Mixing Process in the Jet Flows of Lobed Nozzles

advertisement

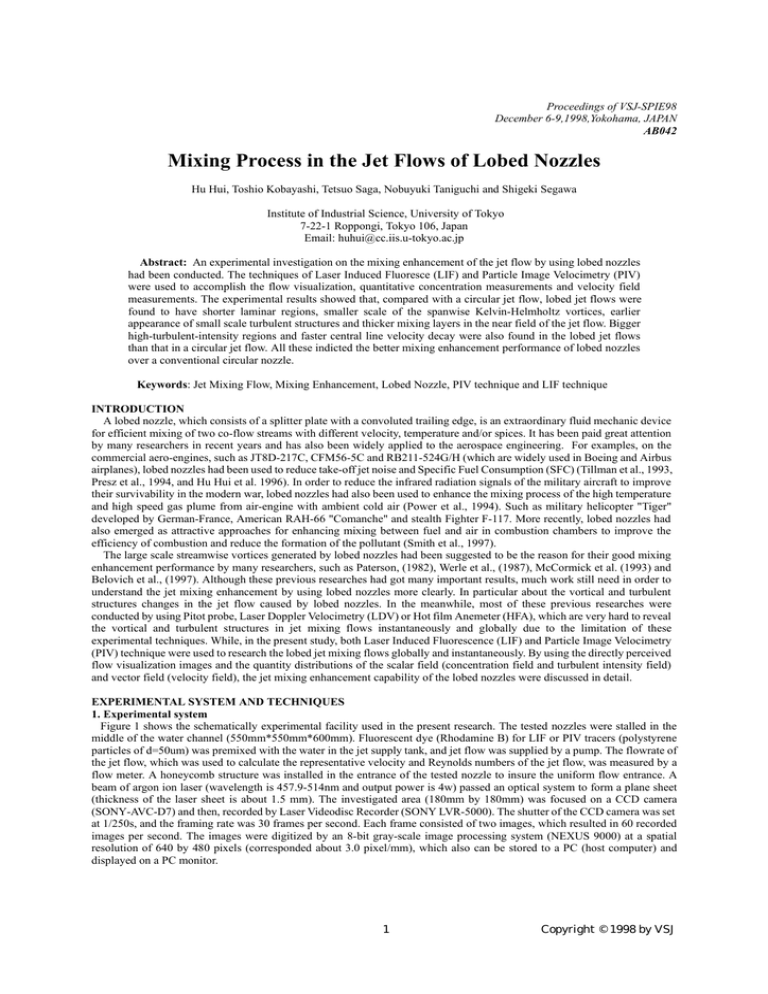

Proceedings of VSJ-SPIE98 December 6-9,1998,Yokohama, JAPAN AB042 Mixing Process in the Jet Flows of Lobed Nozzles Hu Hui, Toshio Kobayashi, Tetsuo Saga, Nobuyuki Taniguchi and Shigeki Segawa Institute of Industrial Science, University of Tokyo 7-22-1 Roppongi, Tokyo 106, Japan Email: huhui@cc.iis.u-tokyo.ac.jp Abstract: An experimental investigation on the mixing enhancement of the jet flow by using lobed nozzles had been conducted. The techniques of Laser Induced Fluoresce (LIF) and Particle Image Velocimetry (PIV) were used to accomplish the flow visualization, quantitative concentration measurements and velocity field measurements. The experimental results showed that, compared with a circular jet flow, lobed jet flows were found to have shorter laminar regions, smaller scale of the spanwise Kelvin-Helmholtz vortices, earlier appearance of small scale turbulent structures and thicker mixing layers in the near field of the jet flow. Bigger high-turbulent-intensity regions and faster central line velocity decay were also found in the lobed jet flows than that in a circular jet flow. All these indicted the better mixing enhancement performance of lobed nozzles over a conventional circular nozzle. Keywords: Jet Mixing Flow, Mixing Enhancement, Lobed Nozzle, PIV technique and LIF technique INTRODUCTION A lobed nozzle, which consists of a splitter plate with a convoluted trailing edge, is an extraordinary fluid mechanic device for efficient mixing of two co-flow streams with different velocity, temperature and/or spices. It has been paid great attention by many researchers in recent years and has also been widely applied to the aerospace engineering. For examples, on the commercial aero-engines, such as JT8D-217C, CFM56-5C and RB211-524G/H (which are widely used in Boeing and Airbus airplanes), lobed nozzles had been used to reduce take-off jet noise and Specific Fuel Consumption (SFC) (Tillman et al., 1993, Presz et al., 1994, and Hu Hui et al. 1996). In order to reduce the infrared radiation signals of the military aircraft to improve their survivability in the modern war, lobed nozzles had also been used to enhance the mixing process of the high temperature and high speed gas plume from air-engine with ambient cold air (Power et al., 1994). Such as military helicopter "Tiger" developed by German-France, American RAH-66 "Comanche" and stealth Fighter F-117. More recently, lobed nozzles had also emerged as attractive approaches for enhancing mixing between fuel and air in combustion chambers to improve the efficiency of combustion and reduce the formation of the pollutant (Smith et al., 1997). The large scale streamwise vortices generated by lobed nozzles had been suggested to be the reason for their good mixing enhancement performance by many researchers, such as Paterson, (1982), Werle et al., (1987), McCormick et al. (1993) and Belovich et al., (1997). Although these previous researches had got many important results, much work still need in order to understand the jet mixing enhancement by using lobed nozzles more clearly. In particular about the vortical and turbulent structures changes in the jet flow caused by lobed nozzles. In the meanwhile, most of these previous researches were conducted by using Pitot probe, Laser Doppler Velocimetry (LDV) or Hot film Anemeter (HFA), which are very hard to reveal the vortical and turbulent structures in jet mixing flows instantaneously and globally due to the limitation of these experimental techniques. While, in the present study, both Laser Induced Fluorescence (LIF) and Particle Image Velocimetry (PIV) technique were used to research the lobed jet mixing flows globally and instantaneously. By using the directly perceived flow visualization images and the quantity distributions of the scalar field (concentration field and turbulent intensity field) and vector field (velocity field), the jet mixing enhancement capability of the lobed nozzles were discussed in detail. EXPERIMENTAL SYSTEM AND TECHNIQUES 1. Experimental system Figure 1 shows the schematically experimental facility used in the present research. The tested nozzles were stalled in the middle of the water channel (550mm*550mm*600mm). Fluorescent dye (Rhodamine B) for LIF or PIV tracers (polystyrene particles of d=50um) was premixed with the water in the jet supply tank, and jet flow was supplied by a pump. The flowrate of the jet flow, which was used to calculate the representative velocity and Reynolds numbers of the jet flow, was measured by a flow meter. A honeycomb structure was installed in the entrance of the tested nozzle to insure the uniform flow entrance. A beam of argon ion laser (wavelength is 457.9-514nm and output power is 4w) passed an optical system to form a plane sheet (thickness of the laser sheet is about 1.5 mm). The investigated area (180mm by 180mm) was focused on a CCD camera (SONY-AVC-D7) and then, recorded by Laser Videodisc Recorder (SONY LVR-5000). The shutter of the CCD camera was set at 1/250s, and the framing rate was 30 frames per second. Each frame consisted of two images, which resulted in 60 recorded images per second. The images were digitized by an 8-bit gray-scale image processing system (NEXUS 9000) at a spatial resolution of 640 by 480 pixels (corresponded about 3.0 pixel/mm), which also can be stored to a PC (host computer) and displayed on a PC monitor. 1 Copyright © 1998 by VSJ water tank Laser sheet Laser beam optical system CCD camera mixing region comb structure flow meter laser tested nozzle Image process system pump jet supply tank monitor Host computer Figure 1. Experimental Setup Figure 2 shows the four tested nozzles: a baseline circular nozzle A and three lobed nozzles with different lobe numbers. Lobed nozzle B has 6 lobe structures, while lobed nozzle C has 12 lobe structures with very sharp lobe trough. The lobed nozzle D, which was the combination the lobed nozzle B and lobed nozzles C, has 9 lobe structures. All the lobed nozzles were designed to have the same lobe structure geometric parameters, i.e., the same lobe height H=15 mm, lobe width W=6 mm, inner penetration angle 22 degree and outer penetration angle 14 degree. The equivalent diameters of these tested nozzles at exit were the same, D=40mm. During the experiment, the flow visualization and quantitative flow field measurements in two specific axial slices (passing the peak and trough of lobe, Fig.2 (e)) of the lobed jet flow were conducted. In the present study, the jet velocity was 0.20m/s, and the Reynolds Number of the jet flows, based on the nozzles exit diameter, were about 6,000. Z lobe width W= 6mm Z X Y inner penetration 0 angle 22 0 14 outer penetration angle b. lobed nozzle B a. circular nozzle A lobe heigth H=15mm c. lobed nozzle C d. lobed nozzle D lobe trough slice lobe peak slice e. two tested axial slices Figure 2. The tested nozzles and studied axial slices 2. Experimental Techniques Laser Induced Fluorescence (LIF) and Particle Image Velocimetry (PIV) techniques are both modem fluid experimental techniques. They can offer many advantages for the study the fluid mechanics over the other conventional experimental techniques. Such as: they can reveal the global structures of the flow field instantaneously and qualitatively without disturbing the flow field, which are very useful and necessary for the research of mixing layers and other complex flows. A lot of the researches on the fluid mechanics by using LIF and PIV techniques had been conducted and many promising results had been obtained in recent years (Yoda et al., 1994, and Adrian, 1991). In the present research, both of the LIF technique and PIV technique were used to study the mixing enhancement performance of lobed nozzles. In the present research, Rhodamine B was used as fluorescent dye. The peak of absorption spectrum of Rhodamine B occurs at 5l7.5mn, while fluorescence spectrum peak is 590nm (Fig. 3(a)). During the experiment, the fluorescent light was separated form the scattered light (wavelength is 457.9-514nm) with an optical filter. It was well known that, only the solution of the fluorescent dye with low concentration can insure the strength of fluorescent light being linear with the concentration of the fluorescent dye and the effect of laser light attenuation is negligible as the laser light sheet propagated through the flow. This also was verified by the calibration profile of the fluorescent light intensity versus the concentration of the Rhodamine B shown on Fig.3(b). In the present study, the concentration of the Rhodamine B solution in the jet supply box is 0.3mg/l. 2 Copyright © 1998 by VSJ (I-Ib)/(I0-Ib) 1 0.8 Laser power=high Laser power=middle Laser power=low Theory Value 0.6 0.4 0.2 C/C0 , C0=0.3mg/l 0 0 0.2 0.4 0.6 0.8 1 a. emission and absorption spectrum of Rhodamine B b. LIF calibration profile Figure 3. Spectrum of Rhodamine B and LIF calibration profiles To obtain fluid velocities by using PIV, two or more images of seeded flow fields are captured digitally at successive points in time, and comparison of these images allows the velocity fields to be constructed. In the present study, rather than tracking individual particle, the cross correlation method (Willert et al., 1991) was used to obtain the average particles displacement of the ensemble of particles. In the PIV image processing, the images were divided into 30 by 15 pixel interrogation regions. A 5 pixel in X direction (radical direction) and 10 pixel in Y direction (jet flow direction) step size were used which resulted in 67% overlapping of the adjacent interrogation. The studied flow fields were represented by a discrete flow fields containing about 2000 velocity vectors (40 by 52), The post-processing procedures which including sub-pixel interpolation (Hu Hui et al. 1998) and velocity outliner deletion (Zhou et al., 1996) were used to improve the accuracy of the PIV measurements. In the present study, both instantaneous flow fields and mean flow fields were used for analysis and discussion. The instantaneous flow fields were the flow field captured by CCD camera at frequency of 30Hz, and every instantaneous frame (two images) was used to get the instantaneous velocity fields. 200 continue frames were used to compute the mean flow field. RESULTS AND DISCUSSIONS 1). LIF results The results of visualizations and instantaneous concentration field measurements of the jet mixing flows by using LIF were shown in Fig. 4 and Fig5. From the figures, it can be seen that: for a circular jet flow (Fig.4), three different regions, which are laminar region, transition region and turbulent region, can be identified clearly in the figure, and which is similar to the results reported by Liepmann et al. (1992). At the end of laminar region (Y/D=l.0), spanwise Kelvin-Helmholtz vortices were found to roll up. The pairing and combining of these spanwise vortices were conducted in the transition region. In the downstream of Y/D=3.0, the small scale mixing (low concentration region) began to occur and much small-scale turbulence and vortical structures began to appear in the flow field. Figure 5.(a) shows the results of the flow visualization and instantaneous concentration field measurement in the axial slice of the lobe trough for the lobed nozzle B. Compared with the circular jet flow (Fig. 4), the jet flow of lobed nozzle B at this axial slice was found to have a shorter laminar region (Y/D=0.2). The scale of the spanwise Kelvin-Helmholtz vortices of the jet flow was much smaller. The transition region in which the pairing and combining process of the spanwise vortices were accomplished also became shorter. In the downstream of the location Y/D=0.8, much small scale mixing and small scale turbulent structures (low concentration region) were found to appear. Figure 4. Instantanous concentration distribution in the circular jet flow 3 Copyright © 1998 by VSJ a. in the lobe trough slice b. in the lobe peak slice Figure 5. Instantanous concentration distribution in the lobed jet flow of lobed nozzle B Figure 5.(b) shows the result of the flow visualization and instantaneous concentration field measurements in the axial slice of the lobe peak for the lobed nozzle B. From the figure, it can be seen that: the laminar region was not a straight cylinder like the circular jet shown in the Fig. 4, and looked like a expansive cut-off cone along the downstream of the lobed structure. Compared with the flow structures shown in Fig.5(a), the "clean" laminar region in the lobe peak axial slice was a bit longer (Y/D=0.4), but it was still shorter than that in the circular jet flow. This is caused by the different thickness of the boundary layer at the exit of the lobed nozzle (the work of the Brink et al.(1993) had verified that the thickness of the boundary layer at the lobed trough is smaller than that in the lobed peak), and the thicker boundary layer at the lobe peak need a longer stream wise distance to roll-up the Kelvin-Helmholtz vortices (Hussain et al., 1989). In this axial slice, it also can be seen that smallscale mixing and small-scale turbulent structure (low concentration region) were found to appear in the down stream of location Y/D=0.8. The mean concentration (Ci,j) fields and the root-mean-square (r.m.s) value distributions of the concentration fields for the circular jet flow and the lobed jet flows were shown on Fig. 6, Fig. 7 and Fig.8. The mean concentration fields and the rootmean-square (r.m.s) value distributions of the concentration fields showed on these figures were got by the average of 200 frames of the instantaneous flow fields, and they were defined as: N Ci, j = ∑ t =1 c i , j ,t N N , r.m.si , j = ∑ (c t =1 i, j ,t − Ci , j ) 2 N In which ci,j,t is the instantaneous concentration of the jet flows, while the N=200. For the mean concentration field, it can be seen that the circular jet flow (Fig. 6 (a)) was found to have a longer and bigger high concentration region (red color region, which indicted the unmixed region) than that in the lobed jet flows (Fig.7(a), Fig.7(c), Fig.8(a) and Fig.8(c)). In the meanwhile, the thickness of the mixing layers (the yellow color region on these figures) in the circular jet flow was also found to be thinner in the near field of the jet flows. From the root-mean-square value distributions of the concentration fields for the circular jet flow and the lobed jet flows, it can also be seen that, corresponding to the unmixed high concentration region (red color region) shown on the mean concentration fields, there were lower r.m.s value regions in the center of the circular jet flow and lobed jet flows. In the circular jet flow (Fig 6(b)), this lower r.m.s value region was found to be bigger than that in the lobed jet flows (Fig. 7(b), Fig. 7(d), Fig. 8(b) and Fig.8(d)). In the lobed jet flows, the higher r.m.s value regions (yellow color regions on the figures), which indicated the location of extensive mixing process occurring, were found to be much bigger than that in the circular jet flow. All these LIF results indicted that the lobed nozzles had much better mixing enhancement performances than the conventional circular nozzle. From the comparison of the Fig. 7 and Fig. 8, it can be suggested that, the lobed nozzle B have a better mixing performance than the lobed nozzle C. This may be explained by that, as mentioned in the above, the lobed nozzle B and lobed nozzle C were designed to have the same lobe structure geometrical parameters, and only the lobe number of them is different. The lobed nozzle C has 12 lobe structures, which results that the lobe troughs of the lobed nozzle C was much sharper than the lobed nozzle B. The sharper lobe troughs will cause the decreasing of the effective height of the lobe structure. This will result in the scale reduction of the streamwise vortices generated by the lobe structures. (The researches of the Presz et al.(1994) and Werle et al.(1987) had suggested that the scale of the streamwise vortices generated by the lobe structures is equivalent to the effective height of the lobed structures). This resulted in that the mixing enhancement performance of the lobed nozzle C is not as good as the lobed nozzle B, which will also be verified, in the following PIV results. 4 Copyright © 1998 by VSJ 4 4 concentration 0.9934 0.9605 0.9276 0.8947 0.8618 0.8289 0.7961 0.7632 0.7303 0.6974 0.6645 0.6316 0.5987 0.5658 0.5329 0.5000 0.4671 0.4342 0.4013 0.3684 0.3355 0.3026 0.2697 0.2368 0.2039 0.1711 0.1382 0.1053 0.0724 0.0395 0.0066 3 Y/D 2.5 2 1.5 1 0.5 r.m.s 0.2000 0.1933 0.1867 0.1800 0.1733 0.1667 0.1600 0.1533 0.1467 0.1400 0.1333 0.1267 0.1200 0.1133 0.1067 0.1000 0.0933 0.0867 0.0800 0.0733 0.0667 0.0600 0.0533 0.0467 0.0400 0.0333 0.0267 0.0200 0.0133 0.0067 0.0000 3.5 3 2.5 Y/D 3.5 2 1.5 1 0.5 -1 0 1 2 -1 0 X/D 1 2 X/D a. mean concentration field b. root-mean-square value distribution Figure 6. Mean concentration and root-mean-square value of the concentration field in the circular jet flow 4 4 concentration 0.9934 0.9605 0.9276 0.8947 0.8618 0.8289 0.7961 0.7632 0.7303 0.6974 0.6645 0.6316 0.5987 0.5658 0.5329 0.5000 0.4671 0.4342 0.4013 0.3684 0.3355 0.3026 0.2697 0.2368 0.2039 0.1711 0.1382 0.1053 0.0724 0.0395 0.0066 3 Y/D 2.5 2 1.5 1 0.5 -1 0 1 r.m.s 0.2000 0.1933 0.1867 0.1800 0.1733 0.1667 0.1600 0.1533 0.1467 0.1400 0.1333 0.1267 0.1200 0.1133 0.1067 0.1000 0.0933 0.0867 0.0800 0.0733 0.0667 0.0600 0.0533 0.0467 0.0400 0.0333 0.0267 0.0200 0.0133 0.0067 0.0000 3.5 3 2.5 Y/D 3.5 2 1.5 1 0.5 2 -1 0 X/D 1 2 X/D a.mean concentration field (lobe peak slice) b. root-mean-square value distribution(lobe peak slice) 4 4 concentration 0.9934 0.9605 0.9276 0.8947 0.8618 0.8289 0.7961 0.7632 0.7303 0.6974 0.6645 0.6316 0.5987 0.5658 0.5329 0.5000 0.4671 0.4342 0.4013 0.3684 0.3355 0.3026 0.2697 0.2368 0.2039 0.1711 0.1382 0.1053 0.0724 0.0395 0.0066 3 Y/D 2.5 2 1.5 1 r.m.s 0.2000 0.1933 0.1867 0.1800 0.1733 0.1667 0.1600 0.1533 0.1467 0.1400 0.1333 0.1267 0.1200 0.1133 0.1067 0.1000 0.0933 0.0867 0.0800 0.0733 0.0667 0.0600 0.0533 0.0467 0.0400 0.0333 0.0267 0.0200 0.0133 0.0067 0.0000 3.5 3 2.5 Y/D 3.5 2 1.5 1 0.5 0.5 -1 0 1 2 -1 X/D 0 1 2 X/D c.mean concentration field(lobe trough slice) d.root-mean-square value distribution(lobe trough slice) Figure 7. Mean concentration and r.m.s value distribution of the concentration field of the lobed jet flow (lobed nozzle B) 5 Copyright © 1998 by VSJ 4 4 concentration 0.9934 0.9605 0.9276 0.8947 0.8618 0.8289 0.7961 0.7632 0.7303 0.6974 0.6645 0.6316 0.5987 0.5658 0.5329 0.5000 0.4671 0.4342 0.4013 0.3684 0.3355 0.3026 0.2697 0.2368 0.2039 0.1711 0.1382 0.1053 0.0724 0.0395 0.0066 3 Y/D 2.5 2 1.5 1 0.5 -1 0 1 r.m.s 0.2000 0.1933 0.1867 0.1800 0.1733 0.1667 0.1600 0.1533 0.1467 0.1400 0.1333 0.1267 0.1200 0.1133 0.1067 0.1000 0.0933 0.0867 0.0800 0.0733 0.0667 0.0600 0.0533 0.0467 0.0400 0.0333 0.0267 0.0200 0.0133 0.0067 0.0000 3.5 3 2.5 Y/D 3.5 2 1.5 1 0.5 2 -1 0 X/D a. mean concentration field (lobed peak slice) 2 b. root-mean-square value distribution (lobed peak slice) 4 4 concentartion 0.9934 0.9605 0.9276 0.8947 0.8618 0.8289 0.7961 0.7632 0.7303 0.6974 0.6645 0.6316 0.5987 0.5658 0.5329 0.5000 0.4671 0.4342 0.4013 0.3684 0.3355 0.3026 0.2697 0.2368 0.2039 0.1711 0.1382 0.1053 0.0724 0.0395 0.0066 3 2.5 2 1.5 1 0.5 r.m.s 0.2000 0.1933 0.1867 0.1800 0.1733 0.1667 0.1600 0.1533 0.1467 0.1400 0.1333 0.1267 0.1200 0.1133 0.1067 0.1000 0.0933 0.0867 0.0800 0.0733 0.0667 0.0600 0.0533 0.0467 0.0400 0.0333 0.0267 0.0200 0.0133 0.0067 0.0000 3.5 3 2.5 Y/D 3.5 Y/D 1 X/D 2 1.5 1 0.5 -1 0 1 2 -1 0 X/D 1 2 X/D c. mean concentration field (lobed trough slice) d. root-mean-square value distribution (lobed trough slice) Figure 8. Mean concentration and r.m.s. value distribution of the concentration field in the lobed jet flow (lobed nozzle C) 2). PIV results The PIV measurement results of the circular jet flow and lobed jet flows were showed in the Fig. 9 to Fig.11 which included mean velocity fields and mean turbulent intensity fields in the circular jet flow and the axial slices of lobe peak and lobe trough of the lobed jet flows. As motioned above, the mean velocity fields and mean turbulent intensity fields showed on these figures were got by the average of 200 frames of the instantaneous flow fields. The mean velocity (Ui,j and Vi,j )and mean turbulent intensity Tij shown on these figures were defined as: u i , j ,t t =1 N U i, j = ∑ N Ti , j = ∑ (u '2 vi , j ,t t =1 N Vi , j = ∑ i, j , t +v '2 i, j,t turbulent intensity 0.7000 0.6767 0.6533 0.6300 0.6067 0.5833 0.5600 0.5367 0.5133 0.4900 0.4667 0.4433 0.4200 0.3967 0.3733 0.3500 0.3267 0.3033 0.2800 0.2567 0.2333 0.2100 0.1867 0.1633 0.1400 0.1167 0.0933 0.0700 0.0467 0.0233 0.0000 3.5 3 2.5 2 ) 1.5 t =1 N N = N 4 Y/D N In which N=200, ui,j,t and vi,j,t are the instantaneous velocities in the X and Y direction, while u'i,j,t and v'i,j,t are the instantaneous turbulent velocities. ∑ (u t =1 1 N i, j ,t − U i , j ) 2 + ∑ (vi , j , t − Vi , j ) 2 0.5 -1 i =1 0 1 2 X/D N Figure 9. Mean velocity and turbulent intensity distribution in the circular jet flow 6 Copyright © 1998 by VSJ 4 4 turbulent intensity 0.7000 0.6767 0.6533 0.6300 0.6067 0.5833 0.5600 0.5367 0.5133 0.4900 0.4667 0.4433 0.4200 0.3967 0.3733 0.3500 0.3267 0.3033 0.2800 0.2567 0.2333 0.2100 0.1867 0.1633 0.1400 0.1167 0.0933 0.0700 0.0467 0.0233 0.0000 3 Y/D 2.5 2 1.5 1 turbulent intensity 0.7000 0.6767 0.6533 0.6300 0.6067 0.5833 0.5600 0.5367 0.5133 0.4900 0.4667 0.4433 0.4200 0.3967 0.3733 0.3500 0.3267 0.3033 0.2800 0.2567 0.2333 0.2100 0.1867 0.1633 0.1400 0.1167 0.0933 0.0700 0.0467 0.0233 0.0000 3.5 3 2.5 Y/D 3.5 2 1.5 1 0.5 0.5 -1 0 1 2 -1 0 1 X/D 2 X/D a. in the lobe trough slice b. in the lobe peak slice Figure 10. Mean velocity and turbulent intensity distribution in the lobed jet flow. (lobed nozzle B) 4 4 turbulent intensity 0.7000 0.6767 0.6533 0.6300 0.6067 0.5833 0.5600 0.5367 0.5133 0.4900 0.4667 0.4433 0.4200 0.3967 0.3733 0.3500 0.3267 0.3033 0.2800 0.2567 0.2333 0.2100 0.1867 0.1633 0.1400 0.1167 0.0933 0.0700 0.0467 0.0233 0.0000 3 Y/D 2.5 2 1.5 1 turbulent intensity 0.7000 0.6767 0.6533 0.6300 0.6067 0.5833 0.5600 0.5367 0.5133 0.4900 0.4667 0.4433 0.4200 0.3967 0.3733 0.3500 0.3267 0.3033 0.2800 0.2567 0.2333 0.2100 0.1867 0.1633 0.1400 0.1167 0.0933 0.0700 0.0467 0.0233 0.0000 3.5 3 2.5 Y/D 3.5 2 1.5 1 0.5 0.5 -1 0 1 2 -1 0 1 X/D 2 X/D a. in the lobe trough slice b. in the lobe peak slice Figure 11. Mean velocity and turbulent intensity distribution in the lobed jet flow. (lobed nozzle C) For the nature jet flow (Fig.9), between two higher turbulent intensity region (yellow color region, which corresponding the mixing layers in the nature jet flow), a low turbulent intensity region (blue color region, which represent the potential core region of the jet flow) was found in the center of the nature jet flow. However, in the lobed jet flows (Fig.10 and Fig.11), the low turbulent intensity regions (blue color region) was much smaller. In the meanwhile, most of the high turbulent intensity regions (yellow color region) were found to concentrate in the near field of the lobed jet flows, which means the most of the mixing was completed in the near field of the lobed jet flows. While, in the circular jet flow, its high turbulent intensity regions expend much downstream. From the comparison of the Fig.10 and Fig.11, it can be seen that, in the jet flow of lobed nozzle B (Fig.10), the high turbulent intensity region will be bigger than that in the jet flow of lobed nozzle C (Fig.11). The low intensity region in the center of the jet flow was found to be smaller and shorter in the jet flow of lobed nozzle B than that in the lobed nozzle C. The conclusion of the lobed nozzle B had a better jet mixing enhancement performance than the lobed nozzle C can also be suggested from the PIV results, which verified the above LIF results. 1 .0 5 1 0 .9 5 0 .9 circu lar n ozzle A lobed nozzle B 0 .8 5 lobed nozzle C 0 .8 lobed nozzle D 0 .7 5 Y /D 3.95 3.75 3.55 3.35 3.15 2.95 2.75 2.55 2.35 2.15 1.95 1.75 1.55 1.35 1.15 0.95 0.75 0.55 0.35 0 .7 Figure. 12. The central line velocity decay of the circular jet flow and lobed jet flows 7 Copyright © 1998 by VSJ In order to give a more quantitative comparison of the mixing enhancement performance of the lobed nozzles with the conventional circular nozzle, the central line velocity decay performance the circular jet flow and lobed jet flows were given on the Fig.12. From the figure it can be seen that, the central line velocity of the circular jet flow almost keeps in constant in the measurement region (Y/D<4.0). While, for the lobed jet flows, the central line velocity was found to begin to decay in the downstream of Y/D=1.5. This means that the length of the potential core region of the lobed jet flows is about 1/2 to 1/3 of the circular jet flow. Among the three tested lobed nozzles, the central line velocity in the jet flow of the lobed nozzle B was found to decay fastest. The lobed nozzle C, which has 12 lobe structure and sharper lobe trough, was found to have slowest central line velocity decay, which also verified the results suggested in the above analysis. The lobed nozzle D, which was the combination of lobed nozzle B and lobed nozzle C, is in the gap between the lobed nozzle B and lobed nozzle C. SUMMURY From the above LIF and PIV results, it can be seen that, compared with a circular jet flow, lobed jet flows were found to have shorter laminar instability regions, smaller scale of the spanwise Kelvin-Helmholtz vortices, earlier appearance of the small scale turbulent structures. The thicker mixing layers and bigger high-turbulent-intensity regions were also found in the near fields of the lobed jet flows. In the meanwhile, the lobed nozzles can reduce the potential core region length of the jet flows to 1/2 ~ 1/3 of that in the circular jet flow. All these indicated the mixing enhancement performances of lobed nozzles over a circular nozzle. From the comparison results of the three tested lobed nozzles, it can also be suggested that, the lobe configuration has an important effects on the mixing efficiency of the jet flows, and it must be properly considered in the optimism design of a lobed nozzle. It should be pointed out that the present experiment research was conducted at a very low speed. Some detailed differences are expected at higher speed case. However, it can be expected that the gross mixing enhancement of a lobed nozzle over a circular nozzle would be very similar at both low and high-speed flows. ACKNOWLEDGMENTS The authors appreciate the helpful discussions and advisable suggestions from Prof. Wu Shousheng and Prof. Shen Gongxin of Beijing University of Aeronautics and Astronautics, P. R. China. The research fellowship provided by Japan Society for Promotion of Science (JSPS) to the first author and the supported for the Original Industrial Technology R&D Promotion Program from the New Energy and Industrial Technology Development Organization (NEDO) of Japan are also grateful acknowledged. REFERENCE Adrian R. J., 1991 "Particle-Imaging Techniques for Experimental Fluid Mechanics", Ann Rev. Fluid Mech. Vlo.23, (1991), pp 261-304. Belovich V. M. and Samimy M, "Mixing Process in a Coaxial Geometry with a Central Lobed Mixing Nozzle" AIAA Journal, Vol.35 No.5, pp838-84l (1997) Brink B.K.and Foss J.F., "Enhancement Mixing via Geometric Manipulation of a Splitter Plate" AIAA 93-3244 (1993) Hu Hui, Liu Huoxing and Wu Shousheng, "Experimental Investigation on the Aerodynamic Performance of the 2-D Lobed Exhaust Ejector System" ASME 96-GT-243 (1996) Hu Hui, Saga. T., Kobayashi T., Okamoto K. and Taniguchi N.," Evaluation of the Cross Correlation Method by Using PIV Standard Images", Journal of Visualization, Vol.1, No.1, pp87-94 (1998). Hussain F. and Husain H.S., "Elliptic jets. Part 1: Characteristics of unexcited and excited jets" J.Fluid Mech. Vol.208, PP257-320 (1989) Liepmann D. and Gharib M., "The Role of Streamwise Vorticity in the Near Field Entrainment of Round Jets", J. Fluid Mech. Vol. 245, pp643-668 (1992). McCormick D. C. and Bennett J.C.Jr. "Vortical and Turbulent Structure of a Lobed Mixer Free Shear Layer" AIAA93-2l9 (1993). Paterson R. W., "Turbofan Forced Mixer Nozzle Internal Flowfield." NASA-CR-3492 (1982). Power G. D., McClure M. D. and Vinh D., "Advanced IR Suppresser Design Using A Combined CFD/Test Approach", AIAA94-32l5 (1994). Presz W.M. Jr, Renyolds G. and McCormick D., "Thrust Augmentation Using Mixer-Ejector-Diffuser Systems"AIAA94-0020 (1994). Smith L.L, Majamak A.J., Lam I.T. Delabroy O., Karagozian A.R., Marble F.E. and Smith, O. I., "Mixing Enhancement in a Lobed Injector" Phys. Fluids, Vol.9, No.3, PP667-678 (1997) Tillman T.G. and Presz W. M. Jr, "Thrust Characteristics of a Supersonic Mixing Ejector" AIAA93-4345 (1993) Werle M.J., Paterson R. W. and Presz Jr. W. M., "Flow Structure in a Periodic Axial Vortex Array" AIAA 87-6l0 (1987). Willert C. E. and Gharib M., "Digital Particle Image Velocimetry" Experiments in Fluids, Vol.l0, ppl8l-l993 (1991). Yoda M., Hesselink L. and Mungal M. G., "Instantaneous Three Dimensional Concentration Measurement in the Self Similar Region of a Round High-Schmidt Number Jet", J. Fluid Mech., Vol.279, pp3l3-350 (1994). Zhou M. and Garner. C. P., "Particle Image Velocimetry measurements of the flow field within an enclosed rotating disk-stator system and comparisons." Optical Diagnostics in Engineering, Vol.1 Part 2 (1996). 8 Copyright © 1998 by VSJ