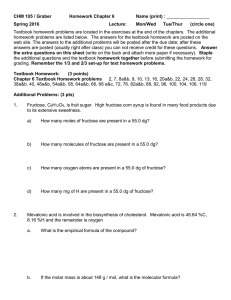

Photochemical treatment of flowback water for pentachlorophenol using UV-light and fructose

advertisement

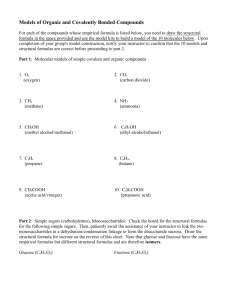

Photochemical treatment of flowback water for pentachlorophenol using UV-light and fructose Shaila Nayak, Sean-Erik O’Donnell, Saeed Keshani, Christopher Sales, Rohan Tikekar, Juan Muniz Center for Hospitality & Sport Management and Civil, Architectural & Environmental Engineering departments, Drexel University INTRODUCTION • Hydraulic fracturing process: Well stimulation technique in which rock is fractured by a hydraulically pressurized liquid (made of water, sand and chemicals). • Many concerns have risen over its potential environmental impacts such as groundwater contamination. • Flowback water: Water released within the initial two weeks following the hydraulic fracturing process. • This water is highly saline (about 15% w/v) and contains large number of organic contaminants exceeding their MCL. • Pentachlorophenol (PCP) has been detected at an average level of 33 µg/L in flowback waters. • PCP is carcinogenic and toxic to plants, animals and humans (causing mutations) • Fructose has shown significant reactivity upon exposure to 254 nm UV light. • Past studies have shown that UV exposure of fructose generates miscellaneous reactive oxygen species (ROS), however, characterization and identification of these species have not been done. • This is the first study that involves a novel use of fructose as a photo-catalytic compound for degradation of PCP in flowback water. Hydraulic fracturing process Flowback water Photochemical treatment For removal of organic contaminants For removal of solids and colloidal particles OBJECTIVES • To investigate and quantify the oxidative species generated during UV-light exposure of aqueous fructose solution • To degrade PCP using UV- light and fructose and compare it with UV- TiO2 system. RESEARCH POSTER PRESENTATION DESIGN © 2012 www.PosterPresentations.com MATERIALS AND METHODS 1) UV treatment of fructose solution (at λ= 254nm, I= 48 mW/cm2) a) Effect of pH on photosensitization by fructose Fructose solution in Fructose solution in distilled water phosphate buffer + 1µM Fluorescein dye solution (pH 6.7) + 1µM Fluorescein dye solution Bench top UV chamber RESULTS a) Effect of pH on photosensitization by fructose Sample Fructose in DW 10 mM 100 mM 500 mM Fructose in 10 mM phosphate 100 mM buffer of pH 500 mM 6.7 d) Photochemical degradation of PCP Fluorescein degradation Rate constant (min-1) 0.05±0.001 0.56±0.1 1.35±0.17 0.03±0.01 0.18±0.05 0.58±0.34 pH of 500 mM solution decreased from 5.79±0.01 to 3.53±0.25 Measure fluorescence of fluorescein at excitation/ emission λ= 485/510 nm b) Hydrogen peroxide generated by fructose b) Detection of hydrogen peroxide generated by fructose Ferrous oxidation- xylenol orange method (FOX assay) Xylenol orange + Ferrous sulfate + sorbitol + sulfuric acid + UV exposed fructose solution Measure absorbance at 560 nm using UV- Vis spectrophotometer c) Detection of singlet oxygen generated by fructose SOSG- EP UV exposed fructose solution + (endoperoxides) Singlet oxygen sensor green probe(SOSG) Measure fluorescence of SOSG- EP at excitation/ emission λ= 504/ 525 nm 2) Photochemical degradation of pentachlorophenol (PCP) a) PCP + Distilled water (DW) b) PCP + 500 mM fructose solution in DW c) PCP + 10% salt solution d) PCP + 500 mM fructose solution in 10% salt Bench top UV chamber λ=254 nm, I= 48 mW/cm2 Solution PCP degradation rate constant (min-1) Control 1 (Distilled water) 0.58 ± 0.08 Control 2 (10% salt solution) 500 mM fructose (in DW) 0.076 ± 0.03 500 mM fructose (in 10% salt) 125 mM TiO2 (in 10% salt) 0.47 ± 0.13 1.18 ± 0.03 0.139 ± 0.02 CONCLUSIONS Solution Fructose (in DW) Fructose (in buffer of pH 4.5) Fructose (in buffer of pH 6.7) Hydrogen peroxide generated after 7 min of UV exposure (µM) 63.7±1.11 52.91±1.07 67.08±1.08 c) Singlet oxygen generated by fructose • Fructose on exposure to UV light at 254 nm generates • Acidic species • Hydrogen peroxide • Singlet oxygen • These oxidative species are capable of degrading PCP in highly saline water at a rate that is 6.18 times faster than the control and 3.38 times faster than TiO2 REFERENCES • Aachen Elsinghorst, Rohan V. Tikekar (2014). Generation of oxidative species from ultraviolet light induced photolysis of fructose. Food Chemistry, 154, 276–281 • Can He, Xuhan Wang, Wenshi Liu, Elise Barbot, Radisav D. Vidic (2014) Microfiltration in recycling of Marcellus Shale flowbackwater: Solids removal and potential fouling of polymeric microfiltration membranes. Journal of Membrane Science, 462, 88–95 ACKNOWLEDGEMENTS Collect samples after every 1 min of UV treatment up to 4 minutes This research was supported by IExE Seed Grant and USDA-NIFA award. CONTACT HPLC for measuring PCP concentration Shaila Nayak. Email id: srn38@Drexel.edu Phone: 316-210-2500