PIV and LIF Measurements on the Lobed Jet Mixing Flows

advertisement

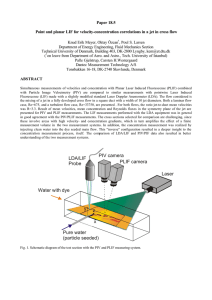

Proceedings of 3rd International Workshop on PIV, Santa Barbara, USA, Sep.16-18, 1999 PIV and LIF Measurements on the Lobed Jet Mixing Flows Hui HU, Toshio KOBAYASHI, Tetsuo SAGA, Shigeki SEGAWA and Nobuyuki TANIGUCHI Institute of Industrial Science, University of Tokyo, 7-22-1 Roppongi, Tokyo 106, Japan E-mail: huhui@cc.iis.u-tokyo.ac.jp Abstract: The effect of lobed nozzle on the vortical and turbulent structure chnages in the near field (X/D<3.0) of the jet mixing flow had been conducted experimentally in the present study. The techniques of planar Laser Induced Fluoresce (LIF) and Particle Image Velocimetry (PIV) were used to accomplish the flow visualization and velocity field measurements. The experimental results showed that, compared with a circular jet mixing flow, lobed jet mixing flows were found to have shorter laminar region, smaller scale of the spanwise Kelvin-Helmholtz vortices, earlier appearance of small scale turbulent structures and thicker mixing layers in the near field of the jet mixing flow. Bigger high-turbulence intensity regions were found to concentrate at the region of X/D<2.0 for the lobed jet mixing flows. All these indicted the better mixing enhancement performance of a lobed nozzle over a conventional circular nozzle at the near field of a jet mixing flow. Introduction A lobed nozzle, which consists of a splitter plate with a convoluted trailing edge, is an extraordinary fluid mechanic device for efficient mixing of two co-flow streams with different velocity, temperature and/or spices. It has been paid great attention by many researchers in recent years and has also been widely applied to the aerospace engineering. For examples, on the commercial aero-engines, lobed nozzles had been used to reduce take-off jet noise and Specific Fuel Consumption (SFC) (Tillman et al. 1993, Presz et al. 1994, and Hu et al. 1996). In order to reduce the infrared radiation signals of military aircrafts to improve their survivability in the modern war, lobed nozzles had also been used to enhance the mixing process of the high temperature and high speed gas plume from air-engine with ambient cold air (Power et al., 1994). More recently, lobed nozzles had also emerged as attractive approaches for enhancing mixing between fuel and air in combustion chambers to improve the efficiency of combustion and reduce the formation of the pollutant (Smith et al., 1997). The large scale streamwise vortices generated by lobed nozzles had been suggested to be the reason for their good mixing enhancement performance by many researchers, such as Paterson, (1982), McCormick et al. (1993) and Belovich et al., (1997). Although these previous researches had got many important results, much work still need in order to understand the mechanism of jet-mixing enhancement by using lobed nozzles more clearly. In particular about the vortical and turbulent structure chnages in the jet mixing flow caused by a lobed nozzle. In the meanwhile, most of these previous researches were conducted by using Pitot probe, Laser Doppler Velocimetry or Hot film Anemeter, which are very hard to reveal the vortical and turbulent structures in jet mixing flows instantaneously and globally due to the limitation of these experimental techniques. While, in the present study, both planar Laser Induced Fluorescence (LIF) and Particle Image Velocimetry (PIV) technique were used to research the lobed jet mixing flows globally and instantaneously. By using the directly perceived LIF flow visualization images, velocity vectors, vorticity distributions and turbulence intensity distributions got by PIV measurement, the changes of the turbulent and vortical structures in the near field of jet mixing flow caused by a Overflow water tank Laser sheet Laser beam water tank optical system CCD camera For PIV mixing region Double pulsed YAG laser tested nozzle Convergent section and comb structure flow jet supply tank For LIF CCD camera monitor mage process I system Host computer pump lobed nozzle were studied in detail. Figure 1. Experimental Setup Experiment set-up Figure 1 shows the schematically experimental facility used in the present research. The test nozzles were fixed in the middle of the water tank (600mm*600mm*1000mm). Fluorescent dye (Rhodamine B) for LIF or PIV tracers (polystyrene particles of d=20-30μm, density is 1.02) was premixed with water in jet supply tank, and jet mixing flow was supplied by a pump. The flowrate of the jet mixing flow, which was used to calculate the representative velocity and Reynolds numbers, was measured by a flow meter. A convergent unit and honeycomb structures were installed at the upstream of test nozzles to insure the turbulent levels of jet mixing flows at the exit of test nozzles were less than 5%. The pulsed laser sheet (thickness is about 1.0 mm) used for LIF visualization and PIV measurement was supplied by a Twin Nd:YAG Laser with the frequency of 10 Hz and power of 200 mJ/pulse. The time interval between the two pulses can be adjustable. A 1008 by 1016 pixels Cross-Correlation CCD array camera (PIVCAM 10-30) was used to capture the LIF and PIV images. The Twin Nd:YAG Laser and the CCD camera were controlled by a Synchronizer Control System. The LIF and PIV images captured by the CCD camera were digitized by an image processing board, then transferred to a work station (host computer, RAM 1024MB, HD20GB) for image processing and displayed on a PC monitor. Rhodamine B was used as fluorescent dye in the present research. The fluorescent light was separated from the scattered laser light by installation a high pass optical filter at the head of the CCD camera. A low concentration Rhodamine B solution (0.5mg/l) was used to insure the strength of fluorescent light being linear with the concentration of the fluorescent dye and the effect of laser light attenuation being negligible as the laser light sheet propagated through the flow (Hu et al. 1999). For the PIV image processing, rather than tracking individual particle, the cross correlation method (Willert et al., 1991) was used in the present study to obtain the average displacement of the ensemble particles. The images were divided into 32 by 32 pixel interrogation windows, and 50% overlap grids were employed. The resolution the PIV images for the present research case is about 120μm/pixel. The average displacement of the particles is about 4 to 6 pixels between the two laser pulses (dt=1ms to 4ms). The post-processing procedures which including sub-pixel interpolation (Hu et al., 1998) and velocity outliner deletion (Westerweel, 1994) were used to improve the accuracy of the PIV result. Z Z Y X lobe peak slice lobe trough slice a. circular nozzle lobe width W= 6mm lobe side slice lobe heigth H=15mm inner penetration angle 220 140 outer penetration angle c. three studied axial slices b. lobed nozzle Figure 2. The test nozzles and three studied axial slices Figure 2 shows the two test nozzles used in the present study: a baseline circular nozzle A and a lobed nozzle B with six lobes. The height of the lobes is about 15mm and the inner and outer penetration angles of the lobe structures are about 220 and 140 respectively. The equivalent diameters of these two nozzles at the exit were designed to be the same, i.e. D=40mm. In the present study, the jet velocities were set as about 0.1m/s and 0.2m/s. The Reynolds Number of the jet mixing flows, based on the nozzle exit diameter, were about 3,000 and 6,000. In the present study, the turbulent and vortical structure changes caused by lobed nozzle in the three axial slices were firstly investigated, which are the lobe trough slice, lobe peak slice and lobe side slice (Figure 2(c).). Then, LIF visualization and PIV measurement were also conducted at several cross sections for the lobed jet mixing flow and circular jet mixing flow. For the PIV measurement results, the mean velocity vectors, mean streamwise vorticity distributions and mean turbulence intensity fields were used to compare the lobed jet mixing flows with circular jet flow. The mean values of the PIV measurements were calculated based on the average of 400 frames of the instantaneous flow fields, which were obtained at the frequency of 10 Hz. Results and discussion 1. In the axial slices Figure 3 shows the LIF visualization and PIV measurement result in the axial slice of a conventional circular jet mixing flow at the Reynolds number of 6,000. From the LIF flow visualization(Fig.3(a)), it can be seen that there is a laminar region at the exit of the circular nozzle. At the end of the laminar region (X/D = l.5), spanwise Kelvin-Helmholtz vortices were found to roll up. Pairing and combining of these spanwise vortices and the transition of the jet mixing flow to turbulence were found to conduct in much downstream (X/D=4-6), which is out of the CCD camera view of the present study. None of the small scale turbulence and vortical structures can be found in the investigated region (X/D<3.0). The LIF visualization got by the presnt study is very similar as the result reported by Liepmann et al (1992). From the mean velocity distribution (Fig.3(b)) and turbulence intensity distribution (Fig.3(c)) at the same Reynolds number level obtained by PIV measurement, it also can be seen that the circular jet mixing flow began to expended just after the spanwise Kelvin-Helmholtz vortices rolling up at the downstream of X/D>1.5. A low turbulence intensity region in the central of the circular jet mixing flow, which is called the potential core region, can be found at the jet mixing flow, which extent to the downstream of the X/D>3.0 for the circular jet mixng flow. Figure 4 shows the LIF visualization and PIV measurement result in axial slice passing the lobe trough of the lobed jet mixing flow. Compared with the circular jet mixing flow, the laminar region of the lobed jet mixing flow became much shorter in this axial slice (Fig.4(a)). The spanwise Kelvin-Helmholtz vortices were found to roll up almost just from the trailing edge of the lobed nozzle. It also can be found that the size of these spanwise Kelvin-Helmholtz vortices became much smaller compared with that in the circular jet mixing flow. Some small scale turbulent and vortical structures began to appear in the flow field from the downstream of X/D>1.0. From the PIV measurement results (Fig.4(b) and Fig.4(c)) at this axial slice, it can also be seen that the lobed jet mixing flow began to expend almost just from the trailing edge of the lobed nozzle. The expand angle of the lobe jet mixing flow was found to be the angle of the outer penetration angle at the lobed nozzle within the downstream region of X/D<2.0, and then changed to the expand angle of circular jet mixing flow. It can also be found that most of the high-turbulenceintensity regions for the lobed jet mixing flow concentrated at the region of X/D<2.0. While, in the circular jet mixing flow, these regions were found to be much downstream. It also can be found that the potential core region (low-turbulence-intensity) at the central of the lobed jet mixing flow was much smaller and shorter than that of the circular jet mixing flow. Figure 5 shows the LIF flow visualization and PIV measurement result in the axial slice passing the lobe peak (Fig.2(c)) of the lobed jet mixing flow. The laminar region at the exit of the lobed nozzle at this axial slice was not a straight cylinder like that in the circular jet, and looked like a expansive cut-off cone along the downstream of the lobe structure instead. Compared with that in the lobe trough slice, the laminar region in the lobe peak axial slice was a bit longer (X/D=0.4), but it was still much shorter than that in the circular jet mixing flow. This may be caused by the different thickness of the boundary layer at the exit of the lobed nozzle (the work of the Brink et al.(1993) had verified that the thickness of the boundary layer at the lobe trough is smaller than that in the lobed peak), and the thicker boundary layer at the lobe peak need a longer streamwise distance to roll-up the Kelvin-Helmholtz vortices (Hussain et al. 1989). In this axial slice, it can also be seen that small-scale turbulent and vortical structures were found to appear in the flow field from the downstream of location X/D=1.0. Form the PIV measurement results (Fig. 5(b) and Fig. 5(c)), it also can be seen that most of the high-turbulence-intensity regions were concentrated at the downstream of X/D<2.0. The potential core region at the central of the lobed jet mixing flow at this axial slice is also much smaller and shorter than that in circular jet mixing flow, which is the same as that in the lobe trough slice for the lobed jet mixing flow. Figure 6 gives the LIF flow visualization and PIV measurement result in the axial slice passing lobe side (Fig.2(c)) of the lobed jet mixing flow. In this axial slice, some streak flow structures can be seen clearly in the downstream of the lobe structure trailing edge. These structures were the Kelvin-Helmholtz vortical tubes shed periodically from the lobe training edge, which was observed and called “normal vortex” by McCormick et al.(1993). At the downstream of the location X/D = 1.0, small scale turbulent and vortical structures were found to appear in the flow field. As the same as that in the axial slices passing lobe peak and lobe trough of the lobed jet mixing flow, most of the high intensity region was found to concentrate at the region of X/D<2.0. The potential core region at the central of the lobed jet mixing flow in this axial slice was also much smaller and shorter than that in the circular jet mixing flow. 2. In the cross planes Figure 7 shows the LIF flow visualization of the lobed jet mixing flow in six cross planes. From the figures it can be seen that, at the location of X=l0mm (X/D=0.25, Fig.7(a)), the existence of the streamwise vortices in the form of 6 petal “mushrooms” at the lobe peak can be seen clearly in the jet mixing flow. The spanwise Kelvin-Helmholtz vortices rolled up at the lobe trough parts were found to be as six crescents at this cross section. As the streamwise distance increased to X = 20mm (X/D=0.5), the “mushrooms” at the lobe peak grew up (Fig.7(b)), which indicated the intensification of the streamwise vortices generated by lobed nozzle. As the streamwise vortices distance increased to X= 30mm (X/D=0.75), the streamwise vortices generated by the lobed nozzle in the form of “mushrooms” structure keep on intensification. Six new counter-rotating streamwise vortex pairs also can be found at six lobe trough. Though the existence of the horseshoes structure at the trough of the lobe structure had been suggested by Paterson (1992), this is the best known visualization and provides unquestionable evidence of their existence. At the location of X=40mm (X/D=1.0, Fig. 7(d)), some small scale turbulent and vortical structures began to appear in the flow and the interaction between the streamwise vortices and Kelvin-Helmholtz vortices made adjacent “mushrooms” merging with each other, which indicated the process that the streamwise vortices deform the Kelvin-Helmholtz vortical tube into pinch-off structure suggested by McCormick et al.(1993). At the location of X=60mm (X/D=1.5, Fig.7(e)) and X= 80mm (X/D=2.0, Fig.7(f)), the “mushroom” shape structures almost disappeared and the flow was almost fully filled with small scale turbulent and vortical structures. While for the circular jet mixing flow at the same Reynolds number level, the jet mixing flow is still in this laminar region at the location of X=40mm (X/D=1.0, Fig.8(a)). The spanwise Kelvin-Helmholtz vortices were found to roll up at the location of X=80mm (X/D=2.0, Fig. 8(b)). At the downstream location of X=120mm (X/D=3.0, Fig.8(c)), some streamwise vortices due to the azimuthal instability (Liepmann et al. 1992) were found to be appear in the flow field. However, neither small-scale turbulent sturtures nor small scale vortical structures can be found at the cross planes of these locations for the circular jet mixing flow. Figure 9 shows the PIV measurement results at four typical cross planes.As the same as LIF visaulization, basides the six mushroom like large-scale streamwise vortices, the existance of the counter rotating horseshoes vortices at the lobe trough region can also be seen clearly in the lobed jet mixing flow. As the distance inceased to the downstream of X=60mm, the large scale streamwise vortices were found to break down into many small scale vortices, and the flow field were fully filled with small scale turbulent and vortical structures. Conclusion The LIF visualization and PIV measurement result revealed the great differences of the turbulent structure and vortex scale between the lobed jet mixing flow and circular jet mixing flow. Compared with a circular jet mixing flow, the lobed jet mixing flow was found to have shorter laminar region, smaller scale of the spanwise Kelvin-Helmholtz vorices, earlier appearance of small-scale turbulent and vortical structures and bigger turbulence intensity in the very near downstream. All these indicated the mixing enhancement performances of a lobed nozzle over a circular nozzle. Based on the result of the present experimental research, the analysis to reveal the mechanism of the mixing enhancement performance of lobed nozzles and the suggestions to do optimism design of the lobed nozzles will be conducted in the future work. References Belovich V. M. and Samimy M. (l997) Mixing Process in a Coaxial Geometry with a Central Lobed Mixing Nozzle. AIAA Journal,Vol.35, No.5,PP838-84l. Brink B.K.and Foss J.F. (l993) Enhancement Mixing via Geometric Manipulation of a Splitter Plate. AIAA93-3244. Hu H., Liu H.X. and Wu S. S. (l996) Experimental Investigation on the Aerodynamic Performance of the 2-D Exhaust Ejector System. ASME96-GT-243 Hu H., Saga. T., Kobayashi T., and Taniguchi N. (1998) Evaluation the Cross Correlation Method by Using PIV Standard Image. Journal of Visualization, Vol.1, No.1,pp87-94 Hu H., T. Kobayashi, Wu S. S., and Shen G.X. (1999) Research on the Vortical and Turbulent Structure Changes of Jet mixing flow by Mechanical Tabs. Proc. Instn. Mech. Engrs, Vol.213, Part C, Journal of Mechanical Engineering Science (in print), Hussain A.K.M.F. (l986) Coherence structure and Turbulence. J .Fluid Mech. Vol.l73, PP303-356 Hussain F. and Husain H.S. (1989) Elliptic jets. Part 1: Characteristics of unexcited and excited jets. J.Fluid Mech. Vol.208, PP257-320 Liepmann D. and Gharib M., (1992) The Role of Streamwise Vorticity in the Near Field Entrainment of Round Jets", J. Fluid Mech. Vol. 245, pp643-668. McCormick D.C. and Bennett J.C.Jr. (l993) Vortical and Turbulent Structure of a Lobed Mixer Free Shear Layer” AIAA93-2l9. Paterson R. W. (l982) Turbofan Forced Mixer Nozzle Internal Flowfield. NASA-CR-3492. Presz W.M. Jr, Renyolds G. and McCormick D. (l994) Thrust Augmentation Using Mixer-Ejector-Diffuser Systems”AIAA94-0020. Power G. D., McClure M. D. and Vinh D. (l994) Advanced IR Suppresser Design Using A Combined CFD/Test Approach. AIAA94-32l5. Smith L.L, Majamak A.J., Lam I.T. Delabroy O.,Karagozian A.R., Marble F.E. and Smith, O. I., (l997) Mixing Enhancement in a Lobed Injector. Phys. Fluids, Vol.9,No.3,PP667-678 Tillman T.G. and Presz W. M. Jr, (l993) Thrust Characteristics of a Supersonic Mixing Ejector. AIAA93-4345 Willert C. E. and Gharib M. (l99l) Digital Particle Image Velocimetry. Exp. In Fluids, Vol. l0,PPl8l-l993. Westerweel, J. (1994) Efficient Detection of Spurious Vectors in Particle Image Velocimetry Data. Exp. In Fluids, Vol.16, pp236-247 3.5 3.5 0.2 m/s 0.02 0.010 6 10 0 .0 0 .0 Y Y 3 0.026 0 .03 0.018 2 0.0 33 0.01 8 2 0.026 2.5 0.01 8 2.5 0.02 6 3 0.01 0 3 1 0.5 0.5 0.010 1 0.010 1.5 16 1.5 0.0 18 0.010 0 0. 0 -2 -1 0 1 2 -2 -1 01 8 0 1 X 2 X a.LIF visulization b.mean velocity distribution by PIV c.turbulence intensity distribution Figure 3. LIF visulization and PIV measurement result in the circular jet mixing flow (Re=6,000) 3.5 3.5 0.2 m/s 2 2 0. 2.5 0.03 1 2.5 17 3 0 .0 3 01 0.0 31 7 0 1 2 3 00 7 0.0 31 0 .0 44 0.0 58 0.044 0.05 8 7 -1 -2 0.044 0 .0 1 0 -2 03 0.0 31 44 0.00.031 0.01 7 0 0.031 0 .0 1 0.5 0 .0 0.0 17 0.5 0.0 31 1 0. Y Y 7 1 1 01 1.5 0 .0 3 0.031 0. 1.5 -1 0 1 X 2 X a.LIF visulization b.mean velocity distribution by PIV c.turbulence intensity distribution Figure 4. LIF visualization and PIV measurement results of lobed jet mixing flow in the lobe trough slice (Re=6,000) 3.5 3.5 -1 0 1 2 X a.LIF visulization b.mean velocity distribution by PIV -2 0.028 0.028 0.0 0. 01 6 0. 02 8 0. 02 8 0. 02 8 -1 0 0 . 02 8 04 0.0 28 01 6 40 0. 0 -2 0. 0.04 0 0 0 6 01 0.0 38 18 . 0 0 .0 28 0 0.5 0. 04 02 8 Y Y 0.016 0. 04 0 0. 0.5 28 1 0.0 1 6 1.5 0. 02 8 0 .0 1 1.5 0. 2 16 2 0.0 2.5 28 2.5 0. 0 3 0. 0 3 28 0.2 m/s 0 1 2 X c.turbulence intensity distribution Figure 5. LIF visaulization and PIV measurement results of the lobed jet mixing3.5flow in the lobe peak slice (Re=6,000) 3.5 0.2 m/s 2 02 9 17 2 0. 0 -2 -1 0 1 2 -2 -1 3 0 X 0.0 05 0.01 7 04 0.102 9 0.02 9 0 .0 5 0 0. 0.017 1 0 .0 4 0.0 29 20 0.005 0 .0 0.04 1 0.029 41 0 .0 29 4 1 0 .0 0 .0 17 0.5 29 0.5 0 .0 1 0.0 Y Y 9 1 9 02 1.5 02 0. 0. 0 .0 17 0.00 5 1.5 0 .0 0 5 0 .0 0 .0 2.5 05 2.5 29 0 .02 9 0 0. 3 0.01 7 3 1 2 X a.LIF visulization b.mean velocity distribution by PIV c.turbulence intensity distribution Figure 6. LIF visualization and PIV measurement results of the lobed jet mixing flow in the lobe side slice (Re=6,000) a.X=10mm b.X=20mm c.X=30mm d.X=40mm e.X=60mm f.X=80mm Figure 7. LIF visulization of the lobed jet mixing flow in the serveral corss planes (Re=3,000) a.X=40mm b.X=80mm c.X=120mm Figure 8. LIF visulization of the circular jet mixing flow in the serveral corss planes (Re=3,000) 0.00 0 1 2 0.02 0.01 00 0 0.75 02 0 0. 6 0. Y -1.3 07 0 .0 10 0 .0 14 0 .0 14 0.0 0.01 4 0 0 0 .0 1 0.01 0 .0 1 7 7 Y 00 4 0.004 0. 9 -2.2 0 .9 0.9 -0 .6 0.9 2. 4 0. 01 -0 .6 .6 -2 .2 0.9 -0 0.9 .6 -0 0.01 4 0.020 0.020 0 .0 .6 10 0.0 04 0 .0 07 0.0 04 0.9 0 -0.5 0 0.0 14 08 0.0 17 17 8 -0 . 17 7 0. 0 4 01 0. 7 01 0. 4 0 .0 1 0 .0 0 .0 11 08 0 .0 Y -0.8 -0 .8 -0.8 0 .0 0. 1. -0.8 0.4 1.7 0.4 0 .0 11 1 -0.8 4 7 0.4 -2 .0 1. 7 0 .0 -0.8 4 0. 0. 4 0.4 -0 .8 -0.8 0.4 -2 -2.0 .0 4 0. 7 0 .4 7 17 14 0 .0 01 0 14 14 0. 0.0 0 .0 20 1. 4 14 01 4 0 .0 1 .7 8 0. 0.0 1 107.0 Y 00 11 11 0.0 08 -0.5 4 7 01 0. 20 0 0. 01 -1 0 .0 0 .0 0 .0 0. 1 0 .0 01 20 17 0.01 7 -1 14 11 0 .0 0.00 8 0.01 1 -0.8 7 7 0.01 4 01 0 .0 -0.75 01 0. 0.5 4 0. 0. 14 -0.8 -0.5 0.0 0.0 08 1 1 0 .0 0.014 0 0. 0 .0 Y 14 11 0.4 4 0. 0. 0. 17 0 .0 -0.25 11 0 .0 1 4 0 -0 .8 0 0.25 1.7 .0 -2 -2.0 -0.8 1 .7 X 0 .0 0.4 01 0.01 4 01 0. -0.8 -0.5 .8 1.7 -0.8 - 8 0. 0. -0.81 .7 7 1. -1 0.4 a. mean velocity distribution 1.7 1 0.4 4 0.5 X 1 .7 0 .4 -1 -0.8 4 4 0. -1 0.4 -0.75 -0 .8 0 .4 .8 -0.75 0. -0 .8 -0.5 -0 0 .4 0. -0.5 -0 .8 0.4 1.7 1.7 -0 .8 -0.8 -0.25 -0 .8 -0.25 .8 1 0.5 2. 9 7 .8 -0 7 1 . 0.4 0 1. -0 0.4 0 0 .4 1 .7 0 .0 1 0.75 -0 .8 0.25 1 c.turbulence intensity distribution 0 .4 0 .4 1 .7 0.25 0 .4 -2.0 0.5 -0.8 0.5 0.5 0 .0 0.4 0.03 m/s 0 -1 X -0 0.4 0.75 0.4 0.75 -0.5 1 b.streamwise vortices C. X=60 mm -0.8 a. mean velocity distribution -1 0.5 X 0 .0 1 -0.5 4 -1 0 .0 1 1 0.01 7 0.5 -1 -2 .0 -2 .0 0. 4 0 X 0.01 0 -0.75 0.01 7 -0.6 20 7 -0.6 0. -0 9 .6 0.0 0.0 0. 0 .9 0 .9 2 .4 9 10 01 0. 0. -0 .6 17 0.007 .6 -0.5 0 -0.5 6 -0 . -0 -1 01 7 0 .0 17 4 0 .0 1 0.9-0 .6 .2 -2 0. 01 -0 .6 1 0. 0.0 20 0.017 07 14 -0 4 0.9 0.9 0.5 0 .0 Y 2 4 12 0 .0 .6 Y 0.00 0 0.00 7 9 0. -1 0.9 01 -0.25 .6 -1 -0 -0.75 0.9 2 .4 -0.6 -2 .2.7 -3 .2 -2 0.9 4 2.4 -0.75 2. 0.9 0.9 -2.2 -0.5 -2 .2 0.0 0 -2 .2 -0.5 -2 .2 -0.6 -0 .6 - 0.25 -0 .6 -0 .6 0.9 .6 -2.2 -0 2 2. 8 0.5 -0 .6 -2.2 -0 -0 .6 00 c.turbulence intensity distribution 0. 2 .4 .6 0 -0.25 0. 0.0 12 00 8 6 01 -0.5 0.75 0.9 9 0 0.01 0. 2. 0 2 .0 0.008 0 .0 1 6 -4 .6 -1 .3 2.0 -1 .3 01 0 2. -1.3 0.004 5. 2 Y Y 0. 3 -1 . -1 .3 0.0 -1 0.004 0. 0 .9 -0.25 0.9 0. 20 X -2 .2 -0.6 -0 0.9 0.0 04 1 0 .9 0.25 -0 .6 -2 .2 0.25 -0 .6 0.9 -0 .6 6 0 .0 -1 0.5 0.75 0.5 01 2 0.03 m/s 0.5 0 -0.75 5. 0 -0.6 0. 0. 02 12 0.0 08 0 .0 0 .0 04 -0.5 b.streamwise vortices B. X=40 mm 0.75 1 6 20 0.0 0.0 0.01 2 0 .0 24 0.02 0 0.016 X a. mean velocity distribution 8 0.020 4 00 00 -0.5 2.0 -1 2 .0 1 -1 .3 8 .5 -4 .6 0. 6 2.0 0.5 X -0.25 5.2 -1.3-4 .6 5 .22 .0 -1 0 -1.3 -4 .6 -0.75 -1 2. -7 .8.6 -4 .3 -1 -0.75 .6 4 .6 - .3 -1 0 .3 -0.5 2 .0 5.2 -1 -4 -1 .3 0 04 0. .3 -0.25 -0.5 -1.3 0 2. -1.3 02 0.0 0. 01 2 16 0 .0 2 0 .0 1 8 0 .0 0 -1 -0.25 0.25 .3 2 .0 0 0.008 0.0 1 0. .9 -1 .3 -1 0 0.5 2 .0 -4 .6 0.012 2 .0 -2 .3 - 1.0 2 0.25 1 c.turbulence intensity distribution 01 6 0.012 0 -4 .6 -4 1 .3 .6 0.5 X -1 .3 2 .0 -4 .6 2 .0 0.5 0 -0.5 -4.6 2. 0.75 0.03m/s -0.5 -1 b.streamwise vortices A.X=20 mm 0.25 0.01 0 0 .0 0.5 2.0 a. mean velocity distribution -1 01 0. 5.6 1.6 .6 -1 0 1.6 -0.5 X 0.5 1 -1 -1 X 0.75 0.0 0. 01 4 0.0 10 1 0. 00 1 .6 9 .7 1 .6 -6 .6 1.6 -2.5 9 .7 1.6 Y 0.5 0.00 0 02 00 -0.5 -0.75 0 -1 0 .0 5.6 -1 -6.6 -0.75 -1 0. 00 0. -6.6 2 0.01 0 0.0 0.0 1 6 1. -6.6 .5 -2 .5 1 .6 -0.5 1 01.0 0 .0 0.0 01 0. 0.0 1 -0.25 -2 5 7 .5 .6.6 0 0. 1 -2 .5 1 .6 -2 .6 -1 0 5.6 -6 .6 -2.5 -0.5 -0.75 0 0. .0 1 00 0 -0.25 -0.5 0 .0 0 .0 1 0 .0 -0.25 0 .0 1 2 0.0 0 .0 1 0. 02 01 0 .02 Y 0 0. 0.0 0.25 0.01 -2 .5 6 1 . 5 .6 2 .5-8.6 1-.6 -2.5 1.6 1 0.02 1 .6 -6 .6 2. 5 .6 1 .6 5 Y 0 -2 .5 9.7 0 .0 0 0. 0.25 0 .0 0.0 0 0.25 0.5 1.6 1 .6 0.5 0 0.5 0 .0 .6 -2.5 0.03 m/s 0.75 -6 1.6 0.75 5 .6 0.75 0 .0 11 08 0.5 1 X b.streamwise vortices c.turbulence intensity distribution D. X=80 mm Figure 9. PIV measurement results in serveral cross planes of the lobed jet mixing flow (Re=3,000)