MITLibraries

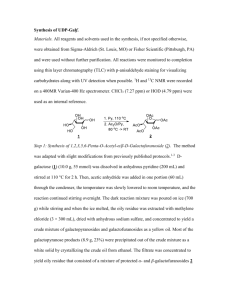

advertisement