MODEL PATHWAYS IN LIGNIN THERMOLYSIS and

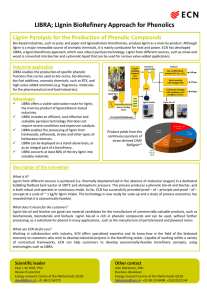

advertisement