Document 11130566

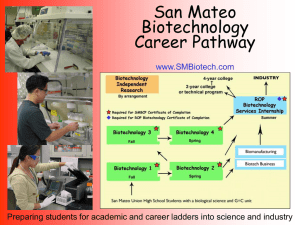

advertisement