Bottomless Culvert Scour Study: Phase I Laboratory Report Publication No. FHWA-RD-02-078

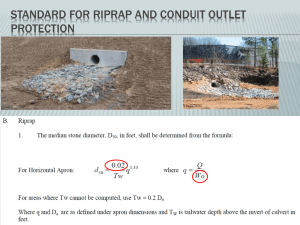

advertisement