CP-225917

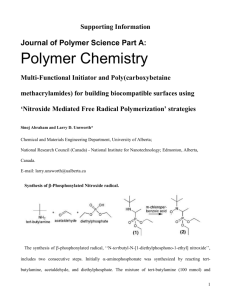

advertisement