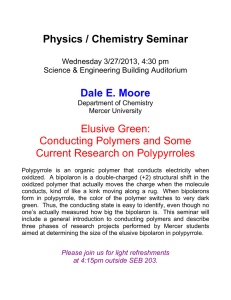

Fabrication and Use of Conducting Polymer

advertisement