Shipboard Power Management Using Constrained Nonlinear Model Predictive Control

advertisement

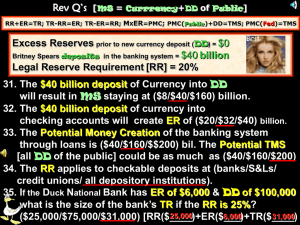

Shipboard Power Management Using Constrained Nonlinear Model Predictive Control Philip Stone and Daniel F. Opila GE Power Conversion Pittsburgh, PA USA Hyeongjun Park and Jing Sun University of Michigan Ann Arbor, MI, USA Abstract— Both new and existing naval vessels of all sizes face ever-increasing power supply requirements to support advanced mission loads including high power sensors, weapons, and launchers. Adding additional conventional generators to support these loads is infeasible given size and weight constraints and given the pulsed nature of those new loads. Instead, an optimization-based Power Management Controller (PMC) is used to dynamically control power system sources and loads in real time in order to serve system needs with a minimal amount of power supply equipment. In this paper, a Model Predictive Control (MPC) approach is used to dynamically coordinate sources and loads based on future demand. A cost function is used to prioritize various ship goals and objectives, and constraints are added to reflect hardware limitations. A Constrained Nonlinear MPC algorithm is then used to minimize the cost over a finite future horizon and generate control commands in real-time. The PMC is demonstrated to successfully control and improve system performance on a hardware test bed for ship power system research. I. INTRODUCTION The power generation capacity of a shipboard power system is inherently restricted by the weight and footprint limitations of a ship hull. Modern advanced defense systems such as the air and missile defense radar (AMDR) [1], electromagnetic rail guns [2], electromagnetic launch systems [3], and solid-state and free electron lasers [4] represent high power electrical loads that are beginning to place a high demand on the limited capacity [5]. As the respective technologies mature, these weapons are becoming increasingly critical to countering hostile surface, air, and missile targets and maintaining state-ofthe-art offensive capability should it be necessary. Many of these weapons are typically pulsed with a demand on the order of seconds [4]. However, the sum of the total power capacity of each of these weapons plus the ship service loads could quickly exceed the power generation capacity of the ship and thus limit the number of weapons that can be installed unless the available generation capacity is intelligently allocated. To enable the effective employment of multiple high power weapons within the ship power system, a power management controller (PMC) is essential. A shipboard PMC dynamically coordinates the ship power sources (main generators, auxiliary generators, UPS devices, energy storage modules, etc.) and loads to most effectively provide power to the weapons only when they need it. The PMC thus enables multiple high power weapons, a reduction of system mass/volume through reduction Steve Pekarek and Ray DeCarlo Purdue University West Lafayette, IN, USA Eric Westervelt, James Brooks, and Gayathri Seenumani GE Global Research Center Schenectady, NY, USA of power generation requirements, and reduced troop levels due to automated decision-making. The proposed PMC approach employs model predictive control (MPC) [6] that resides at a supervisory level to provide power to loads as they need them while optimizing ship performance. MPC considers a known model of the plant (the ship and its loads/weapons) and looks ahead over a prediction horizon to determine the optimal control references to provide to the local controllers of the power system elements. In this way the PMC can prepare the power system for a short-term high power weapon by taking preemptive action such as ramping up generators, ramping non-vital loads, charging energy storage devices, and reconfiguring the system so as to optimize system performance and deliver the requested power at the required time of the high power pulse (weapon firing). This concept of a PMC is not limited to future ship arrangements with multiple high power weapons. Among other capabilities, existing sophisticated ship power managers can reconfigure breakers and add or shed sources and loads based upon pre-defined load priorities and following a set of rules [7]. The proposed PMC can do these things as well as other tasks such as tracking optimal efficiency points for multiple gas turbine generators to decrease fuel consumption and thus cost. The predictive PMC considers the defined goals and priorities of the ship to ramp up/down generation sources and enforce/relax load demands as necessary on-the-fly. The model predictive approach enables the PMC to look ahead as far as the established prediction horizon and begin compensating for pulse loads before they actually occur and then gracefully recover. Instead of installing a surplus of energy storage modules on a ship, the PMC can coordinate a reduced number of modules along with existing generation capacities to accommodate the ship load demands. The proposed PMC is demonstrated on the medium voltage DC test bed for ship power system research at Purdue University and this test bed is described in Section II. The MPC approach as it pertains to a shipboard PMC is discussed in further detail in Section III. The proposed PMC is tested by establishing a baseline behavior and then attempting to improve that behavior by adjusting the relative priorities of the ship goals with two successive test cases. The test cases for demonstrating the effectiveness of the PMC on the test bed are outlined in Section IV. The testing results are presented and analyzed in Section V. Conclusions regarding the level of success in employing the MPC approach to shipboard power management are discussed in Section VI. II. TEST BED FOR SHIP POWER SYSTEM RESEARCH In order to validate research relative to ship power systems a medium voltage (MV) DC test bed has been constructed at Purdue University [8]. A one-line diagram of the portion of this test bed used for testing the proposed PMC is shown in Figure 1. The system consists of two sources totaling 70 kW of capacity and three loads connected in parallel to a 750 V DC bus. Generation system 1 (GS-1) consists of a four quadrant dynamometer serving as the prime mover (PM-1) that regulates a 59 kW wound rotor synchronous generator (SG-1) to 1800 rpm. AC-DC conversion is performed by a passive diode rectifier (R-1) and the field voltage of the generator is controlled by a voltage regulator (VR-1) to control the output voltage. GS-1 is intended to represent the prime ship power source such as a main gas turbine generator (GTG) set. Generation system 2 (GS-2) consists of a four quadrant dynamometer that regulates the speed of an 11 kW permanent magnet synchronous generator (SG-2) to 3600 rpm. AC-DC conversion is performed by an IGBT-based active rectifier (R2) and the output voltage of the generator may be controlled through the active rectifier by a voltage regulator (VR-2). Alternatively, the PMC may provide a power command to the GS-2 which is then translated to a torque/current command at the local level. GS-2 is intended to represent a smaller, faster ship power generation source such as a diesel generator. The primary load on the system is the ship propulsion system (SPS) which consists of a propulsion drive (PD) and a 37 kW induction machine (IM). A dynamometer typically regulates the IM speed to the rated 1800 rpm, but for PMC Figure 2. Square wave pulse power load (SWPPL) profile. testing the speed will be regulated to 900 rpm limiting the effective maximum propulsion power to 18.5 kW. The PD consists of an IGBT-based inverter with speed and torque control modes; the latter is employed for PMC testing. The pulse power load (PPL) emulates a pulse-power weapon with an energy storage buffer between the load and DC bus. A buck converter charges a capacitor from the bus until a threshold voltage is reached at which time the capacitor disconnects from the bus and discharges into a resistive load. Thus the pulse profile as seen by the bus is a ramp that increases from 0 to 8 kW in ~10 seconds. To place an even greater burden on the system, the square wave pulse power load (SWPPL) may be utilized. The SWPPL consists of a high power buck converter (PS-1) that steps the voltage down to 500 V across a purely resistive load. The SWPPL can sink up to 8 kW for 1 second on, 1 second off intervals for up to 7 cycles before needing time to recover thermally. The profile as seen by the bus can be seen in Figure 2. The PMC testing will only consider the more severe SWPPL as a disturbance to the system. The PMC is implemented in MATLAB Simulink and is converted to real-time-compatible code via Simulink Coder to reside on a B&R 810 industrialized PC. This PC interfaces with the test bed components via a common network switch. The PMC functions in real time using the MATLAB xPC kernel and communicates using the user datagram protocol (UDP). The GS-2 and SPS receive power commands from the PMC via the switch and convert those power commands first to torque commands and then to inverter current commands which they attempt to track using hysteresis control. Each component provides the necessary measurements (e.g., rotor speed, electrical power, mechanical power, DC voltage) back to the PMC via the same switch. Figure 1. Purdue MVDC test bed one-line diagram. The GS-1 is treated as a slack generator by the PMC. Only the droop gain (DGS1) of the voltage controller is exposed as a control input to the PMC. The GS-1 provides the power necessary to balance the power on the bus such that the sum of the power sourced by the GS-1 and the GS-2 is equal to the sum of the power sunk by the SPS and the SWPPL. The PMC thus has three controls: the GS-1 droop gain command DGS1, the GS-2 power command PGS2*, and the SPS power command PSPS*. III. MODEL PREDICTIVE CONTROL APPROACH The PMC optimizes the ship performance to achieve a set of pre-specified objectives while respecting performance and operability constraints. To do so, a multi-objective cost function denoted by J is minimized subject to system dynamic and safety constraints over a given period of time. In this work, the PMC is formulated as a discrete-time optimal control problem described by the following: P(x0 ) : min x: [0, N ]→ R n , u: [0, N ]→ R m J ( x(⋅), u (⋅)) N −1 where J ( x(⋅), u (⋅)) = Φ( x( N )) + ∑ L( x(k ), u ( k )) k =0 s.t. x( k + 1) = f ( x(k ), u ( k )), f : R n + m → R n , x(0) = x0 , x0 ∈ R n , C ( x(k ), u (k )) ≤ 0, C : R n + m → Rl , k = 0, ", N − 1 (1) where, x ( k ), u ( k ) are the power system states and control inputs, respectively, and N is the length of the prediction horizon over which the cost function (J) is minimized and the point wise state and input constraints need to be satisfied. The equality constraint is the dynamic state evolution that describes the power system f ( x (k ), u ( k )) , while the inequality constraint represents the bounds on the states and the control inputs. A model predictive control approach is adopted in order to solve the PMC problem. The approach employs a receding horizon based MPC, where the above optimization problem is solved repeatedly at every time step k and the input elements of the optimal control sequence corresponding to the first time index are applied as the control inputs to the plant. The MPC considers a model of the power system and can leverage apriori information about known load disturbances such as pulse loads in order to optimize ship performance. Computing the solutions to (1) in deterministic real-time is difficult, so two methods were considered to solve the PMC problem in this program, namely, Interior Point Optimizer (IpOpt) (see [9] and references there-in) and Integrated Perturbation Analysis – Sequential Quadratic Programming (IPA-SQP) [10]. The IpOpt is an interior-point based general purpose nonlinear programming solver which is applicable to large scale systems. More specifically, the algorithm is computationally efficient for problems where the gradient and hessians associated with the optimization problem have sparse structure which is the case for the optimal control problem associated with the PMC. In addition, the IpOpt enables using implicit discretization for the equality dynamic constraint which alleviates any numerical issues associated with the discretization. The IPA-SQP is an algorithm developed at the University of Michigan that specifically addresses the computational efficiency of optimization arising in the MPC formulation. It exploits the complementary features of perturbation analysis and sequential quadratic programming, and provides the optimal solution in the predictor-corrector form. In both methods, the optimal control sequence computed at any given instant can be used as a feasible initial guess for the optimization solved at the successive time instant, thereby improving the computational efficiency. A third algorithm employing deterministic dynamic programming (DDP) was also developed under the Compact Power Conversion Technologies program that funded this work. This approach differs from the MPC approach by precomputing most of the optimal solution offline. Due to this feature the DDP algorithm is relatively fast and deterministic, but less flexible than an MPC algorithm. Due to space limitations, this work will only show results from the IpOpt algorithm to sufficiently prove the efficacy of model predictive control as a ship power management tool. Further details on this control algorithm and test results are available [11]. IV. POWER MANAGEMENT CONTROLLER TEST PLAN Ship performance is optimized by minimizing a cost function which defines the performance goals of the ship and assigns relative priority to each goal. The cost function employed by the proposed PMC for the Purdue DC test bed is L( x(k ), u (k )) = p1 (Vbusk − Vbus* )2 + p2 PTotalk 2 + p3 ( PGS 2k − PGS 2* )2 + ... p4 ( PSPSk − PSPS * ) 2 + p5 (ωSPSk − ωSPS * )2 + p6 ( DGS1k − DGS1k −1 )2 + ... (2) p7 ( PGS1k − PGS1k−1 ) 2 + p8 ( PGS 2k − PGS 2k−1 ) 2 + p9 ( PSPSk − PSPSk −1 )2 . Each parameter of this cost function represents an interest of the power system. The weighting factor, p, for each parameter assigns a relative priority to the parameter. The description of each parameter is shown in Table 1. The main bus voltage is Vbus, the powers PTotal, PGS1, PGS2, and PSPS are the total, GS1, GS2, and SPS powers respectively. An asterisk on each represents a target or desired power. The droop gain for GS1 is DGS1, and the SPS shaft speed is ωSPS . Table 1. PMC test plan. Quantity Bus voltage deviation Power tracking error Fuel efficiency Ship velocity deviation GS-1 droop gain ramp rate GS-1 prime mover ramp rate GS-2 prime mover ramp rate SPS prime mover ramp rate Purdue Test Bed Equivalent DC bus voltage deviation Pulsed load power deviation GS-2 tracking to efficiency point SPS induction machine power SPS induction machine speed Ramp rate of GS-1 droop gain Ramp rate of GS-1 electrical power Ramp rate of GS-2 electrical power Ramp rate of SPS electrical power The error between the bus voltage measurement and the target value of 750 V is critical to the proper operation of power system elements. The total power tracking error has some overlap with the bus voltage deviation term and adds another layer of stability by ensuring that the power at the bus is balanced between generation and load. It is assumed that an efficiency curve for the GS-2 is known and that PGS2* is the most efficient point on the curve. The equivalent of ship velocity deviation is accounted for with the target deviation of the SPS power and rotor speed. The ramp rate of the GS-1output power is included to provide a means of limiting the burden on this unit. The GS-1 represents a main turbine generator in this test bed, and therefore it is of interest to limit the power ramp rate so as to limit the wear of the machine and increase its expected lifetime. Finally, ramp rate terms for each of the PMC control inputs are included to prevent large, sudden changes in demand. Based upon the parameters included in the cost function, metrics are developed to quantify the performance of the PMC. The metrics used for the PMC testing on the Purdue test bed were chosen to be the maximum and average deviations of the GS-2 output power, the SPS output power, and the bus voltage from their respective targets. Other metrics are the maximum ramp rate of the GS-1 power and the total time during which the ramp rate exceeds a threshold value. The ramp rate is a basic slope calculation that considers the present value and the value 0.1 seconds ahead. The threshold is an arbitrary value that would be chosen by the user based upon the specific generator tolerance levels. The test plan to demonstrate the effectiveness of the PMC consists of three test cases which are outlined in Table 1. Before testing the PMC, baseline measurements are observed during a Test A Test B p1 p1 Test C p1 p2 p2 p2 p3 p3 p3 p4 p4 p4α ↑ p5 p5 p5 p6 p6 p6 p7 p7α ↑ p7α p8 p8 p8 p9 p9 p9 full SWPPL pulsing cycle (7 pulses as shown in Figure 2) without a PMC and constant power targets being fed to GS-2 and SPS in open loop. After closing the control loop between the PMC and the test bed, the weighting factors are tuned so that the test bed behavior is similar to the behavior without a PMC, thus establishing a baseline PMC behavior as the first PMC test case, Test A. Two follow up test cases seek to improve upon this behavior. The second test case (Test B) consists of increasing the penalty on the GS-1 power ramp rate, which is the equivalent of extending the lifetime of the generator. The third test case (Test C) maintains the new GS-1 power ramp rate penalty and increases the SPS tracking penalty to decrease the deviation from the target. This is the equivalent of asking the ship to maintain a velocity closer to a set point. A trade-off exists between the selection of the PMC sampling time, the prediction horizon over which the PMC can look ahead to assess the optimal control inputs, and the hardware capabilities. Considering these trade-offs and the fastest/slowest dynamics of the system, the test cases consider a model-predictive PMC with a sampling time of 60 ms and a prediction horizon of 6 steps (equivalent to 0.36 s). V. RESULTS AND ANALYSIS The test plan was carried out on a low-order simulation model of the test bed described in Sec. II to assess the expected PMC behavior and reduce risk before testing in the lab. The results for simulation and lab testing are shown and conclusions are drawn based upon comparison of both waveforms and metrics. The chosen set points for the test cases are for GS-2 to generate 3 kW and SPS to sink 10 kW. Time that GS-1 Ramp Rate Exceeds Threshold (60 kW/s) GS-1 Maximum Ramp Rate 1 seconds kW/s 150 100 50 0 A B 0.5 0 C SPS Maximum Power Deviation B C SPS Average Power Deviation 30 40 20 % 60 % A 20 0 10 A B 0 C A GS-2 Maximum Power Deviation C 15 100 10 % 150 % B GS-2 Average Power Deviation 50 0 5 A B 0 C A 3 C 0.8 0.6 % % 2 1 0 B Vbus Average Deviation Vbus Maximum Deviation 0.4 0.2 A B Test C 0 A B Test C Figure 4. PMC simulation metrics. system was disturbed with the 14 second pulse cycle shown in Figure 2, but because the results for each pulse were identical only the results due to the first pulse in the cycle are shown in Figure 3. The 8 kW pulse disturbs the system just after 6 seconds of simulation time and the first pulse lasts for one second. Figure 3. PMC simulation results: a) GS-1 electrical power, b) SPS electrical power, and c) GS-2 electrical power. A. Simulation Results With the PMC in a closed control loop with the model of the test bed, the SWPPL profile was introduced to the system as a known disturbance. The disturbance is “known” to the PMC in the sense that the profile of the disturbance (magnitude and pulse width) is stored offline and the PMC is given a warning signal that the profile is going to be introduced to the system within a preset amount of time (5 seconds in this set of test cases). The amount of warning time could be as low as the prediction horizon without impacting the PMC performance. The simulated electrical power waveforms for GS-1, SPS, and GS-2 are shown in Figure 3 and the chosen metrics for quantifying the system performance are shown in Figure 4. The Observing the GS-1 electrical power in Figure 3(a) it is demonstrated that under Test A the GS-1 is absorbing most of the pulse disturbance power resulting in a very high ramp rate (73.0 kW/s). This abusive ramp rate would limit the expected lifetime of a ship GTG, so under Test B the penalty on the GS-1 ramp rate is increased in the PMC cost function. The results under Test B (shown in red) demonstrate that increasing the GS-1 ramp rate penalty results in a decreased GS-1 ramp rate. The ramp rate is reduced by 45% down to 40.4 kW/s as reflected in Figure 4 and the ramp rate does not exceed the specified threshold of 60 kW/s at all. The PMC accomplishes this by looking ahead over the prediction horizon to control the SPS and GS-2 to sink and source power before and after the pulse as necessary to keep the power on the main bus balanced without placing too much stress on the GS-1. The PMC is effectively ramping up the GS1 power before the pulse occurs. This is reflected in the plot of the SPS power in Figure 3(b). Under Test A the SPS tracks its reference value of 10 kW (shown in yellow) with minimal deviation. Under Test B the deviation increases to compensate for the reduced GS-1 ramp rate. Before the pulse the SPS sinks more power to allow the GS-1 to generate more power and still keep the power on the bus balanced. After the pulse the SPS sinks less power because the GS-1 power has only increased to about half of the pulse power demand. The deviation decreases until the GS-1 is sufficiently ramped up to accommodate the pulse amplitude. GS-1 Maximum Ramp Rate 1.5 seconds kW/s 150 100 50 0 40 A B B C 15 10 % % A SPS Average Power Deviation SPS Maximum Power Deviation 30 20 5 10 0 1 0.5 0 C Time that GS-1 Ramp Rate Exceeds Threshold (60 kW/s) A B 0 C A B C GS-2 Average Power Deviation GS-2 Maximum Power Deviation 100 40 % % 30 50 20 10 0 A B 0 C Bus Voltage Maximum Deviation 1 B C % 1.5 2 % 3 A Bus Voltage Average Deviation 1 0 0.5 A B Test C 0 A B Test C Figure 6. PMC test bed metrics. ramps up in anticipation of the pulse. After the pulse the GS-2 unit provides excess power to accommodate the pulse on the bus while the GS-1 unit gets fully ramped up without exceeding an overly stressful ramp rate. Under Test C emphasis is placed on the SPS tracking and this forces the GS-2 to have to deviate even further from its reference during the pulse. This effect is shown in the third row of Figure 4 as both the maximum and average deviations increase with each test. The last row of Figure 4 shows the metrics for the measured bus voltage. These metrics are important from a stability standpoint. The maximum and average bus voltage deviations do not exceed 1% under any test indicating highly stable conditions. The simulations indicate that the PMC algorithm is working as designed and that bus stability is maintained. Figure 5. PMC test bed results: a) GS-1 electrical power, b) SPS mechanical power, and c) GS-2 mechanical power. The SPS deviation from its reference is analogous to ship speed velocity deviating from a set point. The SPS deviation under Test B is considered to be too extreme, so Test C (shown in green) increases the penalty on SPS tracking and the SPS power more closely tracks the set point of 10 kW. This is reflected in the SPS deviation metrics in the second row of Figure 4. It should also be noted that the GS-1 ramp rate also maintains a significant level of reduction. It was forced to increase slightly, but the value of 44.5 kW/s is still 39.0% less than it was under Test A and the ramp rate did not exceed the threshold at all. Observing the GS-2 electrical power in Figure 3(c), the trend from Test A to Test B is similar to the SPS. The source tracks its 3 kW reference well in steady state, but before the pulse the source reduces its generated power as the GS-1 unit B. Purdue Test Bed Results The system measurements from the Purdue test bed under the control of the PMC for the three test cases are shown in Figure 5. Mechanical power is measured for SPS and GS-2 due to excessive noise on the electrical measurements. The corresponding metrics are shown in Figure 6. As is expected from simulation, the GS-1 absorbs most of the pulse power under Test A and the ramp rate is excessive. Under Test B, the GS-1 ramp rate metrics indicate a reduction in both the maximum ramp rate and the time during which the ramp rate exceeds the 60 kW/s threshold during the pulse cycle. The GS-1 power begins to ramp up in anticipation of the pulse, but there is a sudden transient event lasting ~0.2 s. Analysis of the measured SWPPL data shows that this event occurs because there is a timing mismatch between the expected pulse event and the actual pulse event. The reason for this discrepancy is that the SWPPL in the lab is controlled by a local computer employing a non-real-time operating system. Because the timing of the pulse is not enforced in real time, there is inherently a delay between when the pulse should arrive (5 seconds after requesting the pulse) and when it actually arrives; this delay is uncontrolled and inconsistent. This is a test bed hardware issue that is not an issue on a ship system which typically employs a real time operating system. Thus, the measured data is an indication of how well the PMC works despite the hardware limitation. the reduced primary power ramp rate. The tests demonstrate that the predictive PMC can improve the performance of a ship power system with pulse loads by coordinating sources and loads to optimally minimize a cost function encompassing ship goals and their priorities. The PMC is successful in reducing the GS-1 ramp rate and this is reflected in the metrics, but the PMC performance has the potential to be even further improved as indicated by the measured waveforms outside of the pulse mismatch duration and the simulated data (approximated with dotted lines in Figure 5). From the GS-1 power measurements it can be observed that the GS-1 power begins ramping up over the prediction horizon before the pulse occurs and begins ramping down before the pulse ends. The metrics are reduced from Test A to Test B, but they are also reduced from Test B to Test C. This is because the pulse mismatch was less for Test C than for Test B. Observing the waveforms and the simulated data, it is fair to extrapolate that the GS-1 ramp rate under Test B would have been slightly less than that of Test C if the mismatches were the same. This material is based upon work supported by the Office of Naval Research under Contract No. N00014-09-D-0726. Any opinions, findings and conclusions or recommendations expressed in this material are those of the authors and do not necessarily reflect the views of the Office of Naval Research. The SPS measurements in Figure 5(b) are similar to the simulations. Under Test B the deviation from the reference increases to accommodate the reduced GS-1 ramp rate, but when the penalty for this deviation is increased in the cost function for Test C, the PMC forces the SPS power to more closely track its reference once again. This trend is reflected in the second row of metrics in Figure 6. The GS-2 power in Figure 5(c) is allowed to increasingly deviate as emphasis is placed on other system goals. The average GS-2 deviation decreases from Test B to Test C, but this is again due to the greater timing mismatch. The bus voltage deviation shown in the last row of Figure 6 is slightly larger than it was in simulation, but all excursions are less than 2.5% indicating acceptable stability under all tests cases. VI. CONCLUSION As advanced high power weaponry and mission loads become more readily available, ships are facing and will continue to face the challenge of providing sufficient electrical power to all loads. A Power Management Controller can dynamically allocate generation sources and loads to provide power for constant and pulse loads with reduced generation capacity requirements. Such a PMC employing model predictive control was demonstrated on a representative scaled ship electrical system. The measured data and analysis show that the PMC is successfully able to establish a stable baseline performance under pulse load conditions, reduce an undesirably high ramp rate on the primary generation source, and then reduce the ship propulsion power deviation from a reference while maintaining ACKNOWLEDGMENT REFERENCES [1] Air and Missile Defense Radar (AMDR), ONR Fact Sheet [Online]. Available:http://www.navy.mil/navydata/fact_display.asp?cid=2100&tid =306&ct=2 [2] R. Ellis, “Electromagnetic Railgun,” ONR Fact Sheet [Online]. Available:http://www.onr.navy.mil/~/media/Files/Fact%20Sheets/35/Ele ctromagnetic-Railgun-July-2012.ashx [3] Converteam (now GE Power Conversion), EMKIT: Electromagnetic Kinetic Integrated Technology Datasheet [Online]. Available: http://www.converteam.com/majic/dl/4/doc/Restricted/Naval/EMKIT_da tasheet_GB.7001.gb.06.09.03.pdf [4] R. O’Rourke. (2013, Jan. 22), “Navy Shipboard Lasers for Surface, Air, and Missile Defense: Background and Issues for Congress,” Congressional Research Service Report for Congress [Online]. Available: www.fas.org/sgp/crs/weapons/R41526.pdf [5] R. O’Rourke. (2013, Feb. 14), “Navy DDG-51 and DDG-1000 Destroyer Programs: Background and Issues for Congress,” Congressional Research Service Report for Congress [Online]. Available: http://www.fas.org/sgp/crs/weapons/RL32109.pdf [6] J. B. Rawlings and D. Q. Mayne, Model Predictive Control: Theory and Design, Nob Hill Publishing, 2009. [7] J. D. Stevens, H. J. Hegner, and J. Yan, “The Value of an Integrated Power System Land Based Test Site to the U.S. Navy,” Proceedings of the Electric Machines Technology Symposium (EMTS), 2012 [Online]. Available:https://www.navalengineers.org/ProceedingsDocs/EMTS2012/ Papers/44_Stevens_EMTS2012Paper.pdf [8] M. Bash et al., "A Medium Voltage DC Testbed for Ship Power System Research," Proceedings of IEEE Electric Ship Technologies Symposium (ESTS) 2009, Baltimore, pp. 560-567, 2009. [9] A. Wachter and L.T.Biegler, “On the Implementation of an InteriorPoint Filter Line-Search Algorithm for Large-Scale Nonlinear Programming,” Mathematical Programming, Vol. 106 (2), pp. 25-57, 2006. [10] R. Ghaemi, J. Sun, and I. Kolamanovsky, “An Integrated Perturbation Analysis and Sequential Quadratic Programming Approach for Model Predictive Control,” Automatica, Vol. 45, No. 6, pp. 2412-2418, 2009. [11] H. Park, J. Sun, S. Pekarek, P. Stone, D.F. Opila, R. Meyer, I. Kolmanovsky, R. DeCarlo, “Real-Time Model Predictive Control for Shipboard Power Management Using the IPA-SQP Approach,” IEEE Transactions on Control Systems Technology, Preprint, Vol. PP (99), 2015.