LIBRAR1ES 17 1964 JUN ~1~~ 1_

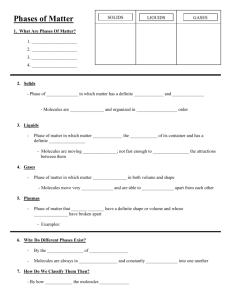

advertisement

~1~~ 1__~~_ ~~L

JUN 17 1964

LIBRAR1ES

CONDENSATION OF GASES ON A COLD SURFACE

by

AMIEL SHULSINGER

Submitted in Partial Fulfillment

of the Requirements for the

Degree of Bachelor of Science

at the

MASSACHUSLETTS INSTITUT: OF TECHNOLOGY

June,

1964

Signature of Author .

.

.

Department of Mechanical Engineering

u

-

Certified by

Certified by

.

-

May 29,

1964

*.

Thesis/upervisor

.

.

.

Accepted by

Chairman, Depart ent Committee on Theses

TABLE OF CONTENTS

Abstract

2

Acknowledgment

3

Introduction

4

Theory

6

Apparatus

10

Procedure and Description of Experiment

14

Results

17

Conclusions

19

References

20

Appendix

21

ABSTIRACT

The purpose of this thesis was to study the rate at

which gas molecules will stick on a cryogenically

refrigerated surface.

The goal was to complete the

building of apparatus that could be used to examine this

problem, and if possible, to obtain data as to a sticking

coefficient for various gases.

The method used was to measure the pressure change

in a gas after it was injected into an evacuated chamber

which contained a cold surface.

The gas that was tested

was carbon dioxide.

Due to many problems encountered during this work,

it was not possible to obtain the desired data.

the feasibility of the apparatus is discussed and

improvements are suggested.

However,

-3-

ACKNOWLEDGMENT

The author wishes to gratefully acknowledge the help

of the following people:

Prof.

Mr.

Robert Stickney

Michael Koskinen

The R.L.E.

Glass

Shop

This work was made possible

by a

grant from the

duPont Fund of the Mechanical Engineering Department.

The author wishes to thank the duPont Company and the

Mechanical Engineering Department for this grant.

The cooperation and support of the M.I.T. Research

Laboratory of Electronics is also gratefully acknowledged.

4

INTRODUCTION

The aim of this thesis is to study the condensation

of various gases on a cold surface.

It

is desired to

find out if the gas molecules, upon striking such a low

temperature surface, will stick to it by condensing.

There are two definite applications for such a

study.

The first is to help develop high speed gas

pumping methods.

Cryogenic pumping is being used today

to get low pressures, and in order to improve the

procedure, it is necessary to know at what rate the

remaining gas molecules will stick to the cold surface

so that the speed of pumping can be regulated and

increased.

The second area of interest is in simulating space

conditions (1).

For example, the gas molecules of the

exhaust of a rocket engine in space will continue to

move away from the rocket and will never return.

Thus,

when testing such an engine here on earth, it is not

enough merely to place it in a vacuum, for the exhaust

molecules will strike the containing walls of the vacuum

system and bounce back to the engine, thereby destroying

the space condition, for this could never happen in

space.

Therefore, some method must be found to prevent

these molecules from bouncing back; this can be

accomplished by cooling down the bounding surfaces to

-5.low temperatures, so that when the molecules from the

exhaust strike them, they will condense.

It is desired

that the molecules stick to the walls the first

time

they strike it, and therefore, this thesis will aid

in determining whether they will do so.

__ __~~_ ~

- 6 THEORY

The basic procedure consists of injecting a known

number of molecules into a known volume which contains

a cold surface, and then seeing how fast the molecules

condense; however, other techniques have also been

used (2j. The number of molecules at any given moment

may be determined by measuring the pressure of the gas

for, from the perfect gas law, the number of molecules

is directly proportional to the pressure.

PV = NRT

where

P = pressure of gas

V = volume of gas

N = number of moles of gas

R = gas constant

T = temperature of gas

Solving for N:

N=

.Y p = constant x P

RT

Finally,

Number of molecules = Avagadro's number x N

= Avagadro's nurmber x constant x P

= constant x V

______ _ __

_I_

I

- 7The basic equation which describes the experiment is:

----

Se

where

4V

t

P = pressure of gas

Pi = initial pressure of gas

A = area of cold surface

V = volume into which molecules are injected

5 = mean speed of molecules (at room temperature)

t = time

o = sticking coefficient (probability that a

molecule colliding with the area is pumped)

This equation is derived from the fdllowing equation

for the pumping speed of an orifice or condensing area,

which is based on kinetic theory:

dN9

I

Ns

N' = number of molecules

= LN

where L is

Avagadro's number.

From the perfect gas law,

RT

N = -RT

;1__ ____

____

-8-

Therefore

L PV

R T

Since R = kL, where k = Boltzman's constant,

PV

kT

and, .. ,

V dP

kT dt

dN'

dt

since V and T are constant.

Substituting back into the original equation,

dN'

dt

or

dP

P

V dP

1

P

- I i o<'lti cA

kT dt

A=

=

CWcV

dt

Integrating,

t

dP

p

f dt

4V

ep

0

results in

P

In -

Pi

or

P

Pi

=

Z-A

-o-oTv

-t t

4V

-IA

- 9 -

Thus, the purpose of the experiment is to determine

this sticking coefficient for different gases.

This can

be done from a graph of pressure vs. time, since all the

other terms are known beforehand.

This graph should

look something like this:

P

rnolecules condens'i7y

Injected

gas injected

It is desired that V be much larger than A, for

otherwise, the pressure will drop off too fast and it

will be difficult to get a meaningful graph.

Similarly,

Pi should be low enough, for otherwise, the molecules

will once again condense at too fast a rate.

-

10 -

APPAKATUS

A previous thesis student (3)

considered the methods

and partially built the apparatus, which I then completed.

The entire apparatus is made almost exclusively of glass.

Main system:

The pumping system is made up of a mechanical pump

and a diffusion pump (4).

diagram on page 12,

As shown in the schematic

the gas is

injected into a cylindrical

chamber, and the cold surface is the end of a hollow

metal rod which is cooled down by liquid nitrogen.

In

order to minimize heat conduction to the rod, the metal

plate is so constructed that it does not touch the rod.

However,

because of this, some of the injected gas would

be able to escape through the slight opening between the

rod and the plate, and therefore, the area above the

plate was enclosed so that the amount of escaped gas

could be measured.

The gas pressures are measured with

ion gauges.

Originally, it was planned to cool the surface with

liquid helium, and the apparatus was so constructed.

The liquid helium was to be put where the liquid nitrogen

is now, and around it was built an insulating pocket

which was to be filled with liquid nitrogen,

However,

_I;~ _ I _

~

-

11

-

the system as thus constructed did not have sufficient

strength to withstand the stresses when it was evacuated.

The glass kept on cracking, and therefore, the plan to

use liquid helium had to be abandoned; the system was

rebuilt to its present state and uses only liquid

nitrogen.

This severely limits the experiment, for many

of the gases which it was originally desired to test will

not condense at the temperature of liquid nitrogen (76 0 K).

Injection System:

As shown in the schematic diagram on page 13, the

pressure of the injected gas is measured by an oil

manometer.

An expansion chamber was introduced in order

that the injected gas would be at a low enough pressure

after it

expanded again into the main system.

A more

detailed description follows in the next section.

__ I_;~_ i~

1

- 12

-

Main System:

•/'

/d n/,troyen

metal plate

ball valve

surface

/'on gau es

injected

gases -

valve

-

13 -

Injection System:

steop cock v4/ve

mechanict/

V Cuum

Spt'mp

scale

orginal

unexpanded

9gas

ample

egpansion

chamber-

oil

expansion

system

injected

g8S

COR

4"o mai,

system

;ILPIID~ ;"Li~

- 14 PROCEDURE AND DiSCRIPTION OF EXPRIMENT

The pressure in the main system and in the expansion

system was pumped down to approximately 1 x 10-6 mm

g,.

The first gas chosen to be tested was carbon dioxide.

As stated before, the choice of gases is limited (5),

and furthermore, the vapor pressure of the gas chosen

had to be below 1 x 10 - 6 mm Hg at 76°K (See graph of

vapor pressure vs. temperature for some gases on page 16).

The procedure is as follows, with a more detailed

one in the appendix: the injection system

is evacuated

and the desired amount of carbon dioxide is inserted by

measuring its pressure with the manometer.

A sample of

the gas is then taken and expanded in the expansion

chamber.

A sample of the expanded gas is then taken

and injected into the main system.

The pressure

variation as the gas condenses is measured by the ion

gauge and recorded.

Due to the double expansion of the gas, the pressure

of the injected gas after it enters the main system, Pi,

is 6.5 x 10 - 6 of its original pre-expanded pressure as

measured on the manometer.

The manometer can measure pressures ranging from

1 inch of oil (1.7 mm Hg) to 24 inches of oil, and as

a result, Pi can vary from 1.56 x 10-4 mm Hg to

1.11 x 10-5 mm H.

-

15 -

Numerous difficulties were encountered during the

course of the experiment.

Many of them were due to the

fact that it was such a large glass system; for example,

several leaks developed.

The manometer also caused

trouble, as the carbon dioxide was apparently diffusing

through the oil into the vacuum side of the manometer,

and it was difficult to measure the pressure of the

carbon dioxide accurately.

i~l-i~Li

:i -~---;

~

_

4F

16

40

-

200

780

10-1

10-2

10-3

10-6

10-7

10-8

-IO1

I

FIG. I

2

5

50

20

10

TEMPERATURE OK

100

200

VAPOUR PRESSURE DATA FOR COMMON GASES

~L~

-

17 -

RESULTS

Due to the many problems in building the equipmnent

and running the experiment, there was not enough time

to obtain any data.

The only results which were obtained was in testing

whether the carbon dioxide would expand as calculated

(i.e.

without the cold surface in the main system):

Original pressure

in main system

Original pressure

Expected

Actual

(when evacuated)

of carbon dioxide

Pi

Pi

2 x 10 - 6

mm Hg

2 cm.

oil

1.lx10 - 5

mm Hg

1.2x 10 - 5

mm Hg

2 x 10 - 6

mm Hg

2 cm.

oil

1,1 x10 - 5

mm g

1.Ox10 - 5

mH Hg

In order to give some indication of what the

results should look like, curves were plotted for the

values

0( = i

o( = I

(1

(z,

time constant = 9.23 sec.) and

= 4.62 sec.) on the graph on page 18, with

Pi taken to be 10 x 10-6 mm Hg.

T

+

i iiiIiif

f

T

T,

i

I

ii

I t

T

!,,i''I

itci

T ,t

ITT

Ti

t

4-

-rT

_14I

.. :

T

FI

T'

4

4i

11

T~i

t

1L

I

ii -

I

'I~T~FfFi~i~

t

Ff47

11 T- I r ,IM

Il

Il l1l~

l fT rl r +t~~#~"~

ir ]

TTI'

4T--

I t r,

i-i

q117

TI

I

411

i

T

fti-tiPt~ti~i

rm-rrrrrmtt,

I5S

''""~'

U~

11;

-1

Ii-,

111

I

1;

t

II

i ;I

t441t

; ii t i t?'-"

'

r

"

4t

r~~i

11

~~'114Th I14

I

,~

I

i~''T~ '

: 1I

a

mT~"

"CM~t?

~""

mjijj4Lj4 ffir'

I I I.I~

I 11;.;

II I I

.

1T +44

-

41 T

I ,

i ii

rr

I

III I, 1111,

I

:1

T

1. I'1

1il

I.

TII I

l i iiPtt

<

s fFh

r

I212iLEUJ~

ILLF

llllllIII

lI llliT4i

ll ilil rlf lr+XII

l llf IF hF

~

i

I II

I

I

~ ~ ~ ~i ~

I

4+4

I

I

iI

I

I1i1I1ii

11 14

if hLH

1 .7

I!lJlllfl

r

I I FTLT

-

11 __

T

L

14

.1-- . 14

.-

r--

-'-4T

4

--

t

4

T

....

.

f:

I

+

R

4j1~d4

1,

1fj

I

TF7

II T

1__

TI

1 1f

'T

i

iI j 1

-7

t

- --

tt

i

i

E~ii iiii

ii;

tl

t

TT

t

Ii~

7Ttc~-t~

iT

I

r

T

t

-

-

ii

T-,

+

ti

4

I

iii

14

i N, t

44

-if~

iflT

;RE~

{k~dih'dt Ltl

8ft-

-1~t

L

-l

1

1

+H

iT

I-T

T,

1

T

4

ti:

4T

i

T-i

'4

Fiati llTili

V Ti

+

i-;:+

h

I

<ft144

j{Hrf4

TITt -1

wfy+

-4;

i

4,

j

-1,

L~t4dPtit,

,

Pi

4 4' 1+

+4

T

"

:,

T

!- 4444I-4-L44

1

"44441

_TT

71115t

+

T II. . I. . . ..~~;I I

H-

4

fl~iI

FLll

&

Tt

Lii

W

It~til-t-i-i-t

if-'-

t

T# fht-t

I 44d+H ++

4-

k+ 4t

TT,

,,

_+

>4tt

W5

A TI--rrT----4-------4 MiF

F Itf-tI-ftl t Theh-i d

4+

4

-A4+:L

T:

-jj

.

U)-YCUC-;-.ITf Li- .i.L

4

F

11 t++d-H

r4

4

a-e+H-

4

't-P

44-U4--

•

ttttti-tI-H-H+

.

,

,

crilil

l

l

ii

AJ

-

19

-

CONCLUSIONS

One basic problem remains and that is the manometer,

as mentioned previously.

the oil with mercury.

A solution might be to replace

To make up for the fact that a

mercury manometer could not measure as low pressures as

an oil manometer could (the density of mercury is about

thirteen times the density of the oil), a second

expansion system could be built into the injection system.

Otherwise, it seems feasible that the experiment

could be run and the desired data obtained.

already indicated,

However, as

the scope would be very limited due

to the fact that liquid helium cannot be used.

i

mw

- 20

-

REFERNCES

i.

Chuan, Raymond L. "Rating Performance of a SpaceSimulation Chamber." Research/Development Magazine,

pp. 44-46, January 1964.

2.

Stickney, W. W., and Dayton, B.B. 'The Measurement

of the Speed of Cryopumps." Consolidated Vacuum Corp.

3.

Stokes, Andrew B. "The Measurement of Sticking

Coefficients of Various Gases to a Metal Surface

Cooled to Cryogenic Temperatures." M.I.T., B.S. Thesis,

Mechanical Engineering,

4.

1963.

Dushman, Saul. Lafferty, J. M., editor. "Scientific

Foundations of Vacuum Techniques." 2nd ed. New York,

John Wiley and Sons, Inc., 1962.

5.

Santeler, D. J. "Theory and Design of Cryogenic

Pumping Systems for Space Environmental Simulators."

Second Annual Symposium of Space Vacuum Simulation,

Arthur D. Little, Inc., June 16, 1961.

T-F

- 21 APPENDIX

Manometer Oil:

Octoil-S

specific gravity = 0.9103,

1 inch oil = 1.7 mm Hg

Expansion of Gas:

Volume of unexpanded gas sample = 8.0 cc.

Volume of injected gas sample = 7.6 cc.

Volume of gas after first expansion = 523.8 cc.

(Above two volumes plus volume of expansion chamber)

Volume of main system = 17,300 cc.

expansion expands the gas 67.5 times.

The first

The second expansion expands the gas 2,280 times.

The totnl expansion is therefore 1.536 x 105 times.

Area of Cold Surface:

0.326 cm.

2

-

22 -

Planned Detailed Procedure:

Aefering to the diagram on pale 13,

1)

Close valve 4, open valves 5, 6, and 7, and evacuate

expansion system through main system.

Turn valves

3, 6, and 7 until further turning does not affet the

pressure (but leave them open).

2)

Open valves 1 and 3, and evacuate rest of injection

system with mechanical pump.

3)

Close valves I and 3.

4)

Let in carbon dioxide very slowly by opening valve 2

very slightly.

This should force the manometer oil

all the way to the top.

5)

Open valves 2 and 3, and flood system with carbon

dioxide.

6)

Close valve 2 and evacuate once argain with the

mechanical pump.

7)

Let in carbon dioxide slowly by carefully opening

valve 2 until desired pressure is

8)

reached.

Take sample of unexpanded gas by closing valve 5

and opening valve 4.

9)

Expand gas by closing valves 4 and 7 and opening

valve 5.

10)

Close cut-off valve on main system (see diagram on

page 12).

_ ~_~_~ii;~

~

I

I -L--~enru~inEuB--

.

11)

23 -

Inject expanded gas into main system by closing

valve 6 and opening valve 7; record the pressure

variation.