Document 11129660

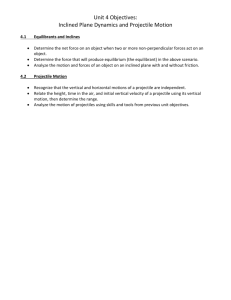

advertisement