III. PHYSICAL ACOUSTICS Academic Research Staff

advertisement

III.

PHYSICAL ACOUSTICS

Academic Research Staff

Prof. K.

U.

Ingard

Graduate Students

V. K. Singhal

J. A, Tarvin

A..A. loretta

S. R. Rogers

A.

ATTENUATI\ON

OF' SOUND IN TURBULEUNT PIPE F'LOW

U. S. Navy - Office of Naval Research (Contract N00014-67 -A-0204-0019)

U. Ingard, V. K.

Singhal

In turbulent pipe flow there is a static pressure drop along the length of the pipe,

xwhich is caused by turbulent friction. This turbulent friction can also attenuate the fundamental acoustic

is presented here.

mode propagating in the duct.

A theoretical analysis of this effect

The variation of static density along the duct axis and the change

of friction factor with Reynolds number are included in the theoretical model.

Also,

some experimental data are compared with results of this analysis.

It has been found experimentally that the static pressure gradient dpo,/dx is almost

a constant along the pipe when the entrance and the exit sections are ignored.

present analysis dp /dx is taken from experiment.

dp

d

dx

In the

Let

-a = experimental constant.

(1)

Here a > 0 if x increases in the direction of flow.

"barotropic"; that is,

and also that the fluid is

ratio of specific heats.

We assume a one-dimensional model

p - p , where 1

<

f < y, with y the

The continuity and momentum equations for the steady basic

unperturbed flow in the duct are

pu

= constant

du

dx +

m o

(2)

m-

dpo

puo o =

(3)

dx

2

dp

pu

.

The term

-- a

where a is related to the friction factor f and is defined as

dx

2

1

2

to be

-( CP oU 0 represents the turbulent shear stress. The equation of state is assumed

Po

Po

QPR No.

p

Pref

r(4)

Pref

109

PHYSICAL ACOUSTICS)

(III.

where f = 1 for isothermal basic flow, and

e = y for adiabatic basic flow.

Equations 1-4

can be combined to give the basic flow.

Po

Pref-

PO

ref

(5)

ax

b

(6)

x

m

u

m

r

Pref

I

x

Pref

(1

\

1x ,

P

P

(7)

/ref

where

b Pref

apo

Pref

Po

b -P

(8)

and subscript ref denotes the conditions at x = 0.

We retain only first-order terms in the pressure gradient a oi

and ignore all second-order terms,

are neglected.

2

2

such as ab, b , a .

"density" gradient b,

2dx

Thus, d u odx 2 and d2

29

Also, a is assumed to be a function of u

alone.

o

The continuity and momentum equations for the sound field are

aP

8

1

(Pou+PlUo) = 0

at +

auu

Po -

+-

1

1

aul1

+ me

m

a

-o 5u

O

u

au

o

+ (Poul+uo)

o 1

+ 2

p c u

0ooI

1

+xOamoU1 +-

:-

2

ap uo

aP1

ax

(10)

Here pV is the attenuation of sound caused by viscosity and heat conduction.

To separate the effects of variations in static density, we redefine the acoustic variables.

p1(x, t)

po(x)

and

t)

V= - u (x,

u 0 (x)

(11)

The first-order acoustic flow is taken as adiabatic so that

2

P 1 = coPl.

QPR No.

109

(12)

(III.

PHYSICAL ACOUSTICS)

Equations 9 and 10 when transformed to new variables become

_)x_

(at + u

a

T-+ uo 8x

2

apo

a

+u

2

0

ax

c +

2P vo

ax

m

Sau

°

+

(13)

a

U

8xo 8x

o

+

2

o0

m

aax

ax

2

18

V

uo

--o U

y ap

mO ax

m

(14)

R = 0.

14 with respect to x, eliminating av/ax, using Eq. 13 and the

Differentiating Eq.

basic flow solution leads to the wave equation

82R

o axat

a2R

at2 + 2u

at 2

+ u

+ u 2o aax2 2

8x

aR

-

1 8a

2 au

o ax

2a

at

o

1

aa 2

- + 2p c +

2 au0 Uo

vo

m0

aR

+ -

2

au

2

o

2

a(y+ 1)7

m

2 82R

o ax2

(15)

ax

o0

This is a linear second-order partial differential equation with variable coefficients

2a

aa

2a

(y+1) are conand

for the density perturbation R. The coefficients p v, -, O a,

O

O

stants, but c

o

and u

o

are functions of x.

k(x) dx] Eq.

For a wave solution of the form exp[-it + if

15 gives a dispersion

relation for the wave number k.

k

1-2

ak

- i(1-2)

+ i

+ kMll

o0

OO

2

+i

c

where M

O

= u

/c

2a(y+1)

o----

o

W

2a

m c

o0

aa

a-f

2 av

1

+

+

v

2

aa

m

2

21

o

ao

2

o

(16)

=0,

o

is the Mach number of the basic flow.

0

The real part of the wave number k is likely to be

0/C

for the right traveling

+

o

-C/c

wave, and

1 - NI

used in Eq. 16.

QPR No. 109

for the left traveling wave.

We shall use this to find ak/ax to

be

After obtaining the solution we can check to see whether this is a

(III.

PHYSICAL ACOUSTICS)

+

1 +M

a?

1

+

+~ M

+

0

16 yields

The solution of Eq.

consistent approximation.

°

a

m c

o

00

b

(1+2M )(1-1

0

4 -9o

-/C

1

0

1-

v

O0

4

a

o4

o

0)

(

o

4 "yM4

o

4

aC

0

+ 4

4

3

4

o

'o

4

o

1

(1-2 Mo )(1+MI ) + 4

0

4 a I

0

+

(17)

0

2

0

0

(18)

provided

3

2

c

2a

+

V

1+±I

2

)

1, aa

2

me C

o0 0

a-I

aC 0

M2

9

o

o

o

< 1

for

k,-

«<1

for

k

L

2

ya

2PoC2

0p 0

)

b(1+2A 0)( 1-l

2 1 p0

o

and

a

m c

v

Cc

O

(1+

O

2) + 21

c

aMIO

M 2

-

o

o0

ya

2

S2

2

We note that ak ,ax

b(1-2_I o)(1+Io

0o

o

)

is a second-order quantity in a, b ,

,

' so we were right in

approximating ak/ax. xWe note that

a \1

a

m

c

o o

4{9

4fp0

o

(19)

2

:8

8

f

o

(20)

o

Therefore

QPR No.

109

42

(III.

1

P

k. =

1+

(1+M

0

)

+

v

1

8a

1 aM

4 a x0

~ M

XI

2 + a lo

0 (2+M)

o

(1+31)

4

1

1-

i

o

+ IM (1+,)

- 2M

(21)

0

S0a

k

PHYSICAL ACOUSTICS)

0

8+ 4 o DAaa

+

o.

n

a-0

-2-Al0

(22)

(1(-M

Obviously the attenuations are a function of the Mach number.

the attenuation is

due to viscosity and heat conduction.

At zero -Mach number

It is interesting to note that the

attenuation at very low Mach numbers can be made smaller than that resulting from

viscosity and heat conduction if the following relations between

satisfied.

ak.

1

Only the first three terms in Eqs.

< 0

if

a i

3

2-A 2-M

-3

+

v 4(1-M )

MI(4-3AI 2-1) o

)

8

CZ+

4(1-ATo )

o

0

2

oiI+AI o )

a2a

2I

4

a nd

ak.

1

< 0

aI

o

I2

(2v

+ +

AM 3 )

2

4(1+M )

A(

2+ M 3

11

4-3

a +D

A 2 (1-M

+

4

4

o)

o

D2 a

2

o

QPR No. 109

aa

4(l+M )

o

a,

,,

and

nI0 are

21 and 22 are kept for this purpose.

<0.

(III.

PHYSICAL ACOUSTICS)

= 0 and a/'2 >

At high Mach numbers (at high Reynolds numbers) aa/MIo

0

P.V

Hence

attenuation increases with Mach number in that region.

For the sake of simplicity, we shall use the power law for the friction factor for

2a

2

aa

-1/4

are

L

M and M

. In this approximation M

smooth pipes. Then a = (const)M1

o M2

oM

o0

Then, to lowest order, aki

of the order of a.

1

/aM 0V

< 0 if

P + 21a/64 < 0,

which is

Therefore, upstream attenuation always increases with Mach number.

21a

< 0. This means

Similarly, for the downstream attenuation, if p > 64-, then 8ak /Mo

impossible.

then the downstream attenuation will decrease initially with

that if a < (const) NT,

fT, then by turning

If the pipe roughness is so controlled that a < (const)

Mach number.

on a very low speed flow the sound attenuation can be reduced to a level less than

This result is very interesting and may

that caused by viscosity and heat conduction.

have useful application in the transmission of sound signals through long pipes.

that

v is proportional to the square root of the acoustic frequency f.

the constant depends on the viscosity and thermal

conductivity

of

Note

The value of

the

gas

and the

hydraulic diameter of the pipe.

Now we correct Eqs.

21 and 22 for the change in static density.

We use the nota-

tion

(23a)

R ~ exp[ikx-it]

exp[ik'x-i"t]

pl

(23b)

to obtain

ki

k.

1

k.

i++

:

+

ki

-

= k.

1

=

a

2

2

A

l

1

I

o

1

S

1 + M o0

-

:

1

i - M 0O

0

+

4

2

o

v

-

M

(2+M )

o

4

2

(25)

- 2M2

(26)

3(1-C) + M (3-f) + 2

M

8 f

I

o

aM

8a

a

o

+

PV

+ 4

+

QPR No. 109

(24b)

i

1

+

k.

(24a)

m

0

+

o

4

(2-M )

o

3(-1) + M(3-

0

(III.

PHYSICAL ACOUSTICS)

is approximately equal to (1+M )/(1-M ). But

Note that for small Mach numbers k.i/k.

for large Mach numbers

k.

+

k.

1- M

1+M

k.

+

]

1

o

o

k.

o

For isothermal basic flow these relations give

k

__1

+

M2

o

1 + M4

i

k

=

M

1

1 - M

1

v

4

i

+

-

ki

k

1 -

o

I

O

4

v

v

o

+

aM

o

2

o

4

2)

( +yM +lyM]

(

(27)

(28)

-y o+y

basic flow they yield

M

1

1 + M

aM

2

O

whereas for adiabatic

=

aM

aa

5 I

O

-

k

o

8a

a

M o

aM

o

+

+

aM

0

o

a

M

am

a

aM

O

+

2

2

o

8

2

o

M 21

o a

4

aM

o

+

o

o

8

( 5 - 3 y) + M (3-h') + 21\12

(3-y-5)

+

M 0(3-y)

(29)

-

-

(30)

2

We note that the "attenuation" caused by change in static density is the same in both

directions, whereas the attenuation caused by turbulence is different.

Also note that

the increase in static density in the upstream direction tends to amplify the sound signal, hence to decrease its attenuation resulting from turbulence.

For isothermal basic flow we note from Eqs. 21,

22, and 24 that the ratio of atten-

uation resulting from turbulence and static density variation goes as follows.

aa/ao = 0,

we get for the upstream direction

0

2+

2y-)M - m

2yMo(1-mio

0

- Yio

and for the downstream direction,

QPR No.

109

When

(III.

PHYSICAL ACOUSTICS)

3

2

2 - (2y-1)MI

-

y ,

2y NIo(1I

o)

At low NMach numbers this ratio is fairly large,

ation may be ignored.

cannot be ignored.

so that the effect of static density vari-

lach numbers the effect of static density variation

But at large

As the Mach number increases,

the contribution of static density

completely overshadows the turbulent attenuation on the downstream side.

UPSTREAM MEASURED

UPSTREAM CALCULATED,

0

,0d

7

/

FE

M

MEASURED

0.2

0.1

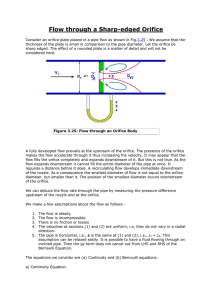

Fig. III-i.

0.3

0.4

Mleasured and calcul2ated upstream and downstream

attenuation of sound in turbulent pipe flow.

The attenuation of an acoustic pulse xwas measured with and without flow in a duct

of square cross section with a 3,/4 in.

The speaker was pulsed at 1240 Hz.

by proper design.

side.

Two microphones were placed 6 ft apart.

Interference from the pipe termination was avoided

Figure III-1 shows the experimental results, as well as the values

calculated from Eqs. 27 and 28 with

a

QPlR No.

-0. 32

4

),

0. 0014 + 0. 0125 Rey

d

-d

109

(31)

PHYSICAL

(III.

ACOUSTICS)

where d is the side of the square cross section of the duct, and Rev is the Reynolds

number of the mean flow.

The attenuation increases slowly with Mach number at low Mach numbers but for

MIach numbers greater than 0. 25 the effect of turbulence is very large indeed.

The

downstream attenuation increases at a slower rate than does the upstream attenuation.

That the downstream attenuation can decrease with increasing Mach number is evident

at Al = 0. 1 on the calculated curve.

The downstream measured curve deviates significantly from the downstream calculated curve in the 1Mach number range 0. 1-0. 32.

The reason for this is that in

in the transition range from laminar to turbulent flow.

this region the basic flow is

This effect also appears on the upstream measured curve.

sound waves and high-frequency scattering cannot be detected

Turbulence scatters

quantitatively with the simple pulse technique that we used.

This sc'attering of

the

incident harmonic sound pulse train is neglected in the present analysis and mcv account

for some of the observed discrepancies.

The friction-factor

expression.

law, Eq. 31,

used for the calculations

Our measurements show higher friction factors.

it is very hard to get a good estimate of c.

is the commonly accepted

In the transition region

The errors in the constant a are obviously

reflected as errors on the calculated curves in Fig. III-1.

B.

ORIFICE

FLOW NOISE

Navy -- Office of Naval Research (Contract NO0014-67-A-0204-0019)

U. S.

U. Inpard

In one of our recent experiments in which air was sucked through an orifice in a

plate forming one of the walls of a suction chamber, we focused attention mainly on the

noise on the upstream side of the orifice plate.

Of particular interest was the depen-

dence of the noise emission on the static pressure ratio in the vicinity of the critical

value of this ratio.

In these experiments we also studied the sound emission into the suction chamber.

Figure III-2 shows the measured sound-pressure level (SIL) inside the chamber as

a function of the static pressure ratio across the orifice plate.

It is interesting to try to interpret the observed dependence of the SPL on the pressure ratio in terms of the expression

W

QPR No.

2

= C

109

n

c

2

oA

o

(1)

(III.

PHYSICAL ACOUSTICS)

for the acoustic power W 2 emitted from the flow on the downstream side of the orifice

plate.

In this expression C

n

is a numerical constant, V

o

is the velocity in the orifice,

The

P2 is the fluid density in the suction chamber, and A is the orifice area.

n

factor C n(Vo/C2) can be regarded as the efficiency of noise emission by the jet stream

discharging kinetic energy at the rate p 2 XVA /2 (the difference between the density

0

po

in the jet at the orifice and the density pc in the chamber is ignored). The exponent n

depends on the nature of the flow fluctuations in the stream.

For flow pulsations n = 1

lateral-flow fluctuations and corresponding pressure fluctuations

(monopole),

orifice plate correspond to n = 3 (dipole),

on the

and fully developed turbulence in the stream

In general, the emitted noise is contributed by all

(quadrupole) corresponds to n = 5.

three effects and we may set

V

W2=

C

Sm c2

V 3

+ Cd

5

q2

Cq

V

2

A

(2)

o

We shall show in this report that our experimental data can be fitted well to an expression of this form.

1.

Pressure Drop

In our experiments we did not measure directly the Mach number in the orifice but

rather the static pressures P1

and P

2

outside and inside the orifice plate.

We shall

relate these pressures by making the assumption that the flow is isentropic from the

outside of the chamber to the orifice and that there is very little "pressure recovery"

in the suction chamber on the downstream side of the orifice plate.

The pressure in the

jet, P , as it leaves the orifice is then assumed to be the same as the pressure P.

in the chamber. The local temperature To and the density po in the jet at the orifice

will be somewhat different from the corresponding quantities in the almost quiescent air

in the suction chamber.

Under these conditions, we obtain

2 - 2 °1 I2- (P

S

o y-1

P

where

c1 is

)7

2

-1

cC1 1 - 1 - AP

P -

the sound speed outside the chamber,

- P

1

o"

If we neglect pressure recovery, we have AP

chamber,

,3)

P1 the static pressure outside the

and AP the pressure drop P

sure inside the chamber.

QPR No. 109

- P 2 , where P

2

is the static pres-

Since the temperatures inside and outside the chamber are

the same, we may set cl = c 2 .

be written

P

The expression for the acoustic power in Eq.

2 can then

(III.

P2C1

2

C F(x) + C F3(x) + C F5(x) F 3 (x)

Finay,

if we set pCd=

(x)

we obtain

=

Finally, if we set p2

=

Pl

(l - x )

PHYSICAL ACOUSTICS)

we obtain

,

F 4 (x) +

+ C d4x

dF 6 (x)

+C

W2

= [C

x +C

m

/C/)

3

(P

F 8 (x) (1-x)

I0/

where x = (P

1 -P 2 )/P1 - APiP 1 .

In Fig. III-2 the functions represented by the three terms in Eq. 5 (including the

C d , and C

factor (1-x)) are shown, with the constants Cq,

q

d'

m

adjusted to produce a best

fit with the experimental data.

*/

/

0//

0//

-

*-- 7

/

-10--

-20

>

,

f

e" /

MONOPOLE

*

0

*

0

EXPERIMENTAL DATA

DIPOLE

/

QUADRUPOLE

I

SI

I

I

II

I

I

I

0.1

AP/P

Fig. 111-2.

QPR No.

109

I

I

I

1.

1

Orifice flow noise.

We find that the best fit is obtained if C

expression for W 2 becomes

i

m

140 C , C d

q'

d

19 C

q

so that our empirical

(III.

PHYSICAL ACOUSTICS)

z

C [140 F1' +19

6

+

8

](1-x.

(6)

Once our "reverberation" chamber (suction chamber) has been calibrated, the value of

C

q

can be determined from our measurements.

QPtR No.

109