DEC 2009 LIBRARIES ARCH\FcS

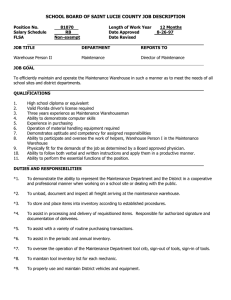

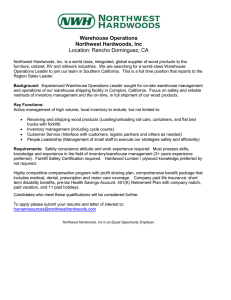

advertisement