was to use the LM18293 chip, a component designed specifically for

driving motors.

At this point, everything is in place-the LM18293 can be controlled directly

by the R31JP, or by a peripheral chip. And the motor can be connected directly to

the LM18293 output. Furthermore, the motor can be driven either in a unipolar

or a bipolar mode, depending on how it is connected.

To connect a motor in unipolar mode, simply ground one of the motor leads,

and connect the other to the output of an LM18293 buffer.

To connect a motor in bipolar mode, connect each of the motor leads to the

output of a separate LM18293 buffer.

By alternating the states of these two

buffers, you will be able to drive the motor in both directions. And when the two

buffers are set to the same state, the motor will be stopped.

44

5.2.2

Robot Arms

A collection of cheap, 5 degree-of-freedom robot arms were bought for use in 6.115.

These arms are available from OWI as "Robot Arm Trainers", and can be found

at any number of robot hobby stores (such as Carl's Electronics [1]). The robot

arm has a plastic frame, and is driven by low-quality DC motors, without any

sensors or feedback. But it does have its advantages: the low cost makes it easier

to afford more arms, enough to provide for a large class and keep a supply of

spares, as well. Furthermore, each of the motors is coupled with a gear box and a

slip clutch, allowing the motor to disconnect from the joint if too much external

torque is applied. This mechanism protects the motor and gear box from serious

damage, and it also allows the user to move the joints without back-driving the

motor.

This OWI robot arm has two parts: the arm itself, and a little keypad used to

control the arm. To make things interesting for the 6.115 students, we decided to

connect both the arm and the keypad directly to the R31JP (instead of to each

other). In this configuration, the microprocessor assumes complete control over

the robot arm, and is responsible for monitoring the user inputs on the keypad.

This design configuration brought up some interface issues: the robot arm

and keypad were not designed to connect to the R31JP and NUBUS lab kit. The

keypad can be connected fairly easily-it can be plugged directly into the NUBUS

lab kit, with the use of some header pins. The robot arm is slightly more difficult

to interface. In the default configuration, one lead from each of the motors is

connected to a common ground, while the other lead is left unconnected (with

the idea that it will be powered from a positive or negative voltage, to move it

forward and backward).

For 6.115, the motor terminals should all be unconnected, giving the user

complete control.

In order to use the LM18293 chip to drive the motor in a

bipolar configuration, the LM18293 must have control of both motor terminals.

45

To achieve this, a small printed circuit board was designed and built, which routes

all the motor terminals to a connector cable. This small circuit board is designed

to fit inside the robot arm, replacing the circuit board which was originally inside

the arm. The connector cable is a 16-pin cable with DIP connectors on either end;

the DIP connectors make it easy for the robot arm to interface with the NUBUS

lab kit.

It would have been possible to find robot arms with a better design and more

useful features (such as sensors for feedback control), but at this point in time,

the funds were not available. If, in the future, more funds are available for 6.115

course development, I would recommend investigation into more advanced robot

arms.

Lynxmotion [4] sells a five-axis robot arm which is driven entirely by servo

motors, allowing for precise and accurate position control. Available for $195,

this model is designed to be controlled via a serial port, but could probably be

adapted to interface with the R31JP. I recommend this model as a possibility for

future use in 6.115-much more than the OWI robot arm, it could be used to

perform precise and delicate tasks in a reliable fashion.

There is one engineer who claims to have designed a sensor system for the

OWI Robotic Arm Trainer, enabling closed-loop feedback and position control.

The limited information I found is on the Xantz Innovations website [9]. This

would be another excellent area for further investigation.

5.3

5.3.1

Implementation

Voltage for a DC Motor

As mentioned earlier, an ample amount of current must be supplied in order to

drive a DC motor. But even with an adequate current supply, there is still another

issue: DC motors are analog. There is not a single "on" voltage, and a single "off"

46

voltage. DC motors respond to a whole range of voltage inputs; these different

voltages will drive the motor at different speeds.

One possible method for driving DC motors would be to use a digital-to-analog

converter (DAC), feed that analog signal through a high-current buffer (probably

an op amp), then use the output to drive the motor. However, a simpler solution

exists, one which takes advantage of the motor's physical characteristics.

The inertia of the motor's drive shaft creates a mechanical low-pass filter.

Thus, if the motor input voltage is a high frequency signal with a DC offset, the

motor shaft will rotate smoothly, as if it were only being driven by the DC part of

the signal. This property can be exploited by digital systems to drive DC motors

at various speeds; the technique is called pulse width modulation.

A pulse-width modulated (PWM) waveform is a signal that alternates between

two different voltage levels.

The signal is usually set to have a fixed period;

however, the time spent at the high voltage relative to the time spent at the low

voltage (the duty cycle) is varied. Varying this relation will change the average

value of the signal. Driving a motor with a PWM signal (provided the frequency

is high enough) is essentially the same as driving the motor with a DC voltage

equal to the duty cycle times the high voltage.

5.3.2

Creating a PWM Waveform

There are several ways to generate PWM waveforms with the 8051 microprocessor,

and each has its own advantages and disadvantages. For this 6.115 exercise, the

students will be asked to explore these different methods of implementing PWM

waveforms.

There are a couple ways to create a PWM signal using just the 8051. The first

method involves using a counter/timer in the 8-bit auto reload mode. Suppose

you want a PWM signal with a period that is equal to 200 machine cycles on the

8051. To create such a signal with a duty cycle of 40the signal must be held high

47

for 80 cycles, then held low for 120 cycles. Here's where the timer comes in: first

we set the PWM signal high, then set up the timer to interrupt after 80 clock

cycles, by giving it the appropriate reload value. When the interrupt occurs, we

pull the PWM signal low, and change the timer reload value so that it is now set

to interrupt after 120 cycles. By alternating the timer reload value in this fashion,

and toggling an output pin on each interrupt, we can create the desired PWM

signal.

The second method for 8051 PWM generation involves more straightforward

calculation. A timer must be set up generate an interrupt at a specific frequency

(it is up to the user to decide what frequency this should be). Each time this

interrupt occurs, we increment a counter. This counter will count up through

an entire period of the PWM waveform (which would be something like 16, 64,

or 256 interrupts), and then it will roll over to zero and start again. Each time

the counter rolls over to zero, the PWM output pin is set to '1'. To create the

PWM waveform, we calculate a number (call it the "duty period") equal to the

duty cycle times the number of interrupts in a period. Every time the counter

is incremented, the current counter value is compared to the high period. If the

counter is greater than this number, the output pin is pulled low, and is left there

until the counter rolls over again.

One other method for generating PWM waveforms is to use a peripheral

chip.

The 8254 counter/timer works very well for this purpose.

One of the

counter/timers can be used to determine the period of the PWM, and another

counter/timer (the 8254 has three of them) can be used to determine the length

of the low portion of the PWM.

Table 5.1 shows a comparison of the each of these three methods, with the

respective ranges of frequency and duty cycle that each can achieve. Method 1 for

the 8051 is the method which uses a counter/timer in auto reload mode, alternating reload values to acheive a pwm waveform. Method 2 is the method which uses

48

Min Frequency

Max Frequency

Min Duty Cycle

Max Duty Cycle

8051 Method 1

80c1 Method 2

8254

(alternating reload)

(4-bit counter)

with 10 MHz clock

3.6 kHz

35 kHz

5% (at 3.6 kHz)

50% (at 35 kHz)

95% (at 3.6 kHz)

50% (at 35 kHz)

880 mHz

3.4kHz

0%

153 Hz

5 MHz

0%

93.8%

99.998% (at 153 Hz)

50% (at 5 MHz)

Table 5.1: Achievable Ranges for Various PWM Generators

a software-implemented counter to determine the PWM signal. Specifications for

the 8254 PWM genarator assume a 10 MHz clock crystal.

5.3.3

Monitoring the Robot Keypad

The robot keypad is used to distinguish between three different states: "forward",

"backward", and "off". The keypad consists of 5 terminals, representing the 5

motors in the robot arm. There are also two voltage rails representing forward

and backward motion. When a key is in the "off" position, it is not connected

to either voltage rail. When it is in the "forward" or "backward" position, it is

connected to the corresponding voltage rail.

Now, when connected straight to the robot arm, the keypad is a fairly straightforward system. However, attempting to read the robot keypad from the R31JP

presents an interesting challenge. The problem is to be able to distinguish between

the three states using binary logic.

Here is the solution: connect the keypad to Port 1 on the 8051.

We will

make use of the fact that Port 1 has internal pull-up resistors-this means that

the default input is 'high'.

Begin by setting all the Port 1 pins high. Then,

pull the "forward" voltage rail low, and read the value of the 5 terminal pins. If

any are connected to the "forward" voltage rail, they will be 'low'. Otherwise,

49

because of the pull-up resistors, the pins should all remain 'high'. Then, clear

Port 1 by setting all the pins 'high', and repeat the process, this time pulling the

"backward" voltage rail 'low', checking to see if any of the other pins are pulled

'low'. By alternating in this fashion, it is possible to determine the states of all

the keys on the keypad.

5.3.4

Recording Robot Motion

The capstone of this laboratory exercise, after tinkering with DC motors, will be

to record and automatically play back the robot arm's motion. This can be done

fairly easily.

An 8051 timer interrupt can be set up to generate the sampling/playback rate.

Each time an interrupt occurs, the 8051 will perform some action, depending on

the operating mode. Here's how the various operating modes in such a system

could work:

Regular Mode When interrupt occurs:

1. Poll keypad for user input

2. Send user command to robot arm

Record Mode When interrupt occurs:

1. Poll keypad for user input

2. Send user command to robot arm

3. Write copy of command data to memory

Playback Mode When interrupt occurs:

1. Read command data from memory

2. Send command to robot arm

50

The final problem for this lab exercise will be to combine robot arm code with

the PWM generating code. The resulting program should allow the user to drive,

record and play back robot motion at varying speeds.

51

52

Chapter 6

Feedback Control

6.1

Motivation

Electro-mechanical devices are used in a large range of commercial and industrial

systems. However, for many of these applications, it is necessary that various

system attributes be regulated to within a certain tolerance.

In practice, it is very difficult for an open-loop system to achieve that kind of

accuracy. Without sensors and feedback, a system is driving blindly, unaware of

the actual state of the system parameters. For any system requiring a high degree

of accuracy, closed-loop control is essential.

In closed-loop control, the relevant system parameters are periodically sampled, using sensors. The measured value is compared with the desired value; then,

the appropriate actuators are given new commands which are intended to compensate for the error. A closed-loop system, if well designed, will maintain a very

accurate and stable system. Even with external disturbances, the feedback will

bring the system back to the desired state.

The idea of closed-loop control is an important aspect of electro-mechanical

systems. Furthermore, microprocessors are very well-adapted for providing digital

feedback in these closed-loop systems. This makes feedback control an excellent

53

topic for study in 6.115.

6.2

Hardware

For a first-order system, we decided to use an RC circuit (resistor and capacitor

in series), because it is-by far-the easiest system to build, drive, and measure. With electro-mechanical systems (such as motors, engines, and other moving mechanisms), it is often more difficult to drive the system, and it is definitely

more difficult to measure the output. So for now, the RC system will have to suffice. And the RC circuit will serve as a very good approximation of a DC motor's

characteristics.

In the future, it would be more interesting to use an actual motor or some

other physical system for this portion of the lab exercise. But that addition will

be left as a project for future generations.

For studying second-order systems, a Buck converter lab station was used.

The Buck converter is a very efficient power converter which uses an RLC circuit.

Designed and built by Warit Wichakool [11], the lab station uses a PWM waveform

as input. The duty cycle of the PWM signal determines the ratio of the regulated

output voltage to the input voltage.

6.3

Implementation

In all closed-loop feedback systems, the physical system is being controlled to

achieve some desired result. The source of this "desired result" is either a realtime input coming directly from a user, or some programmed behavior which is

encoded in the system. For 6.115, adding a user input would mean wiring up

another A-to-D converter, since a user input is most easily implemented as a

variable analog voltage. So, to make the problem simpler, we decided to have all

54

the desired system behavior encoded within the feedback program.

An 8051 counter/timer interrupt could be reserved for generating data to represent the desired system behavior.

For the feedback control, another counter/timer interrupt on the 8051 could

be used to set the sampling and update rates. In order for the system to remain

stable, it is helpful to have the control system sampling and sending out commands

at a consistent rate.

The actual assembly code for closed-loop feedback control is fairly simple:

during each pass/check of the feedback system, first read the value of the system

variable (using the A-to-D converter). Then, subtract this value from the desired

value, and multiply by a specified gain. The result of this calculation is the new

value with which you drive the system, so the final step is to write this new value

out to the system actuator.

Of course, there may be some translation necessary, because the input (drive)

signal may not be in the same form, or on the same scale, as the output (sensor)

signal. For a detailed description, please see the code listed in the appendix.

55

56

Chapter 7

Programmable Logic

7.1

Motivation

Much of the focus of the new 6.115 course has been on interfacing peripheral

devices, controlling them to achieve a desired result. For most applications, it is

possible to find integrated circuits which contained all of the desired functionality,

and are suitable for interfacing with a microprocessor. But there may be cases in

which the ideal chip-one which contains all the desired functionality-is hard to

find. In this case, the best solution is to create that ideal device.

In recent years, there has been a growing trend to use programmable logic devices in hardware design. These programmable chips can be programmed with any

functionality, up to a certain level of complexity. Any hardware design engineer

who works with microprocessor systems will realize the value of these devicesthey are highly versatile and reusable. Programmable logic is an excellent topic

for exploration in 6.115, since it is becoming a crucial feature of digital hardware

systems.

57

7.2

Hardware and Development Tools

In order to begin working with programmable logic devices, there is a set of

minimum hardware and software requirements. Here is a basic overview of these

requirements:

" A Hardware Description Language

* A Compiler and a Synthesis Tool

" A Programmable Logic Chip

" A Device Programmer

7.2.1

Hardware Description Language

The first (and most crucial) step, when using programmable logic devices, is to

specify the functionality of the device, describing the logic to be implemented.

This can be done by writing instructions in any number of hardware description

languages. VHDL and ABEL were the two languages considered for possible use

in 6.115.

The VLSI Hardware Description Language (VHDL) is becoming an industry

standard for programmable logic design. Because of this, it seemed to be the

most practical option-of all the HDLs currently in use, VHDL is the one that

6.115 students will most likely see again, when working in the industry. Furthermore, VHDL is device independent. VHDL code can be written without committing to a specific device; a specific VHDL program could be implemented on any

programmable device, provided it has the necessary logic capabilities. Another

advantage of using VHDL is that it is also taught and used by 6.111 (MIT's digital electronics laboratory course) [6]. Using the same language for both courses

could reinforce students' knowledge and understanding of the language. The only

58

disadvantage of using VHDL is that the syntax takes a little longer to learn and

understand.

ABEL, on the other hand, has a much more straightforward and simple syntax. However, it is not necessarily device independent, since device data and pin

assignments are included in the code. Furthermore, it is not used as widely as

VHDL is.

If choosing between the two languages for use in 6.115, the author recommends

using VHDL instead of ABEL.

7.2.2

Compilation and Synthesis Tools

After encoding a design with a hardware description language, the next step is to

compile and synthesize the design. This process will convert it into a format that

can be programmed directly onto a device.

When looking for the appropriate software tools, two major manufacturers of

programmable devices were investigated: Cypress and Xilinx. These two companies distribute compiler and synthesis software, to be used in conjunction with

their respective programmable devices.

Cypress offers Warp, a VHDL compiler and synthesis package, but it is not

free [8]. MIT has a license for this software package, which enables students to

compile VHDL code within the Athena computing environment. However, this

licensed software can only be used for two different chips: a 22V10 and a Cypress

C3721 [5].

Xilinx, on the other hand, offers a suite of design, synthesis, and simulation

tools, completely free, which can be easily down-loaded from their web site [10].

This software package can be used to compile both VHDL and ABEL, and it is

capable of implementing the code on a standard 22v10 package, or on any of the

XILINX programmable logic devices. This software will not run on athena, but

it will run on any Windows machine (provided it meets the appropriate system

59

requirements).

7.2.3

Programmable Logic Devices

The two types of devices considered for 6.115 were the Cypress and Xilinx chips,

to be used with their respective compiler and synthesis tools. 6.111 uses a Cypress chip-the C3721-and it is readily available at the instrument desk in the

6.111/6.115 lab. This device is available in a 44-pin PLCC package, and can be

inserted into a NUBUS lab kit by using a PLCC-to-DIP adapter.

Xilinx offers a similar device-the XC9536-which is also small enough to be

used on a 6.115 lab kit. The XC9536 is the part used on the R31JP to control addressing modes and memory-mapped I/O. Making use of the XC9536 both for the

R31JP and for exercises in programmable logic would be advantageous: it reduces

the number of different hardware devices required for 6.115. It also provides an

excellent opportunity to reconfigure the R31JP: if students are equipped to program Xilinx devices, they will also be equipped to re-program the XC9536 which

resides on the R31JP, allowing them to re-design and re-configure that system.

7.2.4

Device Programmer

As it turns out, the 6.115 universal programmers which were being used to burn

EEPROMs are also capable of burning programmable logic devices, such as the

XC9536 or a 22V10. So there is no need to find an additional programmer.

7.2.5

Conclusions

In the end, the Xilinx software and the XC9536 were chosen to be used by 6.115,

for reasons stated above. The Xilinx software is free, and is quite flexible. Since

it supports both ABEL and VHDL, there is no need to choose between the different languages. And a large supply of Xilinx XC9536 chips have already been

60

purchased as spares for the R31JP board, so the parts are available and in stock.

Implementation

7.3

7.3.1

Implementing Designs in VHDL

Before implementing large scale designs, it is important to understand the basic

concepts and structure of VHDL and programmable logic. The sections that

follow contain a brief overview of those details.

VHDL Framework

When describing a design using VHDL, there is a basic framework which must

always be included. Many design entry tools, including the Xilinx WebPack software, will generate this framework automatically. Here is an example of that

framework, for 'halfadd', a design with two inputs ('a' and 'b') and two outputs

('sum' and 'c'):

In VHDL, two dashes ('--')

--

specify a comment line.

The following four lines add the standard logic libraries

This allows the program to use the

-- to this VHDL file.

-IEEE standard for digital logic.

library IEEE;

use IEEE.STDLOGIC_1164.ALL;

use IEEE.STDLOGIC_ARITH.ALL;

use IEEE.STDLOGIC_UNSIGNED.ALL;

--

--

The entry declaration describes the interface of a

--

new design component.

entity halfadd is

--

The port declaration within the entry declaration

specifies the name and type of each input and output

--

of this component.

--

port (a, b : in std-logic;

sum, c : out std-logic);

end halfadd;

61

--

The architecture declaration describes the internal

logic and functionality of this component.

Each architecture can be given its own name (in this case it

--

is 'comp').

---

architecture comp of halfadd is

begin

end comp;

A VHDL Case Study

To further describe and explain the syntax of VHDL, consider the following case

study: the problem is to create an 8-bit incrementer, a component which adds

one to an 8-bit number.

This problem can be broken down into two smaller problems. The first is to

design an adder-a component which adds two bits, producing a 2-bit result (a

sum bit and a carry bit). An adder of this type is commonly referred to as a

'half-adder'. Here is a VHDL implementation of such an adder:

-- File halfadd.vhd

library IEEE;

use IEEE.STDLOGIC_1164.ALL;

use IEEE.STD-LOGICARITH.ALL;

use IEEE.STD.LOGICUNSIGNED.ALL;

entity halfadd is

port (a, b : in stdlogic;

sum, c : out stdlogic);

end halfadd;

architecture comp of halfadd is

-- Purpose: add two bits, producing a sum and carry bit

--

All logic description occurs between the 'begin' and 'end'

--

statements.

begin

--

The following two statements are concurrent statements.

In a concurrent assignment statement, such as these, the

output will be updated and changed every time one of the

--

inputs change.

---

62

These two statements essentially implement an AND gate

-and an OR gate.

c <= a and b;

sum <= a xor b;

--

in

VHDL is

--

'<=

--

in C or Java.

an assignment operator,

similar to

'='

end comp;

The second part of building an 8-bit incrementer is to combine several one

bit adders into the proper configuration. An 8-bit incrementer is essentially an

8-bit adder, in simplified form. It is possible to string eight of the half-adders

together, in a ripple-carry design, to create the desired incrementer. Here is the

implementation of that design:

-- File addl_8bit.vhd

library IEEE;

use IEEE.STDLOGIC_1164.ALL;

use IEEE.STDLOGICARITH.ALL;

use IEEE.STDLOGICUNSIGNED.ALL;

entity addl_8bit is

Any inputs or outputs which are more than a single bit can

be declared as a "std-logic-vector".

Port ( a-in : in std_logicvector(7 downto 0);

out std-logic-vector(7 downto 0));

a_out

end addi_8bit;

---

architecture simple of addi_8bit is

Purpose: performs an increment operation on an

-8 bit number, using a chain of half adders.

--

--

When incorporating another VHDL component into a design,

a 'component' statement must be used within the

-architecture statement, but before the begin statement.

component halfadd

--

--

The port statement within a component declaration should

be identical to the port statement within the component's

--

original entity declaration.

--

port (a , b : in stdlogic;

sum, c : out std-logic);

end component;

63

--