Document 11105135

advertisement

A Fully Numerical Lifting Line Method for the

Design of Heavily Loaded Marine Propellers with

Rake and Skew

MASSACHUSETTS INSTTUTE

OFT"E0HNOLOLGY

by

Giovani Diniz

JUL 3 0 2015

Submitted to the Department of Mechanical Engineering

in partial fulfillment of the requirements for the degree of

LIBRARIES

Master of Science in Naval Architecture and Marine Engineering

at the

MASSACHUSETTS INSTITUTE OF TECHNOLOGY

June 2015

@ Massachusetts Institute of Technology 2015. All rights reserved.

Author ......

Signature redacted

e Ament of Mechanical Engineering

May 8, 2015

:5

A

Certified by...

Signature redacted

(

Stefano Brizzolara

Research Scientist and Lecturer

Assistant Director for Research MIT Sea Grant

Thesis SuDervisor

-

redacted

Signature

- -- -- -

A ccepted by ..........-

David E. Hardt

Chairman, Departmental Committee on Graduate Students

Department of Mechanical Engineering

..-. .-s..--

-

2

A Fully Numerical Lifting Line Method for the Design of

Heavily Loaded Marine Propellers with Rake and Skew

by

Giovani Diniz

Submitted to the Department of Mechanical Engineering

on May 8, 2015, in partial fulfillment of the

requirements for the degree of

Master of Science in Naval Architecture and Marine Engineering

Abstract

This thesis aims to give a contribution to the design of heavily loaded marine propellers by numerical methods. In this work, a wake-adapted, fully numerical, lifting

line model is used to obtain the optimum circulation distribution along the propeller's

blade via variational method, presented by Coney [9]. In this context, two approaches

to the representation of the wake field are compared: the first approach utilizes Betz's

condition for moderately loaded propellers, in which the wake is aligned with the hydrodynamic pitch angle. The second approach, in which the wake is aligned with the

local velocities, utilizes Kutta's Law to create a zero-lift wake surface. A thorough

comparison of the influence of the effect of tip vortex roll-up is done. A lifting surface

method with fully aligned wake is developed and used to correct the optimum distribution of pitch and camber obtained by the new lifting line method. The resulting

geometries geometries, operating under heavily-loaded conditions, are submitted to

a preliminary analysis in a boundary element-based potential flow code to verify the

consistency of the results. This analysis confirms the better results obtained with the

fully numerical lifting line model and the variations between the approaches in terms

of circulation and pitch angle observed in the lifting line results are verified. Finally,

the performance of propeller geometries generated with the approaches studied in this

work are compared by high fidelity RANSE analysis. The CFD simulations confirm

the higher accuracy of the method in which the wake geometry is aligned with the

local velocities in terms of fulfillment of thrust requirement.

Thesis Supervisor: Stefano Brizzolara

Title: Research Scientist and Lecturer

Assistant Director for Research MIT Sea Grant

3

4

Acknowledgments

First and above all, I would like to thank wife, Sara, for being my best friend and

source of inspiration and motivation and staying by my side through it all.

I would like to thank my dear friend, Guy, for reminding me the value of true

friendship and for being my confident through these years.

Our lunch breaks are

deeply missed.

To my advisor, Professor Stefano Brizzolara, I am deeply thankful for the opportunity to work in his laboratory, working to provide me the necessary funding to

support my studies and for the endless patience and will to help, especially during

the most difficult stages of this work.

Professor Henry Marcus, advisor of the MIT International Shipping Club, was

a great professional and personal mentor who I greatly admire and thank for the

countless advices throughout these two years.

I, finally, would like to thank Professor Hermano Krebs, for a warm welcome to

MIT and his invaluable advices on how to navigate in that brave new world that MIT

was two years ago.

5

6

Contents

1

Introduction

15

2

Circulation Optimization

19

3

4

2.1

Propeller Lifting Line Model . . . . . . . . . . . . . . . . . . . . . . .

19

2.2

Induction Velocity Functions . . . . . . . . . . . . . . . . . . . . . . .

21

2.2.1

HPA Induction Functions

. . . . . . . . . . . . . . . . . . . .

21

2.2.2

LVA Induction Functions . . . . . . . . . . . . . . . . . . . . .

23

2.3

Induced Velocities . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24

2.4

Variational Optimization . . . . . . . . . . . . . . . . . . . . . . . . .

25

2.5

Results and Discussion . . . . . . . . . . . . . . . . . . . . . . . . . .

27

2.5.1

Discretization . . . . . . . . . . . . . . . . . . . . . . . . . . .

28

2.5.2

H ub . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

29

2.5.3

Induced Velocities . . . . . . . . . . . . . . . . . . . . . . . . .

30

Wake Geometry

33

3.1

HPA Wake Geometry. . . . . . . . . . . . . . . . . . . . . . . . . . .

33

3.2

LVA Wake Geometry . . . . . . . . . . . . . . . . . . . . . . . . . . .

34

3.3

H ub

38

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chord and Thickness

41

4.1

Strength . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

41

4.2

Cavitation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

42

4.3

Methodology

43

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7

Results and Discussion . . . . . . . . . . . . . . . . . . . . . . . . .

.

4.4

43

45

5 Lifting Line Results

Convergence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

45

5.2

Induced Velocities . . . . . . . . . . . . . . . . . . . . . . . . . . . .

46

5.3

Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

46

5.4

Hub Radius . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

50

5.5

Rake and Skew . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

50

.

.

.

.

.

5.1

53

7

Lifting Surface Corrections

55

9

. . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

55

7.2

Results and Discussion

. . . . . . . . . . . . . . . . . . . . . . . .

58

.

.

Methodology

61

Results

Loading

61

8.2

Hub Radius

61

8.3

Rake . . .

63

8.4

Skew . . .

65

.

8.1

.

8

7.1

.

Blade Detail Geometry Definition

.

6

67

Verification

10 Validation

71

. . . . . . . . . . . . . . . . . . . . . . .

72

10.2 Heavily-Loaded Condition

. . . . . . . . . . . . . . . . . . . . . . .

73

.

.

10.1 Lightly-Loaded Condition

11 Conclusions

81

8

List of Figures

Design Methodology: both HPA and LVA approaches .

. . . . . .

17

2-1

Lifting line model. Bound and trailing vortices . . . . .

. . . . . .

20

2-2

Induced velocities on the lifting line

. . . . . . . . . .

. . . . . .

20

2-3

LVA scheme for the calculation of the induction function with Biot-

.

.

.

.

1-1

23

2-4

HPA discretization of lifting line . . . . . . . . . . . . .

29

2-5

HPA discretization of lifting line . . . . . . . . . . . . .

30

3-1

HPA model, shape of the trailed (fixed) vortex wake - CT = 1, J = 0.80,

.

.

.

Savart law .. . . . . . . . . . . . . . . . . . . . . . . . .

34

3-2

Local velocity alignment scheme . . . . . . . . . . . . . . . . . . . .

36

3-3

LVA model - CT

1, J = 0.80, wo = 0.1471 and KT = 0.253 . . . .

37

3-4

Comparison of wake cross-sections for HPA and LVA cases - CT

.

.

=

=

=

1,

0.80, wo = 0.1471 and KT = 0.253 . . . . . . . . . . . . . . . .

LVA model wake contraction -

.

J

3-5

.

. . . . . . . . . . . . . . . . . . . . .

wo = 0.1471 and KT = 0.253

CT =

1, J = 0.80, wo = 0.1471 and

.

K T = 0.253 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1

Chord and thickness distributions - CT = 1, J

=

38

0.80, KT = 0.253

.

and wo = 0.1471 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

44

Chord and thickness distributions - CT = 0.5, J = 1.13, KT = 0.253

and wo = 0.1471 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

4-2

38

9

44

5-1

Comparison of convergence of the optimum circulation searching algorithm between different design cases (with and without rake and skew)

and solution methods (LVA/HPA).

5-2

. . . . . . . . . . . . . . . . . . .

Comparison of induced velocities with CT = 1, J = 0.80, KT = 0.253

and wo = 0.1471 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-3

48

Comparison of optimum circulation and hydrodynamic angles /3 calculated by the two methods (HPA/LVA) at increasing loading

5-4

47

. . . .

49

Comparison of results for different hub radii: optimum circulation dis3 , right

tribution (G, left graphs) and hydrodynamic pitch angle (#

graphs ) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-5

51

Optimum circulation distribution - LVA method for cases with rake

and HPA/LVA no rake - CT = 1, J = 0.80, KT = 0.253 and wo = 0.1471 52

5-6

Optimum circulation distribution - LVA method for cases with skew

and HPA/LVA no rake - CT = 1, J = 0.80, KT

6-1

Blade outlines for HPA and LVA cases with CT

0.253 and wo = 0.1471

0.253 and wo = 0.1471 52

1, J = 0.80, KT =

. . . . . . . . . . . . . . . . . . . . . . . . . .

54

7-1

Lifting surface model . . . . . . . . . . . . . . . . . . . . . . . . . . .

56

7-2

Lifting surface geometry - CT = 1, J = 0.80, KT = 0.253 and wo =

0.1471 H PA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-3

57

Comparison of case with and without lifting surface corrections for

CT = 1, J = 0.80, KT = 0.253 and wo = 0.1471 for both HPA and LVA 58

7-4

Lifting surface corrections for camber for CT = 0.5, J = 1.13, KT =

0.253 and wo = 0.1471 HPA and LVA cases . . . . . . . . . . . . . . .

7-5

Lifting surface corrections for angle of attack for CT = 1, J = 0.80,

KT = 0.253 and wo = 0.1471 HPA and LVA cases . . . . . . . . . . .

7-6

Lifting surface corrections for angle of attack for HPA cases with CT

1, J = 0.80, KT

7-7

59

=

=

0.253 and wo = 0.1471, and various hub radii . . .

Lifting surface corrections for camber for LVA cases with CT

J = 0.80, KT = 0.253 and wo = 0.1471, and various hub radii

10

=

59

60

1,

. . . .

60

8-1

CT = 0.2, J = 1.80, KT = 0.253 and wo = 0.1471

62

8-2

CT = 0.5, J = 1.13, KT = 0.253 and wo = 0.1471

62

8-3

CT = 1, J = 0.80, KT = 0.253 and wo

8-4

Blade outlines for HPA cases with CT

=

.

. . . . . . . .

.

. . . . . . . . .

64

Blade outlines for LVA cases with CT = 1, J = 0.80, KT = 0.253 and

.

wo = 0.1471, with and without rake . . . . . . . .

8-7

63

0.80, KT = 0.253 and

.

1, J

. . . . . . . . .

. . . . . . . . .

.

8-6

=

63

1, J = 0.80, KT = 0.253 and

. . . . . . . .

Blade outlines for LVA cases with CT

wo = 0.1471, and various hub radii

. . . . . . . . .

.

8-5

=

0.1471

.

wo = 0.1471, and various hub radii

=

64

Blade outlines for LVA cases with CT = 1, J = 0.80, KT = 0.253 and

65

9-1

Panel method results for lifting line

69

9-2

Pressure coefficient distribution at different radii for the two propellers

.

wo = 0.1471, with and without skew . . . . . . . .

.

designed with HPA/LVA methods . . . . . . . . . . . . . . . . . . .

9-3

Comparison of optimum circulation distribution between propellers

with and without lifting surface corrections for the two HPA/LVA approaches .....

................

............

....

10-1 Pressure distribution for a lightly-loaded propeller - CT = 0.4, J =

.

. . . . . . . . . . . . . . . . . .

10-2 Propeller geometries obtained with the HPA and LVA approaches

.

.

1.26, KT = 0.253 and wo = 0.1471

10-3 Mesh of elements for CFD analysis for HPA case using approximately

.

1.8 million cells in computational domain . . . . . . . . . . . . . . .

10-4 Convergence of simulation for the HPA and LVA geometries.....

. . . . . . . . . . . . .

.

10-5 Pressure distribution for the HPA geometry

.

10-6 Pressure distribution for the LVA geometry . . . . . . . . . . . . . .

10-7 Helicity iso-surface (40m/s2 ) of the blades of the propellers designed

.

with the HPA and LVA approaches . . . . . . . . . . . . . . . . . .

. . . . . . . . . . .

.

10-8 Pressure field at leading edge of HPA geometry

.

10-9 Pressure field at leading edge of LVA geometry . . . . . . . . . . . .

11

10-10Pressure coefficients at blade sections at radii 0.3R and 0.8R, for the

two propellers HPA/LVA . . . . . . . . . . . . . . . . . . . . . . . . .

12

79

List of Tables

Comparison of results . . . . . . . . . . . . . . . . . . . . . . . . . .

.

9.1

68

10.1 Comparison of results from RANS analysis - CT = 0.4, J = 1.26,

. . . . . . . . . . . . . . . . . . . . .

.

KT = 0.253 and wo = 0.1471

10.2 Comparison of results from RANS analysis - CT

1, J = 0.80, KT =

. . . . . . . . . . . . . . . . . . . . . . . . .

.

0.253 and wo = 0.1471

=

72

74

13

I

14

MAP-

Chapter 1

Introduction

The lifting line model was first devised for the wing problem by Prandtl [19] and

later extended to the case of the marine propeller by Betz [2].

In his work, Betz

showed the condition for the optimum distribution of circulation along the lifting line

which Sparenberg [20] later proved to be a general result in the case of lightly loaded

propellers in inviscid, uniform flow.

Lerbs [16] extended the theory for the case of non-uniform inflow and for moderatelyloaded conditions, making use of the velocity potentials presented by Kawada [13].

Morgan [17] and Eckhardt and Morgan [11] contributed on the improvement of the

calculations of the optimum distribution of circulation and Wrench [22] introduced

asymptotic formulae for fast and accurate calculation of induced velocities.

Recent developments have continued to contribute to the improvement of lifting

line based models. Brizzolara et. al [5] revisited Lerb's original theory for contrarotating propellers incorporating modern propeller design techniques. Brizzolara [3]

explored the effects of tip-vortex roll-up and wake contraction for the analysis problem

of a propeller using a boundary element method approach.

The significance of the effects of tip-vortex roll-up and wake contraction, especially

at highly-loaded conditions, has also been explored in the works of Brizzolara et al.

[4], with attention to hub effects, and by Aran and Kinnas [1], with regards to the

adequacy of Betz's condition in the design of heavily-loaded propellers. These works

demonstrate that the shape of the optimum circulation obtained with local velocity

15

alignment may significantly differ from that obtained using the Lerbs (1952)-Wrench

(1965) method.

In the present work, a variational method, such as that presented by Coney [9],

is used to obtain the optimum circulation distribution on the propeller blade, and an

approach to the design of marine propellers is investigated focusing on the alignment

of the wake with local velocities in order to capture the effects of tip-vortex rollup and wake contraction into the optimization algorithm.

The effects of rake and

skew are also considered in this method in which induced velocities are calculated

by direct application of Biot-Savart's Law and chord and thickness distribution are

optimized using combined strength and cavitation criterion with application of the

method presented by Brizzolara et. al. [5].

The effects of rake, skew, loading and hub radius are tested and compared against

results obtained with models based on Betz's condition. Hence, in this study, two

approaches to model the lifting line are presented: the first, based on Betz's condition,

assumes a rigid alignment of the wake with the hydrodynamic pitch angle and will be

referred to as Hydrodynamic Pitch Angle Alignment approach, or HPA; the second

approach, based on the implication of Kutta's Law for a non-lifting surface, makes

sure that the wake is aligned with the local velocities. This approach will be referred

to as Local Velocity Alignment approach, or LVA.

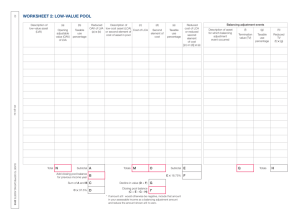

The method developed and systematically tested in this work is that of the diagram of figure 1-1, in which the optimization of circulation is achieved through

an iterative procedure, followed by the optimization of the chord and thickness distributions and the alignment of the wake. Upon convergence, the blade geometry

characteristics is defined and lifting surface corrections are calculated and applied to

the initial geometry to obtain the final blade shape.

Present study focuses on the comparison between the results obtained using the

HPA and LVA approaches.

The former follows the current state of the art in ma-

rine propellers design by numerical methods, while the latter, features the proposed

contribution towards an improved lifting line - lifting surface design method.

These improvements aimed to extend the current methods' capabilities to ac-

16

curately design marine propellers under heavily-loaded conditions and to take into

account for the effects of rake and skew in early design stages.

Lifting Uine

FVh

and

Geo

Lake

etry

Calculate

Velocites

Induced

Indu fielocities

at

Pa Optimize Circulation

Distribution

ake

Optimize Chord

and Thickness

Distributions

Covrgence

Criteria

Definition

Surface

CLifting

Corrections

_

Propeller

Geometry

Figure 1-1: Design Methodology: both HPA and LVA approaches

The geometries obtained with both approaches are then analyzed with a boundary

element method to verify the consistency of the results and their performance are

also validated through high fidelity numerical simulations by means of a state of the

art Reynolds Averaged Navier-Stokes (RANSE) equation solver to verify compliance

with design criteria.

17

18

Chapter 2

Circulation Optimization

2.1

Propeller Lifting Line Model

The idealized lifting line model of a screw propeller represents the blades as radial lines of distributed bound vortices which provide the total required thrust and

prescribe the pitch angle of each section. In the context of inviscid, incompressible,

potential flow theory, Kelvin's Theorem is satisfied by including a series of trailed

(free) vortex lines shed from the lifting line and extending to infinity downstream of

the propeller.

In the continuous case, at each radial position r of the lifting lines, the bound

vorticity has strength F(r), and the vorticity of the shed vortex lines, Ff(r), must

satisfy 2.1.

rf (r) = dF(r)d

dr

(2.1)

In a right-handed cartesian coordinate system, with positive values of the X-axis

increasing upstream of the propeller and positive values of the Z-axis increasing towards the free-surface. Passing from the continuous theoretical model to an approximate discrete numerical model, a discreet model is idealized by a set of M discrete

vortex segments on the lifting line, as in figure 2-1 (for one single blade of the model).

Each horseshoe element, m, positioned at radius r(m), is composed of a bound

19

vortex line with piece-wise constant strength of F(m) and an upper and a lower free

vortex line shed from the edges of the bound vortex lines, with constant strength

ff(m), given by 2.2.

m

(m + 1) - IF(m)

17 (m) =

1 ,2,...,M

(2.2)

Figure 2-1: Lifting line model. Bound and trailing vortices

The lifting line segments and the free vortex lines shed from them are subject to

inflow axial velocity, Va(r), and tangential velocity, wr + Vt(r). The inflow is perturbed

by the self induced axial velocities, u,(r), and self-induced tangential velocities, ut(r),

composing the generalized velocity profile experienced by each section of the blades

shown in the diagram in figure 2-2 below.

ua

Ut

D

V

L

Vinflw

Va

T

Ft

r + Vt

r

Figure 2-2: Induced velocities on the lifting line

20

Each section experiences the generation of lift forces, L, perpendicular to the total

inflow velocities, V, and drag forces, D, parallel, to the inflow velocities. These forces

combined are projected to the global coordinate system to define the thrust, T, given

by each section, and the tangential force, F, that, multiplied by the radius, yields

the torque,

Q,

consumed by that section.

The inflow velocities prescribe the uncorrected hydrodynamic pitch angle, 3 (defined as the ratio between the inflow velocities), and the corrected hydrodynamic pitch

angle,

i (defined as the ratio between the inflow velocities and induced velocities),

as in 2.3 and 2.4, respectively.

tan /3(r)

tan Oi(r) =

2.2

Va(r)

wr + Vt(r)

Va(r) +una(r)

Va (r) + 1(r)

Wr + Ut (r) + V (r)

(2.3)

(2.4)

Induction Velocity Functions

In this work, the induction functions are defined as the velocities induced by a

vortex line of unit strength and are used in the variational optimization to obtain the

optimum circulation distribution.

The real induced velocities are the velocities induced by a vortex line with a given

circulation strength coming out as a result of the optimization procedure.

2.2.1

HPA Induction Functions

The calculation of induction functions for the hydrodynamic pitch alignment approach was made through the use of Wrench's [22] formulae, for the axial component,

ia(m, i), and tangential component, at (m, i), of the velocity induced at the lifting

line collocation point i, positioned at r(i), by a unit strength trailing vortex line m,

shed from the bound vortex located at radius r(m).

21

These velocity components are defined as 2.5 and 2.6, in the case where the collocation point's radius on the lifting line are smaller than the radius of the point which

the helicoidal free vortex line is detaching from.

ia(m, i) =

Z

4irre

6, (rn, i) =

(y - 2.z.y.yo.F1)

(2.5)

2Z2(yo.F1)

(2.6)

27rre

In the case where the collocation point's radius on the lifting line are greater than

the radius of the point which the helicoidal free vortex line is detaching from are

calculated by means of equations 2.7 and 2.8.

Z2

Ua(m,i) =

dt (m, i) =

27rr,

(2.7)

(y.yo.F2 )

(1 + 2.z.yo.F2)

47rr,

(2.8)

Where, F and F2 are functions defined as in equations 2.9 and 2.10.

F 1 =-

F

1

2zyo

F2=ui2zyo

i

I1

U

+

U

U- I

2. (

-a2

+

+

U_

1

U_

U -)]

(2.9)

(2.10)

In which, ai, a2 , U, y and yo are defined as:

a1 =

a2 =

I

24z

9y

y

(2.11)

1+hy 2

2

+2

(1 + y2)1.5

22

3y2-2

2

(1 + y2)1.5

(2.12)

U

=

YO(---y2-1

( +-y2,

_ 1)

exp

1+ y2 -

+ y02

trc

(2.14)

1

(2.15)

r, tan /3

Yo

2.2.2

(2.13)

tan 3j

LVA Induction Functions

Consider a single vortex line shed downstream of the propeller, as in figure 2-3.

The induction functions for the local velocity alignment approach are calculated by

direct application of Biot-Savart's Law, in which the velocity induced at the lifting

line collocation point i, positioned at r(i), by a unit strength trailing vortex line m,

shed from the bound vortex located at radius r(m), are defined as 2.16.

y

Figure 2-3: LVA scheme for the calculation of the induction function with Biot-Savart

law.

n(m, i) = -I Idl x S

23

(2.16)

The calculation of the induction functions via Biot Savart's Law is quintessential for

the purpose of this work in terms of including the effects of wake alignment, rake and

skew into the circulation optimization algorithm. The asymptotic formulae proposed

by Wrench [22] offer the convenience of fast computational time and accuracy in the

lightly-loaded case, but inherently neglect the alterations of the wake geometry under

heavily-loaded conditions and the induced velocities of the lifting line on itself.

This numerical way of calculating the self-induced velocities is, perhaps, the most

important element contributing to the differences (presented in the next sections) in

circulation and hydrodynamic pitch angle due to rake and skew of the propeller blade.

2.3

Induced Velocities

Induction functions are used as input parameters to the optimization algorithm,

as described in the following section, to obtain the circulation distribution along the

radius of the blade.

Once this is done, the induced velocities at the lifting line collocation point i,

positioned at r(i), due to all trailing vortex lines shed from the bound vortices are

calculated by means of equations 2.17 and 2.18 for both HPA and LVA cases.

M

Ua(i)

=

F(m)1Ta(m, i)

(2.17)

i)

(2.18)

m=1

M

ut(i) = )

F(m)'t(m,

m=1

The total inflow velocities, V(m), at each radius, r(m), are thus the vector sum of

all axial and tangential velocities experienced by the section. Its modulus is, hence,

defined by equation 2.19.

V(m) =

[Va(m) + ua(m)]2 + [Vt(m) + wrc(m) + ut(m)]2

24

(2.19)

2.4

Variational Optimization

In this study, the variation method proposed by Coney [9] is used to find the

optimum circulation distribution on the lifting line in which the propeller's thrust

and torque are calculated from the elemental lift force, L, calculated on each bound

vorticity segment by the Kutta's 2.20.

L = pIP x V

(2.20)

Developed thrust, T, and absorbed torque, Q, are obtained by numerical integration

of the lift forces generated at each section, as defined in equations 2.21 and 2.22,

obtained when decomposing the expression for V into its components.

M

T

=

pZ E

[(Vt(m) + wrc(m) + ut(m))] I7(m)Ar

(2.21)

M=1

M

2V (Va(m)

- pZ

+ ua m)) c(m)Cdv(m)Ar]

M=1-

M

Q

[(V1(m) + wrc(m) + ut(m))] ]F(m)r(m)Ar

pZ

(2.22)

m=1

M

[2 V (Va(m)

M=1

+ ua(m)) c(m)Cd(m)r(m)Ar

-

-

- pZ

In accordance with the calculus of variations, an auxiliary function, H, is defined,

as in 2.23, by adding to the torque to be minimized the adjoint term which results

from the multiplication of the so called Lagrange's multiplier A times the difference

between the calculated thrust T and the required value T,.

H = Q + A(T - T)

25

(2.23)

Taking the expressions of the partial derivatives of H, with respect to the unknowns

Fi and Lagrange multiplier, one obtains the system of equations that permits to find

the optimum circulation distribution to maximize efficiency (minimizing torque) while

respecting the constraint of the required thrust.

OH

=H0

ari

=Va(i).r(i)Ar

M

+ 1

[F(m) ii (i, m)r(m)Ar + F(m)Pa(m, i)r(i)Ar]

M=1

(2.24)

+ A [Vt (i) + wr(i)] Ar

M

[F(m)'it(i, m)Ar + F(m)it (m, i)Ar],

+ A1

1

m=

for i = 1, 2, ... , M

OH

OA

0

Tr

(2.25)

M[M

+ pz E

Vt(m) + wr(m) + I3 F(n)t (n, 0)Ar F(m)Ar

m=1

.

n=1

The unknowns in 2.24 and 2.25 are the M strength values of the bound vortices,

1(m), plus the scalar value of the Lagrange multiplier, A, composing a non-linear

system of equations to be solved.

2.24 and 2.25 are non-linear system which is linearized by rewriting these expressions assuming an initial value for the Lagrange multiplier, A, and the tangential

induced velocities, u*. Then the expressions for the partial derivatives of the auxiliary

function H become 2.26 and 2.27.

=

Va(i).r(i)Ar

M

[F(m)ia(i, m)r(m)Ar + F(m)Pa(m, i)r(i)Ar]

+

m=1

(2.26)

+ A [Vt(i) + wr(i')] Ar

+

I

[F(m)ft(i, m)Ar + r(m)lit(m, i)Ar]

,

0

M=1

for i =1, 2,..., M

26

M

T, = pz 13 [Vt(m) + Wr(m) + ztAr + u*(m)] F(m)Ar

(2.27)

M=1

Viscous drag is considered in the optimization algorithm. This force is defined as

in equation 2.28, in which, c(r) and CD,(r) are the chords and two-dimensional drag

coefficient of the sections, respectively.

1

2

One can then substitute T for (T - F,) in 2.23 and carry on the partial derivatives

to account for a deduction in thrust, making 2.27 become 2.29.

M

Tr

pz E3 [V,(m) + wr(m) + ftAr + u* (m)] F(m)Ar

m=1 M(2.29)

+ Ipz E

VW*(m) [Va(m) + u*(m) ] c(m)Cd(m)Ar

M=1

The solution of this linear system (i.e. the values of ri and A) is used to obtain

the new values of u* by equation 2.18 and to update the value of A.

This step is

repeated typically for not more than 6 iterations to reach convergence.

Once the values of A and u* are calculated, the system is recalculated, and so

forth, until convergence.

During these iterations, however, the wake is kept frozen and no changes are made

to the induction functions. So, it is necessary to perform an outer iteration algorithm

that, starting from the initial wake geometry, converges to the final aligned wake,

which gives the final induced velocities.

This procedure is important to ensure the convergence of the method, especially at

higher loading conditions (i.e. CT >1.0), and essential to avoid tip loaded solutions,

as argued by Coney [9].

2.5

Results and Discussion

The operation conditions for all cases presented hereinafter, are given in form of the

thrust coefficient, CT, the advance ratio, J, mean wake coefficient, wo, and propeller

27

thrust coefficient, KT, defined in 2.30 - 2.32, respectively, where R is the propeller's

radius and VA = Vs(1 - wo).

p=R

C

o

pr R2 y2

(2.30)

VA

J = N.D

KT =

(2.31)

Tr

TD

pN2D4

(2.32)

The application cases considered in this work regard a 5-bladed, z

=

5, with a

diameter D = 5[m].

2.5.1

Discretization

The discretization of the lifting line and the wake trailing vortex lines is assumed

to be uniform, as all Ar in the formulae are not functions of the radius.

Figure 2-4 (CT = 1, J = 0.80, KT = 0.253 and wo = 0.1471) shows the results

obtained from a convergence study on the number of elements.

The distribution

of the optimum circulation and of the hydrodynamic angle, 1i along the radius for

M = 15, 20, 25 where there is virtually no difference between the results of the

method, and, therefore, unless otherwise mentioned, M = 15 elements will be used

in all results presented in the rest of the study.

In spite of the equivalence of the formulae presented here with the case of a

cosine spacing discretization, showed by Coney [9], the cosine spacing applied in

this work caused erratic behavior of the numerical method, significantly affecting the

convergence and accuracy of the results, which was not experienced otherwise.

This problem was related to sudden jumps in values of induction functions, for

both HPA and LVA approaches, due to the reduced distances between trailing vortex

lines at the tip.

In order to use a cosine distribution, the expression of Biot-Savart kernel, used

to calculate the induction functions for the LVA approach, have to be changed to

28

0.016

Circulation

,75,

Hydrodynamic

-e-- M = 15

-~M=20

e-

0.014

Pitch Angle

-e-M = 15

70

M = 25

M=

25

66

0.012

60

55

00

45

0.008

40

-

0.006

35

0.2

04

03

05

06

07

0.2

09

08

03

04

05

0

07

0.8

09

1

Figure 2-4: HPA discretization of lifting line

a Rosenhead-Moore kernel (i.e., replacing 1/(IS11)

3

by 1/(JII112+62) , in equation

2.16). This workaround solved the convergence problem but introduced an additional

parameter 3 on which the circulation results are highly dependent.

Therefore, the uniform spacing of lifting line and wake trailing vortices was adopted

through this work, and the results of the method are restricted to a linear spacing on

the lifting line but also highly insensitive to the number of elements, M, utilized to

discretize it.

2.5.2

Hub

The presence of the hub incurs in additional terms to be considered in the optimization algorithm, as indicated in the work of Coney [9]. On one hand, the induction

functions must account for the influence of the image of lifting and trailing vortex

lines, and on the other hand, the expression of forces must account for an additional

hub drag caused by and dependent on the finite circulation at the root of the blade.

The induction functions are calculated using the same formulae utilized for the

wake trailing vortices, 2.5-2.8, for the HPA approach, and 2.16, for the LVA. Hence,

the induced velocities, including the hub, become 2.33 and 2.34.

M

Ua(i) =

, r(m) (fa (m, i) + 9a(ma, i))

m=1

29

(2.33)

M

Ut(j)

=

(2.34)

F(m) (it (m, i) + ft(m

E

m=1

According to Wang [21], a Rankine vortex structure is the appropriate model to

represent the hub. The integration of the pressure field due to the Rankine vortex

structure yields to the additional hub drag, 2.35, proportional to the square of the

circulation at the hub and a function of the hub vortex core radius, ro.

Fh=

167r

(2.35)

log-+ 31 F

ro

If the hub is to be considered in the optimization, equation 2.35 must be included

in 2.21 of thrust for the optimization algorithm, in similar manner as the viscous drag

on each blade has been previously considered.

2.5.3

Induced Velocities

In order to validate the induction functions calculated with the Biot-Savart Law,

defined in 2.16, a hydrodynamic pitch aligned wake (HPA wake geometry) was utilized

to calculate the circulation distributions using Wrench's asymptotic formulae and the

direct application of Biot-Savart's Law.

Circulation

HP

0.015

0 014

iot

0

var-

Hydrodynamic

Pitch Angle

e- HPA-wrenci,

HPA-B t Savart

HPA~~fl~

70 -A

-

-

0013

65

--

0

-

0012

0011

-

0.01

45

-

0009

40

0 008

-

35

0007

0 006

02

-

13

3

03

04

05

06

07

08

09

1

02

03

04

05

06

Figure 2-5: HPA discretization of lifting line

30

07

08

09

As shown in figure 2-5, the results are exactly the same for a propeller with CT = 1,

J = 0.80, KT = 0.253 and wo = 0.1471. So it is concluded that in the HPA approach

the calculation of the induction functions are interchangeable.

Although the method to calculate the induction functions in the HPA cases does

not influence the results, all HPA cases will use Wrench's asymptotic formulae in

this work, unless otherwise mentioned, in order to maintain consistency with current

state of the art referred to in this work and to explicitly present the differences

found between the method currently used to design marine propellers and the method

proposed in this work.

31

I

32

Chapter 3

Wake Geometry

The geometry of the free vortex lines shed downstream of the lifting line are not

known a priori and, in general, should be calculated as part of the solution of the

design problem.

Betz [2] showed that the optimum distribution of circulation was

obtained when the pitch angle of the helicoidal wake trailing vortices is that equal to

the hydrodynamic pitch angle calculated at the lifting line.

Betz's condition is the predominant assumption in all modern propeller design

codes 1 and is used by most authors and propeller designers. This assumption, also

used by Coney [9], is replicated here in the HPA approach to highlight the differences

between this and the LVA method proposed in this work.

3.1

HPA Wake Geometry

Betz's condition, 3.1, has been extensively utilized and studied to model the wake

field and has proven to be suitable to design propellers operating in moderatelyloaded conditions. The helicoidal shape of the free vortex lines are generated keeping

a constant pitch (the corrected hydrodynamic pitch, 3) along the free vortex lines

shed downstream of the blade, according to Lerbs [16].

1such as MIT-PLL,

by Kerwin [14], OpenPROP, by Brenden Epps [12] among others

33

1

tan

tan31

7-1w(r)

(3.1)

1 -- wo

Figure 3-1 shows the lifting line model created using Betz's condition to generate

the propeller wake geometry.

Figure 3-1: HPA model, shape of the trailed (fixed) vortex wake - CT = 1, J

wo = 0.1471 and KT = 0.253

3.2

0.80,

LVA Wake Geometry

A more generalized condition to be assumed on the wake trailing vortices is that

each vortex line should not generate any lift forces. Therefore, in accordance with

Kutta's Law, each segment of the wake must be aligned with the total local velocities

to generate zero-lift forces, as in equation 3.2.

L = p IF x V = 0

(3.2)

The velocity field is composed of the inflow and induced velocities calculated by

means of direct application of Biot-Savart's Law as in 3.3.

U =

_,

4H

JIS-113

34

(3.3)

In the cartesian coordinate system, the velocity components are as in 3.4, where

UX'Y'z are the three components of the induced velocities and 0 is the angle between

the Z and Y coordinates of the control points.

V = (Va + ux)z + (V - w.r. sin 0 + uy)J + (w.r. cos 0 + u,)k

(3.4)

The M + 1 trailing vortices are subdivided into a discrete number N of segments,

and consequently, N + 1 nodes. The coordinate of each node is represented as Xi (M)

and the length of each segment, 6'.

The alignment scheme consists of an iterative procedure. At first, the total velocity

at the midpoint of the segment, 0(m), is calculated and used to determine the new

position of the next point on the vortex line, X'

i+1

(m), by means of 3.5.

.

This points, however, may not be same as the next point in the vortex line, Xi+ 1

Hence, the equivalent displacement between the points, 6 = X'1 (m) - Xi+1 (M) is

calculated and subsequently applied to all points downstream of the starting row (see

figure 3-2(a)).

Once all points of all trailing vortex lines are corrected, the procedure moves on

to calculate the induced velocities in the second row of elements (see figure 3-2(b))

and apply the equivalent displacements to all points downstream of the second row,

and so forth all nodes composing the wake geometry are shifted.

- i+1

X'

(m) = Xi(m) + 6s fi~m

I

for: m

1,2,...,M

and: i

1,2,..N

P()

11(3.5)

In simple words, the algorithm aligns the wake elements with the local velocities

and adjusts the shape of the remaining row of points to match the shape of the parent

row, one row at a time.

In this manner, the variations obtained from the initial geometry are propagated

downstream in a controlled fashion which allows the convergence of the solution. The

35

rii+1\X.1

ri

V,

(M)

X'.I (mk

(a) Step 1

VI.1

X,+ 1

+M

r,

X,+2 (M)

rt

(b) Step 2

Figure 3-2: Local velocity alignment scheme

36

wake geometry generated with this scheme is shown in figure 3-3, is the same propeller

of figure 3-2, i.e. with CT = 1, J = 0.80, wo = 0.1471 and KT = 0.253.

Ati

Figure 3-3: LVA model - CT = 1, J = 0.80, wo = 0.1471 and KT = 0.253

A view of the cross-sections of the wake, for both the HPA and LVA cases, are

shown in figure 3-4 in which the development of the tip vortex roll-up can be clearly

seen starting at about a quarter turn downstream of the lifting line and becoming

fully developed (third curve from right to left) after one complete turn of the wake.

It is worth noting the sections displayed are not evenly spaced nor their heights

reflect the real Z-coordinates of the points actually used for the computation. Each

shape represents a row of points the points in the wake grid. This representation is

ideal for the visualization the shape of the roll-up development but tend to hide the

wake contraction.

The real wake shape reveals the contraction of the wake between consecutive

complete turns of the wake downstream of the blade and it is clearly seen in figure

3-5. At the second complete turn of the wake, a contraction of nearly 4% in diameter

is obtained for a propeller with CT = 1, J = 0.80, wo = 0.1471 and KT = 0.253.

37

Wake Cross-Sections - HPA

3

2.5

'K

-

2

1.5

-

1

0.5

-10

12

-6

-8

-4

-2

0

-4

-2

0

x

Wake Cross-Sections - LVA

3

2.5

1.5

-

2

1 --10

'12

-6

-8

Figure 3-4: Comparison of wake cross-sections for HPA and LVA cases - CT

=

1,

J = 0.80, wo = 0.1471 and KT = 0.253

Figure 3-5: LVA model wake contraction

KT

=

3.3

-

CT

1, J

=

0.80, wo

0.1471 and

0.253

Hub

The propeller hub is modeled by an image vortex method ideally extending infinitely

downstream of the lifting line, while in practice it is approximated with a sufficiently

long extension, i.e., comprising the extent of the wake trailing vortex lines in the

proposed numerical model.

Kerwin and Leopold [15] modeled the image vortex lattice with hub trailing vortex

38

lines positioned at a radii, re, given by equation 3.6, in which, rt, are the radii of the

free vortices at the wake of the propeller.

2

=

-r

L

rt

(3.6)

The authors also showed that the hub image of vortex lines, positioned as above,

should be aligned with the pitch angle given by 3.7 in order to satisfy the impervious

condition of the hub's surface, i.e., null normal velocities at the hub radius.

tan Ov = tan ##r

(3.7)

In the LVA approach, however, the wake lines are not aligned with the hydrodynamic pitch angle, so the alignment of the hub images is performed with the local

pitch angle of each segment in an attempt to hold the condition above as close as

possible to its true meaning.

An alternative approach to avoid this problem would be to model the hub by a

distribution of potential flow singularities (sources or vortices) on the hub surface

through, similarly to what it is done in boundary element methods.

Coney [9] proposed this other method and showed the equivalence of results between the two. In this work, the image vortex method was utilized but the panel grid

should be considered for future development in order to improve the convergence of

the methods featuring larger hub radii, or hubs with variable radii.

39

40

Chapter 4

Chord and Thickness

The method utilized in this work to optimize the chord and thickness distribution

follows the work of Brizzolara et. al.

[5].

In that work, the determination chord

and thickness distributions is performed based on a veery efficient combination of

strength and cavitation criteria proposed by Connolly [10] and Castagneto e Maioli

[8], respectively.

The aim of using these criteria simultaneously is to define chord

and thickness distributions that both provide enough structural strength to the blade

while avoiding the development of cavitation.

4.1

Strength

The semiempirical method proposed by Connolly utilizes the blade bending moment

stresses, -r, and radial centrifugal stresses, a7, defined as in 4.1 and 4.2, respectively,

to define the state of stresses at the propeller's blade.

In 4.1, A 1 and A 2 are tabulated coefficients which are functions of radial position of

the section, R is the propeller's radius, T and

Q

are the developed thrust and torque,

and, the product of the chord and the square of the section's maximum thickness,

ct 2 , represents the section inertia modulus.

2

-,ct =A

R.K

Z

27rR

A1 P T +A2- Q4.1

R

41

(4.1

In 4.2, i and 4 represent the rake and rake angle, respectively, C1 and C2, are

tabulated values, and n is the propeller's rotational speed.

Oc =

n2.R 2

1010

C +

i RC2

t C

s

~Tons

in 2 1

)

(4.2)

The total radial stress is assumed as the sum of both bending moment and centrifugal stresses and is restricted to a fraction 1/K.Krob of the yield stress of the

blade's material as in 4.3.

In this equation, K, is the safety factor and

Krob

is a

calibration factor to weigh the strength over the cavitation criterion, according to

Brizzolara et. al [3].

9c +

, 5

aam =

(4.3)

Ks.Krob

Replacing 4.3 into 4.4, one obtains

[R.K

ct2 =A1

z

4.2

2 1rR

P

T+A2- Q]

R

(4.4)

Gam -

O'c

Cavitation

For cavitation inception, Castagneto e Maioli use a simplified calculation of the

minimum pressure coefficients, C7""n, on each section of the blade and compare it

with the cavitation number, uo, and a safety factor for cavitation Kp, as in 4.5.

Kpor

(4.5)

=CP"a"

The minimum pressure coefficient is estimated by the semiempirical formula 4.6,

in which the h values are tabulated and CLf and CL, are the portions of the lift

coefficient due to camber and angle of attack, respectively.

C

=P

+ h1CLf + h 2 -C + h3CLa

42

1

(4-6)

-

--- -

Defining p = CLf/(CLf)CL),

x

1/V./_ and knowing that CL

CLf + CL,

equation 4.6 can be rewritten as 4.7:

x 3 (h2 V/t 2-+ [(hip + h3(1

4.3

-

p)) CLC + ( -

/1 + Ko-o)

0

(4.7)

Methodology

Since the strength and cavitation criterion depend on interrelated variables, the

chord and thickness optimization problem is solved iteratively. Initially, the centrifu.

gal stresses are assumed null, and equation 4.4 is solved for the section's modulus ct2

Equation 4.7 is solved for x, which defines the section chord, c, and, with the section

modulus, the thickness, t.

The centrifugal stresses are then calculated by means of 4.2 and are included in

equation 4.4, and so forth until the convergence of the method. Brizzolara et. al. [3]

also note the necessity of constraining the minimum tip thickness (around 3%) and

thickness over chord ratio at the root of the blade (no more than 15%) and it is up

to a design criteria to define the proportion of lift generated due to camber and angle

of attack, p, and the safety factors, K, and Kp, and the tuning factor, Krob.

4.4

Results and Discussion

Using the methodology presented above, the chord and thickness distributions for

a propeller under lightly-loaded condition (CT = 1, J = 0.80, KT = 0.253 and

wo = 0.1471, and Kp = 0.75, K, = 5 and K,,b = 1.2, using the HPA and LVA

approaches) is presented in figure 4-1.

While in figure 4-2 are displayed the results for a propeller operating in heavilyloaded conditions (CT

=

0.5, J = 1.13, KT = 0.253 and wo = 0.1471 and Kp = 0.75,

K, = 5 and Krob = 1.2, using the HPA and LVA approaches).

43

0.

Chord-Olameter Ratio

2

Thickness-Chord Ratio

025

-e- HPAI

-,LVA

0. 21

0.2

-

02

0. 19

0 15

-

0. 18

17

0.1

0. 16

0. 15

005

-

0.

13

0.

02

03

04

05

0.6

07

0,8

0.9

02

I

0.3

0.4

05

0.6

0.7

0.8

0.9

Figure 4-1: Chord and thickness distributions - CT = 1, J = 0.80, KT = 0.253 and

wo = 0.1471

Chord-Diameter Ratio

0.14

Thickness-Chord Ratio

0.26

1I9HPAI

A LVAI

0.13

-LVA

0.2

0.12

0.11

r

01

.

0.09

015

0.08

005

0.07

0'

0.2

0.3

04

05

0.6

07

0.8

09

1

02

03

0.4

05

06

xr

07

08

09

1

Figure 4-2: Chord and thickness distributions - CT = 0.5, J = 1.13, KT =-0.253 and

wo = 0.1471

The first case presents significantly large chords at the tip of the propeller, highlighting the effect of the cavitation inception criteria, constraining the minimum chords

at sections under high velocity inflow. In the second case, the propeller operates at a

lightly loaded condition. In this case, the chords at the tips are greatly reduced and

the root thicknesses are significantly larger, highlighting the predominant strength

criteria constraining the section modulus at the root.

44

-

- .........

.

Chapter 5

Lifting Line Results

The results obtained using the HPA and LVA approaches are presented here in

order to highlight the capabilities of the novel LVA approach and draw preliminary

conclusions from the comparison of the results (namely, circulation and hydrodynamic

pitch angle) obtained with the two approaches.

This will be done via sensitivity analysis of the results to a systematic variation of

loading conditions (i.e. thrust coefficient), hub radius and rake and skew distributions.

The study is intended to correlate these parameters with the effects of tip vortex

roll-up and wake contraction, eventually considering how the optimum circulation is

affected by them, in a series of propeller design cases.

At this point, it is worth noting that the totality of current lifting line propeller

design methods (based on Lerb's or Wrench's definition of induced velocities) can

not consider skew and rake and they are eventually recovered in the lifting surface

correction stage of the design.

This is another major advantage of the proposed

method, which consider both these important geometry modification right at the

first step of the design when the optimum circulation distribution is computed.

5.1

Convergence

The convergence of the iterative search for optimum circulation distribution (Chapter 2) is nearly monotonic for all cases considered, as can be seen in figure 5-1. The

45

criteria for convergence is imposed as the relative error between consecutive iterations

constrained to a maximum tolerance of 0.1%.

For HPA cases, even at heavily-loaded conditions, the method required no more

than 4 iterations to achieve convergence with specified tolerance. LVA cases, on the

other hand, whilst also nearly monotonic, achieved convergence in no more then 10

iterations for the same imposed tolerance level.

5.2

Induced Velocities

Figure 5-2 displays the induced velocities calculated at the lifting line of the test

case propeller with CT

=

1, J = 0.80, KT = 0.253 and wo = 0.1471, comparing:

induced velocities using HPA and LVA cases (see figure 5-2(a)); the solution between

a skewed propeller and one without skew using the LVA approach (see figure 5-2(b));

and, the solution between a raked propeller and one without rake using the LVA

approach (see figure 5-2(c)).

From these results, one can infer the strong dependence of the results on the

assumption utilized to describe the wake geometry (i.e., the differences between HPA

and LVA approaches) and the inclusion of both rake and skew in the calculation of

the induced velocities.

5.3

Loading

The comparison of the results obtained between the HPA and the LVA approaches

in terms of the loading of blade shows significant differences between them in both

the distributions of circulation and hydrodynamic pitch angle.

As a general rule, including the effects of tip vortex roll-up and wake contraction

into the optimization algorithm (LVA approach), compared to the HPA approach,

yields circulation distributions that are greater at the root and smaller at, and close,

to the tip.

In terms of the hydrodynamic pitch angle even more significant differences between

46

Relative Gamma Error

Relative Gama Error

2

[%)

[%I

0 _________________________________

--------

-1

-

-2

2

---

-4

3

-6

.8

-1

1.2

1

1.8

1.6

14

2

2.2

26

24

2

1

3

28

4

3

Relative TamBtal Error [%)

Reative TntBtal Error

5

6

7

5

6

7

[%]

-2

2

-3

.4

-6

.5

14

1.2

1

2

18

16

22

28

26

24

3

4

iterhton

3

1

(b) LVA

(a) HPA

Relative Gamma Error [%)

0

-4

-

Rolative Gamma Error [%]

2

-6

-/

3

-1

12

14

I

2

3

4

5

6

7

a

1

9

15

2

25

3

35

4

45

5

4

45

5

Relative Tanietal Error [%J

Relative TanBtIal Error J%I

1

0

0-

-2

-2

3

3

1

15

2

25

(d) LVA

(c) LVA 20' rake

3

35

500

skew

Figure 5-1: Comparison of convergence of the optimum circulation searching algorithm between different design cases (with and without rake and skew) and solution

methods (LVA/HPA).

the methods are observed. Neglecting tip vortex roll-up and wake contraction seems

to underestimate the necessary pitch at nearly every section of the blade to produce

the necessary thrust.

An important aspect of these results is that, as the load on the blades increases,

the negligible differences between the lightly-loaded case, (Ct = 0.2, figure 5-3(a)),

47

Axial

-

3

-

Induced

Velocit es

-+- HPA

-HPA

|--LVAJ

-0.9

IN-

03

-,-LVA

-0.8

2,5

0.2

Tangential induced Velocities

07

0.4

0.5

06

07

00

14

09

2

0.3

04

05

06

0.7

0.8

09

08

09

0

09

(a) Comparison of induced velocities between HPA and LVA approaches

Tangential Induced Velocities

Axial Induced Velocities

-

3

-e- LVA

- -LVA-skew 52-

-e- LVA

-s-- LVA-skew

506

0 5

2

15

.5

05

0

0.2

03

0.5

0.4

0.6

Xf

0.7

0.8

0.9

1

02

03

04

05

07

06

XT

(b) Comparison of induced vel ocities with and without skew

Axial Induced Velocities

-e- LVA

---LVA-rake

-

3

201

Induced Velocities

--- LVA-rake 206

-

1-

0

-

-14

-

15

-

-1.6

-

-

2

Tangential

LVA

---

S-1

02

03

0.4

05

06

07

08

0.9

1

802

03

04

05

06

07

1

(c) Comparison of induced velocities with and without rake

=

become apparent at the heavily-loaded condition (Ct

1, figure 5-3(c)).

=

1, J

0.80, KT = 0.253

Figure 5-2: Comparison of induced velocities with CT

and wo = 0.1471

=

This is an essential fact and a validation criteria of the LVA approach, once it is

known (and proved theoretically) that the velocity profile at lightly-loaded conditions

should satisfy Betz's condition and, hence, the fact that there is virtually no difference

48

Hydrodynamic Pitch Angle

Circulation

+HPA

F--ALVA

-e-HPA

I

0.014

70

LVA _

-

0016

65

60

0012

55

-

0,01

50

45

0008

40

0006

351

02

002

1

-

0004

03

04

0.5

0.6

Xr

07

08

09

1

0.3

O03

05

0.4

04

05

06

06

xr

09

09

00

0.7

0.8

0.7

(a) CT = 0.2, J = 1.80, KT = 0.253 and wo = 0.1471

HPA

-e-A-LVA

--HPA

-A-LVA

Go

-

Hydrodynamic Pitch Angle

Circulation

0025

55

-50

0.02

S45

40

0015

35

F

07

08 05-

30

25

0.01

02

0

3

04

0.5

06

07

08

I

0.2

0.9

0.3

0.5

04

06

07

08

09

1

(b) CT = 0.5, J = 1.13, KT = 0.253 and wo = 0.1471

Hydrodynamic Pitch Angle

Circulation

SHPA

SLVA

-e-HPA

-ALVA

5

50

0.03

45

a40

0025

35

30

0.02

25

20

0012

0.2

03

04

05

06

07

0.8

(c) CT = 1, J =

0.2

09

0.80, KT

=

03

03

04

0.4

0.253 and wo

00

05

=

0006

07

0,7

00

08

05

0,9

1

1

0.1471

Figure 5-3: Comparison of optimum circulation and hydrodynamic angles 3i calculated by the two methods (HPA/LVA) at increasing loading

between the methods seen in 5-3(a) is reassuring of the coherence of the results

obtained with the LVA approach.

49

5.4

Hub Radius

The geometry of the propeller may also feature a wide range of hub radii. Figures

5-4(a) and 5-4(b) display results using the HPA and LVA approaches, respectively,

for several non-dimensional hub radii

(xrh

= 0.2, 0.275, 0.35).

The results show significant variation in terms of circulation distribution for both

HPA and LVA approaches, and nearly no difference in terms of hydrodynamic pitch

angle.

The difference of the optimum circulation, as the next sections will show,

determines the distribution of lift on the blades and will define the distributions of

camber and angle of attack along the span of the blade and generate considerably

different geometries.

In addition, the proportion of lift generated by either camber or angle of attack is

directly related to cavitation inception, as discussed in Chapter 4, and highly impacts

the efficiency of the propeller, especially under heavily-loaded conditions, so these are

important differences to be accounted for.

5.5

Rake and Skew

Following a systematic variation of the rake and skew distributions and using the

heavily loaded case, CT= 1, J

=

0.80, KT = 0.253 and wo = 0.1471, the results

obtained in terms of circulation and hydrodynamic pitch angle are presented in figure

5-5 and 5-6.

Figure 5-5 shows the comparison between the results of a propeller with no rake,

given by the HPA and LVA approaches and two propellers with 4D = 10 and 20 [deg].

The rake of the blades tends to decrease the circulation at lower sections and increase

it at higher sections, closer to the tip. The presence of rake, however, does not seem

to affect the hydrodynamic pitch angle distribution.

Figure 5-6 shows how increased skew angle Os = 300 and 50' tend to increase the

load at the root and relieve the tip of the propeller, and, at the same time, increase

the pitch at the root and reduce it at the tip.

50

Circulation

0.ooo

Hydrodynamic

= 0.2

rh - 0.275

- -rh = 0.35

Pitch Angle

-e- rh = 0.2

A rh = 0.275

e rh = 0.35

-e -rh

.5

0.032

-

0.034

50

003

45

0.028

-

40

CD 0.026

35

0.024

30

0.022

25

002

20

0.018

0.016

0.: 2

0.3

04

005

(a)

06

CT

07

= 1, J

0,8

5

02

09

0.3

0.80, KT = 0.253 and wo

04

05

00

07

08

09

0.1471 - HPA

Circulation

Hydrodynamic Pitch Angle

-e- rh= 0.2

1 rh = 0.275

-- rh - 0.35

-e- rh = 0.2

-rh - 0.275 _

-- e- rh = 0.35

55

-

0035

45

35

-

0025

-

-0

0.03

-

30

25

C

2

0.3

04

0.5

06

0.7

38

-

0.02

02

09

0.3

04

05

06

08

07

0.9

(b) CT = 1, J = 0.80, KT = 0.253 and wo = 0.1471 - LVA

)

Figure 5-4: Comparison of results for different hub radii: optimum circulation distribution (G, left graphs) and hydrodynamic pitch angle (0j, right graphs

In both figures above, the results using the HPA approach were included to highlight the significant variations between the conventional method currently used in

industry and academia. These results reiterate the importance of accounting for the

effects of rake and skew distributions into the circulation optimization and provide

reasonable, consistent results offer interesting insights for further investigation on this

matter.

51

Circulation

. + HPA

-e- HPA

-,LVA

-e-- LVA - rake19

-- LVA - rake 20

0.035

Hydrodynernic Pitch Angle

60

55

-a-LVA

-

-'

0

e-

LVA - rake 10

--

LVA - rake

2

0

1

45

003

40

0.025

35

30

002

25

0.015

20

0.01

1

02

03

0.4

0.5

06

07

0.8

15 1

02

0.9

03

04

05

0M

07

08

1

0.9

Figure 5-5: Optimum circulation distribution - LVA method for cases with rake and

HPA/LVA no rake - CT = 1, J = 0.80, KT = 0.253 and wo = 0.1471

1

0035

-e-

HPA

---

LVA

e

Circulation

1

1

Hydrodynamic Pitch Angle

60

1

55

LVA - skew 30

- -LVA - kew 501

50

-e--e-

HPA

LVA

LVA - skew

. +

LVA - skew

3

0

5

0

1

-

0503

45

40

03 0025

35

-

30

25

0 02 -~

20

(77

15

02

03

04

05

00

07

08

0.2

0.9

03

0.4

0.5

0.6

0.7

0,8

0.9

1

Figure 5-6: Optimum circulation distribution - LVA method for cases with skew and

HPA/LVA no rake - CT = 1, J = 0.80, KT = 0.253 and wo = 0.1471

52

Chapter 6

Blade Detail Geometry Definition

Once convergence is achieved, the initial geometry of the propeller, that is, the

initial distribution of camber, angle of attack and geometric pitch angle, is obtained.

The circulations, F(r), and chords, c(r), are used to define the lifting coefficient of

each section, by means of equation 6.1.

_21'(r)

CL(r)

r(r)

V(r)c(r)

(6-1)

The lift generated at each section is due to both camber and angle of attack. In

order to ensure a sufficient margin to face cavitation, it is good practice to assume

that a proportion p = 90% of the total lift is generated by camber and the remaining

lift by angle of attack.

Hence, the angle of attack can be defined by equation 6.2, in which the slope of

the CL - a curve of the foil is assumed constant and equal to 2.

C (r)=(-p)

2.7r

(6.2)

The maximum camber of the section is defined by equation 6.3, in which Kt and Kf

are the coefficients defined by Castagneto and Maioli [8], and t(r) are the maximum

thicknesses of each section.

53

f (r)

c(r)p.cLi(r)

=

(6.3)

(Kf (1 + Kt('))

In this work, a NACA16 thickness distribution and mean line a = 0.8 are used and

the geometry of each foil that defines the sections of the propeller in the HPA case

with CT

=

1, J = 0.80, KT = 0.253 and wo = 0.1471 are presented in figure 6-1.

Camber-Chord Ratio

Angle of Attack

0.55

0.028

F-e-HPA

-a-LVA

0026

0.024

045

0022

04

0.02

0.35

0018

03

0016

0.25

02

0.3

04

05

0.6

0.7

08

02

0.9

012

03

0.4

Figure 6-1: Blade outlines for HPA and LVA cases with CT

0.0

=

06

0.7

0.8

09

1, J = 0.80, KT = 0.253

and wo = 0.1471

In general, the solution of HPA cases seems to present significantly higher camberchord ratios and angle of attack values, compared compared to the LVA approach,

especially in proximity of the hub.

54

Chapter 7

Lifting Surface Corrections

7.1

Methodology

Having defined the initial geometry of the blades, corrections on angle of attack

and maximum section camber can be made by modeling the geometry of the propeller

by zero thickness lifting surfaces, as proposed by Morgan [18]. In this model, shown

in figure 7-1, horseshoe elements are positioned along the chord of the blade and free

vortex lines are shed downstream, similar to the lifting line model. Assuming a zerothickness blade section, the boundary condition at each radius is the impermeability

of the surface, and, hence, equation 7.1, must be satisfied.

a(r) +

Of (r, xc)U

OXCe

)

-

[

V

(r, Xc)

U

(r)]

V

(7.1)

In 7.1, xc correspond to the chord-wise coordinate a point in section at radius r,

Un is the normal components of the velocities induced by lifting surface at that point

and U is the normal components of the velocities induced by the lifting line.

Defining the non-dimensional circulation as G = F/7rVaD, each horseshoe element

positioned along the chord has non-dimensional strength Gr(r, 6) (where 6 is the

polar angle of that point), which, if integrated along the chord of each section, must

be equal to the total circulation given by the lifting line, as in equation 7.2.

55

Figure 7-1: Lifting surface model

rOt

(7.2)

G,(r, 0)d9

G(r, 9) =]

In order to satisfy Kelvin's theorem, the strength of the circulation of the free

vortex lines, Gf (r, 0), are given by equation 7.3.

Gf (r, 9) = -

dr

dr

(7.3)

dr

Substituting equation 7.2 into 7.3, one obtains:

-

ddr - Gr(r, 01) d r - Gr(r, Ot) dr

(7.4)

+

Gf (r, 9)

From which the induced velocities are then calculated by means of direct application

of Biot Savart's Law, as in 7.5.

il(P) =

GC(r, )

2

_. ddr +

S11 3

56

Gf (r, 9) S_.

2S|1

ddr

3

(7.5)

After some algebraic manipulations, one can obtain the expression for the normalized induced velocities from the lifting surface in equation 7.6, where U/V are the

induced velocities as calculated from the lifting line.

z.

G,(r,0) SX- ddr

+

S-n

The new mean line of each section is reconstructed through the alignment of each

II SV1

Al

Vr Vr

segment with the total inflow velocity (including the velocities calculated by the lifting

surface) by means of equations 7.7 and 7.8, respectively.

f(r,xc) +xca(r)=

-~c[U

dO

(7.8)

The geometry of the lifting surface, shown in the example of figure 7-2, is used to

perform the given calculations for section camber and angle of attack.

Figure 7-2: Lifting surface geometry - CT

HPA

1, J =0.80, KT =0.253 and w0

57

0.1471

Results and Discussion

7.2

The comparison of the angle of attack and camber distributions between a case

corrected for lifting surface and an uncorrected one is displayed in figure 9-3(a), for

the HPA approach, and in figure 9-3(b), for the LVA approach.

This comparison shows the significant increase in angle of attack and a modest

variation in camber defined by the lifting surface corrections. As shown in figure 7-3

the difference in angle of attack for a heavily-loaded case is extremely important.

Angle of Attack [dag]

Camber-Chord

00241

LS

Ratio [m]

-HPA

-7-

-HP

-

LS

022A

-

002

4

0016

-

0018

0 0142

0 012

0.01

C2

0000

0.2

03

0.4

05

0.6

07

0.8

0,9

1

04

0.3

0.5

06

0,7

08

0,9

(a) Comparison of angle of attack distribution between corrected and uncorrected HPA cases

,Angle of

,

7

Attack [deg]

Camber-Chord

Ratio [m]

-e- LVA

-

F-- -LV-A

--- LVA

- LS

0.022-

6

LVA - LS

0.-2-

002

0.018

4

0.016

3

0.014

0.012

001

02

0.3

0.4

0.5

0.6

0.7

0.8

0.008

1

0.2

0.9

0.3

014

05

06

017

08

089

(b) Comparison of angle of attack distribution between corrected and uncorrected LVA cases

Figure 7-3: Comparison of case with and without lifting surface corrections for CT

1, J = 0.80, KT = 0.253 and wo = 0.1471 for both HPA and LVA

58

The differences between the HPA and LVA cases are also significant, especially in

terms of angle of attack. As seen in figure 7-4, the difference between the results of the

corrections for camber are somewhat minor and follow the same trend but displaced

slightly higher for the HPA case. The corrections for angle of attack, however, show

the opposite, with the LVA results being much higher than the HPA results, as seen

in figure 7-5.

I .1o'4

Camber Correction-Chard

Ratio

.

Camber-Chord Ratio [m]

0022

F --- - -, A-

0.02

0

0.018

0016

0014

-3

0,012

0 010.2

03

04

05

06

07

08

09

0.2

0

Figure 7-4: Lifting surface corrections for camber for

04

3

CT

0.5

0.6

07

08

0.9

= 0.5, J = 1.13, KT = 0.253

and wo = 0.1471 HPA and LVA cases

Angle of Attack (deg]

Angle of Attack Correction [deg]

-HPA

--- LVAI

-- LVA

5

5

3

40

0.2

-

-

4

03

0.4

05

0.6

07

08

10,2

09

0.3

0.4

05

06

Figure 7-5: Lifting surface corrections for angle of attack for CT

KT = 0.253 and wo = 0.1471 HPA and LVA cases

59

017

08

0.9

1, J = 0.80,

The lifting surface corrections are also influenced by the hub radius of the design.

For a propeller with CT = 1, J = 0.80, KT = 0.253 and wo = 0.1471, the variation

of angle of attack with hub radius is shown in figure 7-6 in the HPA case, and the

variation of camber in LVA case, shown in figure 7-7.

Angle of Attack [deg)

Angle of Attack Correction [deg)

~A-

-

5

rh - .2

rh - 0.275

rh -0.35

5

-

-9--e-

-+-

5-a-rh

e-

rh rh =

0.2

0.275,

0.5

4.5

4.5

4

3.5

0,

3.5

3

2.5

2.5

2

2

1.5

1.5

0.512

02

47

093

04

05

0.6

07

08

0.8

1

03

02

0.4

05

07

0.6

08

Figure 7-6: Lifting surface corrections for angle of attack for HPA cases with CT

J = 0.80, KT = 0.253 and wo = 0.1471, and various hub radii

10

10,a

--n

Camber-Chord

Camber Correction-Chord Ratio

Ratio

1

09

=

1,

[m]

0

0.024

08 0.275

- -rh- .35

-02

-e-

0.022

rh :0275

rh -0.35

002

-04

0.018

-06

0.016

'1

0,014

-08

0.012

001