The Development and Synthetic Application of Hydrosilylation Methodologies

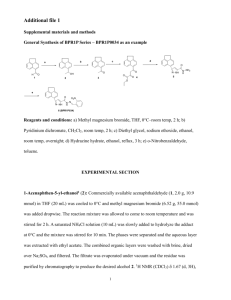

advertisement