PHYSICAL HAZARDS

advertisement

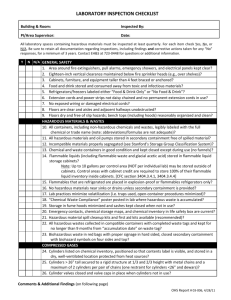

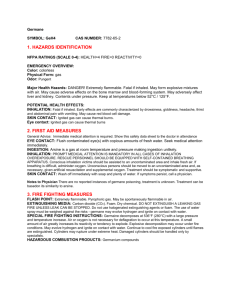

Summary 6 – Working With Laboratory Equipment Read Prudent Practices, Ch. 3 p57­61, Ch 6 p109­131 Read Safety in Academic Labs, p26­31 PHYSICAL HAZARDS Compressed Gases ­ If a compressed gas escapes, hazard can result from the flammability, reactivity, or toxicity of the gas. There is also the possibility of asphyxiation, and risk from rupture of the tank or valve. Nonflammable Cryogens (gases which have been liquefied by cooling well below room temperature ­ most cryogenic liquids are below ­150°C). When a small amount of cryogenic liquid is converted into gas, a very large volume of gas is created – thus there is the risk of explosion.. Cryogens can freeze flesh, causing painful blisters, much like a burn. Prolonged exposure can cause frostbite with pain occuring only when the flesh thaws. Flesh can stick to cold metals. High­Pressure Reactions ­ There is a risk due to explosion from equipment failure. Hydrogenation reactions are frequently carried out at elevated pressures and there is the additional risk of oxygen and hydrogen forming a pyrophoric mixture with the catalys. Supercritical fluids are generally at high pressures. Vacuum Work ­Injury may result from glass breakage – systems under vacuum should always be enclosed (wrapped in duct tape, enclosed in sturdy box, etc.). Precautions should be taken for toxic, flammable, reactive or corrosive materials in the event of a leak. Ultraviolet, Visible, and Near­Infrared Radiation ­ Ultraviolet, visible, and near­ infrared radiation from lamps and lasers in the laboratory can produce a number of hazards including eye damage and blindness within seconds. Appropriate protective equipment should always be used. Do not handle mercury arc lamps with your bare hands. Radiofrequency and Microwave Hazards ­ Extreme overexposure to microwaves can result in the development of cataracts and/or sterility. Microwave ovens are used in laboratories for organic synthesis and digestion of analytical samples. Use of metal in microwave ovens can result in arcing and, if a flammable solvent is present, in fire or explosion. Superheating of liquids can occur – never cap vials or fill them more than ¼ full because of the risk of explosion from pressure buildup within the vial. Inappropriately selected plastic containers may melt. Electrical Hazards – to avoid the risk of electrocution do not undo safety features which are built into electrical devices. All repair and calibration work on electrical equipment must be carried out by properly trained and qualified personnel. Always unplug electrical equipment before doing any work on it. Equipment malfunctions can lead to electrical fires. Everyone should know the location of electrical shutoff switches and/or circuit breaker switches and should know how to turn off power to burning equipment by using these switches. In the laboratory the insulation on wires can be eroded by corrosive chemicals and vapors. Eroded insulation on electrical equipment in wet locations such as cold rooms or cooling baths must be repaired immediately. In addition, sparks from electrical equipment can serve as an ignition source in the presence of flammable vapor. Loss of electrical power can result in dangerous situations. Warming freezers and refrigerators may release flammable or toxic; certain reactive materials may decompose energetically upon warming. Hoods may cease to function and to protect workers. Stirring required for safe reagent mixing may cease. Return of power to an area containing flammable vapors may ignite them. Outlet receptacles should be grounded – no two to three pronged adapters should be used in labs. Use of extension cords should be temporary. FIGURE 6.1 Standard design for a three­wire grounded outlet. A ground fault circuit interrupter (GFCI) disconnects the current if a ground fault is detected. GFCI devices are required by local electrical codes for outdoor receptacles and for selected laboratory receptacles located less than 6 feet (1.83 meters) from sinks. These devices differ in operation and purpose from fuses and circuit breakers, which are designed primarily to protect equipment and prevent electrical fires due to short circuits or other abnormally high current draw situations. Receptacles that provide electric power for operations in hoods should be located outside the hood so there are no electrical sparks inside the hood when a device is plugged in or disconnected. This also allows a laboratory worker to disconnect electrical devices from outside the hood in case of an accident. Cords should not dangle outside the where they can accidentally be pulled out or tripped over. Inspect cords monthly – organic vapors can erode rubber covered cords. Replace frayed or damaged cords before using. Overhead racks and floor channel covers should be installed if wires must pass over or under walking areas. Make sure water lines do not leak or produce condensation, which can dampen power cables nearby. Equipment plugged into an electrical receptacle should include a fuse or other overload protection device to disconnect the circuit if the apparatus fails or is overloaded. If organic vapors may be present only use nonsparking induction motors that meet Class 1, Division 2, Group C­D electrical standards (U.S. DOC, 1993) or air motors instead of series­wound motors that use carbon brushes. Do not use variable autotransformers to control the speed of an induction motor because such operation will cause the motor to overheat and perhaps start a fire. Do not use kitchen appliances (refrigerators, mixers, blenders, and so on) with such motors in laboratories where flammable materials may be present because they are not spark­free. When bringing electrical equipment such as vacuum cleaners and portable electric drills into the laboratory for special purposes, take specific precautions to ensure that no flammable vapors are present. Locate electrical equipment so as to minimize the possibility of spills onto the equipment or flammable vapors carried into it. Minimize the condensation that may enter electrical equipment if it is placed in a cold room or a large refrigerator. If electrical equipment catches on fire, shut off the power to the equipment immediately at a main switch or circuit breaker and unplug the apparatus. Everyone in the lab should know the location and operation of power shutoffs (i.e., main switches and circuit breaker boxes). If a person is in contact with a live electrical conductor, first disconnect the power source and then remove the person from the contact and administer first aid. Additional Safety Techniques for Equipment Using High Current or High Voltage Unless laboratory personnel are specially trained to install or repair high­current or high­ voltage equipment, such tasks should be reserved for trained electrical workers. The following reminders are included for qualified personnel. Always assume that a voltage potential exists within a device while servicing it, even if it is deenergized and disconnected from its power source. For example, a device may contain capacitors, which retain a potentially harmful electrical charge. · If it is not awkward or otherwise unsafe to do so, try to work with only one hand while keeping the other hand at your side or in a pocket, away from all conducting · materials. This precaution reduces the likelihood of accidents that result in current passing through the chest cavity. · Avoid becoming grounded by staying at least 6 inches away from walls, water, and all metal materials including pipes. · Use voltmeters and test equipment with ratings and leads sufficient to measure the highest potential Vacuum Pumps ­ The suction line from the system to the vacuum pump should be fitted with a cold trap to collect volatile substances from the system and to minimize the amount of material that enters the vacuum pump and dissolves in the pump oil. Refrigerators and Freezers The risks of laboratory refrigerators include vapors, the possible presence of incompatible chemicals, and spillage. Laboratory refrigerators should be placed against fire­resistant walls, should have heavy­duty cords, and should be protected by their own circuit breaker. The contents of a laboratory refrigerator should be enclosed in unbreakable secondary containers. The placement of potentially explosive or highly toxic substances in a laboratory refrigerator is strongly discouraged. Never store food or beverages in lab refrigerators. Magnetic Fields ­ The strength of a magnetic field decreases with distance from the source. Powerful magnetic fields are produced by NMRs and MRIs. Objects ranging from scissors, knives, wrenches, and other tools and keys to oxygen cylinders, and wheelchairs have been pulled from a considerable distance to the magnet itself, so care must be taken to keep ferromagnetic objects away from magnetic fields. Superconducting magnets use cryogenic liquid nitrogen and liquid helium for cooling. The health effects of electromagnetic fields are controversial. BIOHAZARDS ­ Biohazards are a concern in laboratories where microorganisms or material contaminated with them is handled, and are beyond the scope of this course. Cuts, Slips, Trips, and Falls ­ Cuts can be reduced by the use of personal protective equipment and following correct procedures (e.g., the procedure for inserting glass tubing into rubber stoppers). Spills can result in falls, thereby risking injury from both the fall and exposure to the spilled chemical. Heavy equipment or supplies stored on high shelves can lead to back injuries. Planning where to store difficult­to­handle equipment and containers (because of weight, shape, or overall size) can reduce the incidence of back injuries. Condensers ­ The use of cooling water can create a flooding hazard. Hose clamps and maintenance can reduce this problem. Heating Devices ­ Laboratory heating devices should be used with a variable autotransformer to control the input voltage by supplying some fraction of the total line voltage, typically 110 V, to the heating element of the device. Ovens ­ Ovens should not be used to dry any chemical sample containing volatiles that might pose a hazard because of acute or chronic toxicity. Most organic compounds should not be dried in a conventional unvented laboratory oven. To avoid explosion, glassware that has been rinsed with an organic solvent should not be dried in an oven until it has been rinsed again with distilled water. Hot Plates ­ Laboratory hot plates are normally used when solutions are to be heated to 100 °C or above and the inherently safer steam baths cannot be used as the source of heat. Heating Mantles ­ used for heating round­bottomed flasks. If the fiberglass coating is not worn or broken, and as long as no water or other chemicals are spilled into the mantle it poses no shock hazard. Heating mantles should be used with a variable autotransformer to control the input voltage and not plugged directly into a 110­V line to avoid overheating. Oil, Salt, and Sand Baths ­ avoid spilling water and other volatile substances into the baths which can splatter hot material and cause serious injuries. Oil baths must be well mixed to ensure that there are no ''hot spots." Heat Guns ­ frequently used to dry glassware or to heat the upper parts of a distillation apparatus during distillation of high­boiling materials. Heat guns almost always pose a serious spark hazard and should never be used near flammable liquids or vapors, or in hoods used to remove flammable vapors. Centrifuges ­ the load must be balanced each time the centrifuge is used and the lid be closed while the rotor is in motion. Use the break to slow down a centrifuge, never your hand. Rotating Equipment and Moving Parts Mechanical hazards also exist. Avoid wearing jewelry and loose clothes around moving parts. Cutting and Puncturing Tools – avoid injuries by keeping all cutting and puncturing devices fully protected. Don’t use razor blades as cutting tools, instead use utility knives. Needles and other sharp objects or instruments should be disposed of carefully rather than simply thrown into the trash bin unprotected. Noise Extremes ­ Any laboratory operation that produces significant noise (85 decibels or greater) requires a program to protect employees from excessive exposure Ergonomics and Lifting ­ Problems due to poor ergonomics include eyestrain, stiff and sore back, leg discomfort, and hand and arm injuries. Lifting injuries are one of the more common types of injuries for laboratory workers. Personnel who are at risk for lifting injuries should receive periodic training. WORKING WITH COMPRESSED GASES Compressed gas cylinders ­ > 40 psi at 21C or 104 psi at 54C. The Department of Transportation (DOT) has established codes that specify the materials to be used for the construction and the capacities, test procedures, and service pressures of the cylinders in which compressed gases are transported. Prudent procedures for the use of compressed gas cylinders in the laboratory include attention to appropriate purchase, especially selecting the smallest cylinder compatible with the need, as well as proper transportation and storage, identification of contents, handling and use, and marking and return of the empty cylinder. Identification ­ The contents of any compressed gas cylinder should be identified clearly. There should be a durable label that cannot be removed from the cylinder where the names of users and dates of use can be entered. All gas lines leading from a compressed gas supply should be labeled clearly to identify the gas, the laboratory served, and relevant emergency telephone numbers. The labels, in addition to being dated, should be color­coded to distinguish hazardous gases—that is, flammable, toxic, or corrosive substances coded with a yellow background and black letters—from inert gases, which are coded with a green background and black letters. If flammable gases are present they should be identified with signs and instructions. For example: HYDROGEN—FLAMMABLE GAS NO SMOKING­NO—OPEN FLAMES Handling and Use ­ The valve protection cap should be left in place until the cylinder is secured and ready for use. Cylinders should be transported on wheeled cylinder carts with retaining straps or chains. Compressed gas cylinders should be secured firmly at all times. A clamp and belt or chain, securing each cylinder middle to a wall or benchtop. In earthquake areas secure at the top and bottom. Pressure­relief devices protecting equipment that is attached to cylinders of flammable, toxic, or otherwise hazardous gases should be vented to a safe place. Cylinders, connections, and hoses should be checked regularly for leaks – soapy water can be used. If a leak at the cylinder valve handle cannot be remedied by tightening a valve gland or a packing nut, emergency action should be taken and the supplier should be notified. A self­contained breathing apparatus and protective apparel may be required, and personnel may need to be evacuated Pressure Regulators – reduce the pressure in the tank to the desired pressure, maintain the pressure and the desired flowrate. Each type of gas has its own pressure regulator to prevent mixing of incompatible gases – never force on a regulator. Standard cylinder­valve outlet connections have been devised by the Compressed Gas Association (CGA). In general, right­handed threads are used for nonfuel and water­pumped gases, and left­handed threads are used for fuel and oil­pumped gases. The cylinder valve should never be left open when the equipment is not in use. Flammable Gases ­ keep all sources of ignition away from cylinders of flammable gases and ensure there are no leaks. A solution of soapy water can be used to detect leaks. Connections to piping, regulators, and other appliances should always be kept tight to prevent leakage, and the tubing or hoses used should be kept in good condition. Cylinders should be grounded properly to prevent static electricity buildup. Empty Cylinders ­ A cylinder should never be emptied to a pressure lower than 172 kPa (25 psi) because the residual contents may become contaminated with air if the valve is left open. Empty cylinders should be clearly marked as empty (MT) and returned to a storage area for pickup by the supplier. Empty and full cylinders should not be stored in the same place. Pressure­Relief Devices ­ All pressure or vacuum systems and all vessels that may be subjected to pressure or vacuum should be protected by properly installed and tested pressure­relief devices. The use of glass or plastic equipment should be avoided with high pressure work.