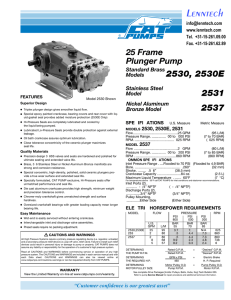

5 Frame Plunger Pump 310, 340, 350

advertisement

Lenntech info@lenntech.com www.lenntech.com Tel. +31-15-261.09.00 Fax. +31-15-261.62.89 5 Frame Plunger Pump Standard Models Special Brass Models 310S, 340S, 350S Sleeved Models Model 310 Shown (Rails and Shaft Protector Sold Seperately) FEATURES l l l l l Triplex design offers high efficiency and low pulsation. Durable high pressure seals are lubricated and cooled by pumped liquid. Pre-set Lo-Pressure Seals provide secondary protection against external leaks and require no packing adjustment. Optional STHT, FPM and EPDM elastomers for compatibility with many liquids and temperaturesup to 200°F Alternate crankshaft strokes offers flexibility with belt, clutch or direct-drive installation. SPECIFICATIONS MODEL 310, 310B, 310S U.S. Measure Metric Measure Flow .......................................................................... 4.0 gpm Pressure Range ........................................ 100 to 2200 psi Pump RPM ............................................................. 950 rpm Inlet Pressure Range ......................................–5 to 60 psi Stroke ........................................................................... 0.709” (15 l/m) (7 to 155 bar) (950 rpm) (– 0.35 to 4 bar) (18 mm) ALTERNATE SPECIFICATIONS MODEL 310, (20 mm) (0.55 l) (71°C) Above 130°F call CAT PUMPS for inlet conditions and elastomer recommendations. Inlet Ports (2) .......................................................1/2” NPTF (1/2” NPTF) Discharge Ports (2) ............................................3/8” NPTF (3/8” NPTF) Shaft Diameter ......................................................... 0.787” (20 mm) Weight .......................................................................19.8 lbs. (9 kg) Dimensions ........................................11.73 x 10.0 x 5.24” (298 x 254 x 133 mm) All High Pr essur e Syst ems require a primar y pressure regulating device (i.e . regulator, unloader) and a secondar y pressur e relief device (i.e . pop- off valve, relief valve). Fa ilure to instal l s uch relief device s coul d result in personal injury or damage to pump or proper ty. CA T P UMP S does no t assum e any liability or responsibili ty fo r the operatio n of a c ustomer’ s h igh pressure sy stem. Read all CA UTIONS and WA RNINGS before c ommencin g se rvic e or operatio n of any high pressur e sy stem. Th e CAU TIONS and WA RNINGS are includ ed in each se rvic e manual and with each Ac c essor y Data sheet. CA UTIONS and WA RNINGS can also be viewed online at www .c atpumps. co m/cautions -w arnings or ca n be reques ted directly from CA T P UMPS. 310B, 310S Flow .......................................................................... 5.0 gpm Pressure Range ........................................ 100 to 1500 psi Pump RPM ...........................................................1190 rpm MODEL 340, MODEL 350, (19 l/m) (7 to 105 bar) (1190 rpm) 340B, 340S Direct Drive Flow .......................................................................... 4.0 gpm Pressure Range ........................................ 100 to 1800 psi Pump RPM ...........................................................1725 rpm Inlet Pressure Range .......................... Flooded to 60 psi Stroke ........................................................................... 0.394” COMMON SPECIFICATIONS Bore ............................................................................... 0.787” Crankcase Capacity................................................... 18 oz. Standard Liquid Temperature ...............................160°F 310, 340, 350 310B, 340B, 350B (15 l/m) (7 to 125 bar) (1725 rpm) (Flooded to 4 bar) (10 mm) 350B, 350S Direct Drive Flow ........................................................................... 5.0 gpm Pressure Range ....................................... 100 to 1500 psi Pump RPM ...........................................................1725 rpm Inlet Pressure Range .......................... Flooded to 60 psi Stroke ........................................................................... 0.472” (19 l/m) (7 to 105 bar) (1725 rpm) (Flooded to 4 bar) (12 mm) ELECTRIC HORSEPOWER REQUIREMENTS MODELS 310 Alternate 340 350 FLOW U.S. gpm 4.0 5.0 4.0 5.0 l/m 15 19 15 19 DETERMINING THE PUMP R.P.M. DETERMINING THE REQUIRED H.P. DETERMINING MOTOR PULLEY SIZE PRESSURE psi psi psi psi 1200 1500 1800 2000 bar bar bar bar 85 105 125 140 3.3 4.1 5.0 5.5 4.1 5.1 N/A N/A 3.3 4.1 5.0 N/A 4.1 5.1 N/A N/A Rated gpm Rated gpm gpm x psi 1460 Motor Pulley O.D. Pump rpm MOTOR PULLEY SIZE psi 2200 bar rpm 155 6.0 950 N/A 1190 N/A 1725 N/A 1725 = = = Using 1725 rpm Motor & Std. 8” Pump Pulley Pulley O.D. 4.4 5.5 Direct Drive Direct Drive “Desired” gpm “Desired” rpm Electric Brake H. P. Required Pump Pulley O.D. Motor rpm See complete Drive Packages [Inclds: Pulleys, Belts, Hubs, Key] Tech Bulletin 003. Refer to pump Service Manual for repair procedure and additional technical information. PARTS LIST ITEM PART NUMBERS 2 5 8 10 11 15 20 25 30 31 32 33 37 38 40 48 49 50 51 53 56 64 65 70 75 88 90 96 97 u 98 99 100 101 106 u 120 121 u 125 139 162 163 u 164 166 167 168 172 u 174 185 188 250 255 260 265 270 275 283 298 299 310, 340 350 30057 92519 125824 43344 43343 43222 14480 45883 43342 44945 43838 44949 828710 43211 14177 92241 44428 92520 126541 25625 23170 48772 48773 48769 43355 43351 43365 43228 43328 45697 43367 43235 17399 14160 46204 45891 104360 45688 43302 43305 45153 48429 76305 45679 14200 11719 48907 43307 44936 46667 22179 48361 43358 44938 48908 43725 43723 43750 44565 17615 15855 48431 43849 44837 126520 118672 30243 30611 30659 30633 30944 34334 76334 34962 34963 810027 MATL STL STZP STCP R AL NBR NBR STL HS FCM FCM FCM AL — ABS NBR — NBR STZP STCP R STCP NBR AL NBR AL POP CM ZZCP NBR S S CC PTFE NBR FPM EPDM CU S PVDF — NBR FPM EPDM ST BB NBR FPM EPDM SNG FPM HT* BBCP D NBR FPM EPDM S S S PVDF NBR FPM EPDM BBCP BBCP STCP R STCP STZP STZP — STL STL — — STZP STZP BBCP u u u u u 310B,340B 350B 30057 92519 125824 43344 43343 43222 14480 45883 43342 44945 43838 44949 828710 43211 14177 92241 44428 92520 126541 25625 23170 48772 48773 48769 43355 43351 43365 43228 43328 45697 43367 43235 17399 14160 46204 45891 104360 45688 43302 43305 45153 48429 76305 45679 14200 11719 48907 43307 44936 46667 22179 48361 43358 44938 48908 43725 43723 43750 44565 17615 15855 48431 43849 49721 126520 118672 30243 30611 30659 30633 30944 34334 76334 34962 34963 818471 MATL STL STZP STCP R AL NBR NBR STL HS FCM FCM FCM AL — ABS NBR — NBR STZP STCP R STCP NBR AL NBR AL POP CM ZZCP NBR S S CC PTFE NBR FPM EPDM CU S PVDF — NBR FPM EPDM ST BB NBR FPM EPDM SNG FPM HT* BBCP D NBR FPM EPDM S S S PVDF NBR FPM EPDM BBCP SBCP STCP R STCP STZP STZP — STL STL — — STZP STZP SBCP DESCRIPTION u u u u u 310S, 340S 350S 30057 92519 125824 43344 43343 43222 14480 45883 43342 44945 43838 44949 828710 43211 14177 92241 44428 92520 126541 25625 23170 48772 48773 48769 43355 43351 43365 43228 43328 45697 43367 43235 17399 14160 46204 45891 104360 45688 43302 43305 45153 48429 76305 45679 14200 11719 48907 43307 44936 46667 22179 48361 43358 44938 48908 43725 43723 43750 44565 17615 15855 48431 43849 46278 126520 118672 30243 30611 30659 30633 30944 34334 76334 34962 34963 816551 MATL STL STZP STCP R AL NBR NBR STL HS FCM FCM FCM AL — ABS NBR — NBR STZP STCP R STCP NBR AL NBR AL POP CM ZZCP NBR S S CC PTFE NBR FPM EPDM CU S PVDF — NBR FPM EPDM ST BB NBR FPM EPDM SNG FPM HT* BBCP D NBR FPM EPDM S S S PVDF NBR FPM EPDM BBCP FBB STCP R STCP STZP STZP — STL STL — — STZP STZP FBB Key (M6x6x25) Screw, HHC, Sems (M6x16) Screw, HHC, Sems (M6x16) Cover, Bearing O-Ring, Bearing Cover - 70D Seal, Oil, Crankshaft - (310, 310B, 310S,350,350B,350S-2) (340,340B,340S-1) Bearing, Ball Rod, Connecting Assy [09/05] Crankshaft, Dual End - M18, 310, 310B, 310S Crankshaft, Single End -M10, 340, 340B, 340S Crankshaft, Dual End - M12, 350, 350B, 350S Cover, Blind Shaft - 340, 340B, 340S Protector, Oil Cap w/Foam Gasket Cap, Oil Filler O-Ring, Filler Cap - 70D Gauge, Oil, Bubble w/Gasket Gasket, Flat, Oil Gauge - 80D Screw, HHC, Sems (M6x20) Screw, HHC, Sems (M6x20) Plug, Drain (1/4”x19 BSP) O-Ring, Drain Plug - 70D Cover, Rear [10/01] (See Tech Bulletin 090) O-Ring, Rear Cover [10/01] (See Tech Bulletin 090) Crankcase [05/02] (See Tech Bulletin 090) Pan, Oil Pin, Crosshead Rod, Plunger Seal, Oil, Crankcase Slinger, Barrier Washer, Keyhole (M18 x 10) Plunger (M20x72) Back-up-Ring, Plunger Retainer O-Ring, Plunger Retainer - 80D O-Ring, Plunger Retainer - 80D O-Ring, Plunger Retainer - 70D Gasket Retainer, Plunger w/Stud Retainer, Seal, 2-Pc [04/06] (See Tech Bulletin 105) Wick, Long Tab Seal, LPS w/S-Spg Seal, LPS w/SS-Spg Seal, LPS w/SS-Spg Seal, LPS w/S-Spg Case, Seal O-Ring, Seal Case - 70D O-Ring, Seal Case O-Ring, Seal Case Seal, HPS w/S Seal, HPS w/SS Seal, HPS “Hi-Temp”, 2-Pc w/S-Support Plug, Inlet (1/2” NPT) Back-up-Ring, Seat O-Ring, Seat - 70D O-Ring, Seat - 70D O-Ring, Seat Seat Valve Spring, Valve Retainer, Valve Spring O-Ring, Valve Plug - 75D O-Ring, Valve Plug -70D O-Ring, Valve Plug -75D Plug, Valve Head, Manifold Screw, HSH, Sems (M10x35) Protector, Shaft (Belt Drive Only) Mount, Direct (Belt Drive Only) Mounting, Angle Rail (Belt Drive Only) Mount, Assy (Inclds: 30611, 30633, 118672) (Belt Drive Only) Assy, Pulley & Key (Inclds: 30058, 30057) (Belt Drive Only) Assy, Hub & Key (Inclds: 30057, 30945) (Belt Drive Only) Kit, Oil Drain (3/8” x 24”) (See Individual Data Sheet) Kit, Oil Indicator, (3/8” x 24) (See Individual Data Sheet) Clutch Assy, Single Groove, 20mm, 12VDC (See Individual Data Sheet) Clutch Assy, Dual Groove, 20mm, 12VDC (See Individual Data Sheet) Head, Complete QTY 1 8 8 1/2 2 2/1 2 3 1 1 1 1 1 1 1 1 1 4 4 1 1 1 1 1 1 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 1 6 6 6 6 6 6 6 6 6 6 6 6 1 2 1 1 1 1 1 1 1 1 1 1 1 EXPLODED VIEW 31 32 250 30 10 11 33 15 5 20 40 37 38 25 49 48 283 50 51 56 65 88 75 70 15 64 174 100 11 53 10 2 8 5 172 168 90 99 97 96 98 167 166 164 101 163 162 106 185 125 121 120 260 DISHCARGE 139 INLET 174 168 172 162 163 164 166 167 188 Models Standard - 310, 340, 350 Special Brass - 310B, 340B, 350B Sleeved - 310S, 340S, 350S June 2012 310, 340 350 MATL 300 310 350 351 — — 30623 34155 33623 u 31163 30821 31821 u 31162 30696 33004 — 6107 NBR FPM HT EPDM* NBR FPM EPDM STZP STZP — — 310B, 340B 350B MATL 30623 34155 33623 u 31163 30821 31821 u 31162 30696 33004 — 6107 NBR FPM HT EPDM* NBR FPM EPDM STZP STZP — — 310S, 340S 350S MATL 30623 34155 33623 u 31163 30821 31821 u 31162 30696 33004 — 6107 NBR FPM HT EPDM* NBR FPM EPDM STZP STZP — — Kit, Seal (Inclds: 97,101,106,121,125) Kit, Seal (Inclds: 97,101,106,121,125) Kit, Seal, “Hi-Temp” (Inclds: 97,101,106,121,125) Kit, Seal (Inclds: 97,101,106,121,125) Kit, Valve, Preassembled (Inclds: 162-164,166-168,172) Kit, Valve, Preassembled (Inclds: 162-164,166-168,172) Kit, Valve, Preassembled (Inclds: 162-164,166-168,172) Plier, Reverse Socket, Seal Case (1/2” Drive) BD Motors - (See Individual Data Sheet) Oil, Bottle (21 oz.) ISO-68 Hydraulic (Fill to specified crankcase capacity prior to start-up) Bold print part numbers are unique to a particular pump model. Italics are optional items. u Silicone oil/grease required. R Components comply with RoHS Directive.[ ] Date of latest production change. *Review individual parts in each kit for material code identification. View Tech Bulletins 002, 003, 008, 024, 027, 032, 035, 036, 043, 045, 046, 049, 052, 053, 054, 073, 074, 077, 079, 083, 090, 105 for additional information. MATERIAL CODES (Not Part of Part Number): ABS=ABS Plastic AL=Aluminum BB=Brass BBCP=Brass/Chrome Plated CC=Ceramic CM=Chrome-moly CU=Copper D=Acetal EPDM=Ethylene Propylene Diene Monomer FBB=Forged Brass FCM=Forged Chrome-moly FPM=Fluorocarbon HS=High Strength HT=High Temp (EPDM Alternative) NBR=Medium Nitrile (Buna-N) POP=Polypropylene PTFE=Pure Polytetrafluoroethylene PVDF=Polyvinylidene Fluoride S=304SS SBCP=Special Brass/Chrome Plated SNG=Special Blend (Buna) STL=Steel STCP=Steel/Chrome Plated STZP=Steel/Zinc Plated ZZCP=Chrome Plated/Steel - Zamak 1 1 1 1 2 2 2 1 1 1 1 11.73 (298) 8.94 (227) 7.79 (198) 4.72 (120) 6.69 (170) 1.10 (28) 1.10 (28) .236 (6) .787 (20) (2) 3/8" NPTF DISCHARGE 2.75 (70) 4.23 (107) 1.46 (37) (2) 1/2" NPTF INLET 4 - M9 .31 (8) 3.15 (80) 3.78 (96) 4.44 (113) 10.0 (254) .62 (16) 5.24 (133) 2.79 (71) .79 (20) 4.92 (125) 1.22 (31) 4.92 (125) 4 - M8 Models 310, 340, 350, 310B, 340B, 350B, 310S, 340S, 350S 4 5 3 6 1 2 6 4 6 Model 310S Shown 1 Special concentric, high-density, polished, solid ceramic plungers provide a true wear surface and extended seal life. 2 Manifolds are a high tensile strength forged brass or special brass for long life, continuous duty and compatibility. 3 100% wet seal design adds to service life by allowing pumped liquids to cool and lubricate on both sides. 4 Stainless steel valves, seats and springs provide corrosion-resistance, ultimate seating and extended life. 5 Specially formulated, Cat Pump exclusive, Hi-Pressure Seals offer unmatched performance and seal life. 6 Precision, press-fit, 304 stainless steel sleeves in both the seal and valve chambers provide extended life (S models only). PN 993111 Rev M 6/12 12271